Faelflora breaks his promise, time to part out car. GIT THE SAWZALL!

#3503

Elite Member

Thread Starter

iTrader: (2)

Join Date: Jan 2007

Location: Los Angeles, CA

Posts: 8,682

Total Cats: 130

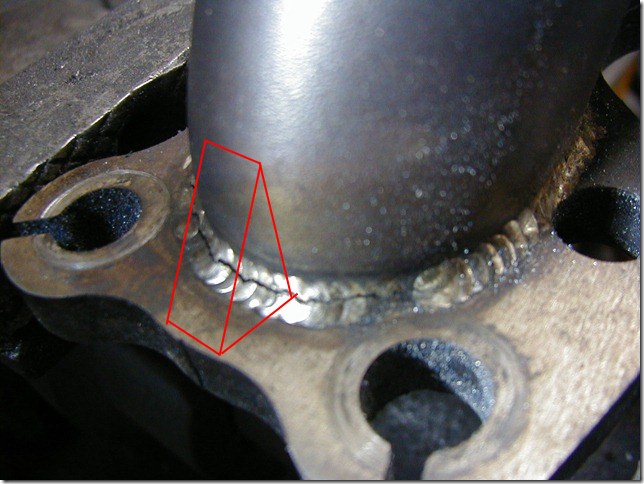

The collector is cracked too :(

I shipped it off to ARTech today.

I also shipped off my Hydra for upgrade to 2.7 to fix the repugnant hot start megafail injector dead time failflest

#3504

Elite Member

Thread Starter

iTrader: (2)

Join Date: Jan 2007

Location: Los Angeles, CA

Posts: 8,682

Total Cats: 130

Oh and so what are your thoughts peoples about how to keep the turbo manfiold from disintegrating in another 1000 miles? What engineering wonderfulness does this need?

1 million gussets?

mega crane?

super attach exhaust with 1 million bouncy hangers? (downpipe already has flex joint)

RTV or something else spoogy?

1 million gussets?

mega crane?

super attach exhaust with 1 million bouncy hangers? (downpipe already has flex joint)

RTV or something else spoogy?

#3507

Gussets, built on bracing, send it out to be stress relieved. I realize parts of it get hot enough when the car is running to stress relieve parts of it, but get the whole thing stress relived to be extra sure. Then I'd see if you can fashion a way to bolt the turbo the the spot the AC bolts to and put a bracket between the downpipe and the tranny. Make sure that **** doesnt break.

#3508

I'm not a welding engineer, nor necessarily a welding expert but I do deal with welding specifications from time to time. That said, I'd be leary of weld's that fail either in the weld (like the other guy showed) or in the HAZ (as Fael's has shown).

Regardless of the application, thermal cycles, stresses, etc. etc. etc. a good weld (at least by our specs) is stronger than the base material. Stronger in static strength, and stronger in fatigue strength.

Now, I don't know Abe and I don't know his work outside of pictures I've seen here so I can't pass judgement. However, like I said before, I'd be worried about weld failures like these.

I'm not saying that you shouldn't brace/support the turbo better, I'm just saying these welds woulnd't meet our weld quality specs...

Regardless of the application, thermal cycles, stresses, etc. etc. etc. a good weld (at least by our specs) is stronger than the base material. Stronger in static strength, and stronger in fatigue strength.

Now, I don't know Abe and I don't know his work outside of pictures I've seen here so I can't pass judgement. However, like I said before, I'd be worried about weld failures like these.

I'm not saying that you shouldn't brace/support the turbo better, I'm just saying these welds woulnd't meet our weld quality specs...

#3509

I'm not a welding engineer, nor necessarily a welding expert but I do deal with welding specifications from time to time. That said, I'd be leary of weld's that fail either in the weld (like the other guy showed) or in the HAZ (as Fael's has shown).

Regardless of the application, thermal cycles, stresses, etc. etc. etc. a good weld (at least by our specs) is stronger than the base material. Stronger in static strength, and stronger in fatigue strength.

Now, I don't know Abe and I don't know his work outside of pictures I've seen here so I can't pass judgement. However, like I said before, I'd be worried about weld failures like these.

I'm not saying that you shouldn't brace/support the turbo better, I'm just saying these welds woulnd't meet our weld quality specs...

Regardless of the application, thermal cycles, stresses, etc. etc. etc. a good weld (at least by our specs) is stronger than the base material. Stronger in static strength, and stronger in fatigue strength.

Now, I don't know Abe and I don't know his work outside of pictures I've seen here so I can't pass judgement. However, like I said before, I'd be worried about weld failures like these.

I'm not saying that you shouldn't brace/support the turbo better, I'm just saying these welds woulnd't meet our weld quality specs...

#3512

Regardless of the base material, whether it be mild steel, stainless, aluminum, copper, inconel, etc.; the ideal weld will be stronger than the base material and the HAZ will also ideally be as strong as the base material. The reality is that is difficult to achieve but not impossible if the correct filler material is used, the welder/weldor do their job, and any necessary post processing is done.

#3516

Elite Member

Thread Starter

iTrader: (2)

Join Date: Jan 2007

Location: Los Angeles, CA

Posts: 8,682

Total Cats: 130

Regardless of the base material, whether it be mild steel, stainless, aluminum, copper, inconel, etc.; the ideal weld will be stronger than the base material and the HAZ will also ideally be as strong as the base material. The reality is that is difficult to achieve but not impossible if the correct filler material is used, the welder/weldor do their job, and any necessary post processing is done.

Sooo what could have gone wrong with my welds?

#3519

Elite Member

iTrader: (2)

Join Date: May 2008

Location: Portland, Oregon

Posts: 3,468

Total Cats: 365

Oh and so what are your thoughts peoples about how to keep the turbo manfiold from disintegrating in another 1000 miles? What engineering wonderfulness does this need?

1 million gussets?

mega crane?

super attach exhaust with 1 million bouncy hangers? (downpipe already has flex joint)

RTV or something else spoogy?

1 million gussets?

mega crane?

super attach exhaust with 1 million bouncy hangers? (downpipe already has flex joint)

RTV or something else spoogy?