Nothing to see here, just project Sisyphus, move along

#782

Elite Member

Thread Starter

iTrader: (37)

Join Date: Apr 2010

Location: Very NorCal

Posts: 10,441

Total Cats: 1,899

Its what I would have done if it was available at the time.

My intention last night was to try and get things together for final test fitting. I wanted to put a head on the block but I didn't want to jack up a new head gasket or destroy the deck surface. To protect said surface I used an old head gasket and made a block protector.

Then I bolted up my spare 6D head with a couple head bolts.

Head looks pretty good sitting on there. Good enough for test fitting and setting up oil drain/feed and coolant lines. Thats when things got fucky with the manifold stud and I decided to call it a night.

My intention last night was to try and get things together for final test fitting. I wanted to put a head on the block but I didn't want to jack up a new head gasket or destroy the deck surface. To protect said surface I used an old head gasket and made a block protector.

Then I bolted up my spare 6D head with a couple head bolts.

Head looks pretty good sitting on there. Good enough for test fitting and setting up oil drain/feed and coolant lines. Thats when things got fucky with the manifold stud and I decided to call it a night.

#784

Elite Member

Thread Starter

iTrader: (37)

Join Date: Apr 2010

Location: Very NorCal

Posts: 10,441

Total Cats: 1,899

For the same reason I made teh rainbow head gasket, its all test fit. I'm not using the 6D head, it was just there so I could bolt up the manifold and start mocking up my plumbing.

I have an oem head gasket, 4W head and ARP studs that will be used in final assembly.

Yes, intentional. Its for bolt retention. When you use a generic stud it will deform around the blob and lock itself in place. Apparently when you use an Inconel stud the unstoppable force meets the immovable object.

I have an oem head gasket, 4W head and ARP studs that will be used in final assembly.

Yes, intentional. Its for bolt retention. When you use a generic stud it will deform around the blob and lock itself in place. Apparently when you use an Inconel stud the unstoppable force meets the immovable object.

#786

Elite Member

Thread Starter

iTrader: (37)

Join Date: Apr 2010

Location: Very NorCal

Posts: 10,441

Total Cats: 1,899

I managed to do that with a 6" open end. I could probably **** up a wet dream if given the opportunity.

See? That's what's pissing me off. I honestly didn't feel like I did put that much force on it when it sheared. Frustrating as ****.

See? That's what's pissing me off. I honestly didn't feel like I did put that much force on it when it sheared. Frustrating as ****.

Last edited by EO2K; 02-06-2015 at 03:12 PM.

#787

Don't be so hard on yourself man. **** like this happens from time to time. It's just a trip to a competent machine shop.

Apparently a good way to remove inconel studs is to use something known as a metal disintegrator.

Sounds fake, but:

Valero Refining Hot Gas Expander | Bolt Removal, Metal Disintegration, Training | CBG Maintenance LLC

I wonder what a metal disintegrator actually is.

Apparently a good way to remove inconel studs is to use something known as a metal disintegrator.

Sounds fake, but:

Valero Refining Hot Gas Expander | Bolt Removal, Metal Disintegration, Training | CBG Maintenance LLC

I wonder what a metal disintegrator actually is.

#789

Elite Member

Thread Starter

iTrader: (37)

Join Date: Apr 2010

Location: Very NorCal

Posts: 10,441

Total Cats: 1,899

When I worked in the machine shop we had a guy who had a portable machine like that. He would come by and burn bolts out of things for us from time to time. He burned a broken stud out of the block on the bosses porsche and basically saved the block. Very cool piece of machinery. Unfortunately he preferred to do meth rather than run his little traveling EDM business so I don't exactly have contact information for him anymore.

#790

Elite Member

Thread Starter

iTrader: (37)

Join Date: Apr 2010

Location: Very NorCal

Posts: 10,441

Total Cats: 1,899

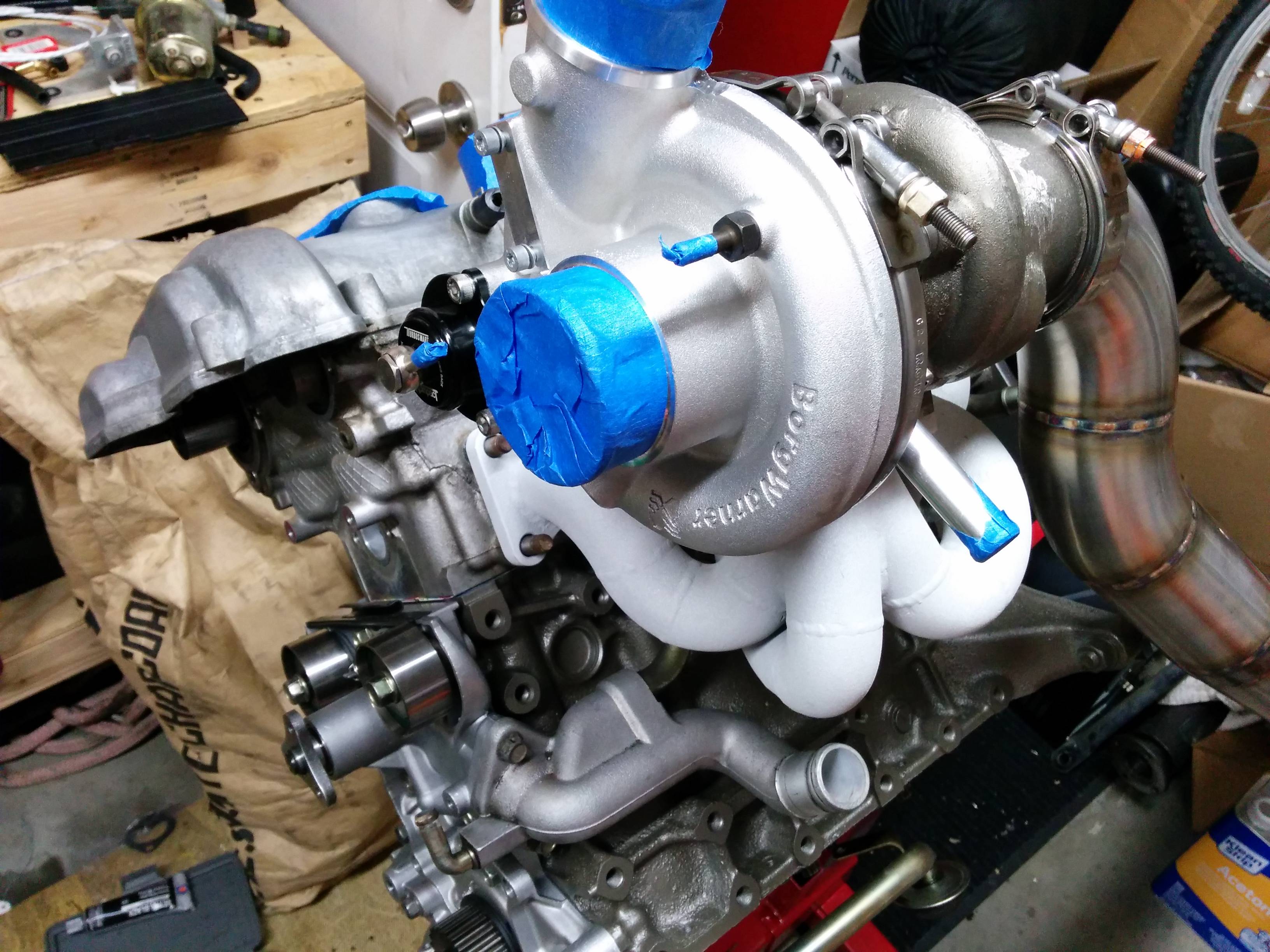

MSM mixing manifold vs stock

Well, that's like eleventybillion times better. I has no A/C so I'm not concerned with compressor clearance.

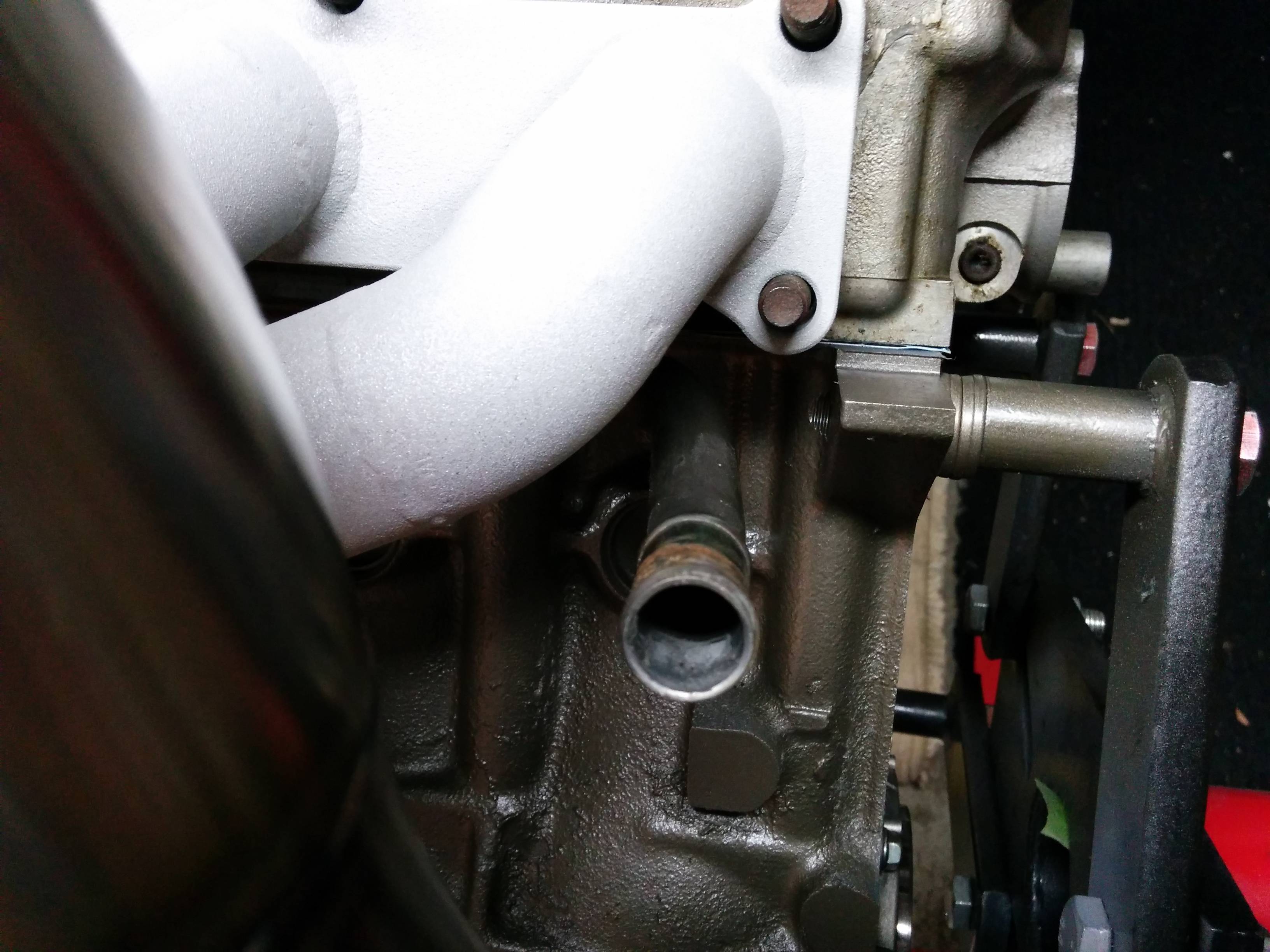

The only problem now is this little guy. The MSM uses this nipple in the heater crossover as I think the return for coolant from the turbo? Its a little mangled and not exactly in a prime location due to the design of the manifold. I actually have another of these MSM crossover tubes but its somewhere in Gesso's garage. If that one does not work, I'll probably cut this one off and figure out how to close up the hole.

I should note that the MSM crossover tube is not compatible with the 4W or 6D mixing manifold, so these should probably be kept in sets.

Here is the other end of the heater line.

Absolutely great clearance with the downpipe and the #4 runner.

And here it is all quazi bolted together and jammed in the corner of my garage

If you look on the right side of the image, sticking out of the bottom of the turbo is my oil return nipple. Its setup for 5/8" ID Gates LOL hose but I'm concerned about clearance with the frame rail? That bastard is sticking WAY out there. I need to dig around and see if I took good pics of the return when it was in the car.

I'm seriously considering ordering a DEI lavatanium blanket for the turbo, or maybe send it to Swain. They come out to be about the same price, but one takes considerably more time than the other. Same quandary with the downpipe. I'd really like to see it coated, but wrap is probably just as effective.

Then there is the part of me that wants to do both

#791

The only problem now is this little guy. The MSM uses this nipple in the heater crossover as I think the return for coolant from the turbo? Its a little mangled and not exactly in a prime location due to the design of the manifold. I actually have another of these MSM crossover tubes but its somewhere in Gesso's garage. If that one does not work, I'll probably cut this one off and figure out how to close up the hole.

#792

Elite Member

Thread Starter

iTrader: (37)

Join Date: Apr 2010

Location: Very NorCal

Posts: 10,441

Total Cats: 1,899

You think you can weld that up? Because that would be awesome! But not that particular one seeing as its not molested. If I end up having you weld on one, it'll be this one. And I think its probably how this will play out. I really like that the 6D and MSM mixing manifolds both have MUCH larger coolant nipples on the front. Using that nipple for the return and a port on the reroute spacer on the back of the head as the feed, what could possibly go wrong?

Also, you can see the tip of the blue tape poking out from under the compressor housing in the pic, like the drain nipple is oriented straight down. It does not appear as though clearance is going to be an issue.

#794

Before you get a blanket for the turbo you should read the turbo blanket thread.

https://www.miataturbo.net/engine-pe...-burden-78139/

I believe the consensus was that blanket have the ability to retain too much heat and can cook the bearings. Sixshooter was the biggest defender of the blankets until he realized his own blanket was severely shortening the life of his turbo by cooking the bearing. He does not run a blanket anymore. I would hate for you to **** up your efr

https://www.miataturbo.net/engine-pe...-burden-78139/

I believe the consensus was that blanket have the ability to retain too much heat and can cook the bearings. Sixshooter was the biggest defender of the blankets until he realized his own blanket was severely shortening the life of his turbo by cooking the bearing. He does not run a blanket anymore. I would hate for you to **** up your efr

#795

Why use hose barbs and clamps for the drain? One of my favorite upgrades for the turbo was the stainless -10 AN drain line.

Also -- time to put the oil pan on.

Since the oil leaving out of the bearing housing through the oil drain is just gravity feed and not pressurized. A threaded fitting and braided line is over kill.

--Ian

Also -- time to put the oil pan on.

Since the oil leaving out of the bearing housing through the oil drain is just gravity feed and not pressurized. A threaded fitting and braided line is over kill.

--Ian

Before you get a blanket for the turbo you should read the turbo blanket thread.

https://www.miataturbo.net/engine-pe...-burden-78139/

I believe the consensus was that blanket have the ability to retain too much heat and can cook the bearings. Sixshooter was the biggest defender of the blankets until he realized his own blanket was severely shortening the life of his turbo by cooking the bearing. He does not run a blanket anymore. I would hate for you to **** up your efr

https://www.miataturbo.net/engine-pe...-burden-78139/

I believe the consensus was that blanket have the ability to retain too much heat and can cook the bearings. Sixshooter was the biggest defender of the blankets until he realized his own blanket was severely shortening the life of his turbo by cooking the bearing. He does not run a blanket anymore. I would hate for you to **** up your efr

Turbo blankets are not bad if the person with the blanket it utilizing the water feed ports (I process alot of warrantys where people do not use those ports). If it is just an oil cooled turbo then definitely no blanket (shielding is ok). The biggest problem I see is if the blanket does keep in too much heat, that the plastic outer races on the Garrett ball bearings may become brittle, though that is no longer the case since they recently changed the bearings in all of the Ball Bearing turbos that utilize the 8mm bearing (GT25R,GT28,GT30,GT35) to a new bearing design with metal through out. With OP having an EFR, that would not be a concern of mine at all, the bearings are tough SOB's and he would like experience turbine wheel fatigue failure way before bearing oil coking. Race Teams use blankets and will go full seasons with 1 set of turbos (GTX/EFR) that exhibit way harsher temps then OP will.

#797

Turbo blankets are not bad if the person with the blanket it utilizing the water feed ports (I process alot of warrantys where people do not use those ports). If it is just an oil cooled turbo then definitely no blanket (shielding is ok). The biggest problem I see is if the blanket does keep in too much heat, that the plastic outer races on the Garrett ball bearings may become brittle, though that is no longer the case since they recently changed the bearings in all of the Ball Bearing turbos that utilize the 8mm bearing (GT25R,GT28,GT30,GT35) to a new bearing design with metal through out. With OP having an EFR, that would not be a concern of mine at all, the bearings are tough SOB's and he would like experience turbine wheel fatigue failure way before bearing oil coking. Race Teams use blankets and will go full seasons with 1 set of turbos (GTX/EFR) that exhibit way harsher temps then OP will.

#798

lol who even cares about how the hotside looks? I thought we were all just joking in Jeffs thread. I mean it will turn to dark/brown poopoo looking texture after a few days anyway.

Unless G is really concerned about heat retention.

Proper heat shields will do that, or you can has your hotside swain'd.

What I'm saying is: stop being silly like me and distracting yourself and delaying the project ( lulz )

I want to drive this thing already!!!!

(you do know I'm gonna drive your car when its done, right?)

Unless G is really concerned about heat retention.

Proper heat shields will do that, or you can has your hotside swain'd.

What I'm saying is: stop being silly like me and distracting yourself and delaying the project ( lulz )

I want to drive this thing already!!!!

(you do know I'm gonna drive your car when its done, right?)

#799

Sixshooter was using both water and oil cooling on his turbo. However, he was using a chinese turbo so the quality of the alloys and other components is not up to par with garret or EFR. I am merely making sure that E02K has all the facts as there were a lot of people who know what they are talking about in that thread mention that the blanket could cause premature wear over the life of a turbo. I wouldn't use race teams as an example since you even mentioned they might go ONE WHOLE SEASON with the same turbo. That is not the timeframe in which we are talking about for wear and tear due to a blanket. I doubt E02K plans to replace his turbo every season or at all unless absolutely necessary. Race Teams, however, can sacrifice long term reliability for short term performance gains because they will replace everything anyways

90% of all turbocharger warranties are oil related claims weather it be oil coking, contamination, lack of oil, or oil drain issues. Only time I see oil coking on to the shaft and bearing system is no oil upon start up or the exhaust piston ring failed and allowed exhaust gases into the bearing housing (mainly journal bearing because they spin freely on the shaft and in the bearing housing) where as ball bearings have the outer race pinned and the inner race is pressed onto the shaft) so you don't really have to worry about wearing the shaft or bearings at all with oil coking on ball bearings. You are more likely to burn, wear and collapse the turbine side piston ring long before that.

When it comes to the chinese turbos, whether SixShooter had a turbo blanket or not, the deterioration of the bearings was inevitable. Comparing a China knock-off brand versus a major manufacturer is not a fair comparison. Alot of them use Aluminum coated bronze or really dirty bronze stock. Their tolerances are much more out of whack and their machining process is more crude. Not to say that the Aftermarket Chinese quality isn't improving, because it is and fast but they still don't have the same QC or material standards that Borgwarner, Garrett, IHI ect have.

I agree with 18PSI that a heat shield will be sufficient and just have fun with it.

No I don't work for Garrett, I work with them at trade shows, SEMA, ADS, Automechanika ect same with other vendors. But I have more direct access to companies like Garrett than the average person you could say. Pic for proof.

Last edited by Turboman17; 02-11-2015 at 11:15 AM.

#800

Elite Member

Thread Starter

iTrader: (37)

Join Date: Apr 2010

Location: Very NorCal

Posts: 10,441

Total Cats: 1,899

Oo! Drama!

But seriously, thanks all for the commentary. I'll read it in more detail and explore the linked threads when I'm not out in the middle of this god forsaken Arizona desert on my cell phone. I can't even get the images to load out here

Of course you will get to drive it, I assumed that would be part of the process after I get you to tune it

But seriously, thanks all for the commentary. I'll read it in more detail and explore the linked threads when I'm not out in the middle of this god forsaken Arizona desert on my cell phone. I can't even get the images to load out here