Prepping my '95 for track

#1

Senior Member

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: durham NC

Posts: 792

Total Cats: 143

Hello,

I am finally getting a custom roll bar welded into my car to accommodate my awkward size (6'4") which means it is time to prep my car for track. I sent the fabricator I am working with a picture of Ryan Passey's half cage and we are going to do something similar but with slight changes for ingress/egress. My long term goal for this car is to get it under 1900lb, and over 150whp while keeping it street legal.

My car so far:

Xida CS 700/400

Poly Bushings with offsets in the front UCA

15x8 6uls with Rivals

Most CSP legal weight loss + more (down to just under 2000lb with a splash of fuel

TCM hardtop

Reverent Ms3 with canbus wideband interface

Borla cat back (came on the car)

Intake

Deka ETX-9

New front hubs with ARP studs

Parts I have waiting for install time

2001 engine

Squaretop

949 1.8 sport clutch with 10lb flywheel

Racing Beat header

Tillett b6f drivers seat

Cobra Suzuka pro XL for passenger

Schroth Profi II 6 point hans harness for me

Gforce 6 point FIA cert harness for passenger

On the to do list before spring:

*Replace rear hubs/pack with better grease + ARP studs

*Re-install stock RSB

*Re-Grease poly bushings and replace failed zerks

*Swap brake master cylinder to NB sport and add prop valve

*Brakes service (pads, rotors, slider pins, flush system)

*Make more secure battery bracket

*More tuning work

Other than having all new parts, my cooling system is stock. I am planning a re-route on the VVT engine and then will probably put in a crossflow radiator at the same time. I am hoping the stock system will hold up for the short term, especially since I am going to be driving pretty slow.

Some fun cutting I did today to prep for the half cage install:

ECU relocation to make space for cage weld in (need to move this again):

Door gutting (will remove more once door bars are in place):

Seat mount removal:

And my current spreadsheet of parts weights:

https://i.imgur.com/BCLug2F.png

I am finally getting a custom roll bar welded into my car to accommodate my awkward size (6'4") which means it is time to prep my car for track. I sent the fabricator I am working with a picture of Ryan Passey's half cage and we are going to do something similar but with slight changes for ingress/egress. My long term goal for this car is to get it under 1900lb, and over 150whp while keeping it street legal.

My car so far:

Xida CS 700/400

Poly Bushings with offsets in the front UCA

15x8 6uls with Rivals

Most CSP legal weight loss + more (down to just under 2000lb with a splash of fuel

TCM hardtop

Reverent Ms3 with canbus wideband interface

Borla cat back (came on the car)

Intake

Deka ETX-9

New front hubs with ARP studs

Parts I have waiting for install time

2001 engine

Squaretop

949 1.8 sport clutch with 10lb flywheel

Racing Beat header

Tillett b6f drivers seat

Cobra Suzuka pro XL for passenger

Schroth Profi II 6 point hans harness for me

Gforce 6 point FIA cert harness for passenger

On the to do list before spring:

*Replace rear hubs/pack with better grease + ARP studs

*Re-install stock RSB

*Re-Grease poly bushings and replace failed zerks

*Swap brake master cylinder to NB sport and add prop valve

*Brakes service (pads, rotors, slider pins, flush system)

*Make more secure battery bracket

*More tuning work

Other than having all new parts, my cooling system is stock. I am planning a re-route on the VVT engine and then will probably put in a crossflow radiator at the same time. I am hoping the stock system will hold up for the short term, especially since I am going to be driving pretty slow.

Some fun cutting I did today to prep for the half cage install:

ECU relocation to make space for cage weld in (need to move this again):

Door gutting (will remove more once door bars are in place):

Seat mount removal:

And my current spreadsheet of parts weights:

https://i.imgur.com/BCLug2F.png

Last edited by asmasm; 09-12-2015 at 12:14 PM.

#2

Senior Member

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: durham NC

Posts: 792

Total Cats: 143

I got my car back from the fabricator today. First impression, ride quality is much improved. Driving over horrible under construction pavement on I40 at 70mph to the fabricator was miserable. Driving home was as comfortable as my 2015 mazda3.

The whole thing is 1.75x.0.95. The drivers side front seat mounting holes have square tube under the tub tied into the cage, frame rails, and the drago trans tunnel notch he welded in. The rear mounts are reinforced with plates welded into the sheet metal. The seat belts are bracketed in for inspection reasons- They will never be used again. The main hoop is much farther back than any off the shelf roll bar, which was necessary for me to keep this car as dual duty. I sit so far back all off the shelf bars would have been right over my head I wasn't comfortable with that on car that I drive about 1000 street miles a year in.

Next up is painting the whole interior gloss white with rustoleum appliance epoxy.

The whole thing is 1.75x.0.95. The drivers side front seat mounting holes have square tube under the tub tied into the cage, frame rails, and the drago trans tunnel notch he welded in. The rear mounts are reinforced with plates welded into the sheet metal. The seat belts are bracketed in for inspection reasons- They will never be used again. The main hoop is much farther back than any off the shelf roll bar, which was necessary for me to keep this car as dual duty. I sit so far back all off the shelf bars would have been right over my head I wasn't comfortable with that on car that I drive about 1000 street miles a year in.

Next up is painting the whole interior gloss white with rustoleum appliance epoxy.

#5

I guess I didn't see this thread before. Hello fellow tall person. I'm 6'5" size big.

You did kind of what I did for starters with the half cage then I ended up going to a full cage for wheel to wheel, too bad yours ended up in a way that you have to take extra points for NASA Time Trials. Too many attachment points. And could have done 1.5" x 0.095" tubing as per the NASA CCR as well for less weight. One other thing to keep in mind is if you want to expand it into a full cage for wheel to wheel racing, the main hoop is illegal (cannot have more than 4 bends) so pretty much the whole thing would have to get cut out to make the jump to wheel to wheel racing in the future. I always said I would never do wheel to wheel and look where I ended up lol.

But all that's kind of irrelevant if you weren't planning on doing competition type events at NASA/SCCA or anyone that uses their cage rules, that's just a guess on my part.

Anyways, cool stuff man. Can't wait to see more progress.

You did kind of what I did for starters with the half cage then I ended up going to a full cage for wheel to wheel, too bad yours ended up in a way that you have to take extra points for NASA Time Trials. Too many attachment points. And could have done 1.5" x 0.095" tubing as per the NASA CCR as well for less weight. One other thing to keep in mind is if you want to expand it into a full cage for wheel to wheel racing, the main hoop is illegal (cannot have more than 4 bends) so pretty much the whole thing would have to get cut out to make the jump to wheel to wheel racing in the future. I always said I would never do wheel to wheel and look where I ended up lol.

But all that's kind of irrelevant if you weren't planning on doing competition type events at NASA/SCCA or anyone that uses their cage rules, that's just a guess on my part.

Anyways, cool stuff man. Can't wait to see more progress.

#6

Senior Member

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: durham NC

Posts: 792

Total Cats: 143

No plans for wheel to wheel. If I was building a car for wheel to wheel racing I would probably pick something larger that I fit into better.

My thought was that with no front hoop this doesn't really constitute a cage and I should go by roll bar guidelines. I could have done lighter tubing for all the door bar sections though.

This started just needing a custom roll bar to be able to fit into the car in a way I felt safe on the street. Then it turned into a "for the weight of door bars I could gut my factory doors" situation.

I am keeping the car streetable but my standard for what I am considering streetable is basically a lotus 7.

My thought was that with no front hoop this doesn't really constitute a cage and I should go by roll bar guidelines. I could have done lighter tubing for all the door bar sections though.

This started just needing a custom roll bar to be able to fit into the car in a way I felt safe on the street. Then it turned into a "for the weight of door bars I could gut my factory doors" situation.

I am keeping the car streetable but my standard for what I am considering streetable is basically a lotus 7.

#8

Senior Member

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: durham NC

Posts: 792

Total Cats: 143

I did the math on the doors bars weight in 1.75x0.95 vs 1.5x0.95. They are 15 feet of tubing total so the weight difference is about 4lb.

Total weight for this, including the seat mount under the floor tied into the cage and plate welded in for the drivers seat looks like it will be just under 90lb.

Gutting the doors saved me about 50lb, and I lost maybe another 10lb cut away seat belt tower, package shelf, and other bits. Basically, for about 30lb of weight gain I made the car massively stiffer, and added really good roll over and side impact protection.

I am trying to convince my wife to let me install some eye bolts as a latch system for our toddler.

Total weight for this, including the seat mount under the floor tied into the cage and plate welded in for the drivers seat looks like it will be just under 90lb.

Gutting the doors saved me about 50lb, and I lost maybe another 10lb cut away seat belt tower, package shelf, and other bits. Basically, for about 30lb of weight gain I made the car massively stiffer, and added really good roll over and side impact protection.

I am trying to convince my wife to let me install some eye bolts as a latch system for our toddler.

#9

Senior Member

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: durham NC

Posts: 792

Total Cats: 143

Holy crap painting tubing and interiors is a pain in the ***. I went with the more is better approach since preventing rust is more important than not having drips. I used rustoleum appliance epoxy paint. In a few weeks when it is cured to 100% hardness I will block sand the worst drips down and re-paint them.

#11

Senior Member

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: durham NC

Posts: 792

Total Cats: 143

Question- How do people paint the inside of taco gussets? I did my best to shoot primer into it but I am sure there is some unpainted surface inside. Is there such a thing as a long nozzle for a spray can that shoots in something like 180 degree pattern?

#14

Senior Member

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: durham NC

Posts: 792

Total Cats: 143

Yeah, I am going to run a bunch of that dual durometer padding. Some on the door bars, and everywhere near my head.

The nice thing about having gone with a really custom route for the roll bar is that everything is positioned so I can't make my head touch it, even when lifting myself out of the seat not wearing belts. The tillet seat is an order of magnitude more rigid than any of the other seats I have messed with, and my floor has plates and tubes tied into the cage and frame rails so they aren't going anywhere. The b6f also has two areas you can tie into the seat back for extra bracing, which I might make a bracket for later on. Basically, this seat is not going to flex much at all.

Also, the answer to my question about painting the inside of taco gussets is this:

The nice thing about having gone with a really custom route for the roll bar is that everything is positioned so I can't make my head touch it, even when lifting myself out of the seat not wearing belts. The tillet seat is an order of magnitude more rigid than any of the other seats I have messed with, and my floor has plates and tubes tied into the cage and frame rails so they aren't going anywhere. The b6f also has two areas you can tie into the seat back for extra bracing, which I might make a bracket for later on. Basically, this seat is not going to flex much at all.

Also, the answer to my question about painting the inside of taco gussets is this:

Last edited by asmasm; 12-23-2015 at 07:58 PM.

#15

Senior Member

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: durham NC

Posts: 792

Total Cats: 143

I got an alien motion 12 cell - This is basically the same as the ballistic evo2 12 cell, same cells, same arrangement, and alien motion used to make ballistic's batteries. I'm sure someone from ballistic would dispute that or claim they get some kind of cherry picked cells from a123 but all the images of disassembled batteries I have seen say otherwise.

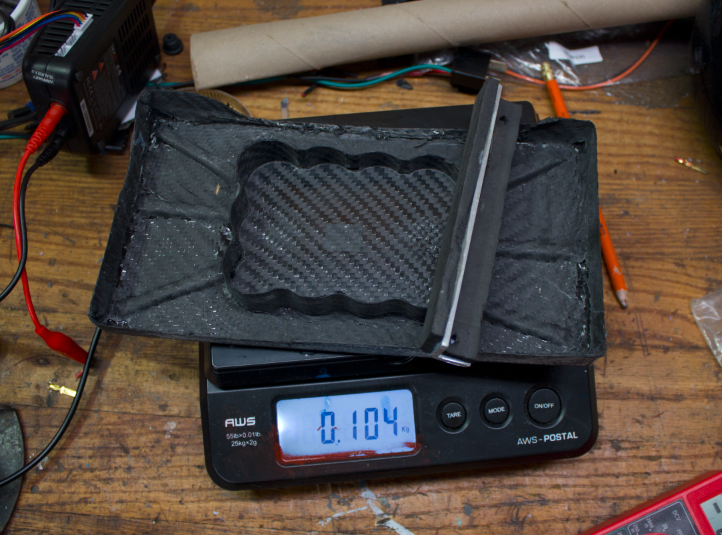

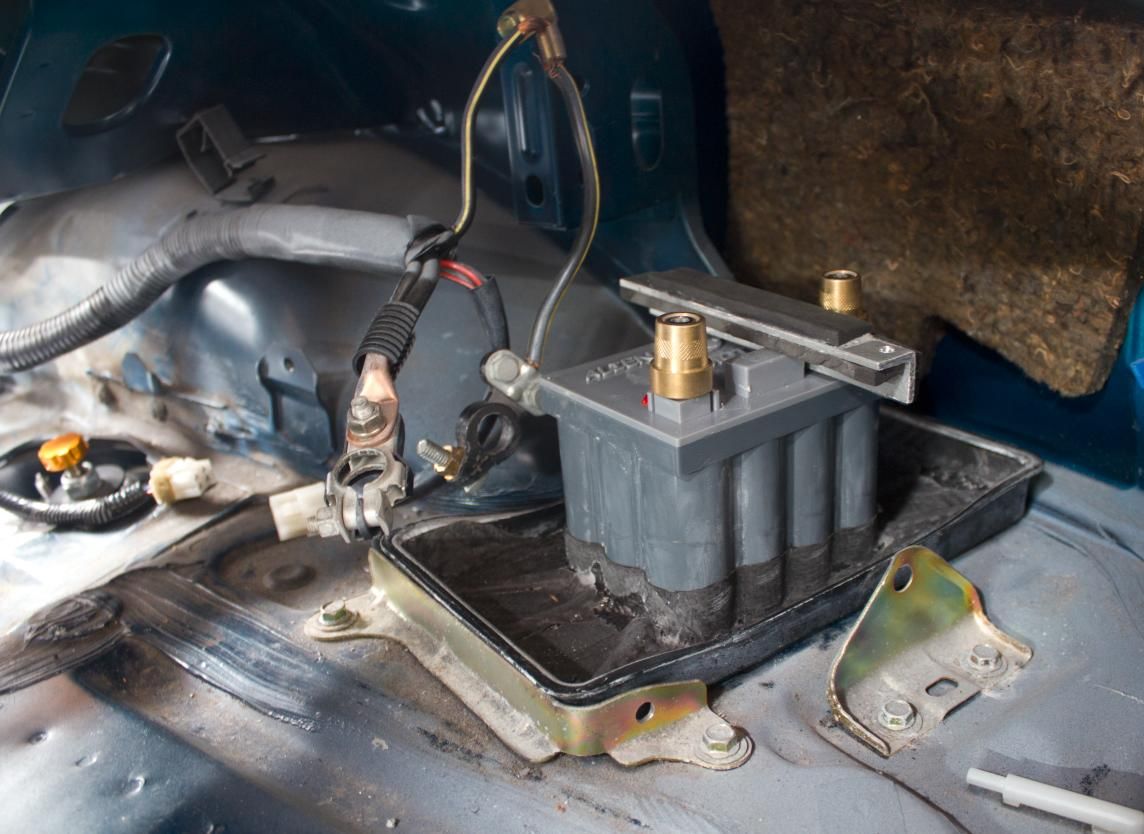

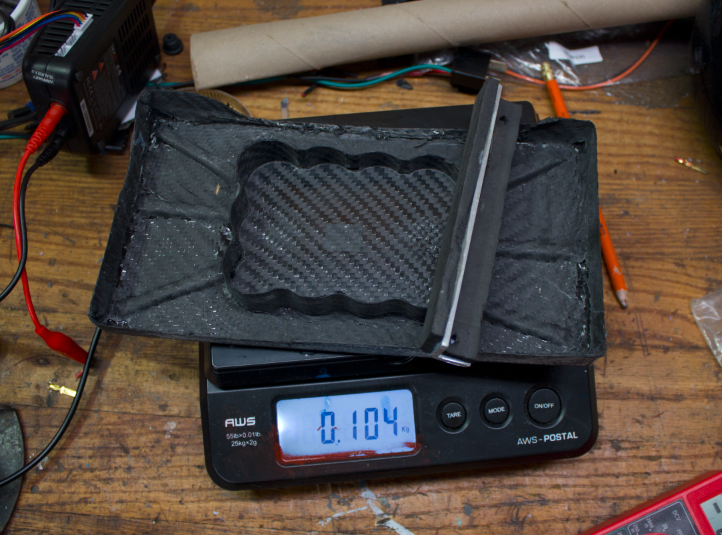

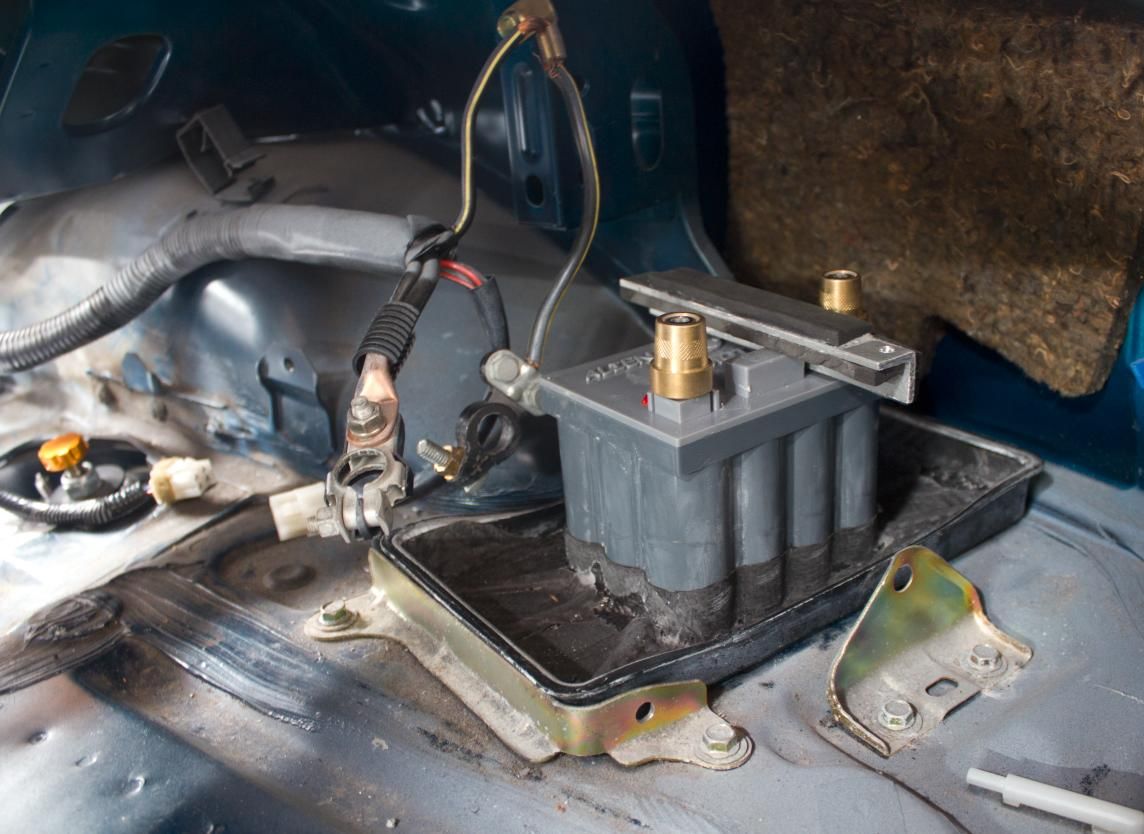

Making a battery mount for it. This is stock battery tray with a sandwich core carbon tray being laminated inside. I am using the actual battery as part of the tool so it has to cure as room temp. Hopefully this all works and I can get the battery back out without destroying the new carbon tray insert:

The three ribs coming from the battery outwards are the sandwhich bit, just some thin strips of foam.

Also, battery hold down some of the same foam glued on for insulation. The terminals are so close together that running a bunch of aluminum between them looked like a bad idea.

Making a battery mount for it. This is stock battery tray with a sandwich core carbon tray being laminated inside. I am using the actual battery as part of the tool so it has to cure as room temp. Hopefully this all works and I can get the battery back out without destroying the new carbon tray insert:

The three ribs coming from the battery outwards are the sandwhich bit, just some thin strips of foam.

Also, battery hold down some of the same foam glued on for insulation. The terminals are so close together that running a bunch of aluminum between them looked like a bad idea.

#16

Looks real good. The Bsci padding would make that seat a nice place to be.

__________________

OG Racing

Your Source For Motorsports Safety Equipment

WWW.OGRACING.COM

800.934.9112

703.430.3303

info@ogracing.com

OG Racing

Your Source For Motorsports Safety Equipment

WWW.OGRACING.COM

800.934.9112

703.430.3303

info@ogracing.com

#17

Senior Member

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: durham NC

Posts: 792

Total Cats: 143

I might do the BSCI padding. I have a trial size of the firmest flexible urethane foam from smooth-on to test out. In my experience the rigid foams are comfortable so long as you aren't wearing a different belt than normal, or left something small in your pocket, in which case they get forced into you a little bit and become uncomfortable over time.

#18

^exactly right. I did a new npo1 car. The driver forgot his iPhone 6 in his pocket. Left a huge imprint in the foam. I had to make a iPhone shaped piece of foam and glue it in.

A seat like yours should only need a medium sized kit. If you come out to a Nasa SE event ill poor it for you. I wave the $300 pour fee for fia seats at Nasa events. I think we'll be at cmp next month.

A seat like yours should only need a medium sized kit. If you come out to a Nasa SE event ill poor it for you. I wave the $300 pour fee for fia seats at Nasa events. I think we'll be at cmp next month.

__________________

OG Racing

Your Source For Motorsports Safety Equipment

WWW.OGRACING.COM

800.934.9112

703.430.3303

info@ogracing.com

OG Racing

Your Source For Motorsports Safety Equipment

WWW.OGRACING.COM

800.934.9112

703.430.3303

info@ogracing.com

#19

Senior Member

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: durham NC

Posts: 792

Total Cats: 143

Thanks for the offer but I have the one man seat insert process down pretty well. I am probably just going to make a lumbar pad as this seat is already really comfortable without any padding and I want something quick and easy to remove without fussing with the belts.

#20

Senior Member

Thread Starter

iTrader: (1)

Join Date: Jul 2012

Location: durham NC

Posts: 792

Total Cats: 143

My battery tray came out messy but still functional. The carbon got pulled out of place on the two narrower edges by the vacuum bag. The tray insert + hold down bar came out to 104 grams. I will hold it down with two small turnbuckles and threaded rod.

Last edited by asmasm; 12-25-2015 at 03:23 PM.

Seriously though I can imagine that must have sucked to paint!

Seriously though I can imagine that must have sucked to paint!