Pat's Ebay Turbo Compound Boost Build

#81

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,297

Total Cats: 476

The big turbo has a 12 psi (80 kpa) WG can, so it's taking in 100 kpa atmospheric air and putting out 180 kpa into the intake of the small turbo.

The small turbo also has a 12 psi (80 kpa) WG can, with the "atmospheric" side of it connected to the outlet of the first turbo. Since it's a diaphragm and a spring, it's going to regulate the WG to produce a fixed delta pressure above the inlet pressure. So it takes 180 kpa inlet air, adds 80 kpa to it and gets 260 kpa, or about 24 psi of boost.

At least, I *think* that's the way a mechanical WG can works?

--Ian

The small turbo also has a 12 psi (80 kpa) WG can, with the "atmospheric" side of it connected to the outlet of the first turbo. Since it's a diaphragm and a spring, it's going to regulate the WG to produce a fixed delta pressure above the inlet pressure. So it takes 180 kpa inlet air, adds 80 kpa to it and gets 260 kpa, or about 24 psi of boost.

At least, I *think* that's the way a mechanical WG can works?

--Ian

The big turbo has a 12 psi (80 kpa) WG can, so it's taking in 100 kpa atmospheric air and putting out 180 kpa into the intake of the small turbo.

The small turbo also has a 12 psi (80 kpa) WG can, with the "atmospheric" side of it connected to the outlet of the first turbo. This means it works at a ratio of 180 kpa / 100 kpA, or a PR of 1.8 Since it's a diaphragm and a spring, it's going to regulate the WG to produce a fixed delta pressure above the inlet pressure. So it takes 180 kpa inlet air and multiplies that by the pressure ratio of 1.8, which gives you 324 kPa out.

324 / 180 = 1.8, same pressure ratio.

This is my understanding, I'll know soon enough once the setup is up and running.

The small turbo also has a 12 psi (80 kpa) WG can, with the "atmospheric" side of it connected to the outlet of the first turbo. This means it works at a ratio of 180 kpa / 100 kpA, or a PR of 1.8 Since it's a diaphragm and a spring, it's going to regulate the WG to produce a fixed delta pressure above the inlet pressure. So it takes 180 kpa inlet air and multiplies that by the pressure ratio of 1.8, which gives you 324 kPa out.

324 / 180 = 1.8, same pressure ratio.

This is my understanding, I'll know soon enough once the setup is up and running.

#82

I'm pretty sure that's not how a WG can works. A belt-driven supercharger will work that way (fixed RPM on the compressor will give you a fixed pressure ratio), but the the WG can works by having reference pressure and a spring on one side of a diaphragm and boost pressure on the other. The can cracks open when the boost pressure times diaphragm area is equal to the reference pressure times area plus the preload force of the spring.

Edit: there's also the pressure ratio acting across the wastegate flapper to think about, which I forgot to include, but I'm not sure how that changes in a compound setup like this.

--Ian

Edit: there's also the pressure ratio acting across the wastegate flapper to think about, which I forgot to include, but I'm not sure how that changes in a compound setup like this.

--Ian

#83

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,297

Total Cats: 476

I'm pretty sure that's not how a WG can works. A belt-driven supercharger will work that way (fixed RPM on the compressor will give you a fixed pressure ratio), but the the WG can works by having reference pressure and a spring on one side of a diaphragm and boost pressure on the other. The can cracks open when the boost pressure times diaphragm area is equal to the reference pressure times area plus the preload force of the spring.

Edit: there's also the pressure ratio acting across the wastegate flapper to think about, which I forgot to include, but I'm not sure how that changes in a compound setup like this.

--Ian

Edit: there's also the pressure ratio acting across the wastegate flapper to think about, which I forgot to include, but I'm not sure how that changes in a compound setup like this.

--Ian

#84

In a standard single turbo setup, with a "12 psi" spring you have 180 kpa of compressor outlet pressure on one side and 100 kpa of atmospheric pressure (assuming sea level) on the other, plus a spring that's delivering enough force to counteract those 80 additional kpa multiplied by the area of the diaphragm.

If P1 is the absolute atmospheric inlet pressure, P2 is the absolute outlet pressure, F is the force of the spring, and A is the area of the diaphragm, we get

P1 * A + F == P2 * A

Solve for P2 and we get:

P2 == P1 + F/A

If we add 80 kpa to P1, then P3 (the new outlet pressure) is:

P3 = (P1 + 80) + F/A

P3 = (P1 + F/A) + 80

P3 = P2 + 80

IOW, since we didn't change the force that the spring delivers, and we didn't change the area of the diaphragm, the WG regulates the turbo to deliver a fixed pressure delta, not a fixed ratio.

(obviously this is simplifying a lot of factors like compressor efficiency and pressure on the flapper door and whatnot).

--Ian

Edit: This is why SAE dyno correction factors are broken even for a straight mechanical wastegate turbo car. A "7 psi spring" is going to deliver 7 psi of boost, even if the atmospheric pressure dropped from 14.7 psi to 12 when you drove to Grand Junction. So a "7 psi spring" delivers 19 psi absolute in GJ, which is a 1.58 pressure ratio, instead of the 1.47 pressure ratio at sea level, thus totally throwing off the correction factors.

Last edited by codrus; 02-05-2016 at 01:49 AM.

#85

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,297

Total Cats: 476

Thanks Ian for the explanation, sounds like you've got it right.

It will be interesting to see how what works best on setting up the wastegates since as you say they are strictly delta-p based.

I'm going to put my 4bar map on the ECU, and the 3 bar to measure pressure going into the small turbo. So I'll be able to see what is happening between stages and adjust the pressures to whatever I want.

It will be interesting to see how what works best on setting up the wastegates since as you say they are strictly delta-p based.

I'm going to put my 4bar map on the ECU, and the 3 bar to measure pressure going into the small turbo. So I'll be able to see what is happening between stages and adjust the pressures to whatever I want.

#86

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,297

Total Cats: 476

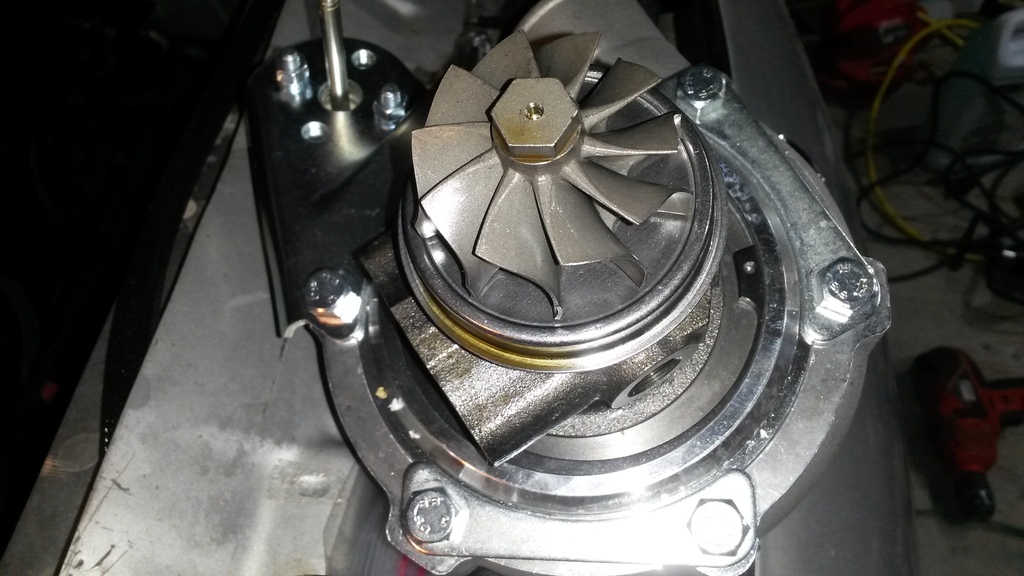

Small turbo arrived. Wow it's tiny. Hope it spools decent, it's wayy small than the old GT32 I used to run. Will take pics of it in a bit, going to port the wastegate on it.

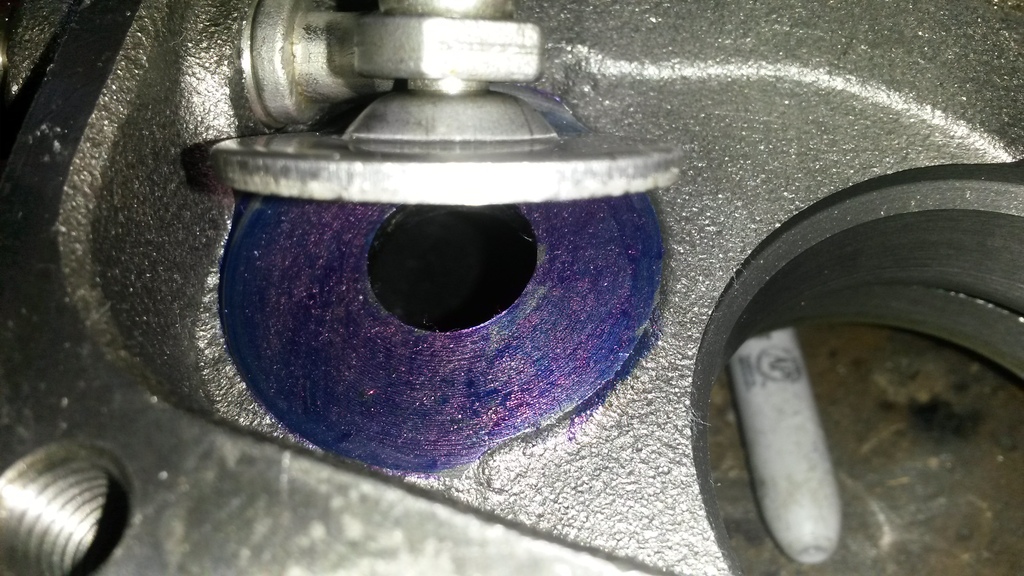

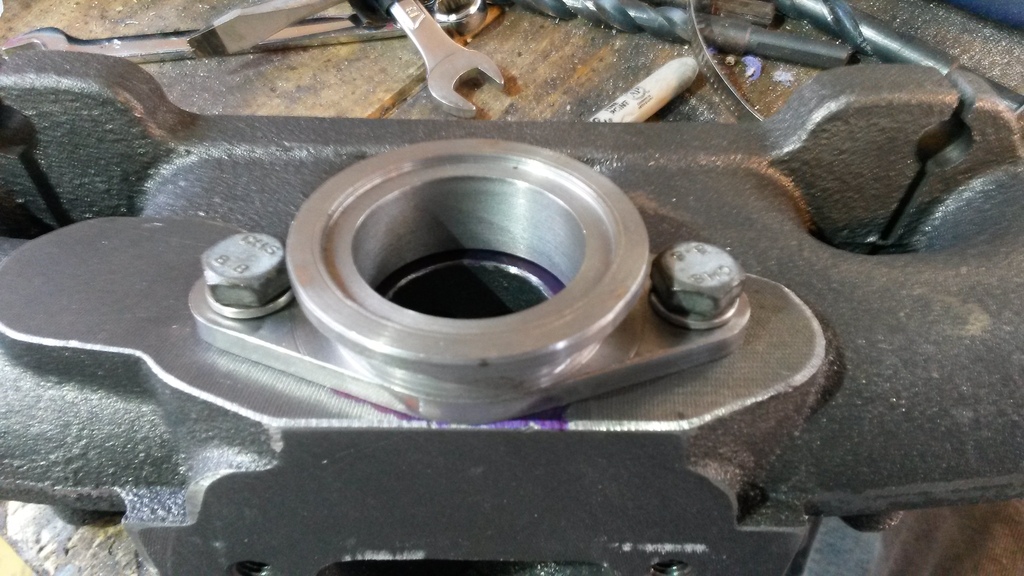

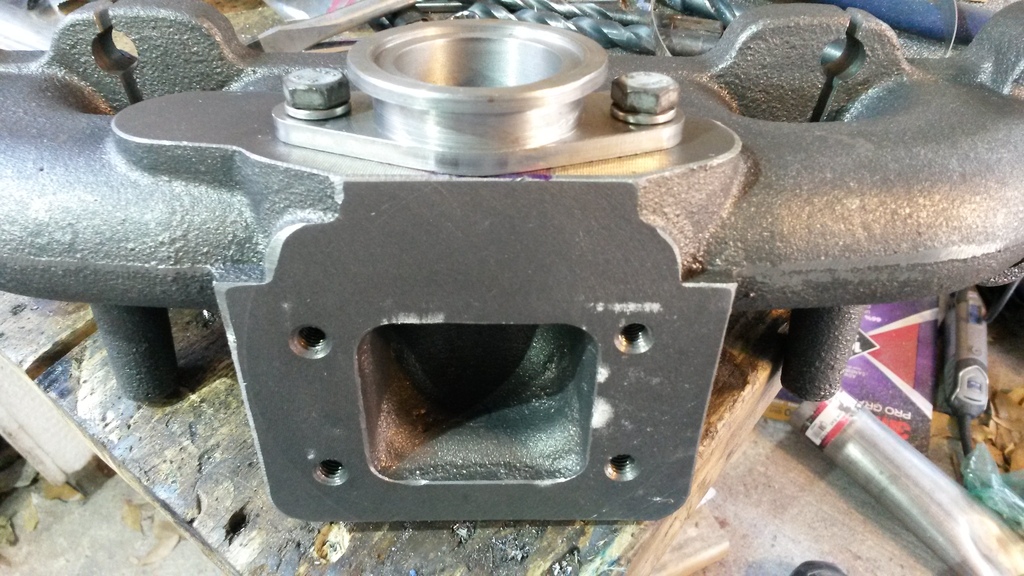

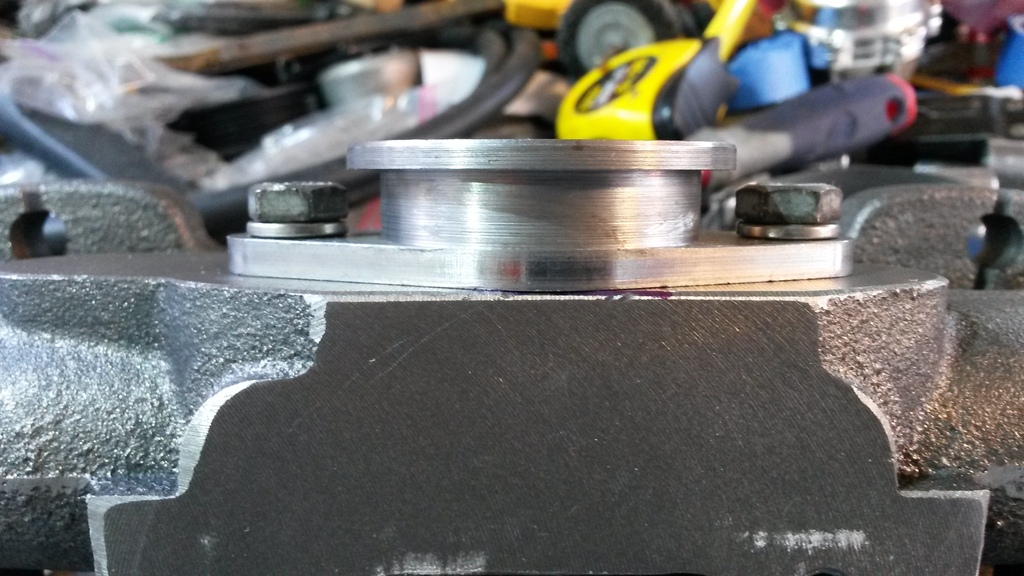

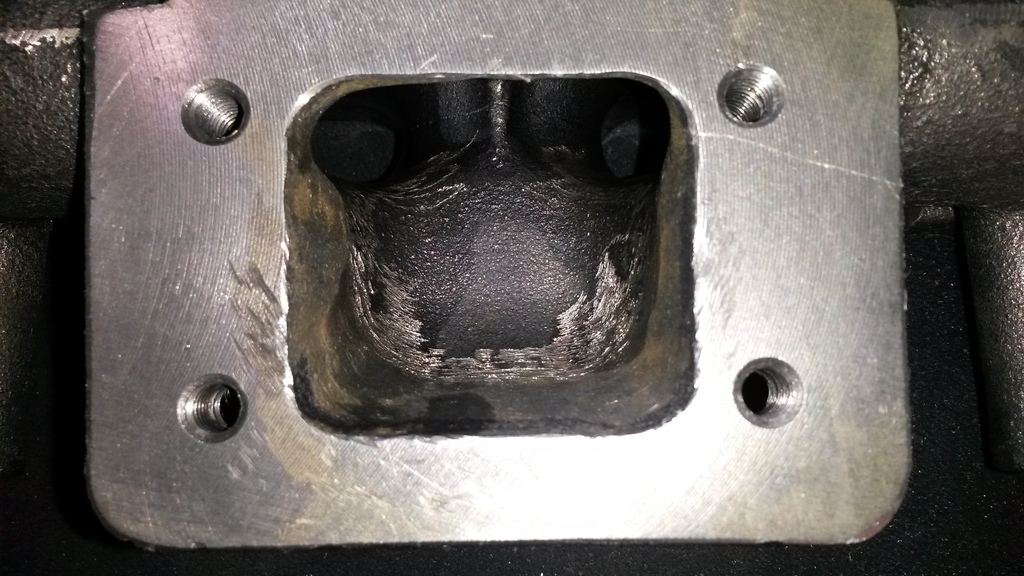

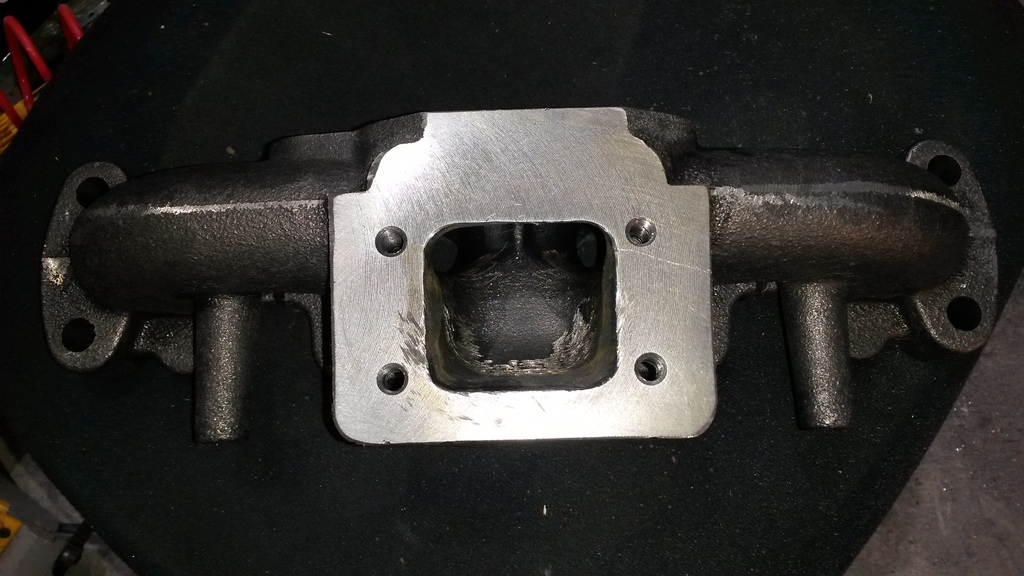

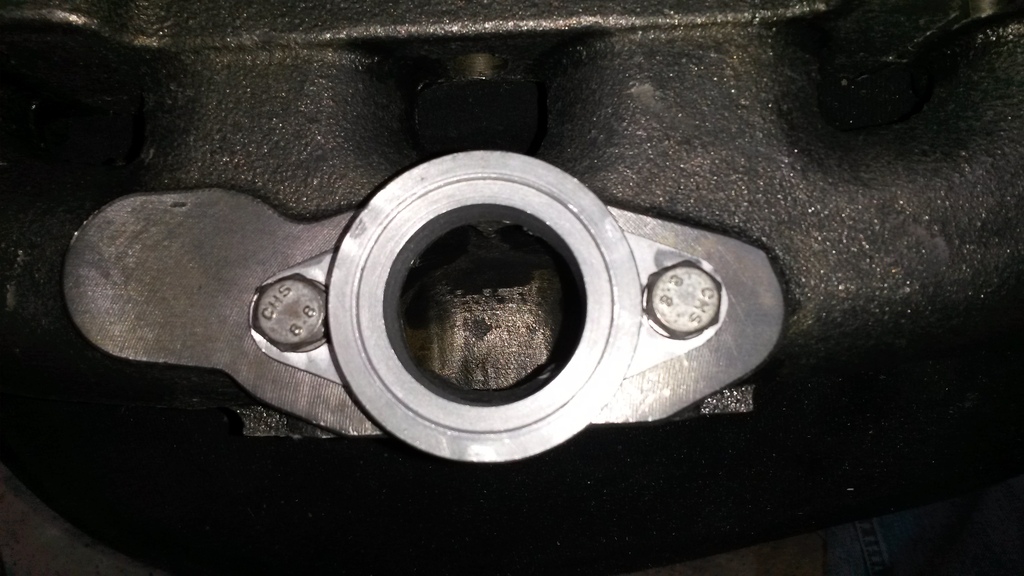

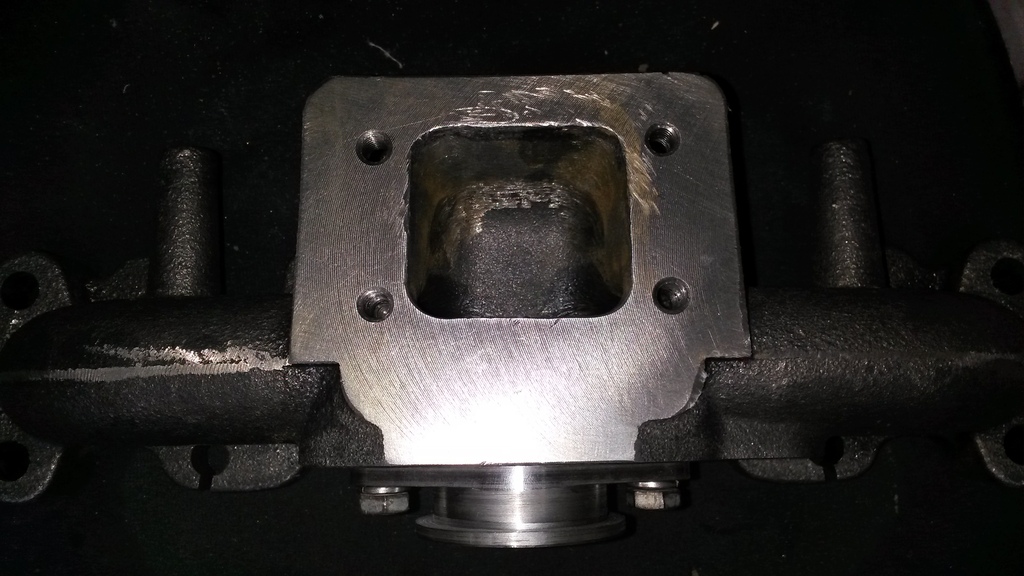

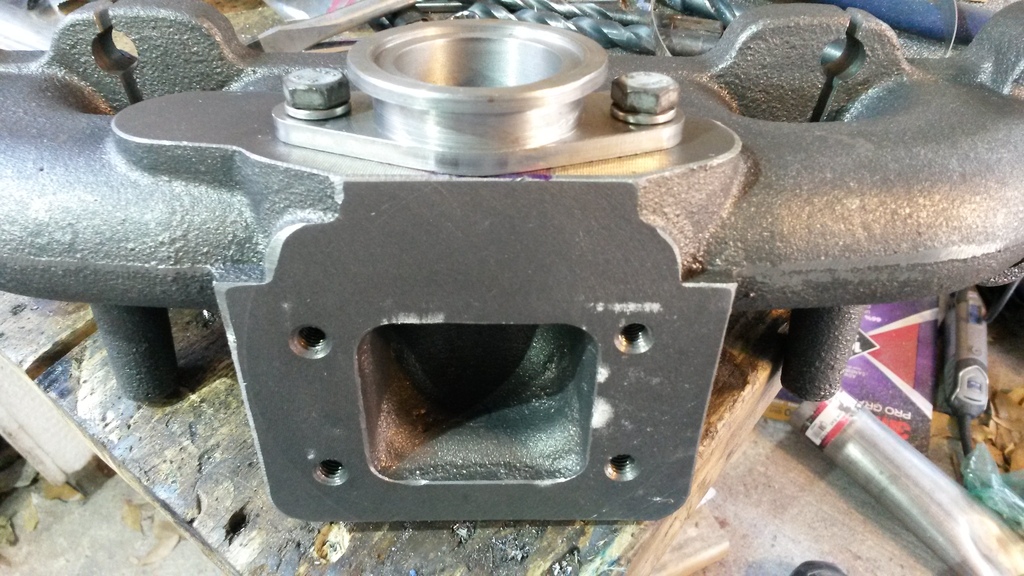

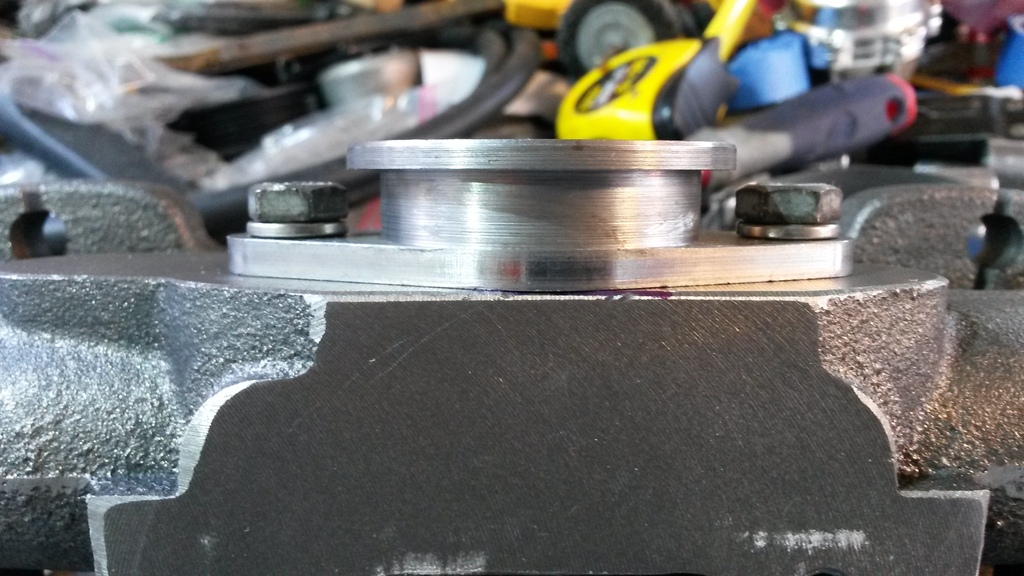

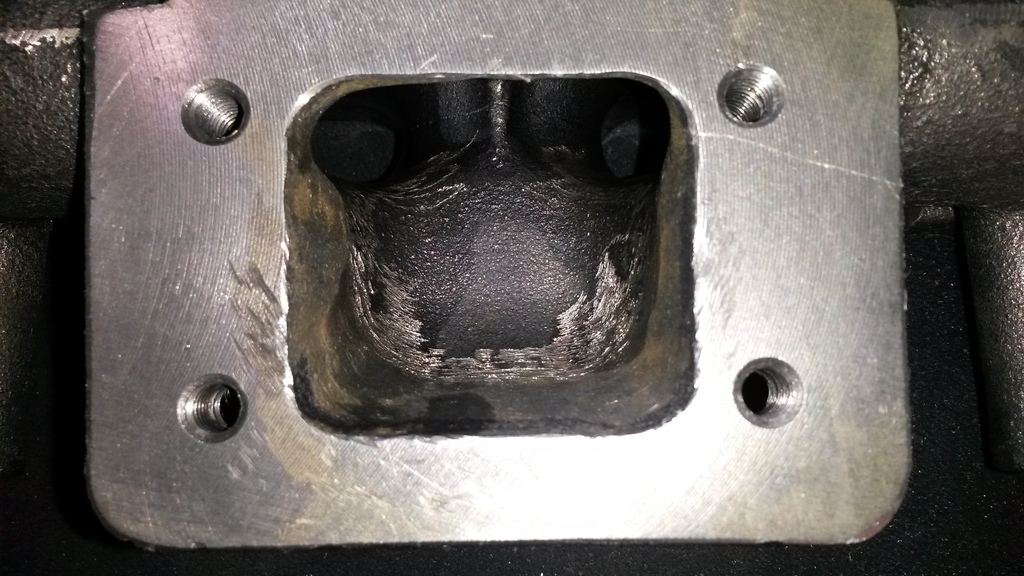

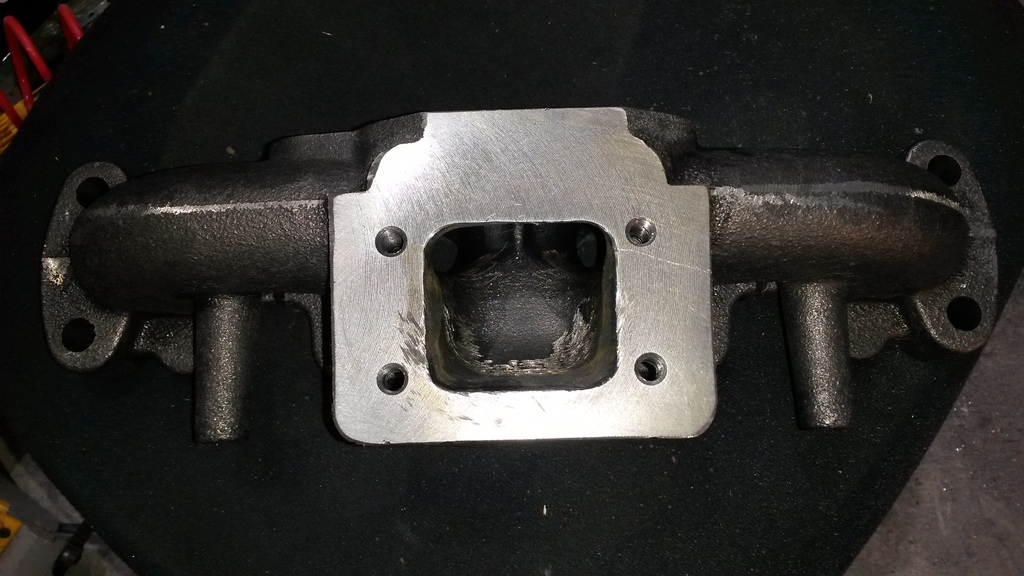

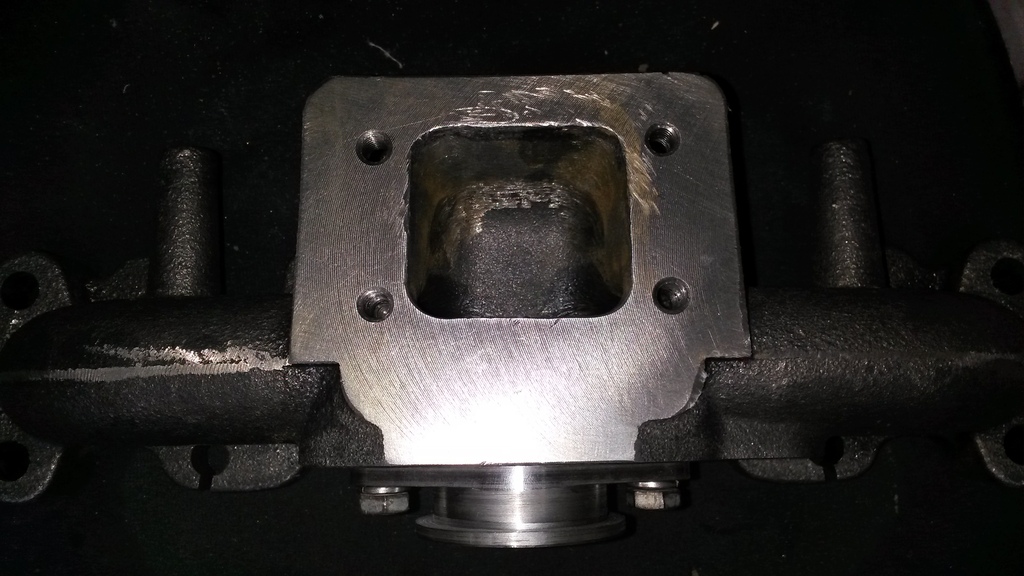

I modified the ebay manifold to flow better to the wastegate, and went ahead and ported it a bit where it meets the turbo too. Manifold has tons of metal around it, so no worries of getting a thin spot porting, everything seems to be 5/16" to 1/2" thick on this thing.... I'd kind of be impressed if it ever cracked.

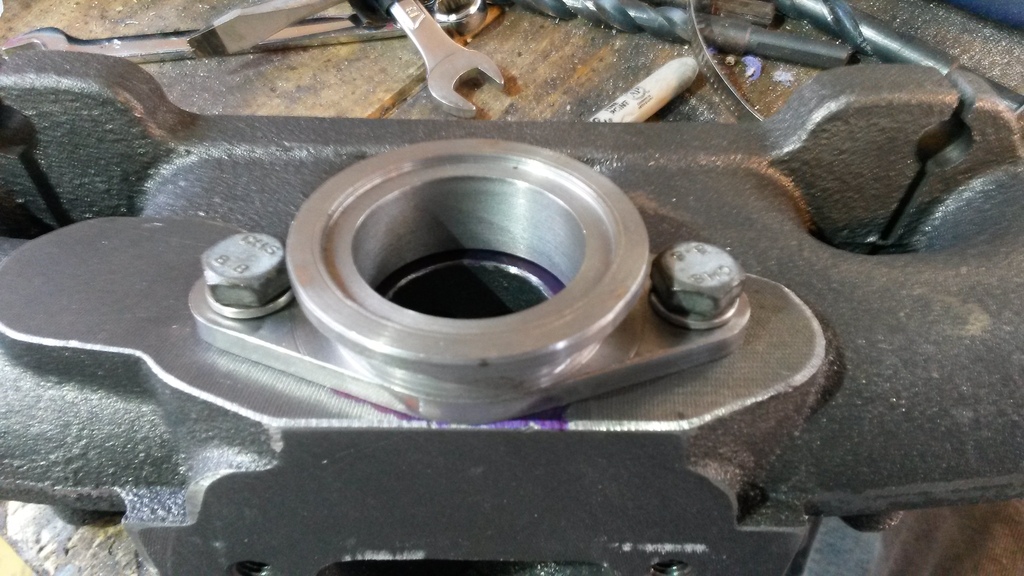

Pics of manifold.

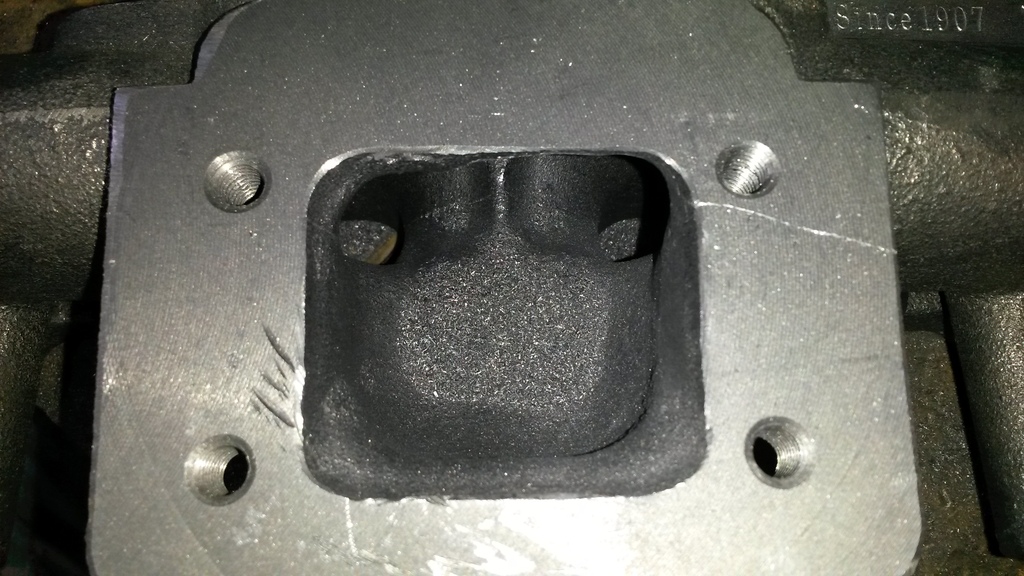

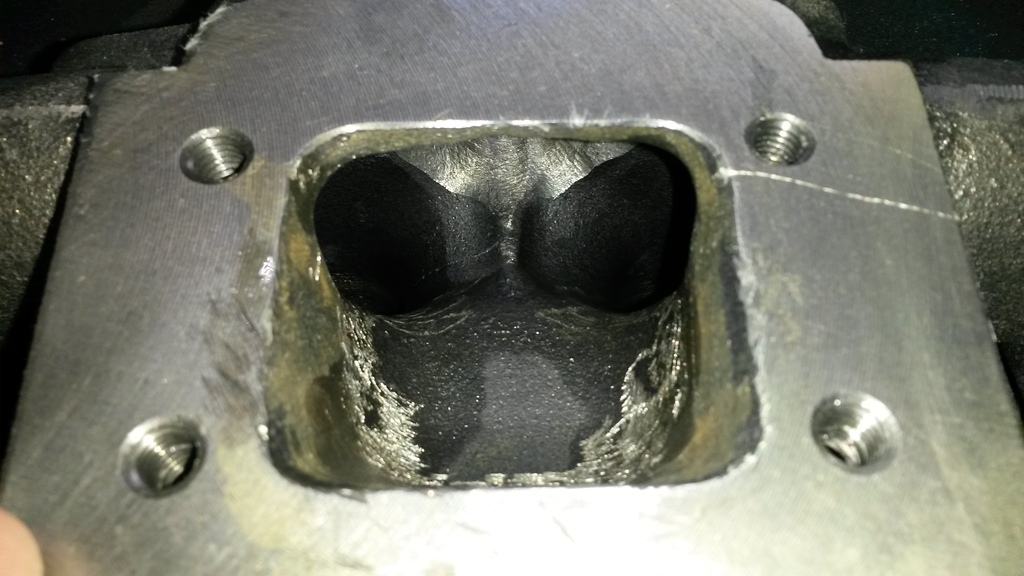

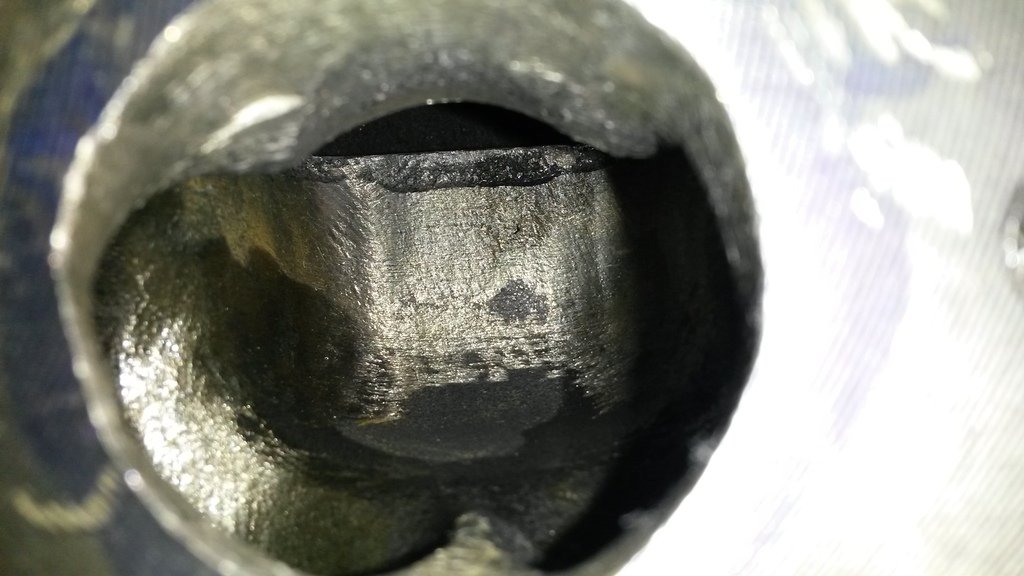

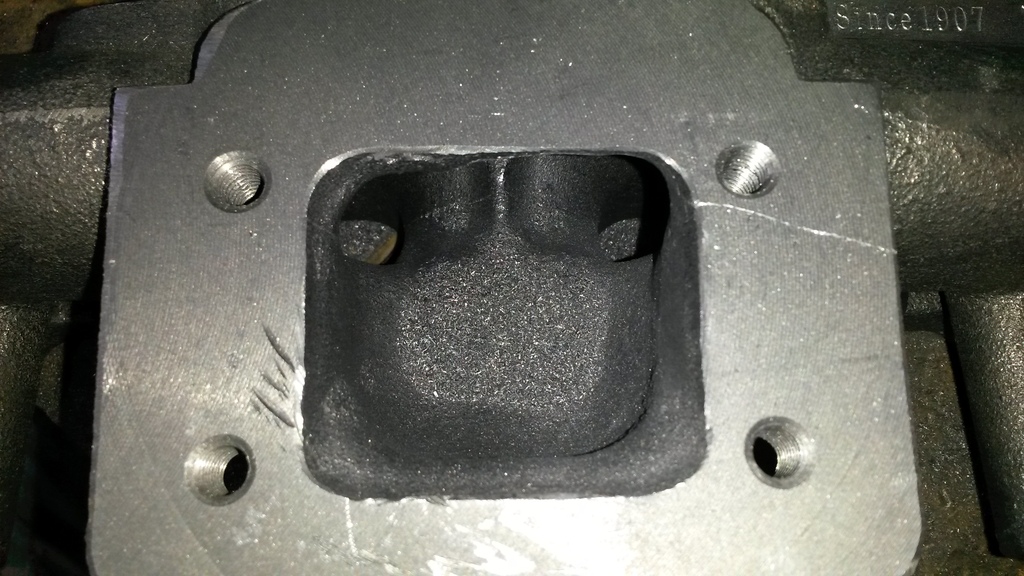

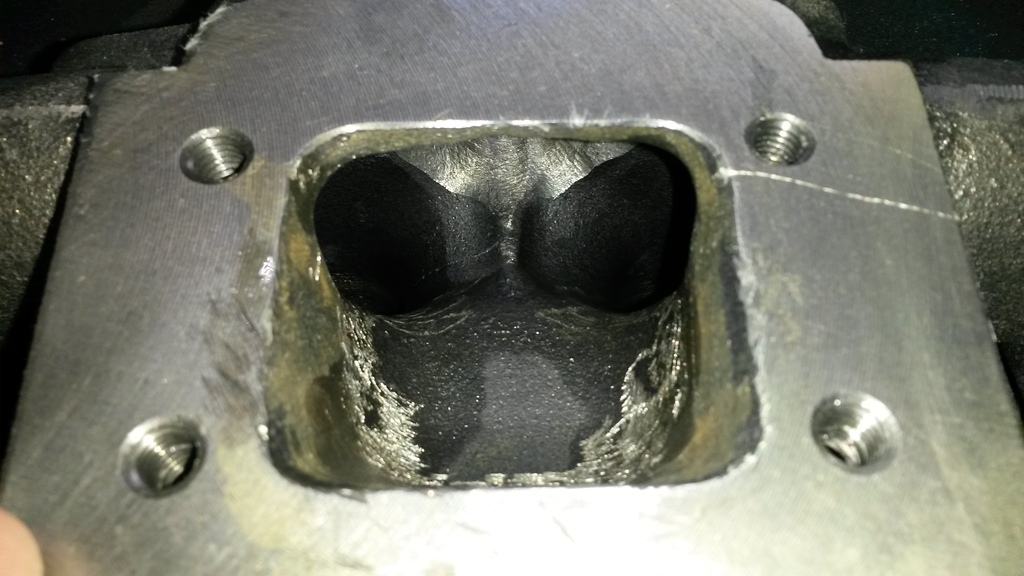

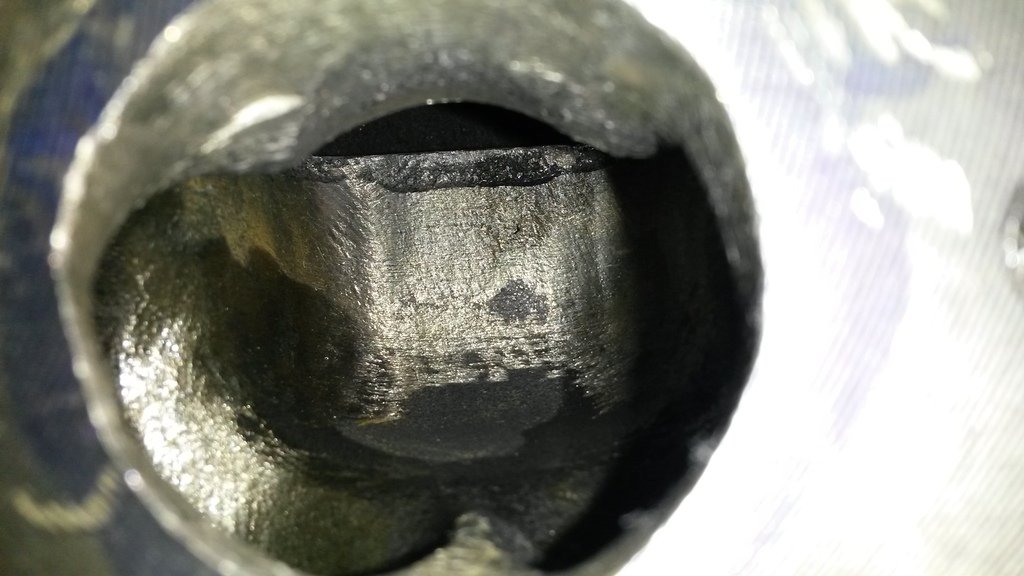

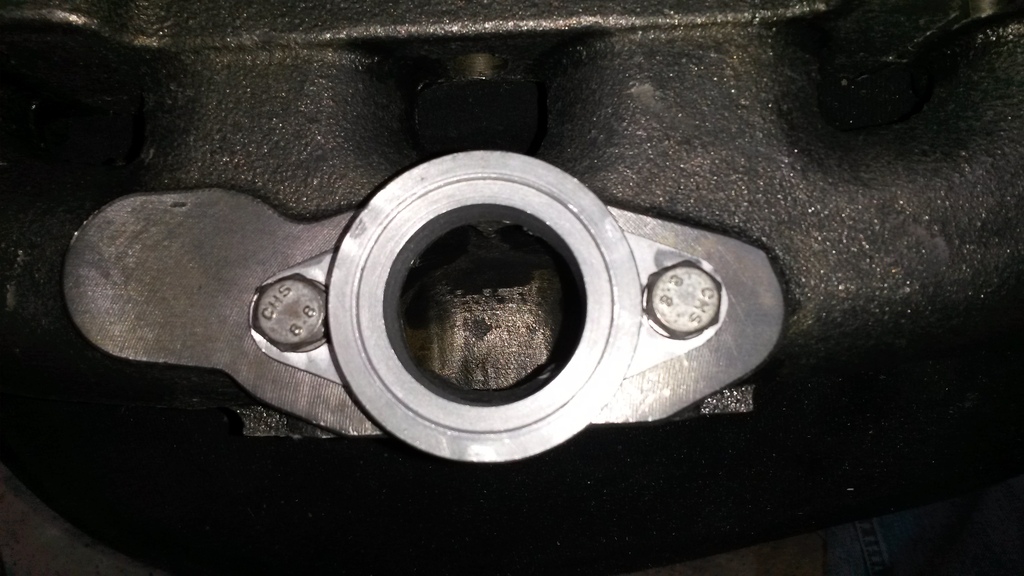

Look at the inlet of the turbo, see all the casting bulges?

Before pic of turbo inlet

I modified the ebay manifold to flow better to the wastegate, and went ahead and ported it a bit where it meets the turbo too. Manifold has tons of metal around it, so no worries of getting a thin spot porting, everything seems to be 5/16" to 1/2" thick on this thing.... I'd kind of be impressed if it ever cracked.

Pics of manifold.

Look at the inlet of the turbo, see all the casting bulges?

Before pic of turbo inlet

#89

Nice 12V Electric Oil Pump Diff Cooler Turbo Scavenge Conversion Gear Pump | eBay

Like this?

These are new, I couldn't find anything other than diaphragm oil pumps when I was looking years ago.

I hear those straight cut bronze gears are noisy! 100x better than diaphragm though...

Like this?

These are new, I couldn't find anything other than diaphragm oil pumps when I was looking years ago.

I hear those straight cut bronze gears are noisy! 100x better than diaphragm though...

#90

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,297

Total Cats: 476

Yeap, that's it. I haven't tested the noise of it yet. Might have to PWM it to slow it down if too noisy. I'm going to take it apart and inspect/clean/debur everything before installing it. Seems to be a good idea on ebay parts that have moving parts.

#91

I'm not sure how much PWM would quiet it down.

Here's a comparison video of diaphragm to gear driven.

From what I've read, having a bit of oil in the brass gears isn't going to make much difference. The gears will contact each other on each revolution, there's nothing to be done to stop that.

A gerotor pump would be boss, but I don't know of anyone that makes a scavenge pump one.

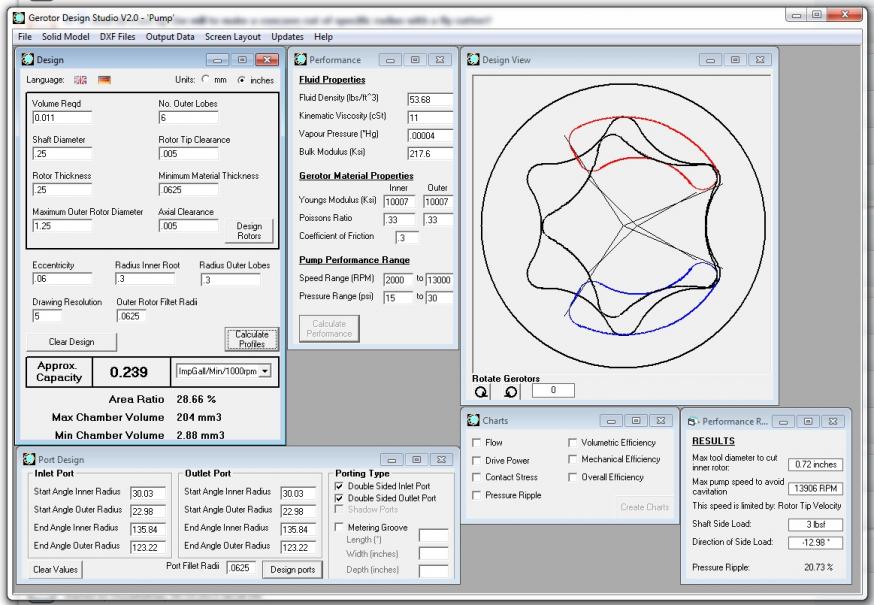

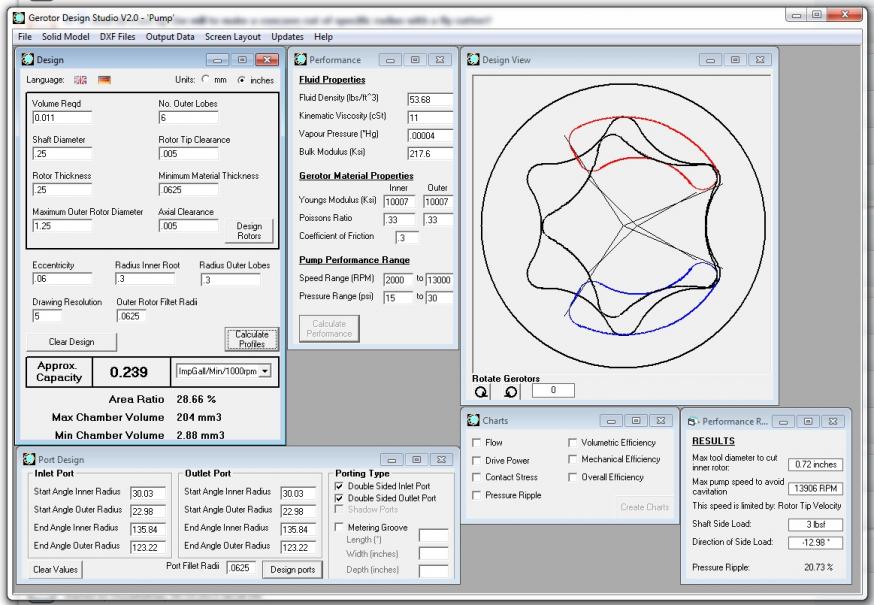

I was looking to make one, like this...

Wish someone would make a scavenge pump like this already...

Here's a comparison video of diaphragm to gear driven.

From what I've read, having a bit of oil in the brass gears isn't going to make much difference. The gears will contact each other on each revolution, there's nothing to be done to stop that.

A gerotor pump would be boss, but I don't know of anyone that makes a scavenge pump one.

I was looking to make one, like this...

Wish someone would make a scavenge pump like this already...

#95

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,297

Total Cats: 476

Is that pump a gear pump or diaphram pump?

I tore the new pump apart, it looked like crap. Really cheap/crappy "machining" if you will. Both gears were contacting the housing, everything was scored up. Had to remove the gears with pliers as they were stuck in the housing.

Ended up cleaning everything up enough to get it to work like it should without parts rubbing things they should not. Takes about 1/10th the power to turn the gears now vs before. Took a couple pics but not really much to see. Will run this pump for now, I think it's ok so long as the oil seal holds up. If it ever leaks, I'll buy a better pump.

I tore the new pump apart, it looked like crap. Really cheap/crappy "machining" if you will. Both gears were contacting the housing, everything was scored up. Had to remove the gears with pliers as they were stuck in the housing.

Ended up cleaning everything up enough to get it to work like it should without parts rubbing things they should not. Takes about 1/10th the power to turn the gears now vs before. Took a couple pics but not really much to see. Will run this pump for now, I think it's ok so long as the oil seal holds up. If it ever leaks, I'll buy a better pump.

#98

All of the "how much total boost?" Questions are related to where the boost pressure is measured from and where its referenced from.

If you have regular internal gate style wastegate cans the reference pressure will always be 100kpa.

If you use the cooler piping to feed the cans then you will make whatever Turbo has the higher pressure.

If you have external gates and you reference inlet pressure, and you feed it with outlet pressure then you will get the multiplication of pressure ratios

If you have regular internal gate style wastegate cans the reference pressure will always be 100kpa.

If you use the cooler piping to feed the cans then you will make whatever Turbo has the higher pressure.

If you have external gates and you reference inlet pressure, and you feed it with outlet pressure then you will get the multiplication of pressure ratios

#100

Not on the inlet side,

Depends how the exhaust side is plumbed.

OK so I read the thread, and pat if you use atmo referenced wastegates you only get the boost that the highest wastegate is.

Your rear turbo might have a 15psi actuator, and so youll make 15psi, but your front gates will see that 15, and being 7psi actuators they will just blow right open fully and that turbo wont contribute at all, as an example.

If you want compound you have to use external gates, with a turbocharger inlet reference.

Depends how the exhaust side is plumbed.

OK so I read the thread, and pat if you use atmo referenced wastegates you only get the boost that the highest wastegate is.

Your rear turbo might have a 15psi actuator, and so youll make 15psi, but your front gates will see that 15, and being 7psi actuators they will just blow right open fully and that turbo wont contribute at all, as an example.

If you want compound you have to use external gates, with a turbocharger inlet reference.

Last edited by nitrodann; 02-06-2016 at 04:16 AM.