Aidan's loose oily bunghole actually runs a track lap

#3381

SADFab Destructive Testing Engineer

Thread Starter

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

<p>Emilio is here!!!</p><p>You seem to be the only person with one piece stainless lines on the M10x1 side. What is the reason for the 3an to NPT adapter on the other side</p>

#3384

Square nuts of the proper size are $.30, and square bolts are .60 and those are individual prices. The reason I like a bolt is it will have solid 3/8 shank for a miniute, and I think we can hang them back out the spindle to actually use the shank. If we use nuts, we can't do that without cutting bolts to size.

Plus it would make much easier install, when the rotor is on it will hold the square bolts in the bracket, they will be captive. There will be studs to hold the caliper as you find nuts and wrenches or whatever.

I think it'd be ****, think I'm gonna try it.

Plus it would make much easier install, when the rotor is on it will hold the square bolts in the bracket, they will be captive. There will be studs to hold the caliper as you find nuts and wrenches or whatever.

I think it'd be ****, think I'm gonna try it.

#3386

Coil Threaded Inserts | Solid Threaded Inserts | E-Z LOK

E-Z LOK 319-6 Thread Insert, Stl, 3/8-16, 1/2L, Pk10 - Walmart.com

I think they ran about $1 per insert and $10 for the tool. These are much better than helicoils.

When I made the first brackets out of 3/4" stock I had to use insert. I ended up paying for the 1" stock instead because it worked out cheaper than inserts, but allowed margin over the required 30 ft/lb torque values of the nice zinc plated flanged grade 8 bolts I used.

What grade are the square nuts you are looking at. Please make sure you use good stuff (I know grade 8 ain't special). This is going on your brakes and your life will depend on your brakes working every time.

E-Z LOK 319-6 Thread Insert, Stl, 3/8-16, 1/2L, Pk10 - Walmart.com

I think they ran about $1 per insert and $10 for the tool. These are much better than helicoils.

When I made the first brackets out of 3/4" stock I had to use insert. I ended up paying for the 1" stock instead because it worked out cheaper than inserts, but allowed margin over the required 30 ft/lb torque values of the nice zinc plated flanged grade 8 bolts I used.

What grade are the square nuts you are looking at. Please make sure you use good stuff (I know grade 8 ain't special). This is going on your brakes and your life will depend on your brakes working every time.

#3390

! I just saw the square nut and modified bracket pics.

! I just saw the square nut and modified bracket pics.120ksi sounds a little high for grade 5. Will have to look up exact values. For the square head bolt you will probably ok. Make a bracket and fit it up to see if it all fits.

I will look at the drawings to see what the minimum crossectional area is of the mounting ear and calculate the shear strength of each ear compared the brackets I made.

Remember that these brackets and bolts are being loaded in shear and these bolts will not be under huge tensile loads that will pull blots out of the threaded holes.

#3391

Yep! That's why I would like to use the shank of a bolt if I could pull it off, 3/8-24 would have even more shear strength, but that hardware is difficult to find. Some baller shoulder bolts would be even better, but finding those of the proper length and diameter would be tedious.

I got the 120k number from mcmaster, not sure how accurate it is. These don't have a shoulder, but they are 1/4" head height which is what I'm planning around. I think the ones I found at ace are the same grade, those have a shoulder though, and are strangely cheaper.

McMaster-Carr

I got the 120k number from mcmaster, not sure how accurate it is. These don't have a shoulder, but they are 1/4" head height which is what I'm planning around. I think the ones I found at ace are the same grade, those have a shoulder though, and are strangely cheaper.

McMaster-Carr

#3392

I started with 3/8-24 hardware because the bolts are a little stronger, but the limitation is on the thread pullout, not the shear or tensile strength of the bolt. The -16 coarse thread works better into soft material like aluminum since each thread has more metal to grip into. I threaded my metal inserts for -24 threads and used -16 for the deep threaded aluminum bolts. I was scared that people would accidently swap thread pitches and screw stuff up so I switched to thicker brackets and all -16 hardware.

I haven't seen any brackets.

Back when I was doing my research it was either Keith or Emelio that told me that they didn't need to have inserts on their BBK brackets, but only used steel inserts so that the average monkey that doesn't know how to use a torque wrench wouldn't easily strip them out.

I haven't seen any brackets.

Back when I was doing my research it was either Keith or Emelio that told me that they didn't need to have inserts on their BBK brackets, but only used steel inserts so that the average monkey that doesn't know how to use a torque wrench wouldn't easily strip them out.

#3394

Oh, I haven't made any drawings of the new brackets, they're just drawn up in solidworks as a solid model. Is there any 3d format you can easily open? I guess I can make some 2d drawings if you'd like though.

The dynalite, and I imagine the dynapro as well, use 5/8 thick ears, .2" flange thickness, so 1 3/4 bolts, those should have a 3/4" shoulder, so all but 1/8" of the whole shebang will be supported by 3/8 shank. At that point there's really no need to not go with 3/8-16, maybe thread the aluminum on the spindle side so there's no need to mill so many pockets.

The dynalite, and I imagine the dynapro as well, use 5/8 thick ears, .2" flange thickness, so 1 3/4 bolts, those should have a 3/4" shoulder, so all but 1/8" of the whole shebang will be supported by 3/8 shank. At that point there's really no need to not go with 3/8-16, maybe thread the aluminum on the spindle side so there's no need to mill so many pockets.

#3395

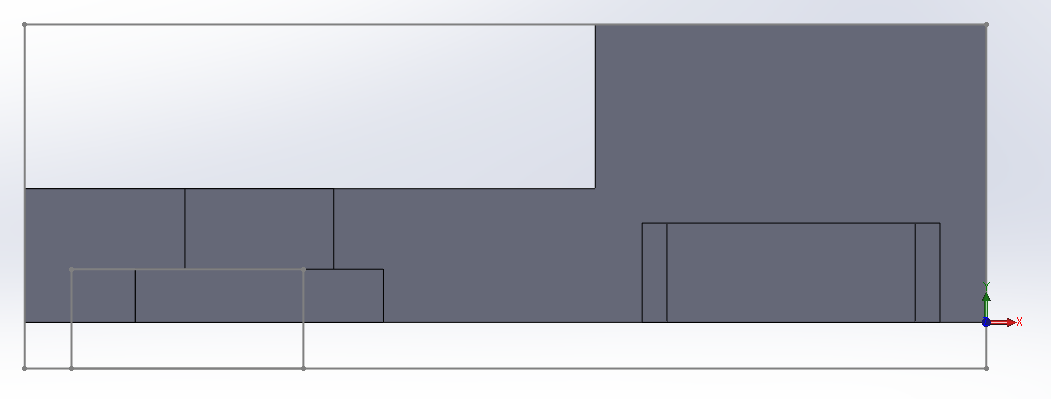

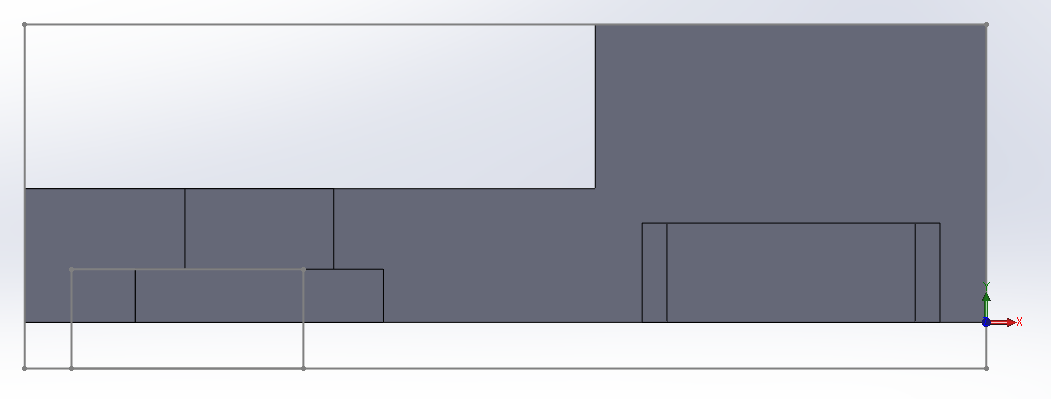

Check this

The rectangle is the 1/4" bolt head, and the other line is the thickness of your bracket, so there should be room, plus plenty of flange still.

The 11" might cut into the thicker half of the bracket, though...

I could also change the direction of the clearance pockets, or even just kiss the bolts against a belt sander real quick and forget the clearance pockets completely. After I drill the 3/8 clearance hole I'll be able to clean out the rest with an 1/8" mill quick, since it's only 1/8" or so deep. There won't be any need to mill the brackets for thickness, so they won't spring like I think you noticed them doing.

The rectangle is the 1/4" bolt head, and the other line is the thickness of your bracket, so there should be room, plus plenty of flange still.

The 11" might cut into the thicker half of the bracket, though...

I could also change the direction of the clearance pockets, or even just kiss the bolts against a belt sander real quick and forget the clearance pockets completely. After I drill the 3/8 clearance hole I'll be able to clean out the rest with an 1/8" mill quick, since it's only 1/8" or so deep. There won't be any need to mill the brackets for thickness, so they won't spring like I think you noticed them doing.

#3396

http://www.summitracing.com/parts/wil-230-0355

These are the clinch nuts wilwood uses on their brackets.

These are the clinch nuts wilwood uses on their brackets.

#3399

The bracket is going to want to compress at the top, and be ripped free at the bottom, load in shear on the bolts shank. I can actually run some stress analysis tests if you'd like, but I don't feel it necessary.

McMaster-Carr

These are more spendy than hex bolts, and will require more material removal than 1/4" head square bolt.

Then there's this. If it holds the wheels on the car, it's good enough for brakes? Nothing big enough on mcmaster, either.

McMaster-Carr

McMaster-Carr

These are more spendy than hex bolts, and will require more material removal than 1/4" head square bolt.

Then there's this. If it holds the wheels on the car, it's good enough for brakes? Nothing big enough on mcmaster, either.

McMaster-Carr