90 FE-dohc (FE3) Turbo

#242

Elite Member

Thread Starter

iTrader: (5)

Join Date: Jan 2005

Location: Atlanta

Posts: 7,485

Total Cats: 372

Yes- it's another step towards precision, mandatory for doing these double flares. That was my first flare and it made a tight seal. I did a lot of reading up before I started in. The biggest concern is getting a squared flare seating surface to the axis of the tube. Other important steps are making sure the tube is cleaned of paint so it doesn't slide during the compression, using slow turns during the process and frequently checking progress. I also warmed the tube end with a propane torch and added a dab of grease on the end.

#244

Elite Member

Thread Starter

iTrader: (5)

Join Date: Jan 2005

Location: Atlanta

Posts: 7,485

Total Cats: 372

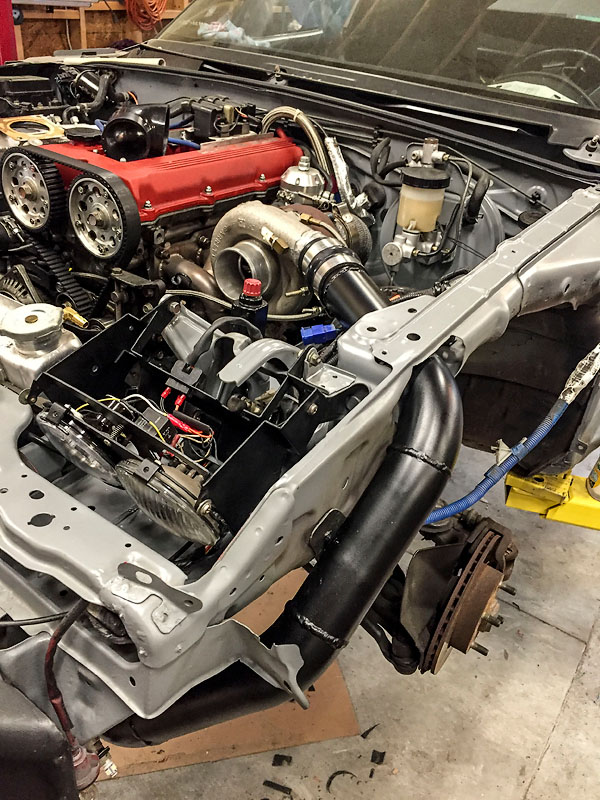

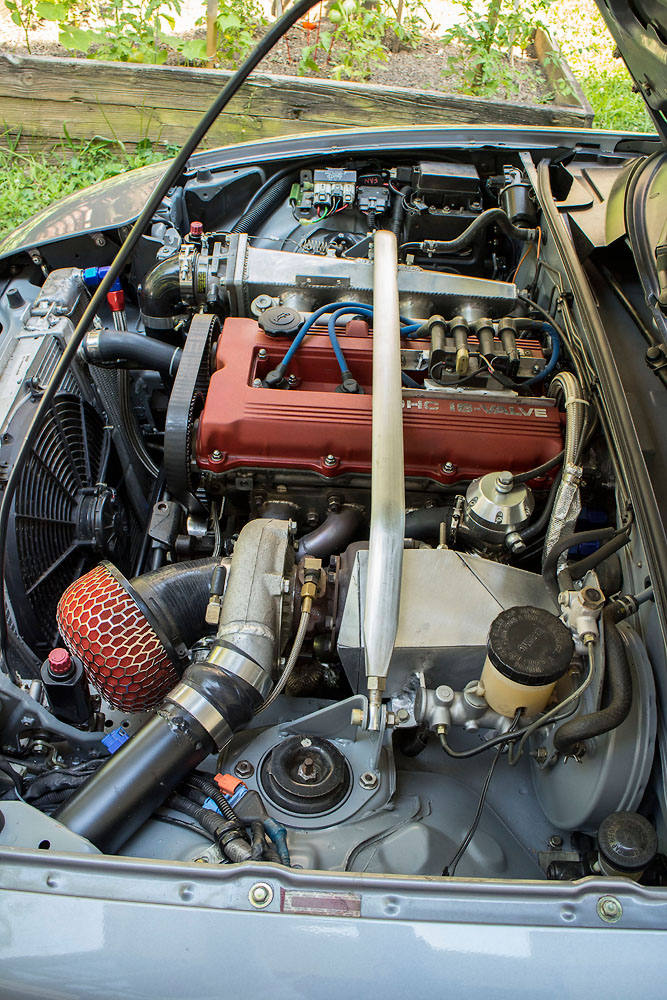

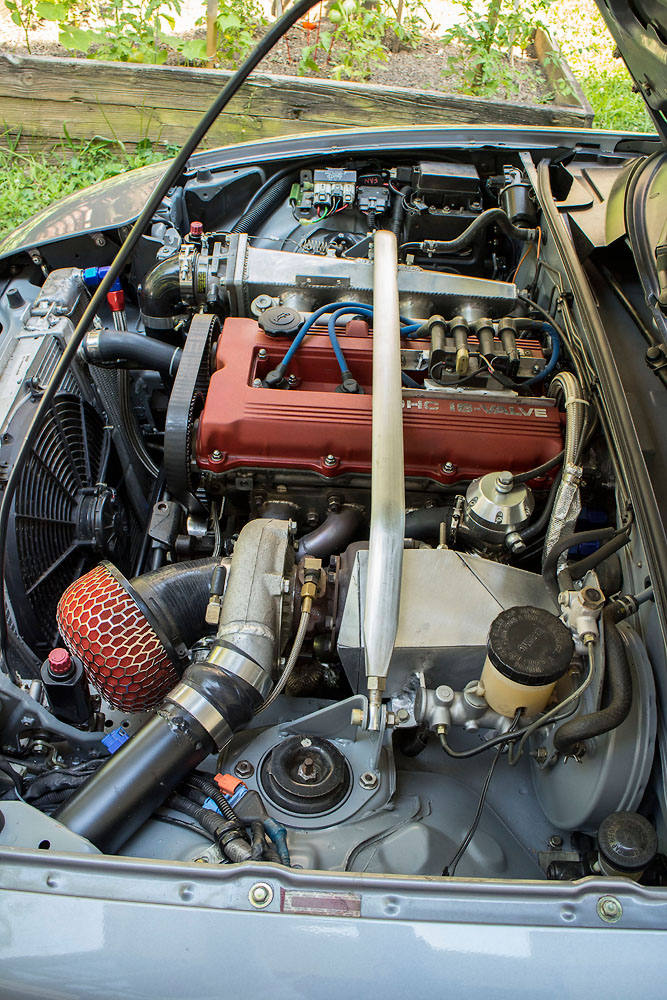

More progress! First time this car has moved out/in of the garage under it's own power in over three years.  Both hot and cold side intercooler pipes have been sorted and tacked- just need to do the final weld on each joint. Everything in the center console is wired: oil temp gauge, volts, stereo and wbo2 controller/gauge/EBC/shift light (wut?). I decided to go with an Innovate SCG-1 multi-function gauge as a stop gap between an MBC and closed-loop EBC. I'd call it "handy" with a configurable display, wbo2 controller, shift light and open-loop EBC, output for datalogging, pc sw configuration. It was an easy solution to full multiple "needs." I've also completed a couple of extended idles of 15-20 minutes to check for leaks, temps and fan cycling. Only had one issue- a massive exhaust leak at the downpipe vband that I never tightened.

Both hot and cold side intercooler pipes have been sorted and tacked- just need to do the final weld on each joint. Everything in the center console is wired: oil temp gauge, volts, stereo and wbo2 controller/gauge/EBC/shift light (wut?). I decided to go with an Innovate SCG-1 multi-function gauge as a stop gap between an MBC and closed-loop EBC. I'd call it "handy" with a configurable display, wbo2 controller, shift light and open-loop EBC, output for datalogging, pc sw configuration. It was an easy solution to full multiple "needs." I've also completed a couple of extended idles of 15-20 minutes to check for leaks, temps and fan cycling. Only had one issue- a massive exhaust leak at the downpipe vband that I never tightened.  Next up is static (no load) tuning in the driveway. From there I'll build a base map based on my prior tune with the maitalink and get this thing rolling for some real load tuning. Of course that'll come after I install all the body parts, repaint the headlight structures and reinstall, install the IAT sensor, complete the IC pipes- including BOV and vacuum ports, and all the other things I've forgotten.

Next up is static (no load) tuning in the driveway. From there I'll build a base map based on my prior tune with the maitalink and get this thing rolling for some real load tuning. Of course that'll come after I install all the body parts, repaint the headlight structures and reinstall, install the IAT sensor, complete the IC pipes- including BOV and vacuum ports, and all the other things I've forgotten.

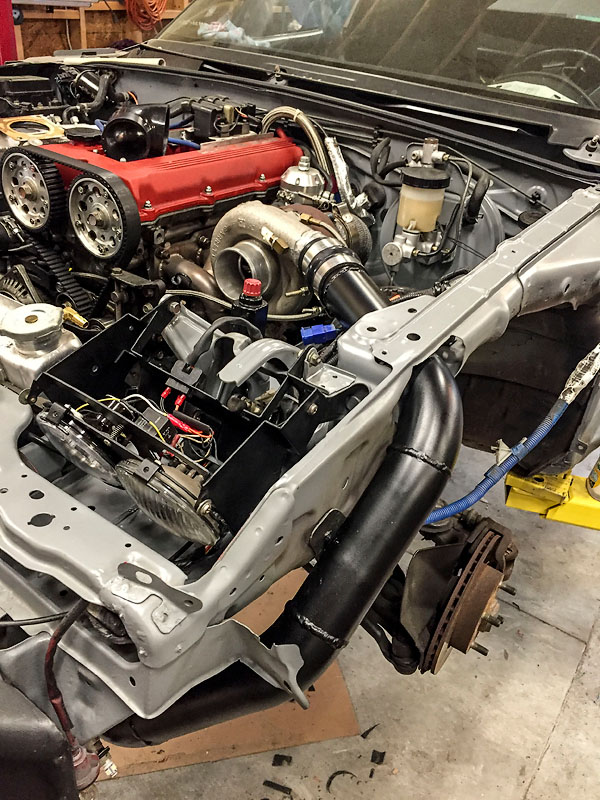

Hot side (TurboTimô) IC pipe routing thru-the-fender

Cold side IC pipe getting tacked up

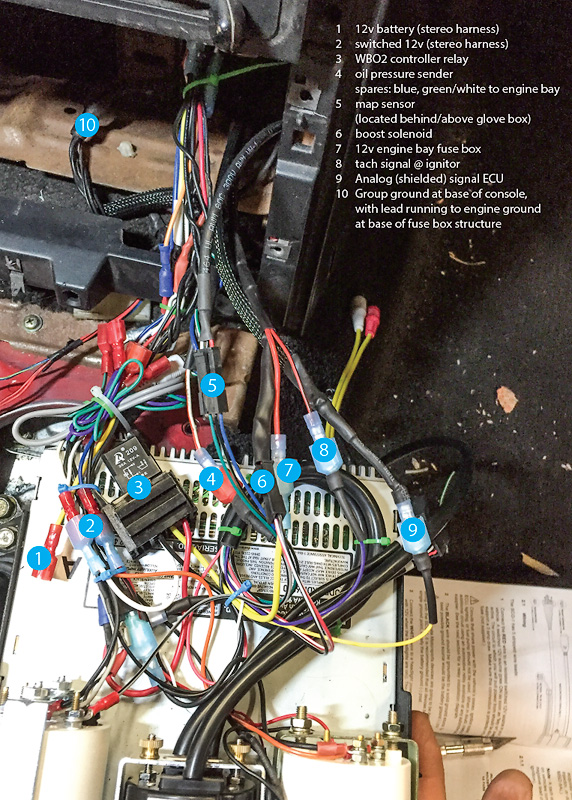

Console wiring (as a diagram for aging brain)

Idle session- I just punched up a bunch of VE cells to get enough fuel for it warm up and run, so high idle.

Both hot and cold side intercooler pipes have been sorted and tacked- just need to do the final weld on each joint. Everything in the center console is wired: oil temp gauge, volts, stereo and wbo2 controller/gauge/EBC/shift light (wut?). I decided to go with an Innovate SCG-1 multi-function gauge as a stop gap between an MBC and closed-loop EBC. I'd call it "handy" with a configurable display, wbo2 controller, shift light and open-loop EBC, output for datalogging, pc sw configuration. It was an easy solution to full multiple "needs." I've also completed a couple of extended idles of 15-20 minutes to check for leaks, temps and fan cycling. Only had one issue- a massive exhaust leak at the downpipe vband that I never tightened.

Both hot and cold side intercooler pipes have been sorted and tacked- just need to do the final weld on each joint. Everything in the center console is wired: oil temp gauge, volts, stereo and wbo2 controller/gauge/EBC/shift light (wut?). I decided to go with an Innovate SCG-1 multi-function gauge as a stop gap between an MBC and closed-loop EBC. I'd call it "handy" with a configurable display, wbo2 controller, shift light and open-loop EBC, output for datalogging, pc sw configuration. It was an easy solution to full multiple "needs." I've also completed a couple of extended idles of 15-20 minutes to check for leaks, temps and fan cycling. Only had one issue- a massive exhaust leak at the downpipe vband that I never tightened.  Next up is static (no load) tuning in the driveway. From there I'll build a base map based on my prior tune with the maitalink and get this thing rolling for some real load tuning. Of course that'll come after I install all the body parts, repaint the headlight structures and reinstall, install the IAT sensor, complete the IC pipes- including BOV and vacuum ports, and all the other things I've forgotten.

Next up is static (no load) tuning in the driveway. From there I'll build a base map based on my prior tune with the maitalink and get this thing rolling for some real load tuning. Of course that'll come after I install all the body parts, repaint the headlight structures and reinstall, install the IAT sensor, complete the IC pipes- including BOV and vacuum ports, and all the other things I've forgotten.

Hot side (TurboTimô) IC pipe routing thru-the-fender

Cold side IC pipe getting tacked up

Console wiring (as a diagram for aging brain)

Idle session- I just punched up a bunch of VE cells to get enough fuel for it warm up and run, so high idle.

#246

Elite Member

Thread Starter

iTrader: (5)

Join Date: Jan 2005

Location: Atlanta

Posts: 7,485

Total Cats: 372

I think my Innovate luck has run out with two good LC-1s. Brand new out of the box, my SCG-1 has failed to produce any measurable analog output voltage regardless of what I do. All else complete and repeatable function. Innovate tech support has been unresponsive so far with emails, phone call and non returned voice mail.  I suspect my next step is RMA since the retailer return period has expired and I'm still within the Innovate warranty.

I suspect my next step is RMA since the retailer return period has expired and I'm still within the Innovate warranty.

The Fe3 Miata is now driving in/out of the garage under it's own power- which hasn't happened in over 3 years. Idle is way lean (~18.0 afr) once operating temp is reached, so I need to fatten VE and lean out my cold enrichment.

I put in 2-3 hours practicing TIG on aluminum with a box of scrap tabs I picked up on eBay for super cheap. It was a good learning experience allowing me to grasp the concept of creating and moving the puddle of molten metal. Also understanding the importance of cleanliness with TiG welding and identifying contamination in the welds. You can see evidence of that in the porosity in the back bead below and the need for more cleaning and heat. This was about an hour in. I certainly got some practice on sharpening tungsten. Spent time covering frequency control and learning how to control the heat with the pedal. Through all of this I am now completely sold on the TIG process. It has 5x the control of MIG welding, providing service that MIG just can't deliver. Wished I'd bought a TIG sooner, and started practicing with this unit back when I got it in August.

Spent time covering frequency control and learning how to control the heat with the pedal. Through all of this I am now completely sold on the TIG process. It has 5x the control of MIG welding, providing service that MIG just can't deliver. Wished I'd bought a TIG sooner, and started practicing with this unit back when I got it in August.

Once I was confident I could stick some aluminum together without making a complete mess, I moved on to the IC pipes. Of course laying down the tack welds was mess. Putting the arc on the edge of the tube proved to be far more difficult than laying down beads on flat pieces. Fortunately TIG is forgiving and that makes it easier than MIG to fix mistakes. Fix meaning functional, not so much pretty. The next big obstacle is running a bead around the circumference of the tube in a consistent motion with torch and filler. I resided to the fact that without some better support for the piece and my hands, I wasn't going to be able to get more than 1-1/2" of weld down at a time. Certainly gave me an appreciation for all the supporting structures the pros use when putting down welds on anything other than a flat piece on a flat surface. I understand why next to cleanliness these pros stress the importance of comfort.

The next big obstacle is running a bead around the circumference of the tube in a consistent motion with torch and filler. I resided to the fact that without some better support for the piece and my hands, I wasn't going to be able to get more than 1-1/2" of weld down at a time. Certainly gave me an appreciation for all the supporting structures the pros use when putting down welds on anything other than a flat piece on a flat surface. I understand why next to cleanliness these pros stress the importance of comfort.

I suspect my next step is RMA since the retailer return period has expired and I'm still within the Innovate warranty.

I suspect my next step is RMA since the retailer return period has expired and I'm still within the Innovate warranty. The Fe3 Miata is now driving in/out of the garage under it's own power- which hasn't happened in over 3 years. Idle is way lean (~18.0 afr) once operating temp is reached, so I need to fatten VE and lean out my cold enrichment.

I put in 2-3 hours practicing TIG on aluminum with a box of scrap tabs I picked up on eBay for super cheap. It was a good learning experience allowing me to grasp the concept of creating and moving the puddle of molten metal. Also understanding the importance of cleanliness with TiG welding and identifying contamination in the welds. You can see evidence of that in the porosity in the back bead below and the need for more cleaning and heat. This was about an hour in. I certainly got some practice on sharpening tungsten.

Spent time covering frequency control and learning how to control the heat with the pedal. Through all of this I am now completely sold on the TIG process. It has 5x the control of MIG welding, providing service that MIG just can't deliver. Wished I'd bought a TIG sooner, and started practicing with this unit back when I got it in August.

Spent time covering frequency control and learning how to control the heat with the pedal. Through all of this I am now completely sold on the TIG process. It has 5x the control of MIG welding, providing service that MIG just can't deliver. Wished I'd bought a TIG sooner, and started practicing with this unit back when I got it in August.

Once I was confident I could stick some aluminum together without making a complete mess, I moved on to the IC pipes. Of course laying down the tack welds was mess. Putting the arc on the edge of the tube proved to be far more difficult than laying down beads on flat pieces. Fortunately TIG is forgiving and that makes it easier than MIG to fix mistakes. Fix meaning functional, not so much pretty.

The next big obstacle is running a bead around the circumference of the tube in a consistent motion with torch and filler. I resided to the fact that without some better support for the piece and my hands, I wasn't going to be able to get more than 1-1/2" of weld down at a time. Certainly gave me an appreciation for all the supporting structures the pros use when putting down welds on anything other than a flat piece on a flat surface. I understand why next to cleanliness these pros stress the importance of comfort.

The next big obstacle is running a bead around the circumference of the tube in a consistent motion with torch and filler. I resided to the fact that without some better support for the piece and my hands, I wasn't going to be able to get more than 1-1/2" of weld down at a time. Certainly gave me an appreciation for all the supporting structures the pros use when putting down welds on anything other than a flat piece on a flat surface. I understand why next to cleanliness these pros stress the importance of comfort.

#247

Elite Member

Thread Starter

iTrader: (5)

Join Date: Jan 2005

Location: Atlanta

Posts: 7,485

Total Cats: 372

Finally got back into the Miata project after an unrelated wrench-crippling injury, surgery and some PT.

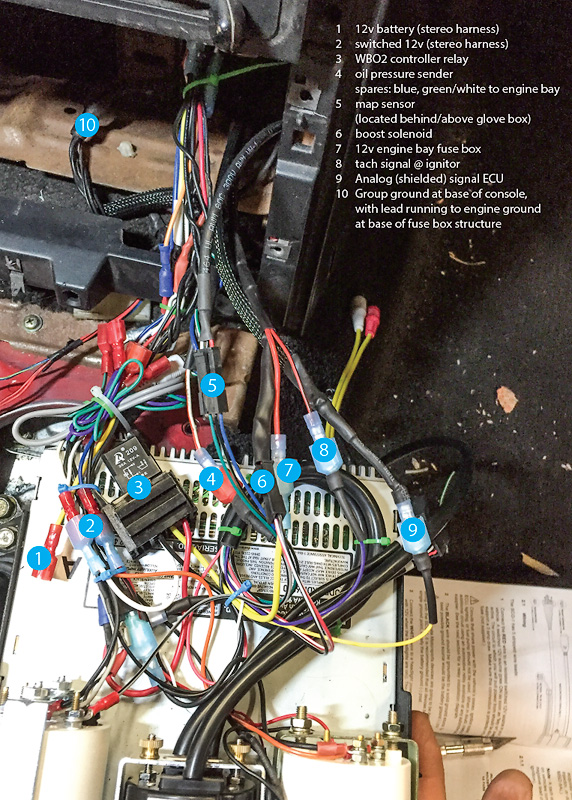

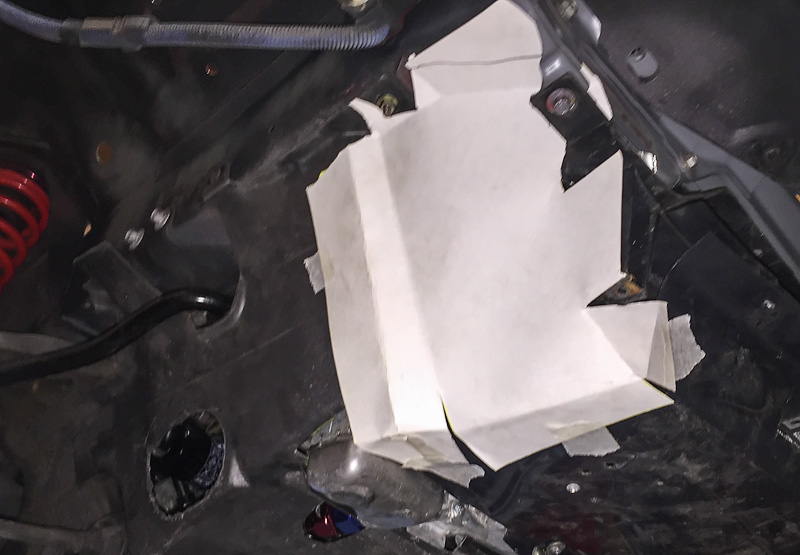

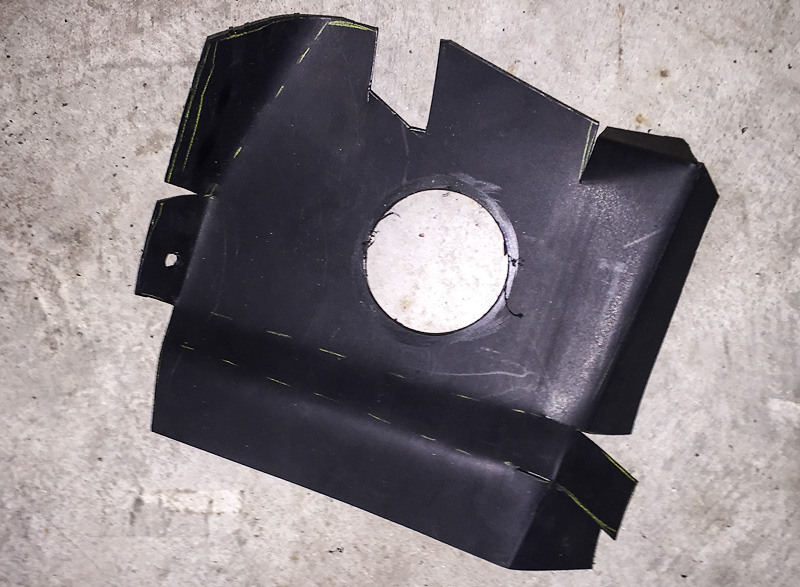

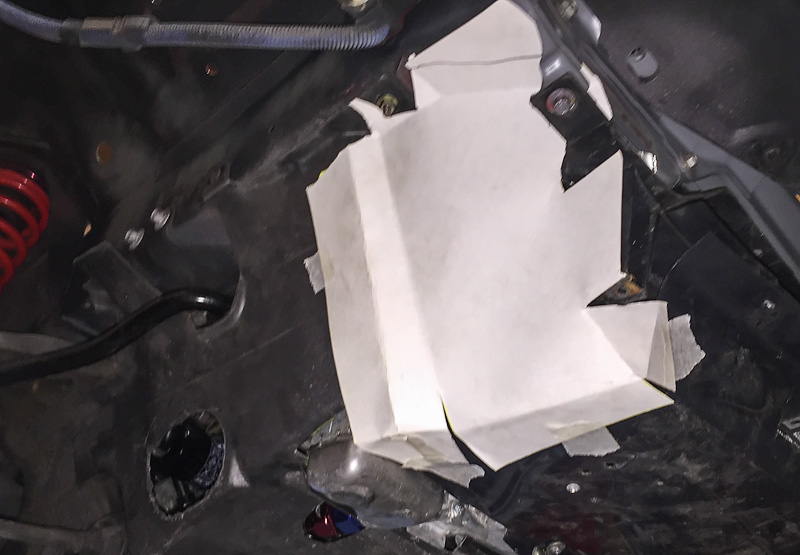

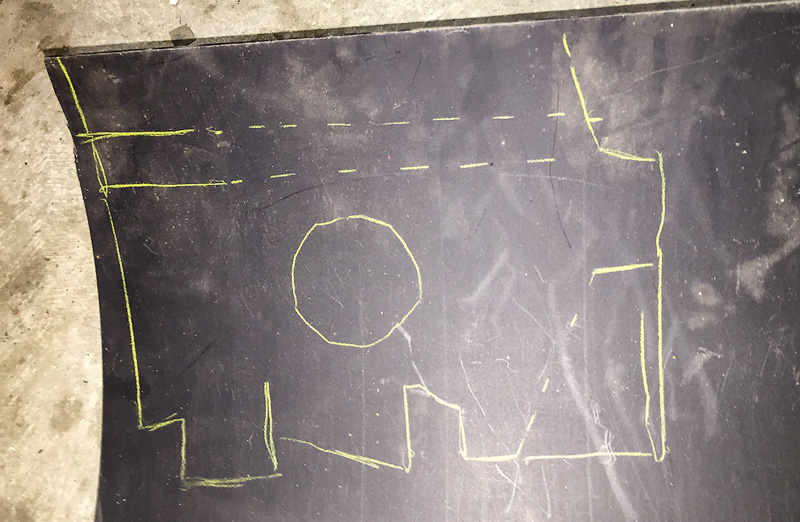

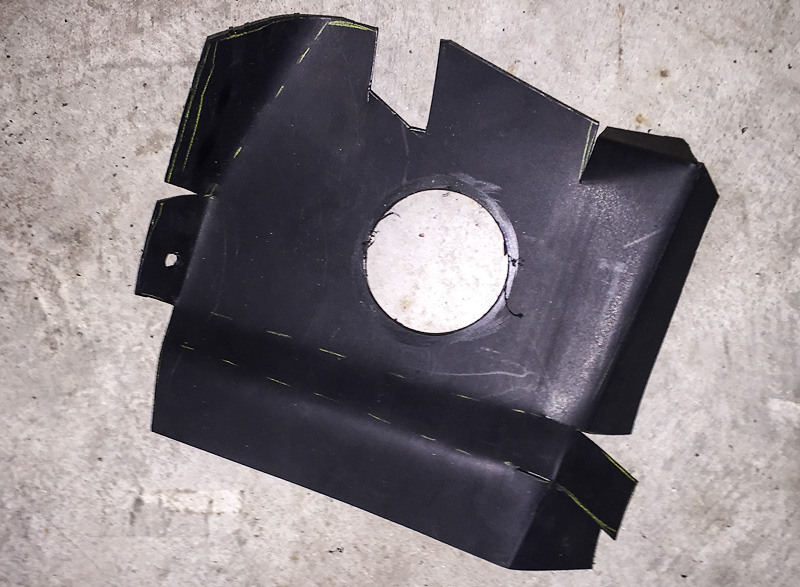

Exchanger inlet box is complete so it accommodates the big intercooler and radiator. Used the stock air guide as the foundation so it would fit up to the nose and then shaped plastic sheet using paper board templates for fit. Bend (used HF Metal Seamer Pliers 98728) and rivet like sheet metal for the final assembly.

Stock under tray is modified to attach to the radiator base and pass the cold side intercooler tube. Riveted the trimmed under tray to an aluminum angle so that it screws to the aluminum flange at the base of the radiator.

Cold side intercooler pipe is installed. Hella driving lights with angel eyes that I picked up on eBay over ten years ago are installed has high beams in the original Brainstorm low profile head light chassis. Also got all the wiring sorted out under the headlights. I forgot just how much room these pop-up headlights use in the engine bay.

Exchanger inlet box is complete so it accommodates the big intercooler and radiator. Used the stock air guide as the foundation so it would fit up to the nose and then shaped plastic sheet using paper board templates for fit. Bend (used HF Metal Seamer Pliers 98728) and rivet like sheet metal for the final assembly.

Stock under tray is modified to attach to the radiator base and pass the cold side intercooler tube. Riveted the trimmed under tray to an aluminum angle so that it screws to the aluminum flange at the base of the radiator.

Cold side intercooler pipe is installed. Hella driving lights with angel eyes that I picked up on eBay over ten years ago are installed has high beams in the original Brainstorm low profile head light chassis. Also got all the wiring sorted out under the headlights. I forgot just how much room these pop-up headlights use in the engine bay.

#249

Fascinating project. I really admire the DIY effort here. I've got a basic inverter box TIG welder and I really need to practice welding aluminum a lot more so that I can actually do some cool project stuff with it. Welding steel is like walking across a small foot bridge versus welding aluminum which is like walking a tight rope.

#250

Elite Member

Thread Starter

iTrader: (5)

Join Date: Jan 2005

Location: Atlanta

Posts: 7,485

Total Cats: 372

@bpt - Was a overly ambitious on the swinging ring section of an obstacle course and suffered a complete tear of the right pectoral tendon. Physically repaired thankfully.

Thanks! I have yet to weld anything but aluminum with my TIG. Spent a lot of time watching youtube videos and reading forums. Probably more time doing that than actually practicing. But I think it really comes down to understanding how to create and control that puddle of molten metal. If you can't, then knowing what to do next is key. That's where the videos/forums help tremendously.

Thanks! I have yet to weld anything but aluminum with my TIG. Spent a lot of time watching youtube videos and reading forums. Probably more time doing that than actually practicing. But I think it really comes down to understanding how to create and control that puddle of molten metal. If you can't, then knowing what to do next is key. That's where the videos/forums help tremendously.

#251

Elite Member

Thread Starter

iTrader: (5)

Join Date: Jan 2005

Location: Atlanta

Posts: 7,485

Total Cats: 372

Bunch of stuff done, but most rewarding is getting body parts installed. Traded my gunmetal chaparrals for some white Koseis I was going to paint black. Then swapped those for these polished 15x8.25 25et DR16s with tires. Adequate for my current needs, completely opposite of my original plan, but I like them with the paint. Ride height is a little jacked since the car was just put on the ground.

#253

Elite Member

Thread Starter

iTrader: (5)

Join Date: Jan 2005

Location: Atlanta

Posts: 7,485

Total Cats: 372

I pulled the LE interior from the car the tree fell on but have yet to install it in this one. I need to find/make another driver side door panel and crash pad for the dash. Would also need to convert this car to power windows or put manual crank holes in the LE door panels.

#255

Elite Member

Thread Starter

iTrader: (5)

Join Date: Jan 2005

Location: Atlanta

Posts: 7,485

Total Cats: 372

I've only used my eBay combo for plasma cutting. I picked up an alpha tig and haven't gotten around to trying the eBay combo for DC tig. Sheuind has a combo, maybe he's tried it by now.

#256

Elite Member

Thread Starter

iTrader: (5)

Join Date: Jan 2005

Location: Atlanta

Posts: 7,485

Total Cats: 372

Did some stuff: Rspeed lip and deck lid spoiler installs, made/installed turbo heat shield, cleaned up strut tower brace and installed it (because it would fit!). I've driven it twice on a VE table I "fabricated" from running through the revs sitting in the driveway. I have yet to find the time to go out when there's not so much traffic on reasonably flat road. I need to do some clutch adjusting. The entire action happens in about 1/2" of throw and right off the floor. That said- I think this is how it was in the prior car based on videos. I've got something rubbing around 3500 rpm and in off throttle coast in gear. I pulled a shim from oil pump while the engine was out and now in the raging summer heat my idle oil pressure is 5-10psi. I regret doing that as I added a significantly larger oil cooler this time around. Tires are rubbing in the rear on hard compression (pot holes at slow speed). I had a leak at the oil pan and block just to the passenger side of the crank pulley first time out. I was able to tighten that oil pan bolt at the leak without much effort and it appears to have remedied the problem this time out. The cooling system seems to work well. Both trips have been in 97f with heavy traffic and the system rises in temp, fan comes on, brings the temp down 10c and repeat. Found out my "junkyard" 04 Miata AC compressor has a bad bearing, so no AC. That sucks. I'll get to put my coolant hose routing to the rad to the test- tried to make it so the compressor could be removed w/o pulling the rad hose.

#259

Elite Member

Thread Starter

iTrader: (5)

Join Date: Jan 2005

Location: Atlanta

Posts: 7,485

Total Cats: 372

I didn't mention it, but the 80/90s Ford V8 throttle body I used came with hole in the throttle plate, that was at some point enlarged. I've learned since the hole is fairly typical for american cars of this era, and enlarging it to mask idle issues is also a common "fix". My issue- car won't idle below 1800rpm because of this big vacuum leak. Patching the hole (the right way) requires removing the throttle plate and brazing the hole shut. Of course removing the throttle plate means grinding the ends off the throttle screws so they can be backed out. Rather than go down that path and raising concerns about ingesting screws in the future, I decided to TIG braze the plate while it was still installed. The idea that the TIG might give me the heat control to keep from warping the plate. That didn't work. The TIG may have the control but I don't. The plate warped the smallest amount, reducing my idle to 1,200 rpm warm because it's still leaking air, just not as much. Fortunately these throttle bodies are dirt cheap. I paid $15 for this one with tps/idle valve, and I just picked up my replacement on eBay for an accepted offer of $11.20. Anybody looking for a cheap TB upgrade, you can go Ford V8 and get 65mm with a TPS (and sometimes idle air valve) included, but make sure there's no holes in the throttle plate. It seems the 1994 Crown Victoria and Grand Marquis are one of those models/years.