Nothing to see here, just project Sisyphus, move along

#342

Elite Member

Thread Starter

iTrader: (37)

Join Date: Apr 2010

Location: Very NorCal

Posts: 10,441

Total Cats: 1,899

Well, surprise surprise. Skunk2 didn't bother to send me anything on Thursday so I called them back.

Thursady afternoon:

Me: Hello, I called in this morning and spoke to X about a part I purchased that had been packed with the wrong ancillary parts. He said he would email me a form I had to fill out and email back. I never received the email so I wanted to follow up.

S2: Nobody by that name works here, your ticket number is not in our system, we don't know what you are talking about.

Me: Ok, let's start over then. What do I need to do to get this moving again?

S2: Email us pictures of box, parts, packing materials and the original invoice. Plus a brief description of what the problem is exactly.

Me: ok, what is your email address?

S2: support@Skunk2

Me: No, what is YOUR email address?

S2: I'm sorry, it has to go to the other address to be assigned a ticket number.

< I was prepared for this, mailed everything off at 3:45pm >

Friday AM

< crickets >

Friday 3:45pm

Me: Hi. Per the request of X at your support desk, yesterday at 3:45pm I emailed information about a product that was shipped with the wrong accessory parts to your support desk. It's been 24 hrs and I've not seen a reply, so I wanted to follow up and make sure I sent all the information you requssted.

S2: Nobody named X works here, there is no ticket number in our system that matches your name or email address, we never received your email, we don't know what you are talking about.

Me: Ok, **** this. Just sell me the part I need because I need to get this resolved. I have my credit card ready.

S2: Humm... I can't seem to find the part number in our system so I can't set up an order. Why don't you give me your info and we can contact you as soon as we get that part number.

Me: When should I expect a call back?

S2: Maybe Monday.

Thursady afternoon:

Me: Hello, I called in this morning and spoke to X about a part I purchased that had been packed with the wrong ancillary parts. He said he would email me a form I had to fill out and email back. I never received the email so I wanted to follow up.

S2: Nobody by that name works here, your ticket number is not in our system, we don't know what you are talking about.

Me: Ok, let's start over then. What do I need to do to get this moving again?

S2: Email us pictures of box, parts, packing materials and the original invoice. Plus a brief description of what the problem is exactly.

Me: ok, what is your email address?

S2: support@Skunk2

Me: No, what is YOUR email address?

S2: I'm sorry, it has to go to the other address to be assigned a ticket number.

< I was prepared for this, mailed everything off at 3:45pm >

Friday AM

< crickets >

Friday 3:45pm

Me: Hi. Per the request of X at your support desk, yesterday at 3:45pm I emailed information about a product that was shipped with the wrong accessory parts to your support desk. It's been 24 hrs and I've not seen a reply, so I wanted to follow up and make sure I sent all the information you requssted.

S2: Nobody named X works here, there is no ticket number in our system that matches your name or email address, we never received your email, we don't know what you are talking about.

Me: Ok, **** this. Just sell me the part I need because I need to get this resolved. I have my credit card ready.

S2: Humm... I can't seem to find the part number in our system so I can't set up an order. Why don't you give me your info and we can contact you as soon as we get that part number.

Me: When should I expect a call back?

S2: Maybe Monday.

#345

Elite Member

Thread Starter

iTrader: (37)

Join Date: Apr 2010

Location: Very NorCal

Posts: 10,441

Total Cats: 1,899

Oh, it is. As much as I hate to say it, its what I've come to expect.

Speaking of expectations, I'm also expecting to be told I bought a knock-off, or that Doap was never an "authorized re-seller" and thus I have no claim for support, so something equally silly. Honestly I don't care at this point. I just want the part so I can install the TB and get it tuned. I'm half tempted to tap the ******* thing for hose barbs and remote mount the IACV like a caveman.

On the bright side, once I get the part I need I'll have both the NA and NB IACV mounts so that'll help resale value when I inevitably give up and part out

Serious question time: Does everyone else have these problems with vendors or is it just me? Are my expectations that far out of whack? Am I expecting too much?

Speaking of expectations, I'm also expecting to be told I bought a knock-off, or that Doap was never an "authorized re-seller" and thus I have no claim for support, so something equally silly. Honestly I don't care at this point. I just want the part so I can install the TB and get it tuned. I'm half tempted to tap the ******* thing for hose barbs and remote mount the IACV like a caveman.

On the bright side, once I get the part I need I'll have both the NA and NB IACV mounts so that'll help resale value when I inevitably give up and part out

Serious question time: Does everyone else have these problems with vendors or is it just me? Are my expectations that far out of whack? Am I expecting too much?

#349

Elite Member

iTrader: (2)

Join Date: May 2008

Location: Portland, Oregon

Posts: 3,468

Total Cats: 365

I have low expectations of other people actually doing their jobs, but you really seem to be a corner case in being able to find true incompetence in both the individual employee as well as company practices and procedures.

#350

Elite Member

Thread Starter

iTrader: (37)

Join Date: Apr 2010

Location: Very NorCal

Posts: 10,441

Total Cats: 1,899

Despite the setbacks, I finished a bunch of crap over the weekend. I'll post progress pics later.

For now, I'd like to get some feedback on this...

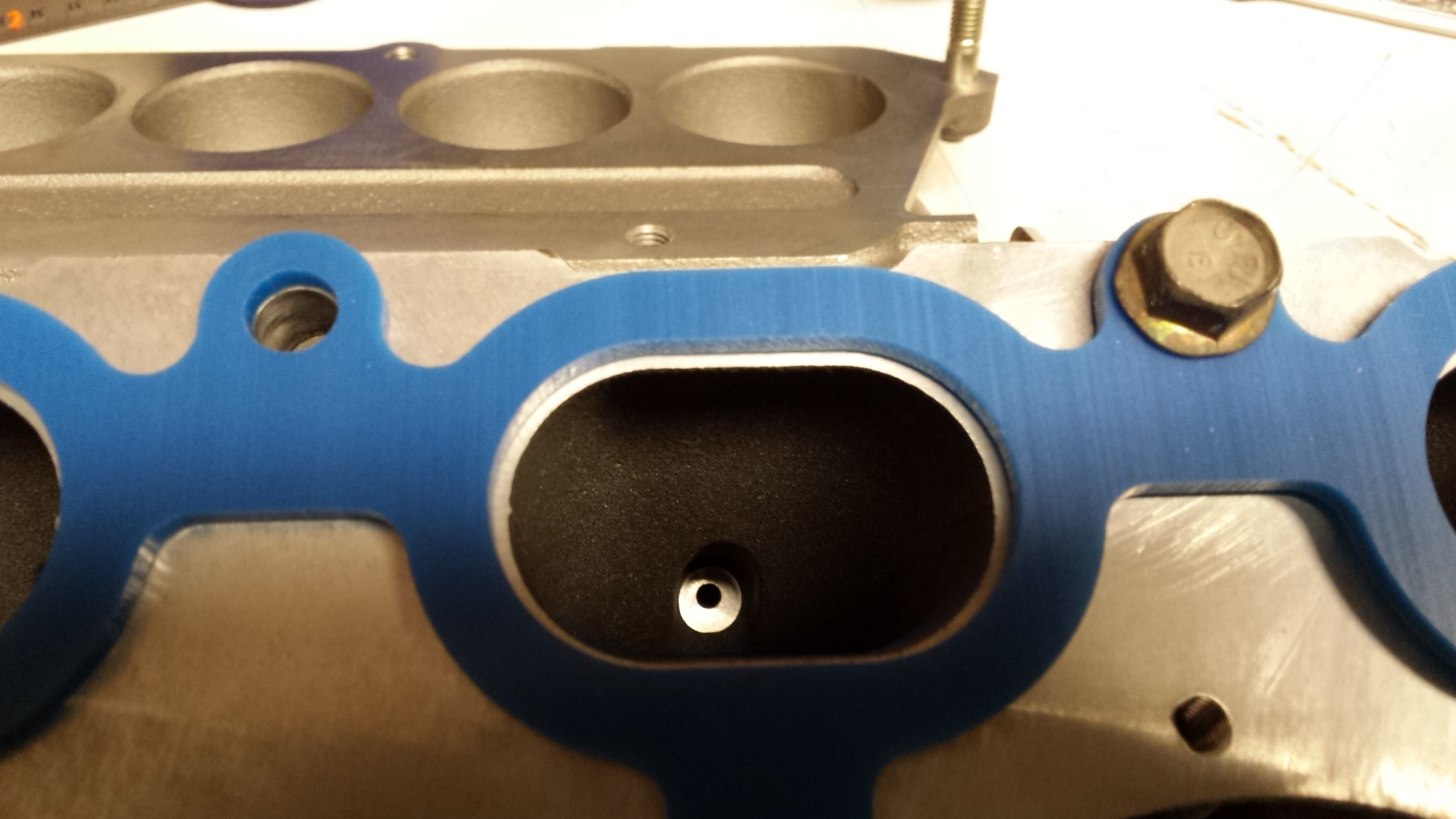

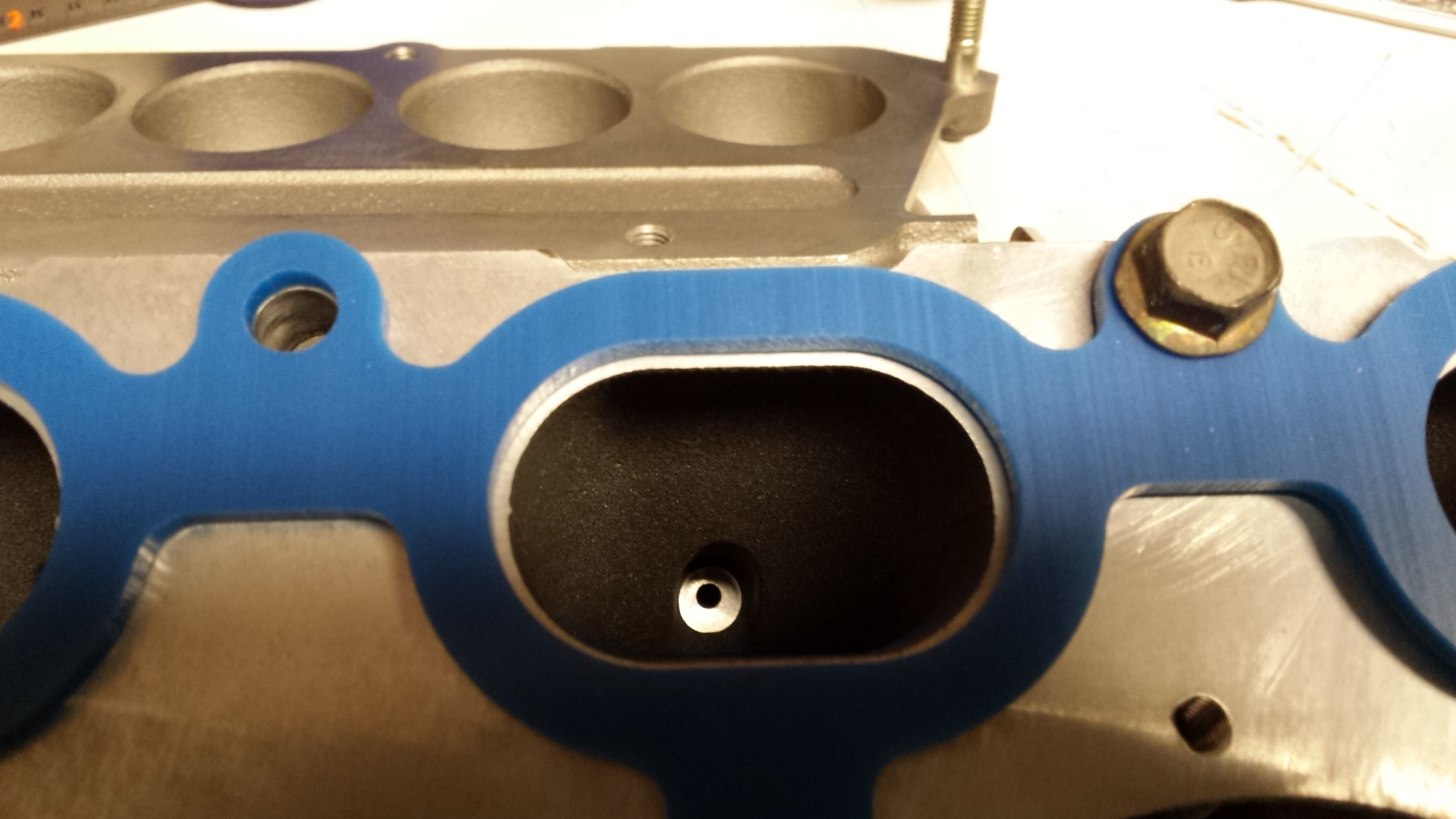

One of the parts I've been sitting on for at least the last 2~3 years is a Hondata thermo isolator intake manifold gasket. It looks like this:

This is one of those "while I'm in there" kind of parts so I figured I'd order it just for good measure.

The manifold and head could be port matched for better flow, but I decided I didn't want to screw around with it for the time being

Its about 3.5mm thick, but its a very hard plastic so I don't expect much compression. With my highly calibrated wrist I torqued the manifold nuts to "angry monkey" tight.

So here is my issue: with this gasket in place, I cannot reinstall the lower manifold brace. I can probably make a spacer of appropriate thickness to fit between the brace and the block to make things line up again, but I'm on the fence as to if I actually "need" the lower brace or not. With the aggressive engine mounts, the vibratory nature of the BP, and the possible compression of the plastic spacer I'm concerned with long term durability. The last thing I need is the manifold coming loose and causing vacuum leaks from hell.

Anyone with any insight into this particular set of circumstances? It's not beyond my ability to create problems that do not exist, but I'd like some feedback if just to prove I'm (not) insane.

For now, I'd like to get some feedback on this...

One of the parts I've been sitting on for at least the last 2~3 years is a Hondata thermo isolator intake manifold gasket. It looks like this:

This is one of those "while I'm in there" kind of parts so I figured I'd order it just for good measure.

The manifold and head could be port matched for better flow, but I decided I didn't want to screw around with it for the time being

Its about 3.5mm thick, but its a very hard plastic so I don't expect much compression. With my highly calibrated wrist I torqued the manifold nuts to "angry monkey" tight.

So here is my issue: with this gasket in place, I cannot reinstall the lower manifold brace. I can probably make a spacer of appropriate thickness to fit between the brace and the block to make things line up again, but I'm on the fence as to if I actually "need" the lower brace or not. With the aggressive engine mounts, the vibratory nature of the BP, and the possible compression of the plastic spacer I'm concerned with long term durability. The last thing I need is the manifold coming loose and causing vacuum leaks from hell.

Anyone with any insight into this particular set of circumstances? It's not beyond my ability to create problems that do not exist, but I'd like some feedback if just to prove I'm (not) insane.

#352

Elite Member

Thread Starter

iTrader: (37)

Join Date: Apr 2010

Location: Very NorCal

Posts: 10,441

Total Cats: 1,899

Its probably a good idea, it just sucks. Not sure where I'm going to find a chunk of 0.138"/3.5mm aluminum. I'll swing by the hardware store tonight and see if I can get lucky with something as simple as a washer.

#357

Elite Member

Thread Starter

iTrader: (37)

Join Date: Apr 2010

Location: Very NorCal

Posts: 10,441

Total Cats: 1,899

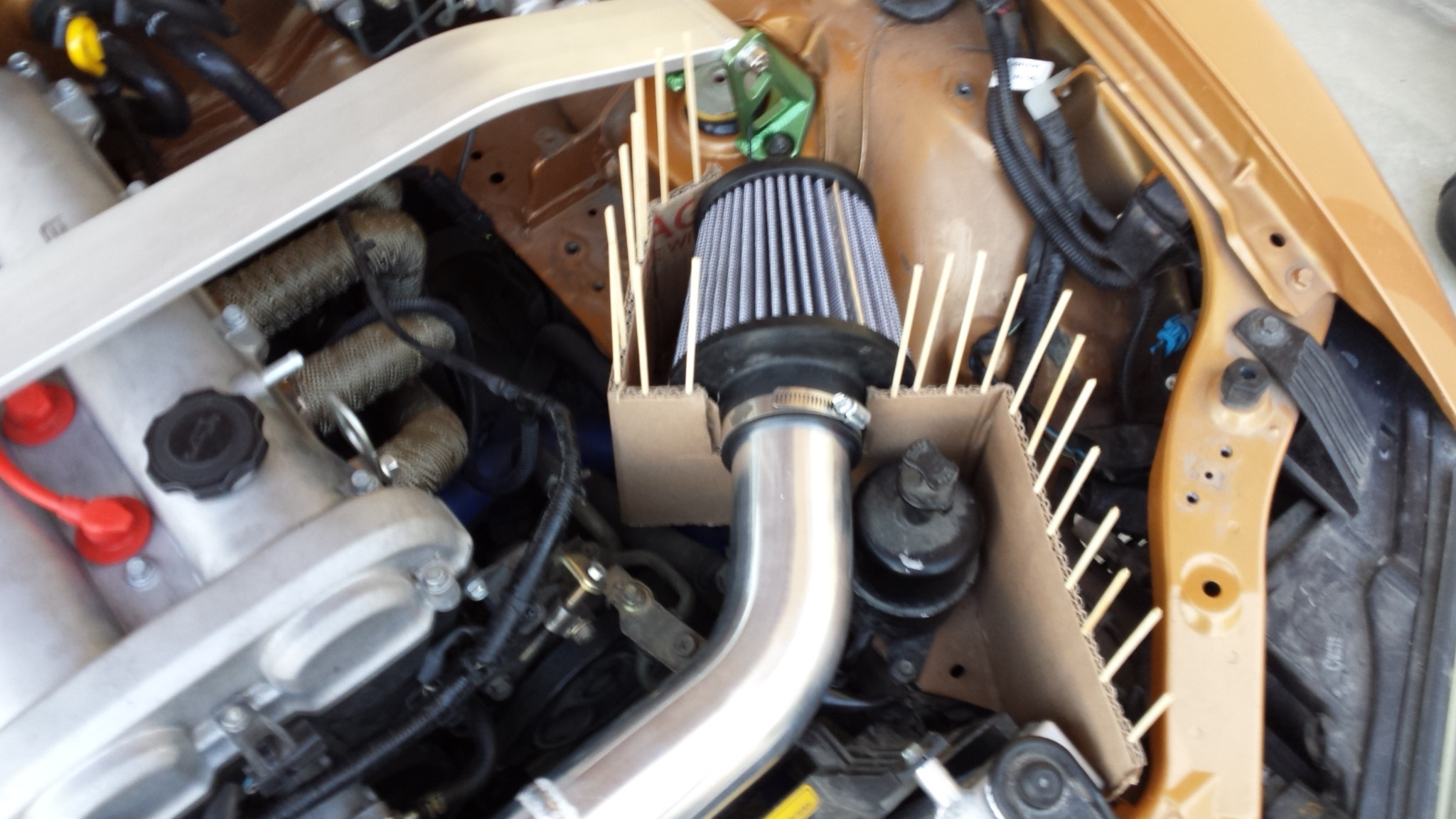

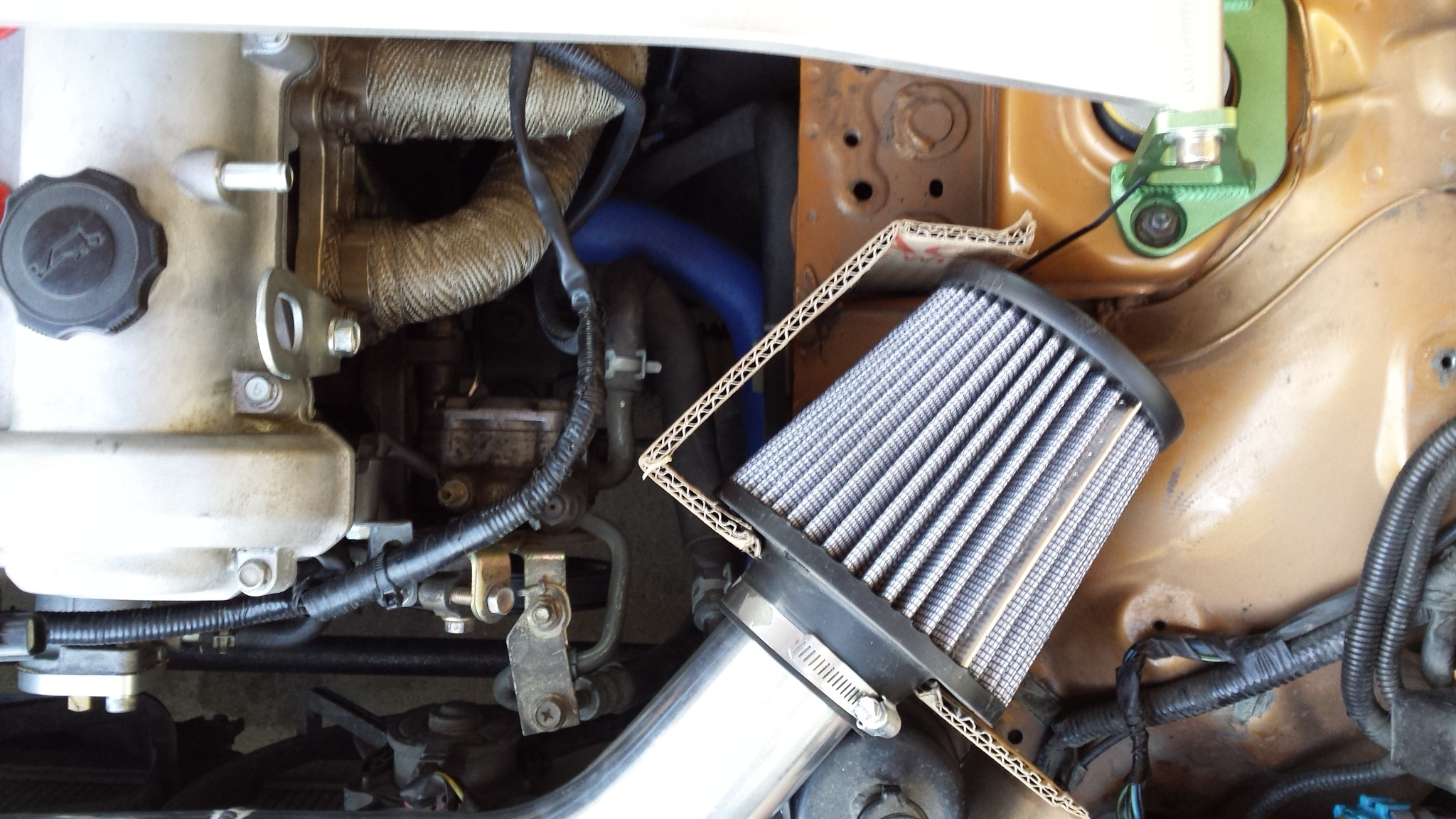

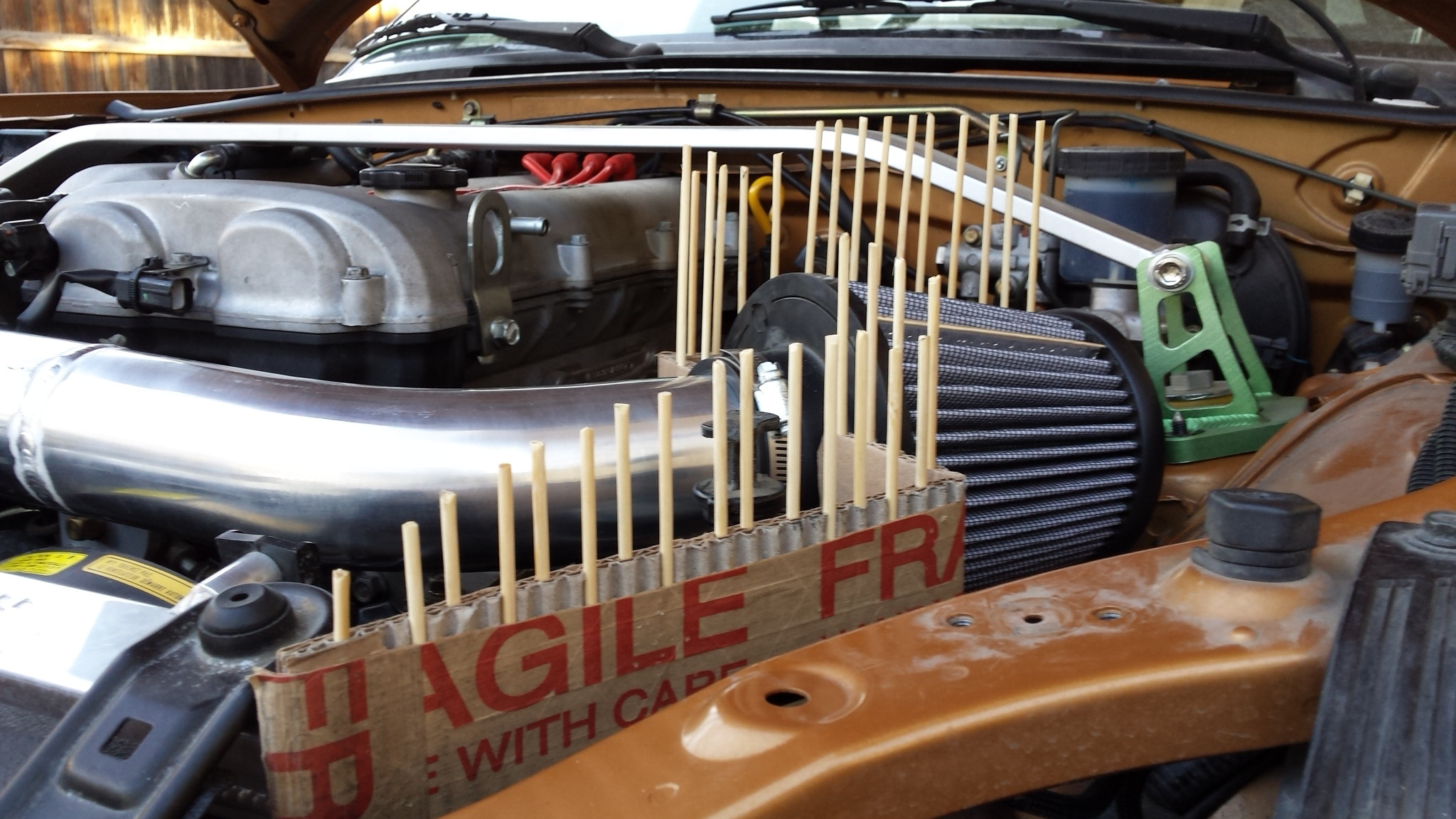

Ok, here is where I was after this weekend

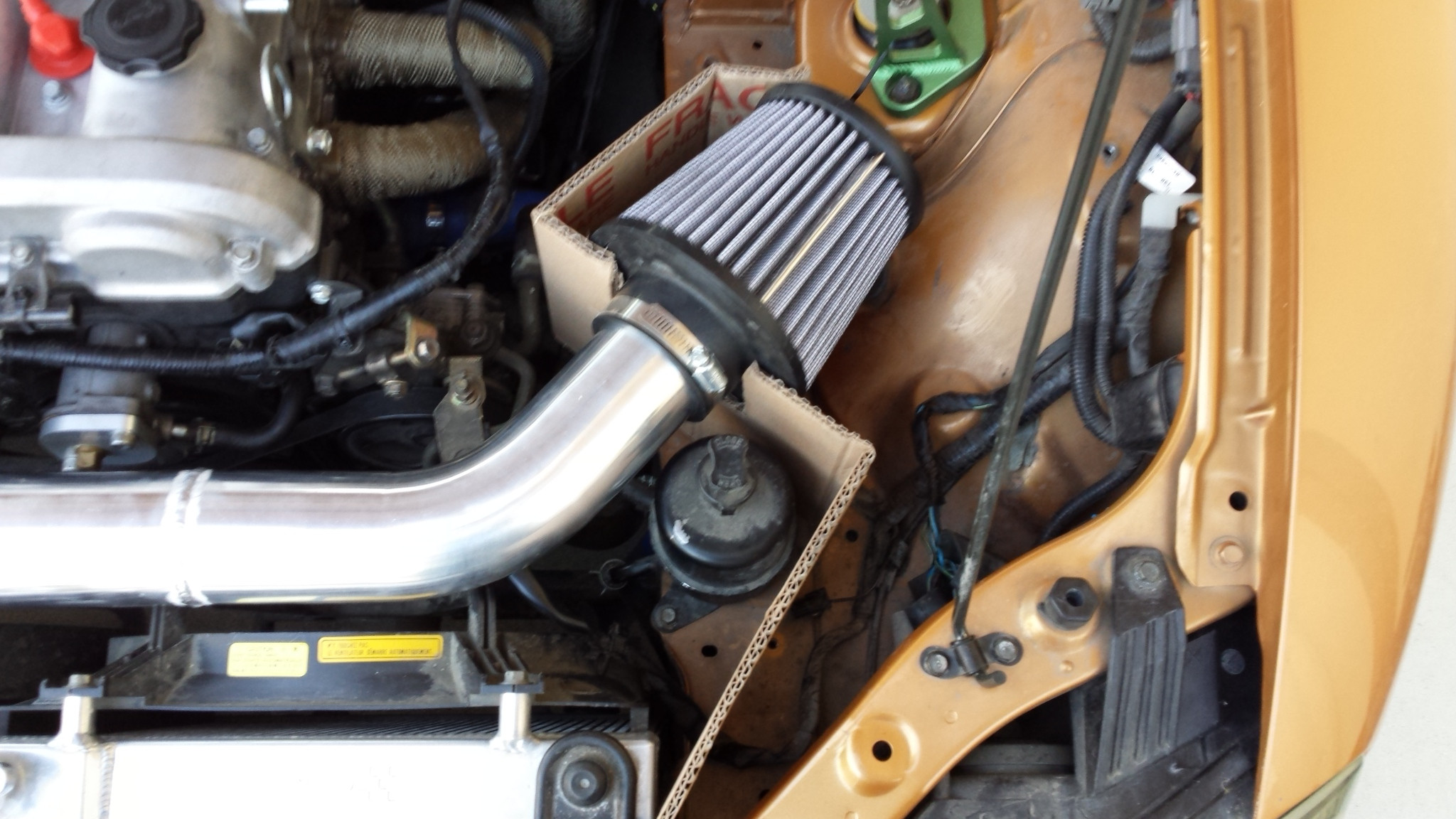

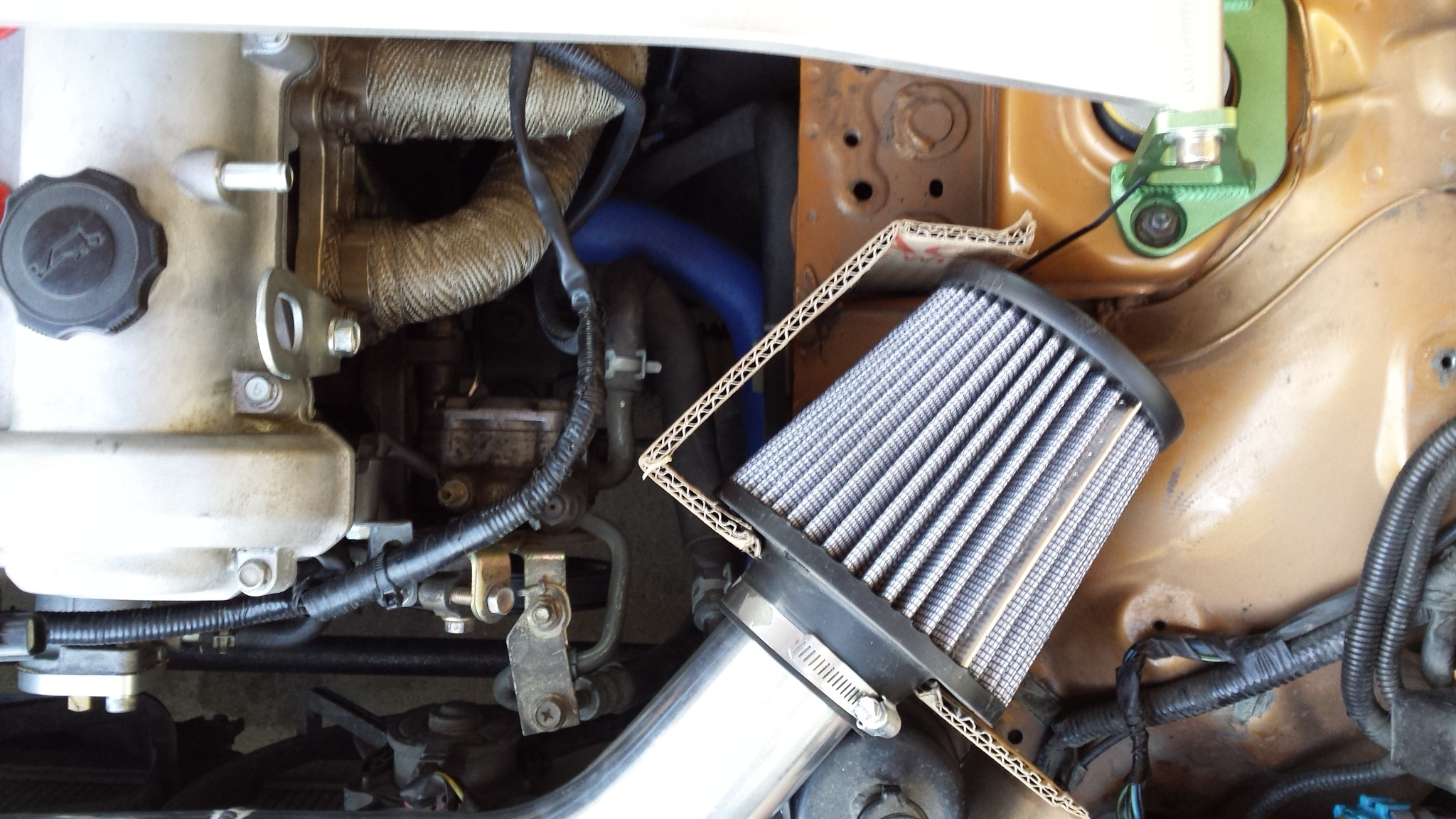

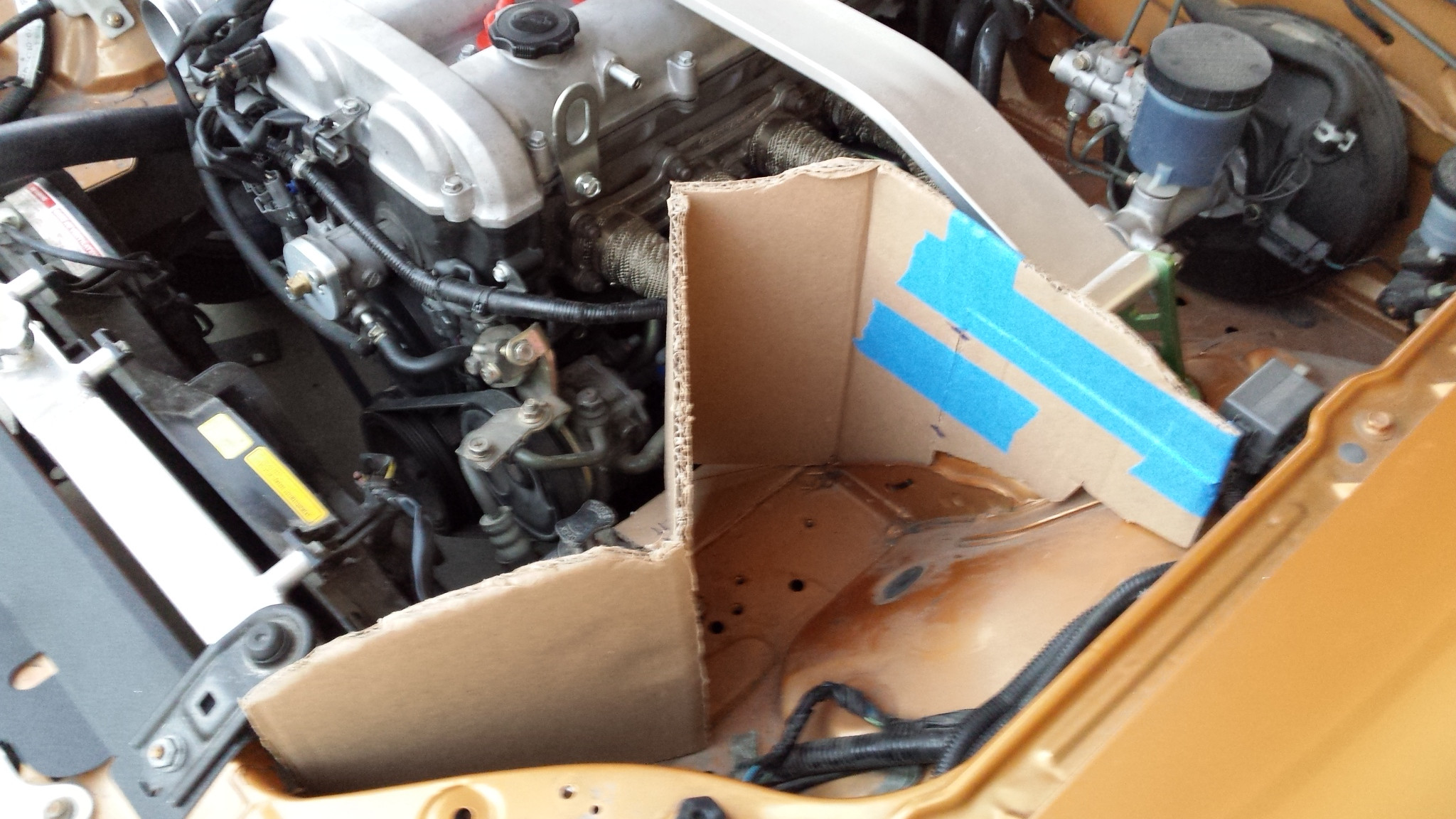

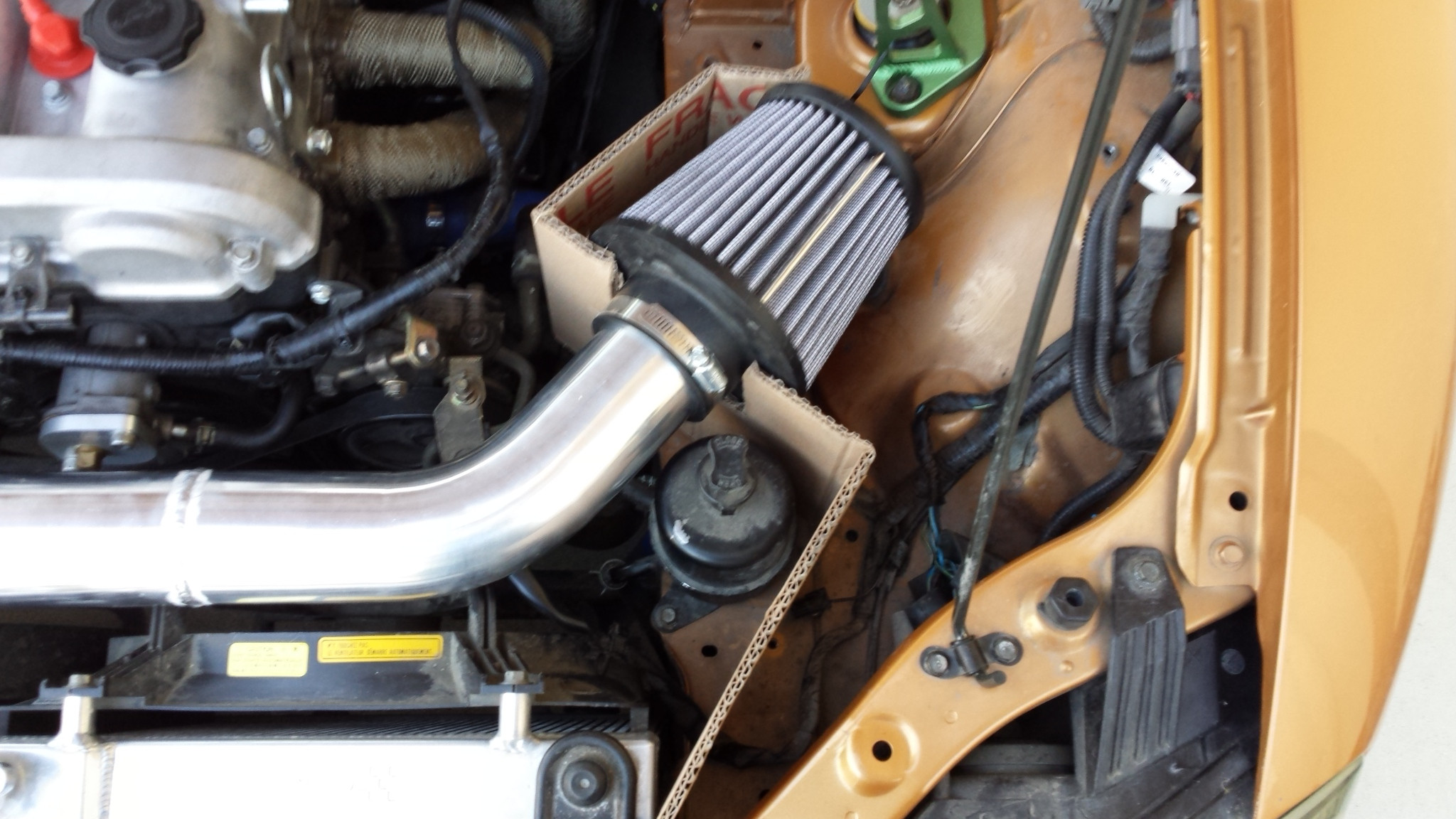

Tonight I installed the intake tube Gesso was kind enough to tig up for me

As its made of aluminum, its going to need some insulation. Its obviously heatshield fabrication time as well, as I don't want all this thermal control going to waste. Now you will all bear witness to my fabrication skills, or rather, lack thereof.

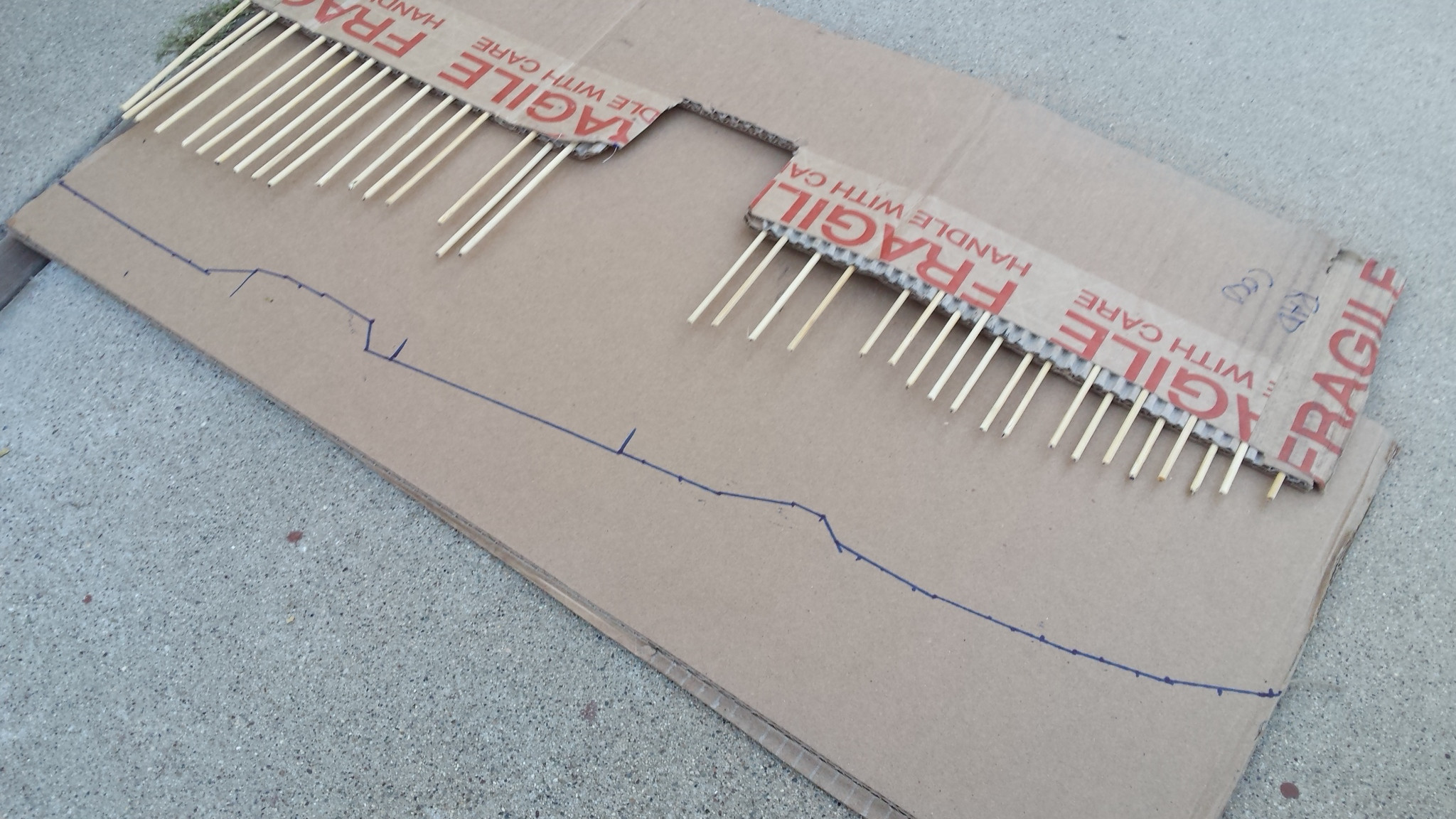

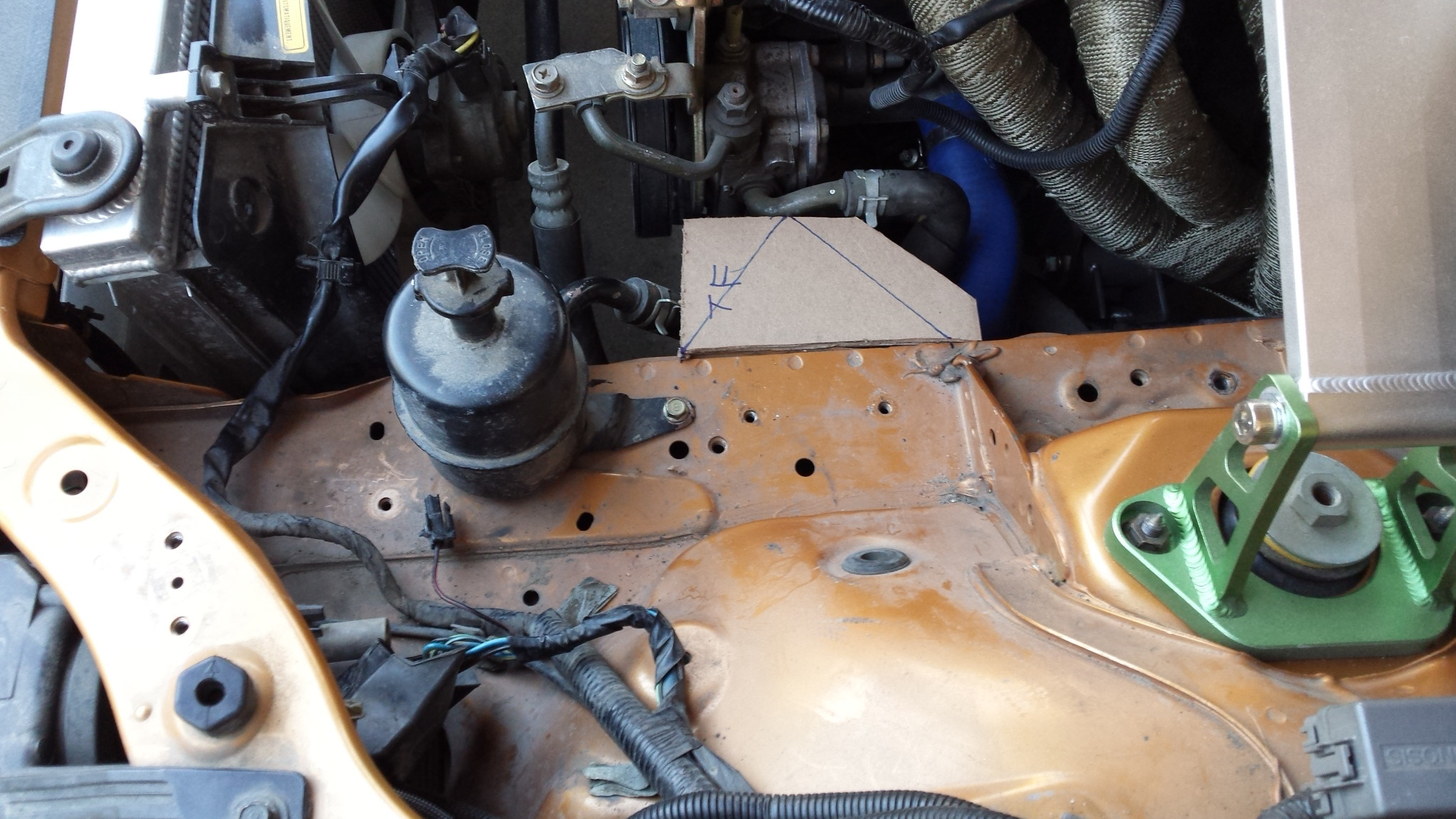

I started with a general shape out of cardboard

Its got some overlap over the framerail but I'll block it later

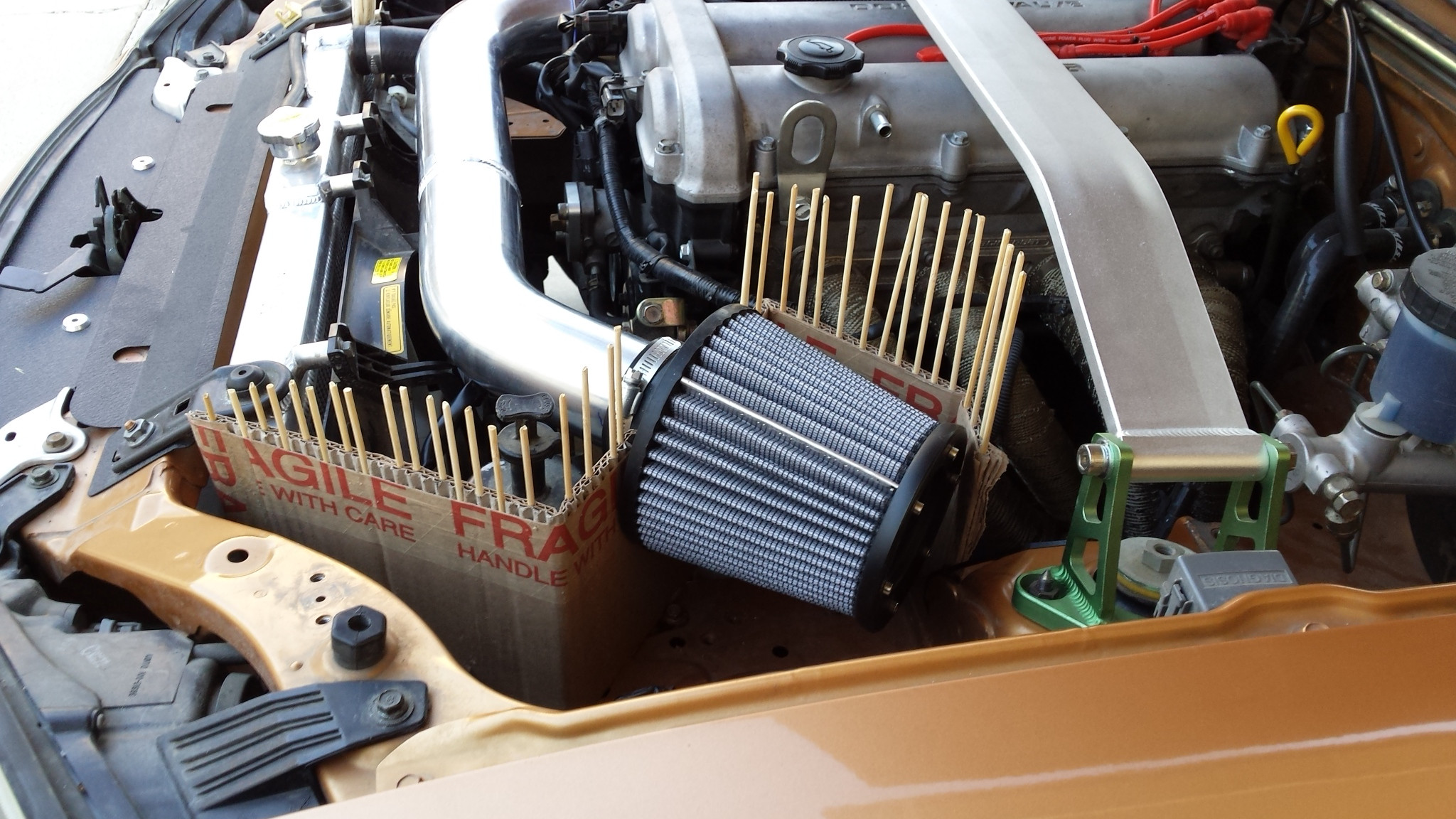

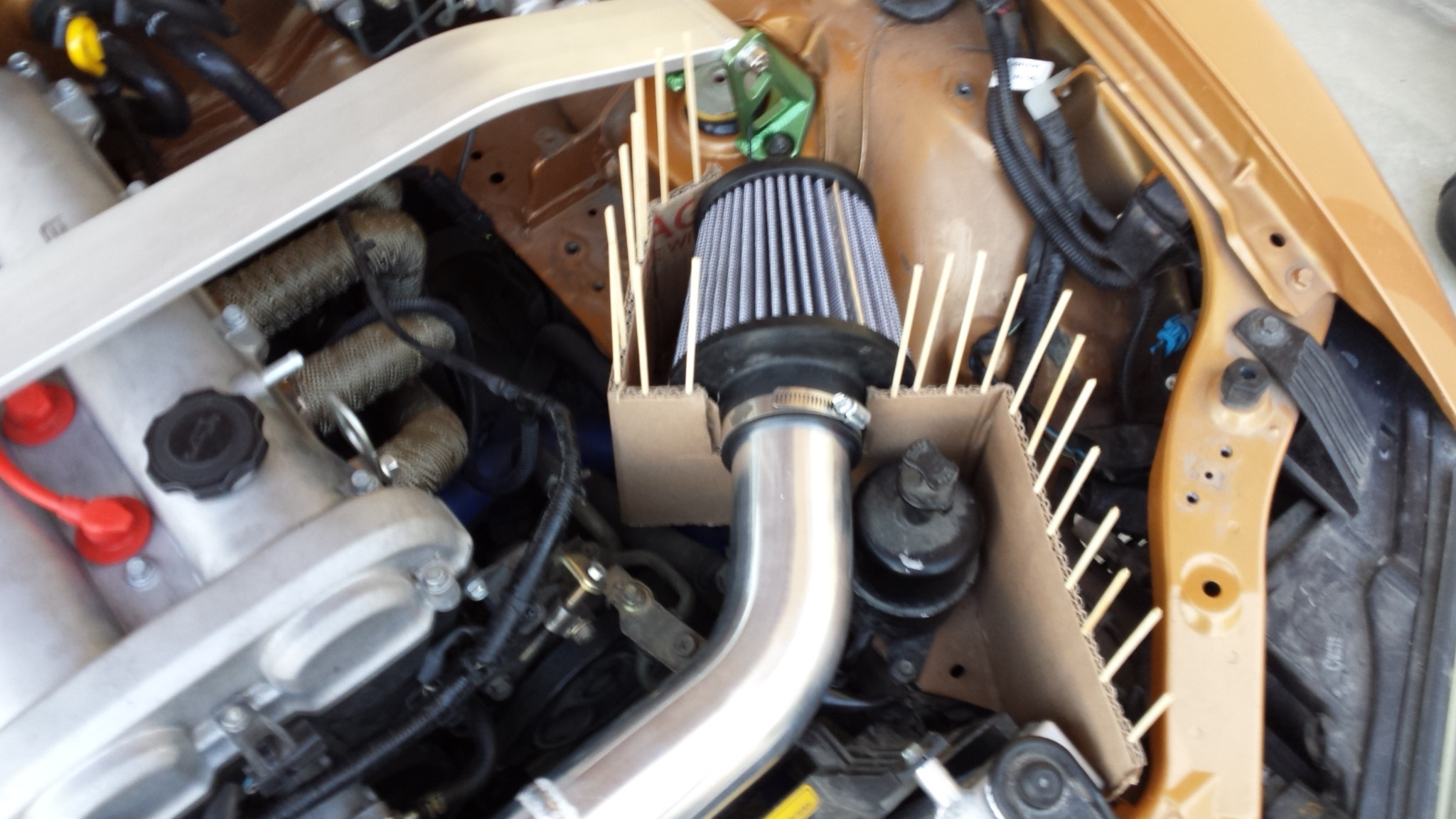

Add some sticks, slam the hood...

TAA~DAA!!

Another angle. You can see the hood ribs

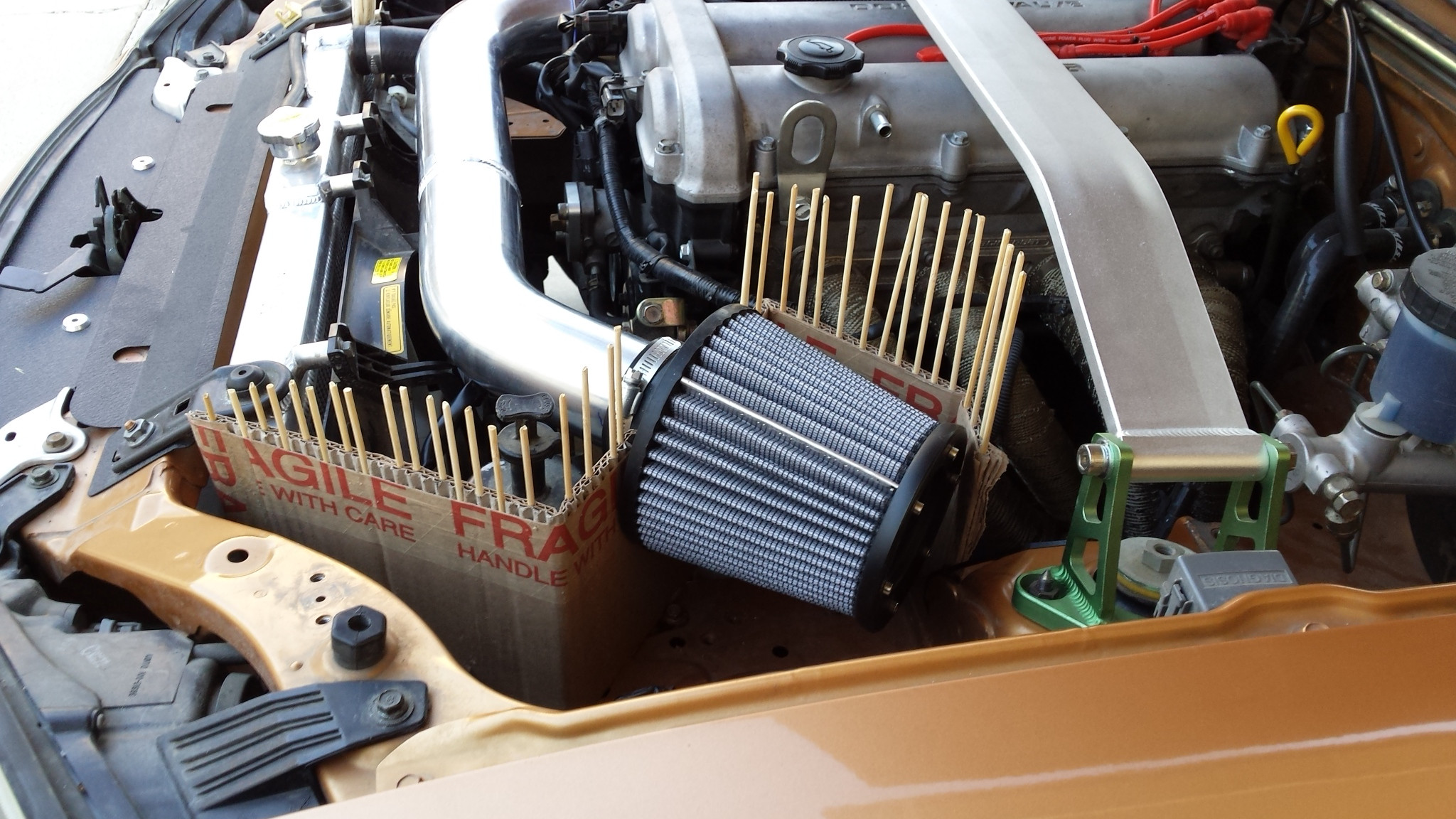

From the front. Its a lot taller than I thought it was

Wooden sword hood prop

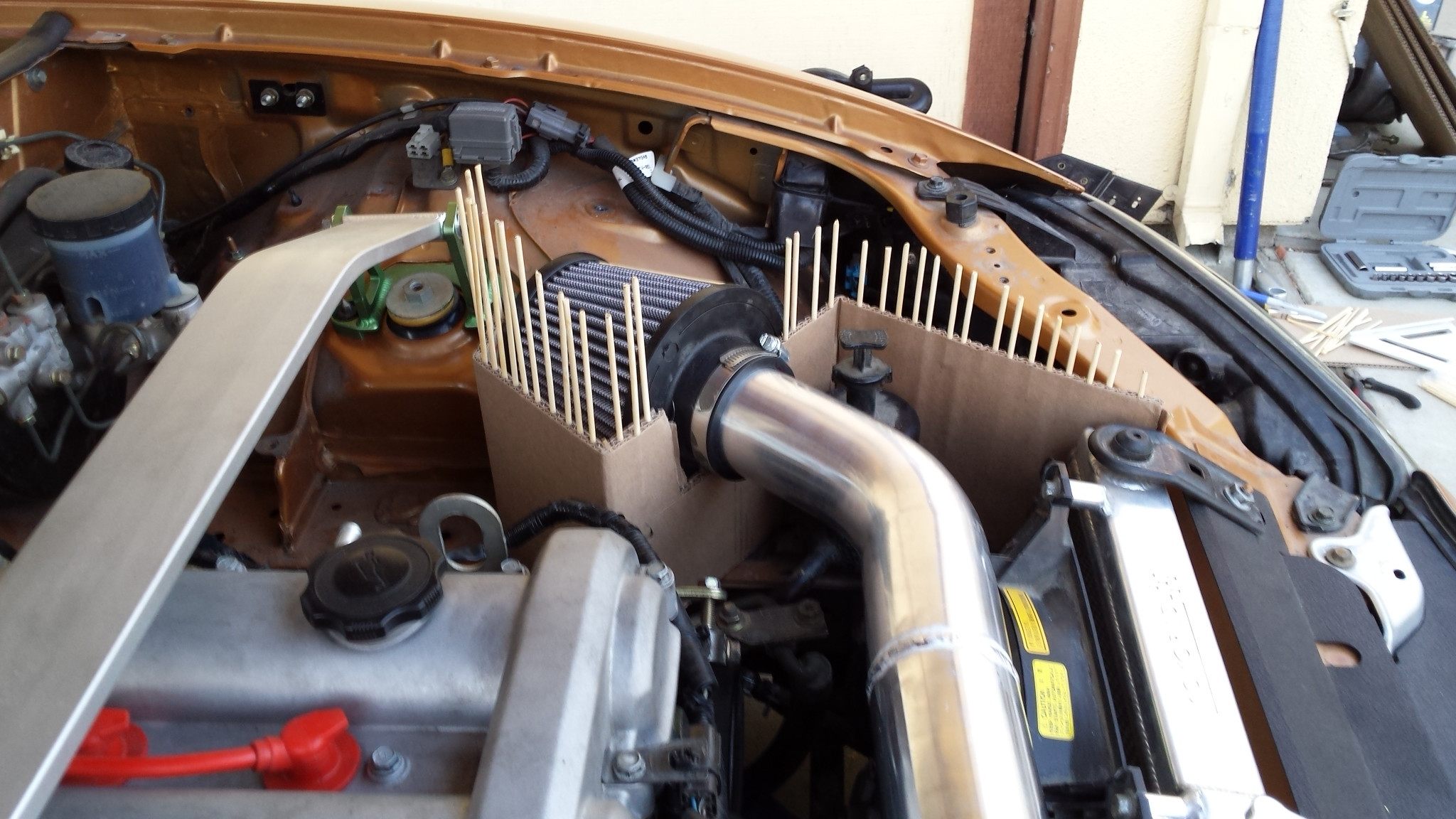

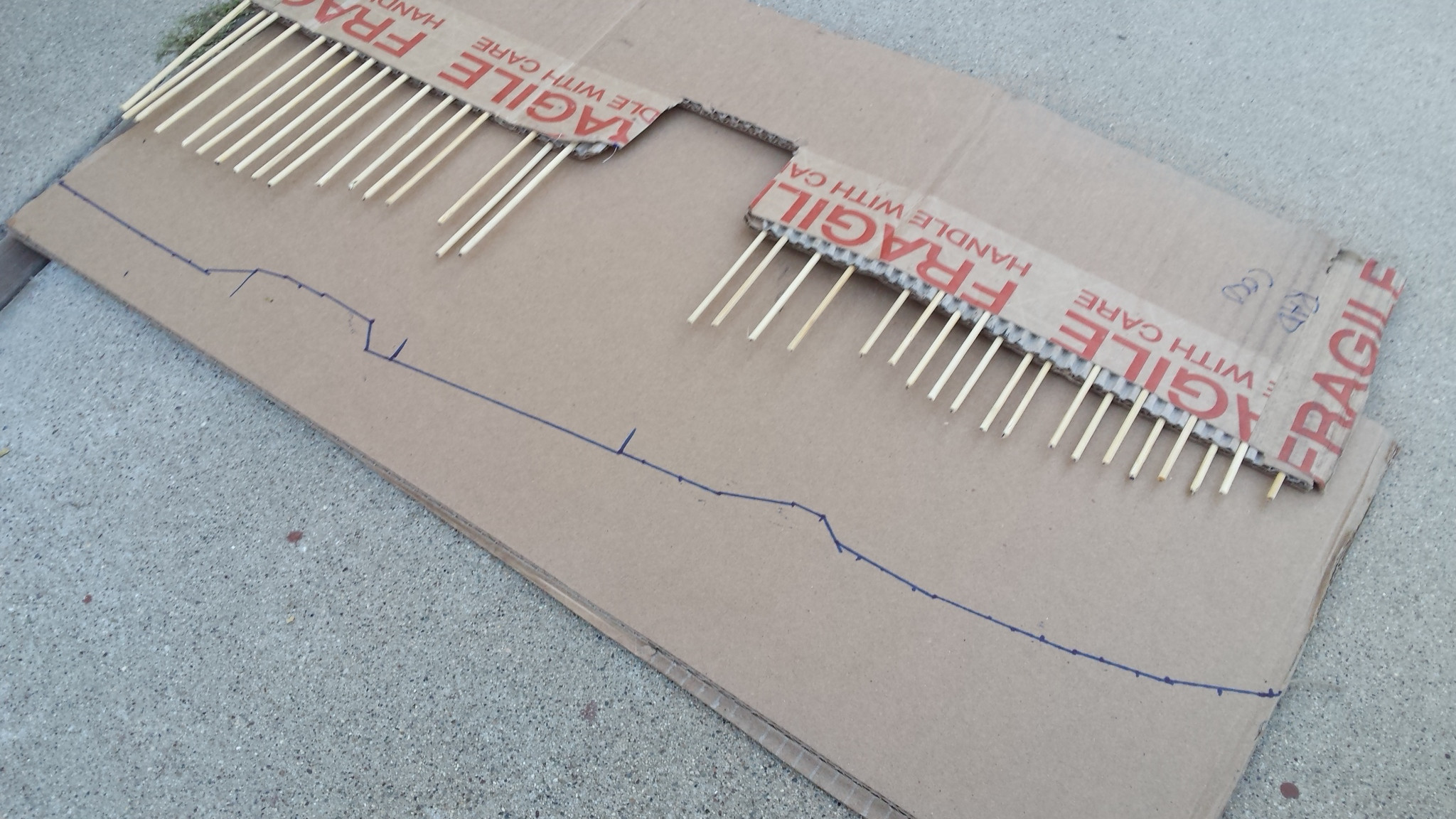

Remove, flatten, transfer to a taller sheet of cardboard with dots

Connect the dots!

Cut it out...

Lookin' good so far

Much, much taller than expected. I had no idea there was this much clearance.

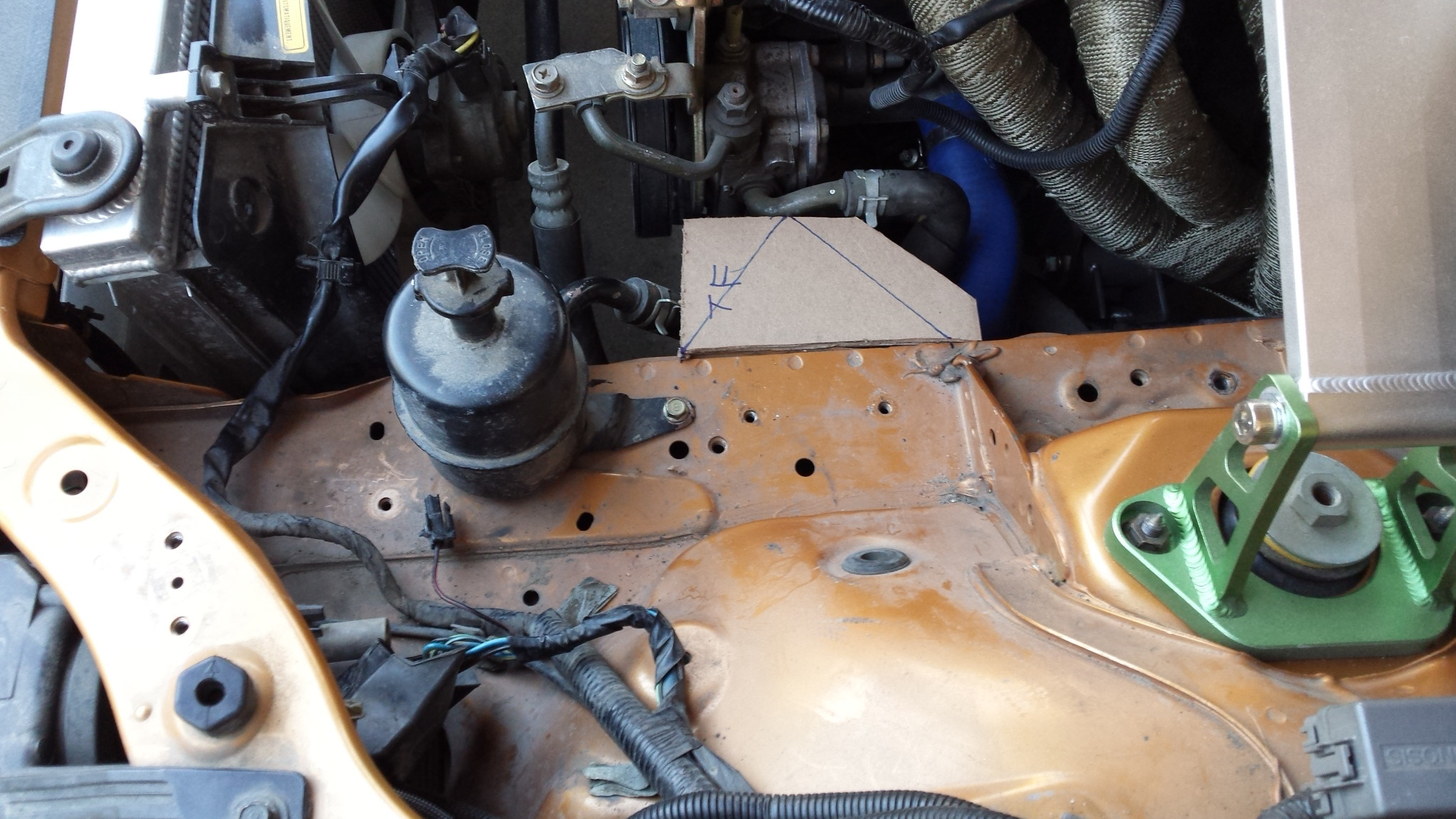

So yeah, re-installed

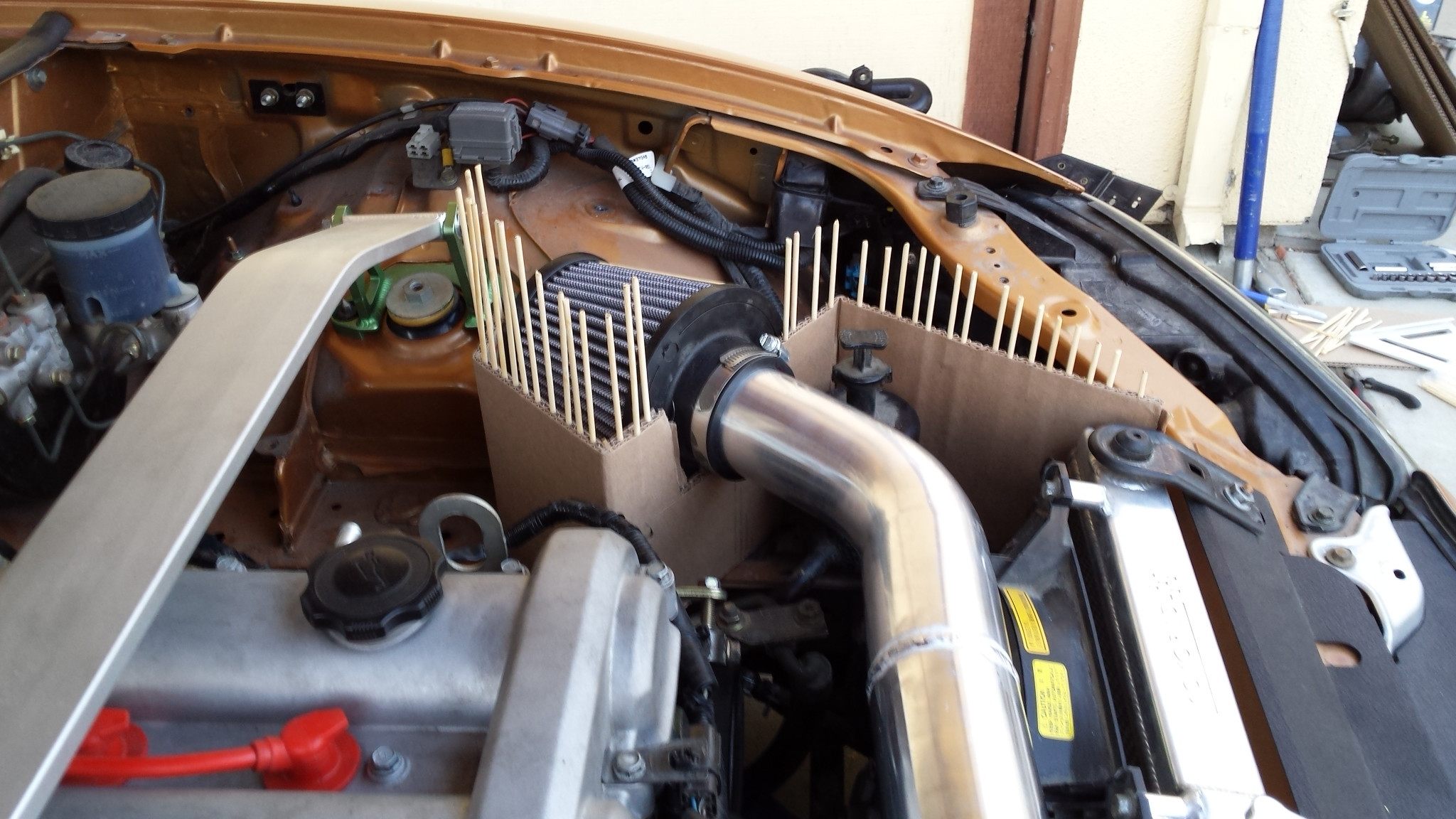

That's the little fill-in corner I was talking about.

Smash it with the hood again a couple times, then trim as appropriate.

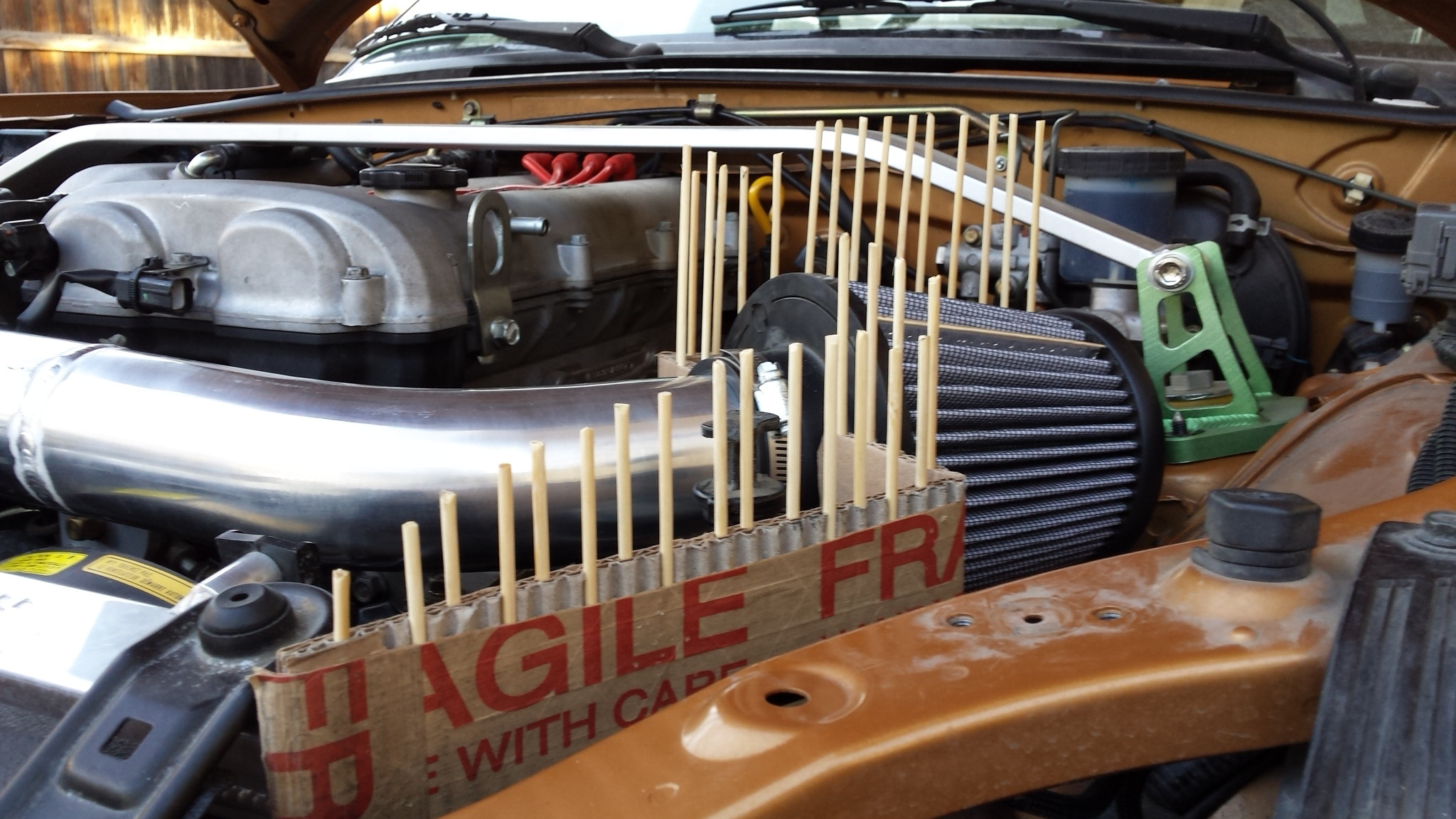

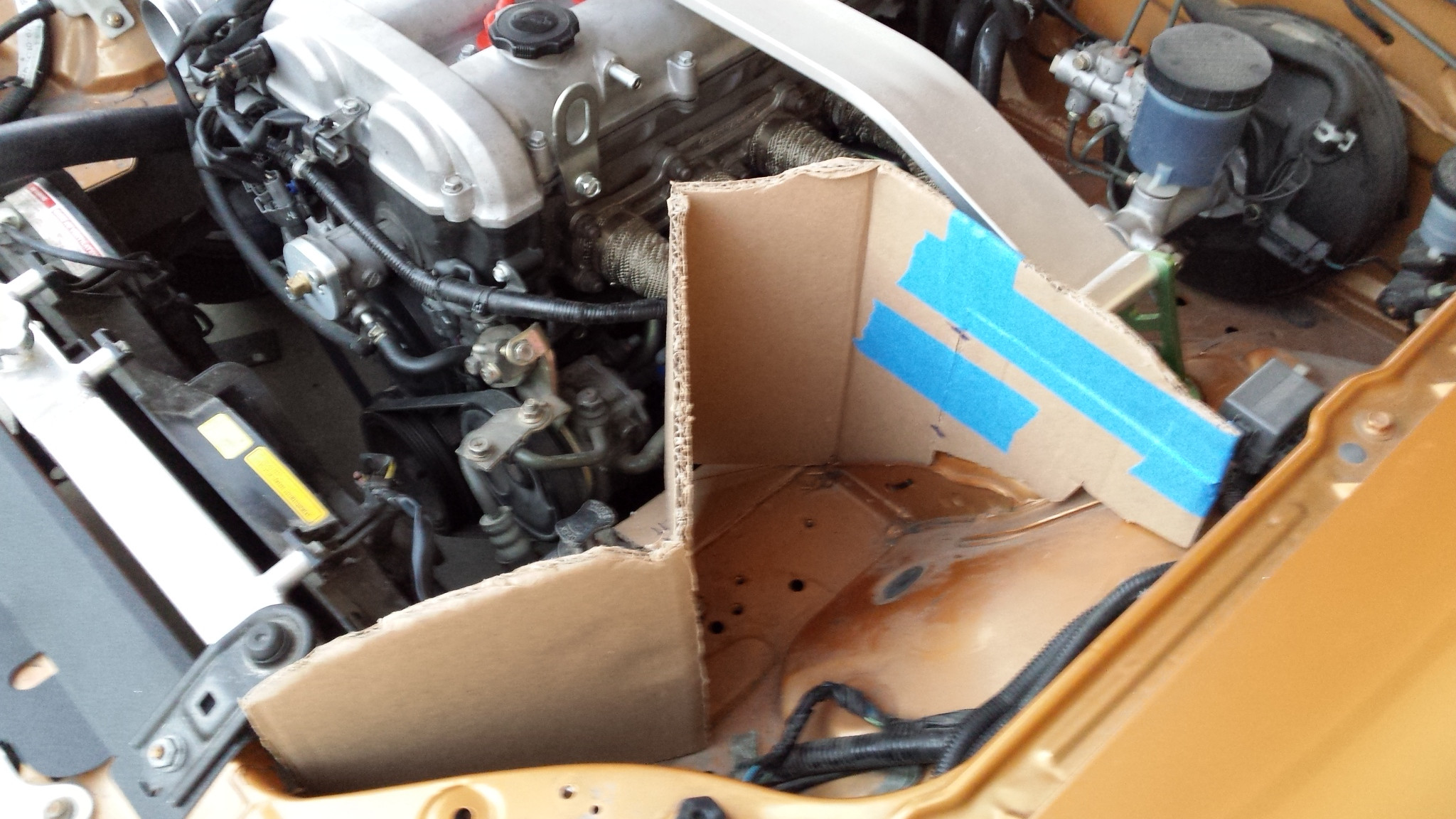

Extend it a bit further and add more sticks, repeat hood abuse.

Scab on some more cardboard and we have a template!

Note to self: use regular cardboard, not double wall heavy duty cardboard.

Now I need to pick some material and actually fabricate this thing. I have almost no fabrication tools so this is going to be a bitch. I need a piece of material that is about 33"x12" and easily shaped.

I'm seriously considering a chunk of black ABS plastic of some sort. I can easily cut and drill it, and bending can be accomplished with a heat gun. For insulation I plan on covering the engine side of the thing with DEI Floor & Tunnel Shield. Its seriously reflective and has an actual insulation layer that's about 1/8" thick. There is no way heat is going to get through this thing, even sitting and idling in traffic.

I also need some sort of rubber trim, kinda like door trim of some sort that will clip to the edge of the ABS. Something like this would be perfect:

I'll undercut my pattern by about 1/2" or whatever and make up the rest of the space with that sort of trim so that it seals up real good.

Off to Amazon to find some plastic and some rubber trim!

- Squaretop

- Hondata intake gasket

- catch can

- Tien strut tower bar

- Cappuccino washer bottle

Tonight I installed the intake tube Gesso was kind enough to tig up for me

As its made of aluminum, its going to need some insulation. Its obviously heatshield fabrication time as well, as I don't want all this thermal control going to waste. Now you will all bear witness to my fabrication skills, or rather, lack thereof.

I started with a general shape out of cardboard

Its got some overlap over the framerail but I'll block it later

Add some sticks, slam the hood...

TAA~DAA!!

Another angle. You can see the hood ribs

From the front. Its a lot taller than I thought it was

Wooden sword hood prop

Remove, flatten, transfer to a taller sheet of cardboard with dots

Connect the dots!

Cut it out...

Lookin' good so far

Much, much taller than expected. I had no idea there was this much clearance.

So yeah, re-installed

That's the little fill-in corner I was talking about.

Smash it with the hood again a couple times, then trim as appropriate.

Extend it a bit further and add more sticks, repeat hood abuse.

Scab on some more cardboard and we have a template!

Note to self: use regular cardboard, not double wall heavy duty cardboard.

Now I need to pick some material and actually fabricate this thing. I have almost no fabrication tools so this is going to be a bitch. I need a piece of material that is about 33"x12" and easily shaped.

I'm seriously considering a chunk of black ABS plastic of some sort. I can easily cut and drill it, and bending can be accomplished with a heat gun. For insulation I plan on covering the engine side of the thing with DEI Floor & Tunnel Shield. Its seriously reflective and has an actual insulation layer that's about 1/8" thick. There is no way heat is going to get through this thing, even sitting and idling in traffic.

I also need some sort of rubber trim, kinda like door trim of some sort that will clip to the edge of the ABS. Something like this would be perfect:

I'll undercut my pattern by about 1/2" or whatever and make up the rest of the space with that sort of trim so that it seals up real good.

Off to Amazon to find some plastic and some rubber trim!

#358

Either aluminum or ABS plastic with some heat wrap like mine. Way way way more hood clearance on the NB than NA, surprised.

You also need a steam cleaner to clean your bay.

Also, I want that cappuccino wiper fluid tank, but couldn't justify the money for it. Luckily when I got my inspection done they overlooked that and the lack of a horn...thank god for car enthusiast techs.

You also need a steam cleaner to clean your bay.

Also, I want that cappuccino wiper fluid tank, but couldn't justify the money for it. Luckily when I got my inspection done they overlooked that and the lack of a horn...thank god for car enthusiast techs.

#359

Elite Member

Thread Starter

iTrader: (37)

Join Date: Apr 2010

Location: Very NorCal

Posts: 10,441

Total Cats: 1,899

My office is out in the middle of a lettuce field, I **** you not. I've been dodging muddy pickup trucks, harvesters and line transfer trucks in this thing on a daily basis for the last 6 years. Honestly I'm surprised its not dirtier.

But yes, I'll pressure wash it in the next couple weeks. Gotta make it pretty again.

I snagged the cappuccino tank off the classifieds either here or CR a couple years ago back when you could still get them for under $50. Its been sitting in my garage ever since.

But yes, I'll pressure wash it in the next couple weeks. Gotta make it pretty again.

I snagged the cappuccino tank off the classifieds either here or CR a couple years ago back when you could still get them for under $50. Its been sitting in my garage ever since.