Build Thread (FE3, RX7 TII, EFR 6258, MS3)

#141

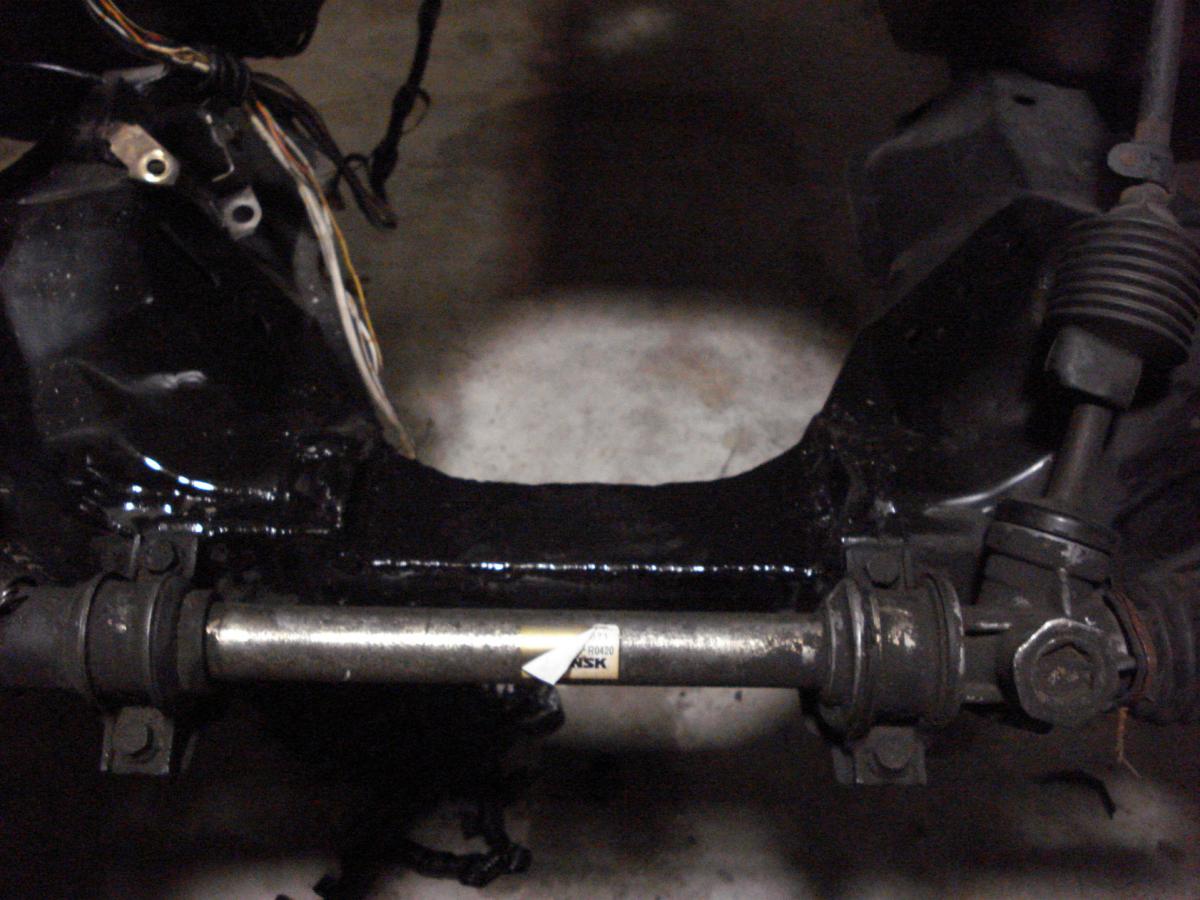

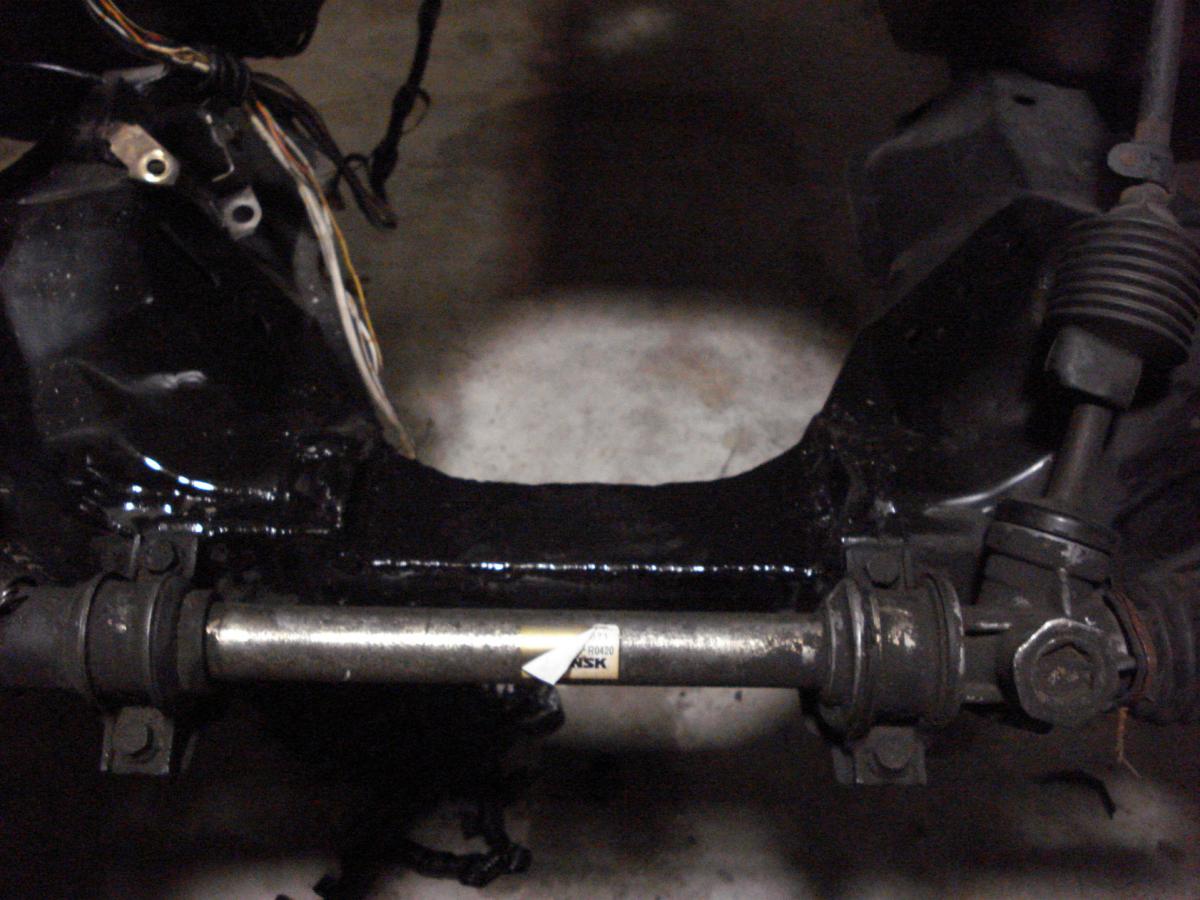

Yeah Ive got to pull the engine one last time to add the gaskets and add the timing belt and such so ill snap some pics then. the notch in the subframe is cut but not closed up yet because i wasnt sure if i would need to take off some more so the pan would fit. everything seems to clear now by at least 3/16" so im planning on doing one last grinding. ( -1/16" ish) and welding it shut.

#146

Finished the coolant reroute tube tonight and then pulled the engine and trans for final assembly. I welded a bracket to support the pipe in the center and added a thick plate to drill and tap for the fan switch right before the coupler on the inlet of the radiator.

I hope to clean up the engine bay tomorrow and do some painting of the brackets and mounts ive made throughout the build process. Still waiting on my hubs to get back from the machine shop...

I hope to clean up the engine bay tomorrow and do some painting of the brackets and mounts ive made throughout the build process. Still waiting on my hubs to get back from the machine shop...

#148

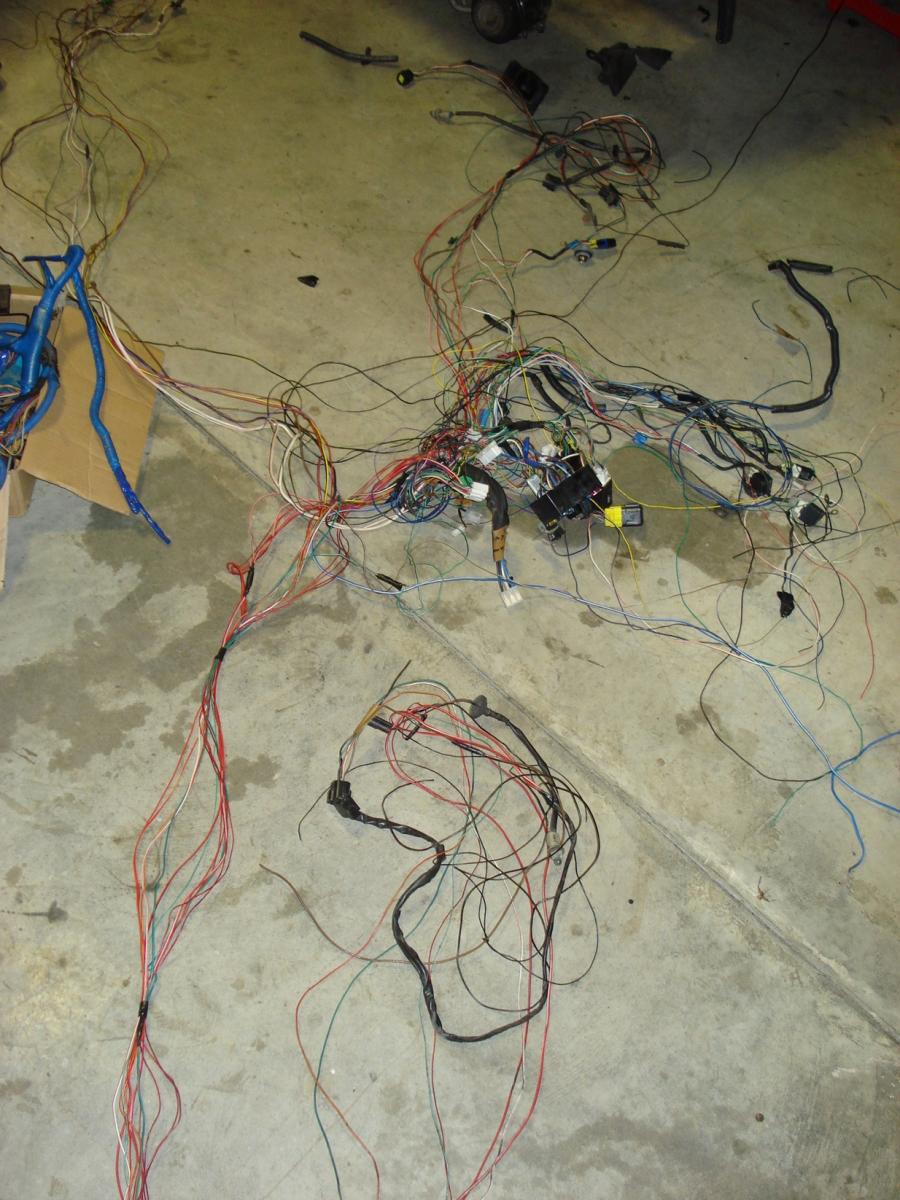

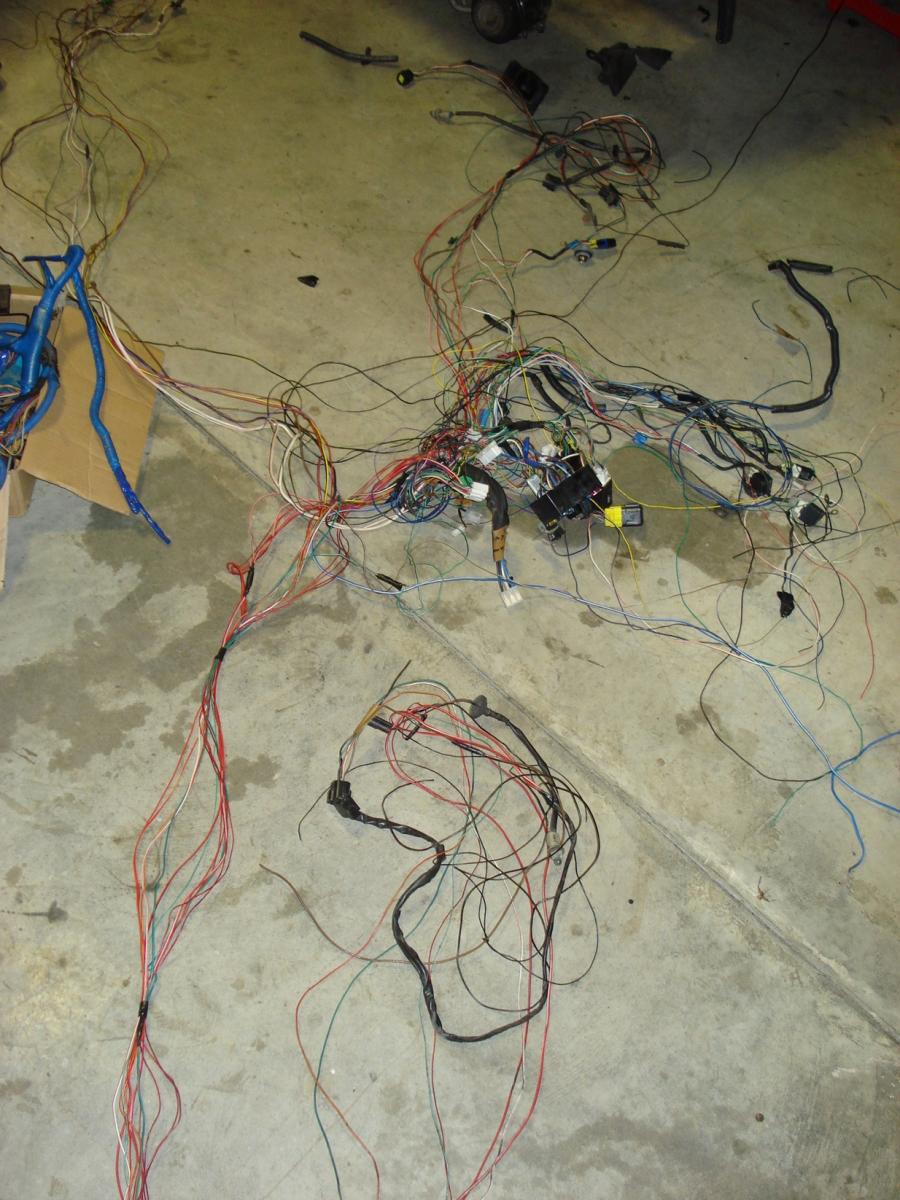

Things are slowing down drastically since school started this past Monday. My current goal is to invest at least 1 afternoon per week on the car. I finished putting the long block together this past weekend and tonight i did a bunch of wiring with a friend. What a freaking mess..

Interior is looking pretty clean though. All that's left is wire for the radio.

FYI. final subframe mods.

and for my question of the day.

What is this thing?

how does it work?

what wires need to go to it?

and

can i get by without it if im running AC?

Interior is looking pretty clean though. All that's left is wire for the radio.

FYI. final subframe mods.

and for my question of the day.

What is this thing?

how does it work?

what wires need to go to it?

and

can i get by without it if im running AC?

#152

Worked on the car some today. mostly making provisions for the wire tuck. I used some compression fittings to clamp onto the existing fuel lines today as well.

#153

I only asked if it was kit because of the contour cuts on the box that holds the bushing/sleeve. That's a nice half circle. I found a bunch poly bushings kits for leaf spring shackles, end links and body lifts- figured it was something from those. I use kit loosely as it is basically a bushing, inner sleeve and specs for the outer tubing to use.

Pressure switch. I'm only aware of one thermosensor and that's in the evaporator. But yeah, I wouldn't do anything w/o looking at the wiring diagram.

Pressure switch. I'm only aware of one thermosensor and that's in the evaporator. But yeah, I wouldn't do anything w/o looking at the wiring diagram.

#157

Yep- all similar to what I found. I'm just impressed by those perfect half circles in the mount box. They look laser cut or stamped.

Oscar has a point- low pressure systems appreciazte nice curves. Water pumps just froth the water if they have too much back pressure (what allows them to contend with a closed thermostat and smaller exits from the engine during cold). I got scolded for something similar and stuck a curved hose in there so never got to see a negative. But if you see higher temps, that will be worthy of investigating.

Water pumps just froth the water if they have too much back pressure (what allows them to contend with a closed thermostat and smaller exits from the engine during cold). I got scolded for something similar and stuck a curved hose in there so never got to see a negative. But if you see higher temps, that will be worthy of investigating.

Oscar has a point- low pressure systems appreciazte nice curves.

Water pumps just froth the water if they have too much back pressure (what allows them to contend with a closed thermostat and smaller exits from the engine during cold). I got scolded for something similar and stuck a curved hose in there so never got to see a negative. But if you see higher temps, that will be worthy of investigating.

Water pumps just froth the water if they have too much back pressure (what allows them to contend with a closed thermostat and smaller exits from the engine during cold). I got scolded for something similar and stuck a curved hose in there so never got to see a negative. But if you see higher temps, that will be worthy of investigating.

#158

Oscar has a point- low pressure systems appreciate nice curves.  Water pumps just froth the water if they have too much back pressure (what allows them to contend with a closed thermostat and smaller exits from the engine during cold). I got scolded for something similar and stuck a curved hose in there so never got to see a negative. But if you see higher temps, that will be worthy of investigating.

Water pumps just froth the water if they have too much back pressure (what allows them to contend with a closed thermostat and smaller exits from the engine during cold). I got scolded for something similar and stuck a curved hose in there so never got to see a negative. But if you see higher temps, that will be worthy of investigating.

Water pumps just froth the water if they have too much back pressure (what allows them to contend with a closed thermostat and smaller exits from the engine during cold). I got scolded for something similar and stuck a curved hose in there so never got to see a negative. But if you see higher temps, that will be worthy of investigating.

Water pumps just froth the water if they have too much back pressure (what allows them to contend with a closed thermostat and smaller exits from the engine during cold). I got scolded for something similar and stuck a curved hose in there so never got to see a negative. But if you see higher temps, that will be worthy of investigating.BUT a 1.5 inch silicone 90 in place of that welded 90 costs about $15 shipped off of ebay and would work awesome

#159

Oscar has a point- low pressure systems appreciazte nice curves.

Water pumps just froth the water if they have too much back pressure (what allows them to contend with a closed thermostat and smaller exits from the engine during cold). I got scolded for something similar and stuck a curved hose in there so never got to see a negative. But if you see higher temps, that will be worthy of investigating.

Water pumps just froth the water if they have too much back pressure (what allows them to contend with a closed thermostat and smaller exits from the engine during cold). I got scolded for something similar and stuck a curved hose in there so never got to see a negative. But if you see higher temps, that will be worthy of investigating.