Faelflora breaks his promise, time to part out car. GIT THE SAWZALL!

#3441

Elite Member

Thread Starter

iTrader: (2)

Join Date: Jan 2007

Location: Los Angeles, CA

Posts: 8,682

Total Cats: 130

If your idle fuel pressure is 70PSI, this explains your leaning problems. Your poor fuel pump is crapping out.

1. Disconnect vacuum line to pressure regulator.

2. Set pressure to 45PSI.

3. Connect vacuum line back.

4. Re-tune the fuel map as it will be too lean

5. Give us a good dyno run on a good dyno!

Remember typically regulators are 1:1. So if your idle is 70psi, your open air is 80ish which means with 35psi of boost you will be at 115PSI. Most pumps will have a hard time getting that high or if they do, the volume flow drops dramatically. You have no reason to run 70psi fuel pressure at idle.

1. Disconnect vacuum line to pressure regulator.

2. Set pressure to 45PSI.

3. Connect vacuum line back.

4. Re-tune the fuel map as it will be too lean

5. Give us a good dyno run on a good dyno!

Remember typically regulators are 1:1. So if your idle is 70psi, your open air is 80ish which means with 35psi of boost you will be at 115PSI. Most pumps will have a hard time getting that high or if they do, the volume flow drops dramatically. You have no reason to run 70psi fuel pressure at idle.

Thank you for the feedback.

The thing is though, it only started to go lean between two back to back runs.

And seriously, these two pumps combined flow like a gallon of fuel in five seconds.

I can indeed lower my fuel pressure and retune but it doesnt explain going lean between runs.

For next steps i was thinking do a pull let it go lean and shut off motor, then look at plugs

#3444

Senior Member

iTrader: (1)

Join Date: Sep 2011

Location: Lambertville, NJ

Posts: 1,215

Total Cats: 74

As has been stated several times now, it's unlikely that your going lean is caused by pump-issues. But it's not impossible.

Picture this: The pumps can barely make the pressure at the required flow, but they can make it. Now the fuel in your tank, sitting in a hot shop near a hot exhaust heats up and as a result the viscosity goes down. And all the sudden, the pumps can't make the pressure anymore because of the lower viscosity.

There may be many other potential reasons for this behavior that I can't think of right now. Fact is, if you're running something on the edge of its' specs or in a way it was never intended to, small random fluctuations of seemingly unrelated factors can cause a system to go from "works just fine" to "POS" in no time flat.

The fuel supply problem scenario is unlikely- granted, but not impossible.

And checking plugs NEVER hurts.

Picture this: The pumps can barely make the pressure at the required flow, but they can make it. Now the fuel in your tank, sitting in a hot shop near a hot exhaust heats up and as a result the viscosity goes down. And all the sudden, the pumps can't make the pressure anymore because of the lower viscosity.

There may be many other potential reasons for this behavior that I can't think of right now. Fact is, if you're running something on the edge of its' specs or in a way it was never intended to, small random fluctuations of seemingly unrelated factors can cause a system to go from "works just fine" to "POS" in no time flat.

The fuel supply problem scenario is unlikely- granted, but not impossible.

And checking plugs NEVER hurts.

#3447

Bosch 044 fuel pump specs:

Minimum Flow @ Outlet: 80 GPH

So he has 160 gallons per hour of fuel pump. That is 2.666 gallons per MINUTE. Unless I am misunderstanding something, they should be operating NOWHERE NEAR their limits.

Unless BOTH pumps are failing, it isn't the pumps. He has 2 still, right?

Minimum Flow @ Outlet: 80 GPH

So he has 160 gallons per hour of fuel pump. That is 2.666 gallons per MINUTE. Unless I am misunderstanding something, they should be operating NOWHERE NEAR their limits.

Unless BOTH pumps are failing, it isn't the pumps. He has 2 still, right?

#3451

Senior Member

iTrader: (1)

Join Date: Sep 2011

Location: Lambertville, NJ

Posts: 1,215

Total Cats: 74

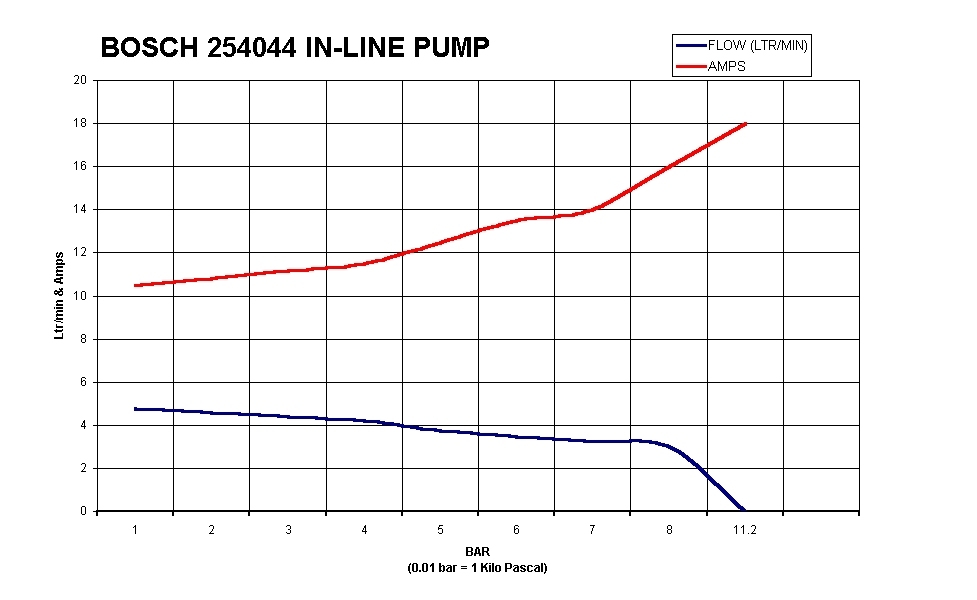

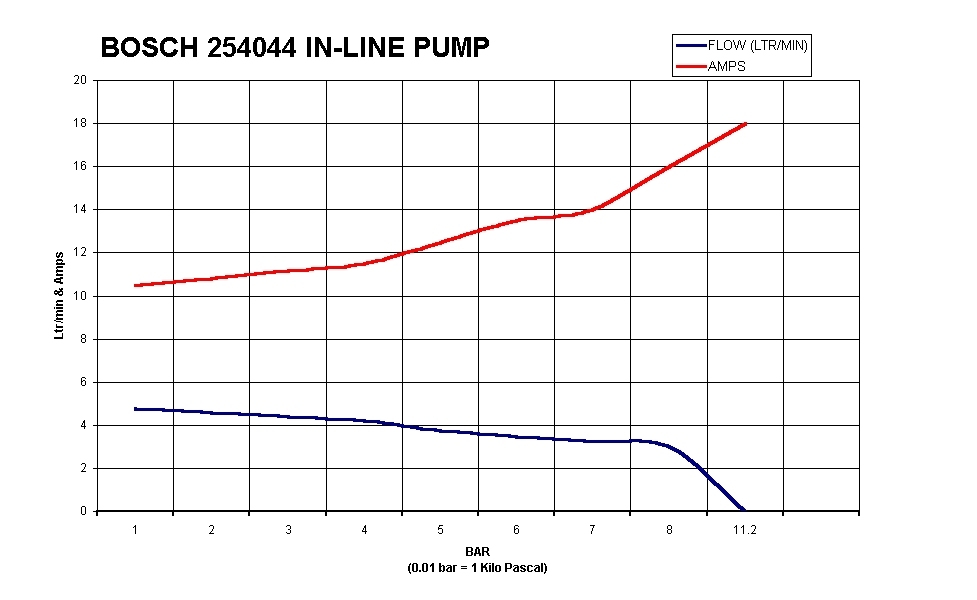

Just found a flow chart for the 044 pump. Looks like it's hitting the limit right around 120psi. That's under lab conditions. So it actually really may be the pumps just running beyond their specs.

#3453

-6AN but don't quote me on that. I have read through a lot of build threads in the last few days.

Edit: Just happened to read through it: https://www.miataturbo.net/build-thr...23/#post755708

-6 from one pump, stock hose from the other. Maybe it is time for wider hosing.

Edit: Just happened to read through it: https://www.miataturbo.net/build-thr...23/#post755708

-6 from one pump, stock hose from the other. Maybe it is time for wider hosing.

Last edited by thenuge26; 08-16-2012 at 05:18 PM.

#3455

Moderator

iTrader: (12)

Join Date: Nov 2008

Location: Tampa, Florida

Posts: 20,652

Total Cats: 3,011

Am I the only one laughing about Fae running such a high fuel pressure and short duty cycle instead of running a normal pressure and a proper duty cycle like everyone else? Why didn't you start with a 138lb base pressure since we're just picking odd numbers to set it to? Seriously, it doesn't matter if that was the pressure it was set to when it came out of the box, you are allowed to turn it down.

IF you have the base pressure set too high, the line pressure might not actually be able to rise at the 1 to 1 ratio being requested by the regulator and may skew the tuning of your VE table. It also may perform differently from day to day or moment to moment since the resulting pressure will be dictated by the temperature of the pumps, available voltage and amperage, fuel tank level, etc. instead of the regulator precisely controlling it.

The only time I see you needing to use a higher than standard base fuel pressure is if your injectors are too small and you are trying to compensate instead of buying larger injectors. Are your ID1k injectors too small?

#3456

I am not saying that will solve your problem. I am saying what you have in there is not ideal and it MIGHT solve your problem.

Let's be realistic here instead of looking at graphs and data.

- The graph shows the pump tanking it at 120psi AT PUMP IN LAB CONDITIONS. Now you are asking 115PSI at the regulator which is after all the injectors. So that means through some lines (which I am not sure are big enough, they might be) and also filters, through rails, and all other restrictions and then getting to the regulator. So exact same thing as on the air side, will happen on the liquid side. So a 115psi at regulator might mean the pumps are pushing higher. Possible 120-125psi. Now add heat to that and you are totally screwed.

You have to step back and first try and see what can be wrong here. It could be something super simple or something complicated. This one sounds like a logical step as it might solve your problem. I have run 400whp in a 323 with a single pump set at 45psi open pressure and 27PSI and that was a small turbo. Anyways one thing at a time. please check that, retune it and see how it is on the street. If it doesn't fix the problem, at least you know it's not that.

By the way how are your two pumps hooked up, series or parallel? I am guessing they are parallel.

Let's be realistic here instead of looking at graphs and data.

- The graph shows the pump tanking it at 120psi AT PUMP IN LAB CONDITIONS. Now you are asking 115PSI at the regulator which is after all the injectors. So that means through some lines (which I am not sure are big enough, they might be) and also filters, through rails, and all other restrictions and then getting to the regulator. So exact same thing as on the air side, will happen on the liquid side. So a 115psi at regulator might mean the pumps are pushing higher. Possible 120-125psi. Now add heat to that and you are totally screwed.

You have to step back and first try and see what can be wrong here. It could be something super simple or something complicated. This one sounds like a logical step as it might solve your problem. I have run 400whp in a 323 with a single pump set at 45psi open pressure and 27PSI and that was a small turbo. Anyways one thing at a time. please check that, retune it and see how it is on the street. If it doesn't fix the problem, at least you know it's not that.

By the way how are your two pumps hooked up, series or parallel? I am guessing they are parallel.

#3457

Elite Member

Thread Starter

iTrader: (2)

Join Date: Jan 2007

Location: Los Angeles, CA

Posts: 8,682

Total Cats: 130

They are flat an spiffy. Logs are in my dyno thread.

I am not saying that will solve your problem. I am saying what you have in there is not ideal and it MIGHT solve your problem.

Let's be realistic here instead of looking at graphs and data.

- The graph shows the pump tanking it at 120psi AT PUMP IN LAB CONDITIONS. Now you are asking 115PSI at the regulator which is after all the injectors. So that means through some lines (which I am not sure are big enough, they might be) and also filters, through rails, and all other restrictions and then getting to the regulator. So exact same thing as on the air side, will happen on the liquid side. So a 115psi at regulator might mean the pumps are pushing higher. Possible 120-125psi. Now add heat to that and you are totally screwed.

You have to step back and first try and see what can be wrong here. It could be something super simple or something complicated. This one sounds like a logical step as it might solve your problem. I have run 400whp in a 323 with a single pump set at 45psi open pressure and 27PSI and that was a small turbo. Anyways one thing at a time. please check that, retune it and see how it is on the street. If it doesn't fix the problem, at least you know it's not that.

By the way how are your two pumps hooked up, series or parallel? I am guessing they are parallel.

Let's be realistic here instead of looking at graphs and data.

- The graph shows the pump tanking it at 120psi AT PUMP IN LAB CONDITIONS. Now you are asking 115PSI at the regulator which is after all the injectors. So that means through some lines (which I am not sure are big enough, they might be) and also filters, through rails, and all other restrictions and then getting to the regulator. So exact same thing as on the air side, will happen on the liquid side. So a 115psi at regulator might mean the pumps are pushing higher. Possible 120-125psi. Now add heat to that and you are totally screwed.

You have to step back and first try and see what can be wrong here. It could be something super simple or something complicated. This one sounds like a logical step as it might solve your problem. I have run 400whp in a 323 with a single pump set at 45psi open pressure and 27PSI and that was a small turbo. Anyways one thing at a time. please check that, retune it and see how it is on the street. If it doesn't fix the problem, at least you know it's not that.

By the way how are your two pumps hooked up, series or parallel? I am guessing they are parallel.

The pumps are hooked up in parrallel.

#3458

Alright, so you are doubling up the volume, but the pressure capacity stays same as a single one.

One more thing: I noticed one place you mentioned you guys added timing to a point just before knocking. Now this does not have anything to do with your problems. But generally the higher the advance does not equate to higher power. You reach a point where the increased pressure in the cylinder actually negatively effects the power. For example I have tuned cars that you could have 40deg of timing without knock at a specific point in the rpm, however the maximum power was made at 36deg of timing at that point. Just remember that next time you are on the dyno. Play around with the timing specially after where the max torque would be (which definitely should be under 6000rpm unlike when the car/dyno issues are fixed). Just a FYI. You are going after so much power, better squeeze every last bit out of there!

One more thing: I noticed one place you mentioned you guys added timing to a point just before knocking. Now this does not have anything to do with your problems. But generally the higher the advance does not equate to higher power. You reach a point where the increased pressure in the cylinder actually negatively effects the power. For example I have tuned cars that you could have 40deg of timing without knock at a specific point in the rpm, however the maximum power was made at 36deg of timing at that point. Just remember that next time you are on the dyno. Play around with the timing specially after where the max torque would be (which definitely should be under 6000rpm unlike when the car/dyno issues are fixed). Just a FYI. You are going after so much power, better squeeze every last bit out of there!

#3459

Alright, so you are doubling up the volume, but the pressure capacity stays same as a single one.

One more thing: I noticed one place you mentioned you guys added timing to a point just before knocking. Now this does not have anything to do with your problems. But generally the higher the advance does not equate to higher power. You reach a point where the increased pressure in the cylinder actually negatively effects the power. For example I have tuned cars that you could have 40deg of timing without knock at a specific point in the rpm, however the maximum power was made at 36deg of timing at that point. Just remember that next time you are on the dyno. Play around with the timing specially after where the max torque would be (which definitely should be under 6000rpm unlike when the car/dyno issues are fixed). Just a FYI. You are going after so much power, better squeeze every last bit out of there!

One more thing: I noticed one place you mentioned you guys added timing to a point just before knocking. Now this does not have anything to do with your problems. But generally the higher the advance does not equate to higher power. You reach a point where the increased pressure in the cylinder actually negatively effects the power. For example I have tuned cars that you could have 40deg of timing without knock at a specific point in the rpm, however the maximum power was made at 36deg of timing at that point. Just remember that next time you are on the dyno. Play around with the timing specially after where the max torque would be (which definitely should be under 6000rpm unlike when the car/dyno issues are fixed). Just a FYI. You are going after so much power, better squeeze every last bit out of there!

#3460

Elite Member

Thread Starter

iTrader: (2)

Join Date: Jan 2007

Location: Los Angeles, CA

Posts: 8,682

Total Cats: 130

Alright, so you are doubling up the volume, but the pressure capacity stays same as a single one.

One more thing: I noticed one place you mentioned you guys added timing to a point just before knocking. Now this does not have anything to do with your problems. But generally the higher the advance does not equate to higher power. You reach a point where the increased pressure in the cylinder actually negatively effects the power. For example I have tuned cars that you could have 40deg of timing without knock at a specific point in the rpm, however the maximum power was made at 36deg of timing at that point. Just remember that next time you are on the dyno. Play around with the timing specially after where the max torque would be (which definitely should be under 6000rpm unlike when the car/dyno issues are fixed). Just a FYI. You are going after so much power, better squeeze every last bit out of there!

One more thing: I noticed one place you mentioned you guys added timing to a point just before knocking. Now this does not have anything to do with your problems. But generally the higher the advance does not equate to higher power. You reach a point where the increased pressure in the cylinder actually negatively effects the power. For example I have tuned cars that you could have 40deg of timing without knock at a specific point in the rpm, however the maximum power was made at 36deg of timing at that point. Just remember that next time you are on the dyno. Play around with the timing specially after where the max torque would be (which definitely should be under 6000rpm unlike when the car/dyno issues are fixed). Just a FYI. You are going after so much power, better squeeze every last bit out of there!

You're talking about MBT, if you go over MBT you just start hammering on the big end bearings and not making any more power. I really doubt that at 35 psi the miata engine can hit MBT before knock. Not even the best fast burn GM heads can do that and their MBT numbers are typically lower than ours and their knock resistance better.

For public knowledge: how did i find the margin? By advancing on the street until it knocked.

This means: forged pistons are really quite a big win. Do not build motor without.