The Portabull LFX Build

#101

From what I've pieced together when my original plan of "connect ECM pin to FP relay - wait, why can't i hear it prime?" fell through..

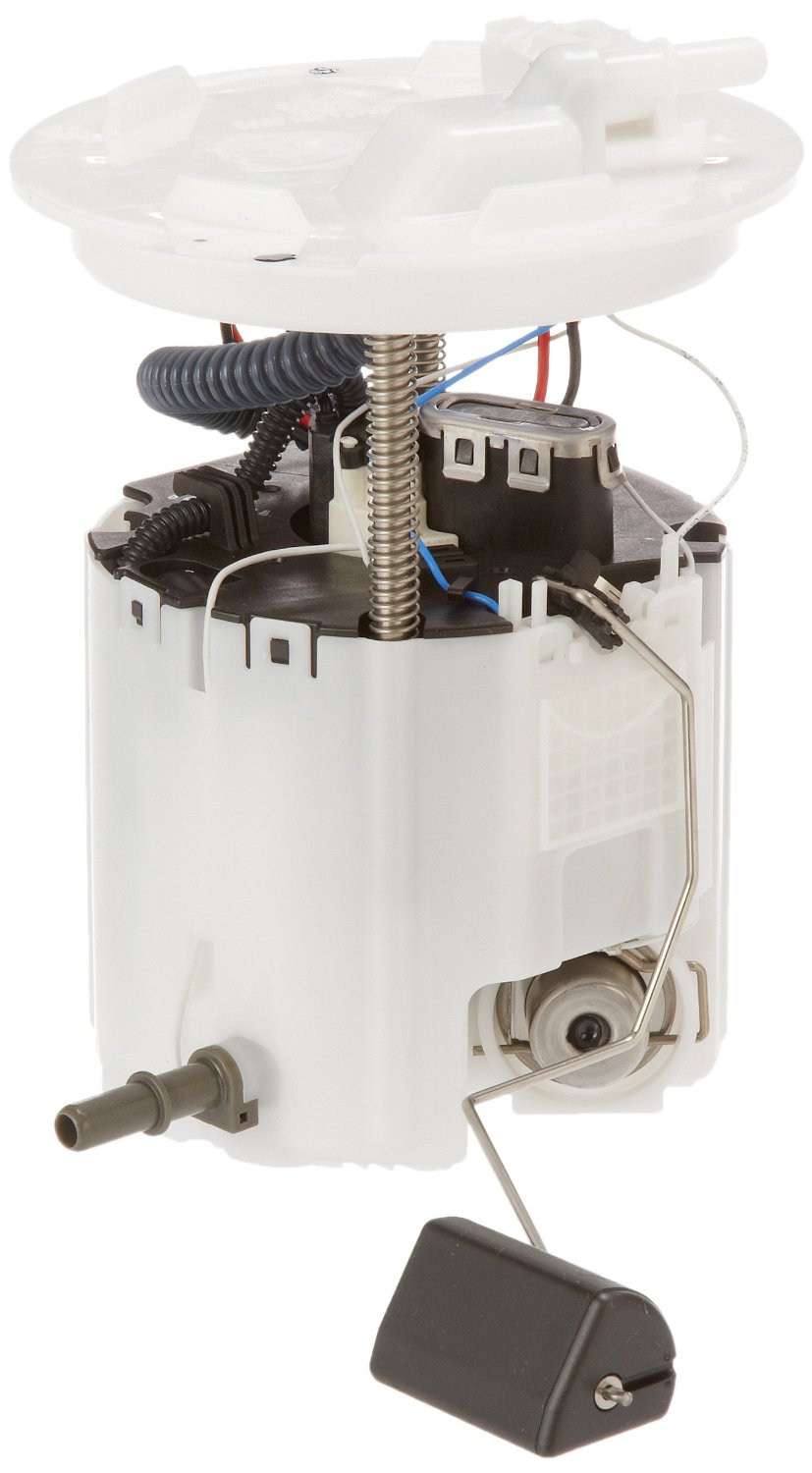

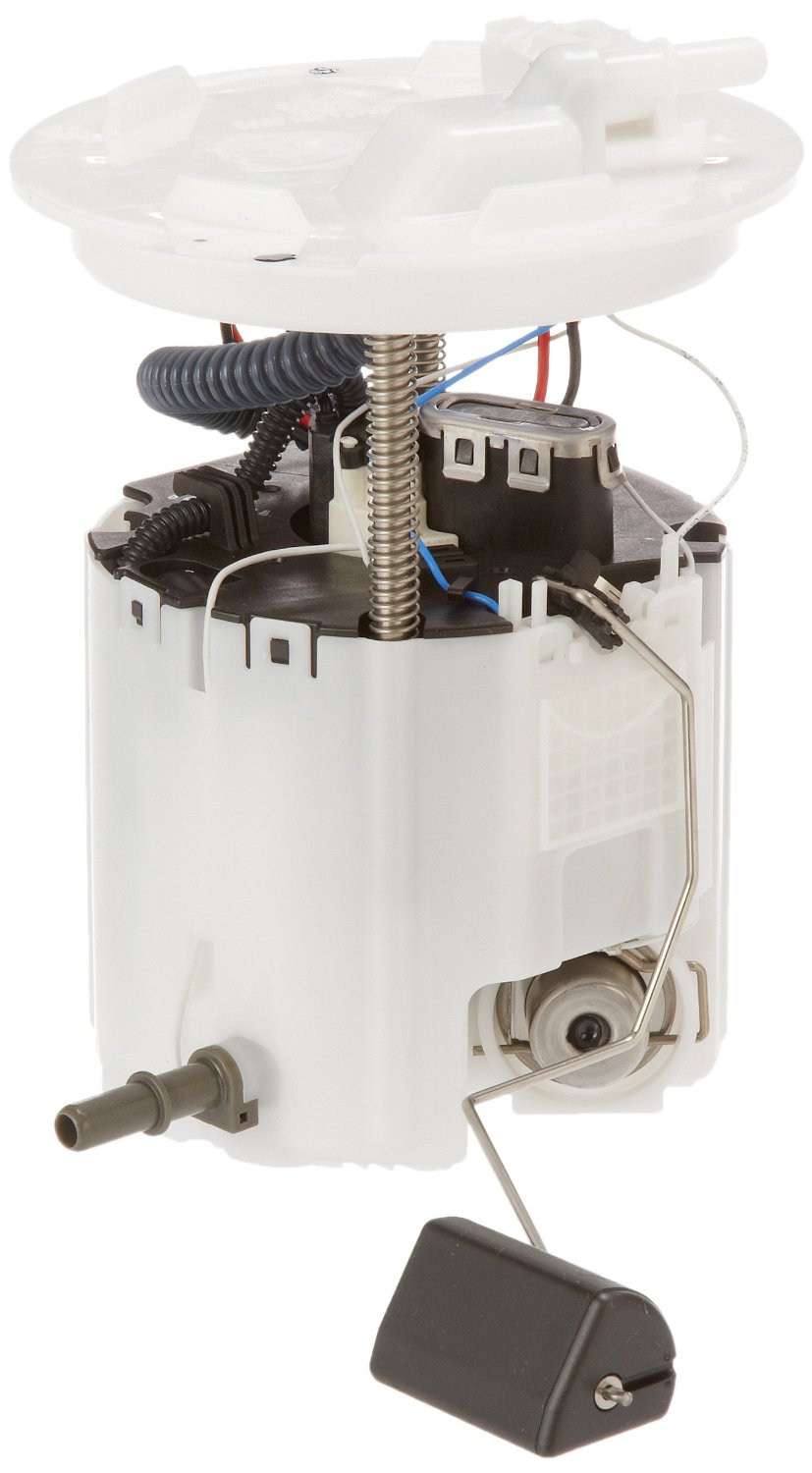

There's a fuel pump drive module (PN 22874300) that reads the square wave (I seem to recall reading somewhere it was 25hz - I haven't bothered dragging my oscope to the shop yet. I was able to see 2.5v on my multimeter though) sent by the ECM, and the module drives the fuel pump via PWM. Since the LFX is direct injection (~2200psi), the fuel pump that's in the tank is more like an old school mechanical pump that draws the fuel to the carb float bowl. The module appears to read line and tank pressure and has some canbus pins - so it's doing pressure regulation without the use of a mechanical/diaphragmed regulator - I think.

Now - since we've got the Corvette FPR we don't have to worry about pressure. But I am thinking about sticking in a inertia switch that'll cut power to the pump in case of a shunt. Otherwise, it'll just whine a lot with the ignition on. After reading up on fuel boil, I don't think it'll be a huge issue since it's a modern tank, but it would be nice to extend the life of the pump if we don't have to don't have to drive it 100% of the time.

I'm still looking into an easy way of doing this - course, I might be overthinking it. I'm sure the way I've got it right now will work.

Oh - and thanks for reminding me about alldata. The AC Delco link I posted earlier does have a little bit better information (I haven't found a wiring schematic on alldata yet), but I hate plopping down $20 every time I need to verify something. I found a coupon code online and snagged a years access for $10.

There's a fuel pump drive module (PN 22874300) that reads the square wave (I seem to recall reading somewhere it was 25hz - I haven't bothered dragging my oscope to the shop yet. I was able to see 2.5v on my multimeter though) sent by the ECM, and the module drives the fuel pump via PWM. Since the LFX is direct injection (~2200psi), the fuel pump that's in the tank is more like an old school mechanical pump that draws the fuel to the carb float bowl. The module appears to read line and tank pressure and has some canbus pins - so it's doing pressure regulation without the use of a mechanical/diaphragmed regulator - I think.

Now - since we've got the Corvette FPR we don't have to worry about pressure. But I am thinking about sticking in a inertia switch that'll cut power to the pump in case of a shunt. Otherwise, it'll just whine a lot with the ignition on. After reading up on fuel boil, I don't think it'll be a huge issue since it's a modern tank, but it would be nice to extend the life of the pump if we don't have to don't have to drive it 100% of the time.

I'm still looking into an easy way of doing this - course, I might be overthinking it. I'm sure the way I've got it right now will work.

Oh - and thanks for reminding me about alldata. The AC Delco link I posted earlier does have a little bit better information (I haven't found a wiring schematic on alldata yet), but I hate plopping down $20 every time I need to verify something. I found a coupon code online and snagged a years access for $10.

Last edited by gooflophaze; 03-09-2016 at 11:00 PM.

#102

I'm thinking there's more to it, if they went through all that trouble for a fuel pump signal. My guess is the engine really needs a variable fuel pressure regulator. Sounds like the money I saved buying a stock clutch is going towards buying a GM factory manual unless you have it figured out by the time I get that far. At a minimum I want the fuel pump to shut off when the engine isn't running.

#103

Nah, it's just a tightly integrated system. You lose the diaphragm (analog technology, fairly reliable, annoying to troubleshoot when it does go bad since you have to hook up pressure gauges and you suspect the fuel pump first) in favor of a pump with a feedback system that can throw DTC's with ease. The pump life is lengthened by using PWM - so lets throw it into an assembly with the fuel pressure sensor and fuel level sensor and it should last past the warranty period. And when it goes bad, we'll just have the tech swap the whole thing instead of plumbing billable time fittings for the pump.

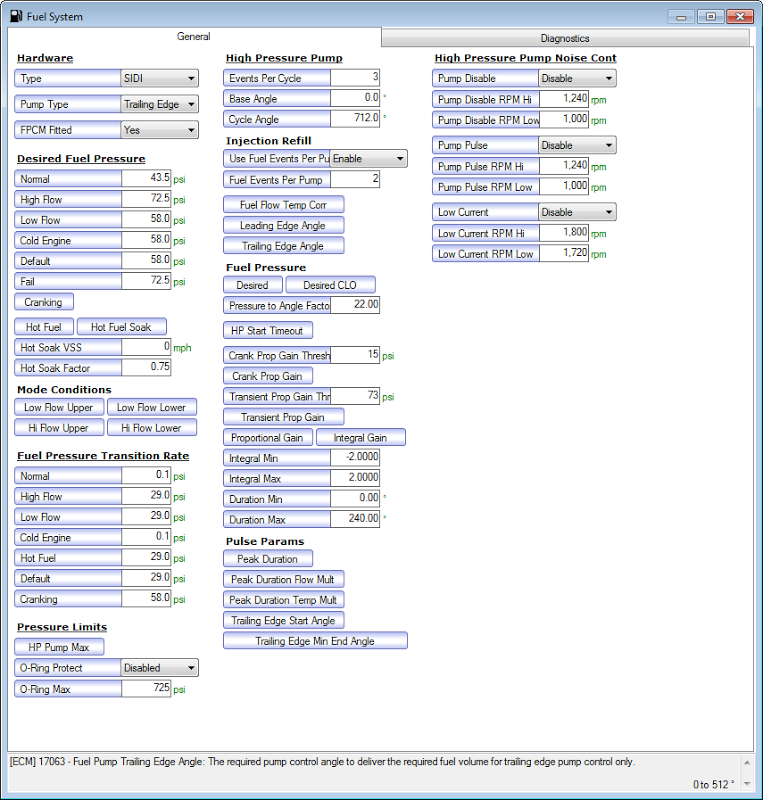

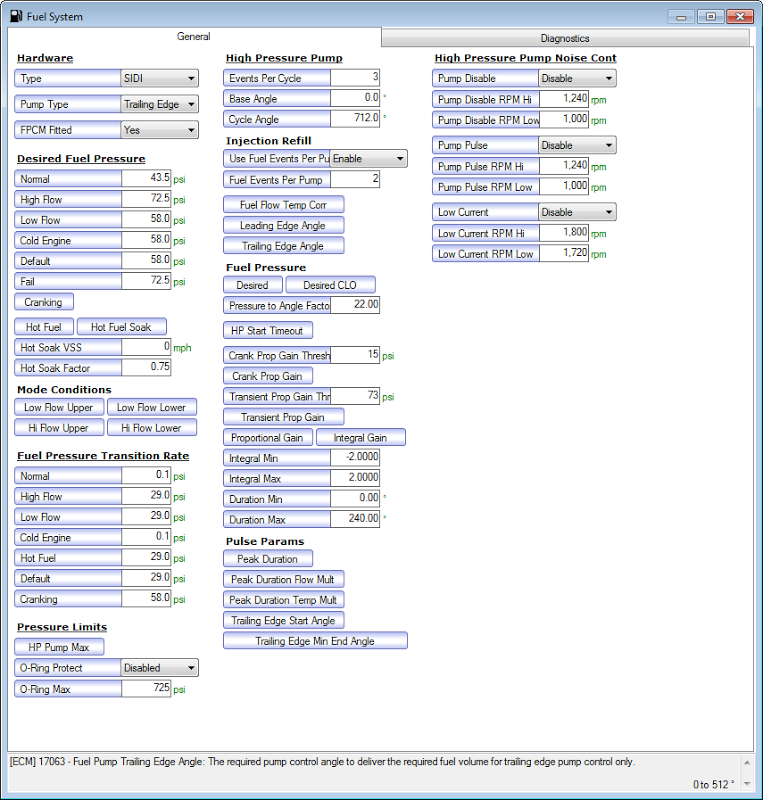

I've dug a little further into HPTuners and looked at the aftermarket - Except for the ZL1 (LT1) Camaro, the SS (LS3) and LFX use the same pump assembly. When you cross over 600hp, people are upgrading to the ZL1 pump assembly. These are the stock settings from HPTuners -

So you can see that the pump is mostly providing your standard 3 bar fuel pressure. Aeromotive makes a fuel controller ($$$$) for > 1000hp v8's ($$$$$$) on top of their own drop-in pump - but its primary market is for the LS3's are still using that 3 bar pressure for fuel injectors, less-so for the LT1.

I'm still confident the C6 vette regulator will do the job. I think that might be possible to turn off the fuel pump by tying it to the powertrain relay - but you'll lose the prime pulse, which'll make starting much harder at the very least and possibly damage the high pressure pump if it's like a diesel (I'm assuming.. I know just enough about diesel engines to be dangerous).

I've dug a little further into HPTuners and looked at the aftermarket - Except for the ZL1 (LT1) Camaro, the SS (LS3) and LFX use the same pump assembly. When you cross over 600hp, people are upgrading to the ZL1 pump assembly. These are the stock settings from HPTuners -

So you can see that the pump is mostly providing your standard 3 bar fuel pressure. Aeromotive makes a fuel controller ($$$$) for > 1000hp v8's ($$$$$$) on top of their own drop-in pump - but its primary market is for the LS3's are still using that 3 bar pressure for fuel injectors, less-so for the LT1.

I'm still confident the C6 vette regulator will do the job. I think that might be possible to turn off the fuel pump by tying it to the powertrain relay - but you'll lose the prime pulse, which'll make starting much harder at the very least and possibly damage the high pressure pump if it's like a diesel (I'm assuming.. I know just enough about diesel engines to be dangerous).

#104

I guess I'm not really surprised the fuel system works this way since GM has apparently been doing this since the vortec engines started being used for the reasons you already stated. My old mans Suburban gave me fits trying to figure out what part of the fuel system had failed. Ended up being the fuel pump control module that was sandwiched between the cross member and the fuel tank so I had to drop the tank anyway just to get to it.

anyway....

I figure I am just going to relay my fuel pump off the "key on constant" like the ECU but I was trying to think of how you would achieve a "as needed" relay. I think you are best off just using a fuel pump switch if you want to be able to shut off the pump in ACC only situations.

anyway....

I figure I am just going to relay my fuel pump off the "key on constant" like the ECU but I was trying to think of how you would achieve a "as needed" relay. I think you are best off just using a fuel pump switch if you want to be able to shut off the pump in ACC only situations.

#105

I did a little researching. The solution isn't so bad. You can buy stuff off the shelf.

PWM output for fuel pump control - ChevyTalk - FREE Restoration and Repair Help for your Chevrolet

or somebody who make a converter (from the above link)

Other Control

PWM output for fuel pump control - ChevyTalk - FREE Restoration and Repair Help for your Chevrolet

or somebody who make a converter (from the above link)

Other Control

#106

That second link looks like it's expecting an analog TPS signal, not sure how well that'd jive with the DBW system.

If I were inclined to make this work like the GM system, I'd try and snag a controller and fuel pump assembly, try and map out the fuel pressure to voltage curve of the built in pressure sensor, find a discrete sensor that closely matched it and install it in line from the tank output. You'd also need to discard the C5 FPR and filter setup, and possibly install a fuel tank pressure sensor for the controller.

Could also put the fp relay in line with a fuel safe pressure switch, that's a fairly simple closed loop system.. not sure how we'll it'd work with hysteresis though..

Could also possibly do a 555 timer to latch a relay for 5 seconds in one shot mode and have that or'd into the powertrain relay.. that'd give you a priming pulse.

Plenty of ways to skin this cat.

Either way.. I picked up an inertia switch from a 90's mustang at the junkyard today for $2 (also snagged: eclipse vents, auto-dimming rearview mirror with compass and homelink, pocket full of fuses, and another NB gauge cluster to test on. Pretty good haul). I'll wire the switch in-line with the relay and stick it under the hood and put my fuel pump concerns to bed.

If I were inclined to make this work like the GM system, I'd try and snag a controller and fuel pump assembly, try and map out the fuel pressure to voltage curve of the built in pressure sensor, find a discrete sensor that closely matched it and install it in line from the tank output. You'd also need to discard the C5 FPR and filter setup, and possibly install a fuel tank pressure sensor for the controller.

Could also put the fp relay in line with a fuel safe pressure switch, that's a fairly simple closed loop system.. not sure how we'll it'd work with hysteresis though..

Could also possibly do a 555 timer to latch a relay for 5 seconds in one shot mode and have that or'd into the powertrain relay.. that'd give you a priming pulse.

Plenty of ways to skin this cat.

Either way.. I picked up an inertia switch from a 90's mustang at the junkyard today for $2 (also snagged: eclipse vents, auto-dimming rearview mirror with compass and homelink, pocket full of fuses, and another NB gauge cluster to test on. Pretty good haul). I'll wire the switch in-line with the relay and stick it under the hood and put my fuel pump concerns to bed.

Last edited by gooflophaze; 03-14-2016 at 10:48 PM.

#108

https://www.dccdpro.com/product/fuelpro/

May be another option and pretty reasonable at $169. Looks like the controller needs a 5 volt square wave signal with a duty cycle of %35 to %95 from the ECU. If you get a chance it would be cool to see what the o-scope has to say on the signal from the ECU. Once we know for sure what it is sending we can look for specific solutions.

May be another option and pretty reasonable at $169. Looks like the controller needs a 5 volt square wave signal with a duty cycle of %35 to %95 from the ECU. If you get a chance it would be cool to see what the o-scope has to say on the signal from the ECU. Once we know for sure what it is sending we can look for specific solutions.

Last edited by griff; 03-11-2016 at 01:09 PM.

#110

3.0 - Thought I needed the segment swapper to change the transmission to a manual, but it looks like it's all settings. I may try out 2.24, 3.0 seems a little underbaked. Plus when I need to look up how to check a setting it's usually 2.2x instructions.

That fuel pump controller looks more right - but I'd need to hit multiple fueling zones to verify outputs, and that's not going to happen without a dyno.

I think I've finally finished my wiring, had the alternator all hooked up and ready to roll today - and the car wouldn't start. Argh. Looks like the E39 hates a weak battery - dropped to 8.3v while cranking and wouldn't start. Hopefully the charger brings it back to life.

That fuel pump controller looks more right - but I'd need to hit multiple fueling zones to verify outputs, and that's not going to happen without a dyno.

I think I've finally finished my wiring, had the alternator all hooked up and ready to roll today - and the car wouldn't start. Argh. Looks like the E39 hates a weak battery - dropped to 8.3v while cranking and wouldn't start. Hopefully the charger brings it back to life.

#111

You can tune with a wideband as well. I'm not an HP Tuners guru, but I've got a coworker who does it all the time. It's a lot of trial and error.

Now you have me curious about the fuel pressure. I see the low and high values in your post. Does fuel pressure change vs RPM or only on WOT? I guess I can pull a download from the HP Tuners forum and check it out.

My understanding is the ECU will always try to drive to 14.7 AFR except under WOT. It makes me wonder if the car will even run right with a standard mechanical FPR and a stock tune without throwing codes.

Now you have me curious about the fuel pressure. I see the low and high values in your post. Does fuel pressure change vs RPM or only on WOT? I guess I can pull a download from the HP Tuners forum and check it out.

My understanding is the ECU will always try to drive to 14.7 AFR except under WOT. It makes me wonder if the car will even run right with a standard mechanical FPR and a stock tune without throwing codes.

#112

You can tune with a wideband as well. I'm not an HP Tuners guru, but I've got a coworker who does it all the time. It's a lot of trial and error.

Now you have me curious about the fuel pressure. I see the low and high values in your post. Does fuel pressure change vs RPM or only on WOT? I guess I can pull a download from the HP Tuners forum and check it out.

My understanding is the ECU will always try to drive to 14.7 AFR except under WOT. It makes me wonder if the car will even run right with a standard mechanical FPR and a stock tune without throwing codes.

Now you have me curious about the fuel pressure. I see the low and high values in your post. Does fuel pressure change vs RPM or only on WOT? I guess I can pull a download from the HP Tuners forum and check it out.

My understanding is the ECU will always try to drive to 14.7 AFR except under WOT. It makes me wonder if the car will even run right with a standard mechanical FPR and a stock tune without throwing codes.

#113

Senior Member

iTrader: (1)

Join Date: Sep 2011

Location: Lambertville, NJ

Posts: 1,215

Total Cats: 74

They are both incredibly non-linear, so I had to replace/remove a few of the resistors (i may be able to dig up my information on that if you're interested). Even with some messing with the resistors they are still quite non-linear, but a microcontroller and pwm-ed FETs take care of that.

#114

Not a tuner by any means, but using V8R's tune, upgraded miata fuel pump, and C6 filter/regulator, and the car runs hard to redline with no hiccips, flat spots, or codes. I'd like to get the car on a dyno here soon and verify how it's running, but after having driven it twice, very happy with it.

As far as the C6 filter regulator, don't you mean C6? I think the C6 filter is in the pump. The later C5 had a returnless fuel rail with the regulator/filter mounted in the back like a lot guys doing with the Miata.

#115

You can tune with a wideband as well. I'm not an HP Tuners guru, but I've got a coworker who does it all the time. It's a lot of trial and error.

Now you have me curious about the fuel pressure. I see the low and high values in your post. Does fuel pressure change vs RPM or only on WOT? I guess I can pull a download from the HP Tuners forum and check it out.

My understanding is the ECU will always try to drive to 14.7 AFR except under WOT. It makes me wonder if the car will even run right with a standard mechanical FPR and a stock tune without throwing codes.

Now you have me curious about the fuel pressure. I see the low and high values in your post. Does fuel pressure change vs RPM or only on WOT? I guess I can pull a download from the HP Tuners forum and check it out.

My understanding is the ECU will always try to drive to 14.7 AFR except under WOT. It makes me wonder if the car will even run right with a standard mechanical FPR and a stock tune without throwing codes.

#116

I was looking through my pictures last night writing the first installment of the wiring section and noticed that this was taken exactly one year ago.

And today we put the interior back in. w00t.

It was indeed the battery that was a little flat. Couple hours on the charger and it cranks right up. Just need to put in the NB cluster, wire the stereo, retape my wiring harness.. and the next week we'll hopefully have the exhaust installed.

Yeap - I'll have to do some correction factors in software once I get full movement. It'll have to be doubly annoying because who knows if you pushed the needle back on at the right position. Then again, you could also make the argument for having the extremes being more sensitive. For the moment in my dads car, I'll be replicating a switch-like threshold.

Sorry, fatfinger/misremember. C5 FPR is what we're running. We put all the carpet in today and despite being an upgraded walbro 255lph hp, it sounds.. like a fuel pump. No more whine.

And today we put the interior back in. w00t.

It was indeed the battery that was a little flat. Couple hours on the charger and it cranks right up. Just need to put in the NB cluster, wire the stereo, retape my wiring harness.. and the next week we'll hopefully have the exhaust installed.

Yeap - I'll have to do some correction factors in software once I get full movement. It'll have to be doubly annoying because who knows if you pushed the needle back on at the right position. Then again, you could also make the argument for having the extremes being more sensitive. For the moment in my dads car, I'll be replicating a switch-like threshold.

Sorry, fatfinger/misremember. C5 FPR is what we're running. We put all the carpet in today and despite being an upgraded walbro 255lph hp, it sounds.. like a fuel pump. No more whine.

#118

No PPF brace - I figure that Mazda spent considerable engineering effort in designing it, and all those calculations go out the window when you shove another power plant, subframe, and crossmember in.

Apologies for not posting up the wiring - I've been very busy. Resurrected our tow vehicle that's been sitting for 3 years, dealing with leaking diesel and glow plug wires grounding against the frame. Ultimately, dropped the car off at the exhaust shop today.

I've got a major issue I'm trying to hunt down - if anyone could lend me a hand with this or just bounce ideas, it'd be much appreciated. I can't get a valid VSS signal from HPTuners - it reads 158mph (0xFF, 255kmh == 158mph). This is a blocking issue for getting the car registered once the exhaust is finished (will need mileage to get the OBDII readiness set). I think it's because my E39a ECM is from an automatic, and despite changing the transmission type in HPTuners. I think the bits are missing. From what I understand - HPTuners just modifies bits, doesn't install new ones. From what I've grok'd from other forums, this is the failure mode when the Transmission Control Module is missing.

The VSS sensor appears to be a hall type, based on A. it makes sense and B. power, ground, and signal wires from the harness. If anyone has their transmission on the ground and could yank the sensor out, count and take a shot of the teeth, and stick something ferrous to see if the teeth are magnetic - it'd be a huge help.

I've poured over the wiring diagrams a dozen times now to verify my inputs. To further complicate things, the alldatadiy diagrams do not match the VSS input pin from the acdelco site (X1 43 vs X2 8). I went so far as to tap the VSS wire with my scope and snag a trace with the car in 5th while idling, but it doesn't look valid. I *think* the VSS pin must have a software-enabled pullup that I'm lacking - if only I had a 10k resistor at my shop I could have verified at the time.

Doesn't help that there's a lot of noise. Either that, or my VSS is busted. I might snag a sensor from rockauto and try it out on the bench.

The other way to fix this is to have someone with GM's tech2 reflash the ECM. I talked briefly with a service manager at a dealership who said they could reflash for $110 - which I'm sure is the price of a stock reflash (insert VIN, push bits out). I wish could have talked directly to a tech. Since I think HPTuners hashes their credits based on the VIN, and I think Tech2 is mostly-automated (input VIN, database lookup for options to program, flash bits). I might be better off snagging another Camaro ECM from a junkyard and burning another 2 hptuner credits on disabling VATS - and then I have 2 (sorta) working ECM's.

Oh - and here's a (mostly complete) picture of the engine bay. Just need to lick this VSS problem then I can finish wrapping the harnesses.

Apologies for not posting up the wiring - I've been very busy. Resurrected our tow vehicle that's been sitting for 3 years, dealing with leaking diesel and glow plug wires grounding against the frame. Ultimately, dropped the car off at the exhaust shop today.

I've got a major issue I'm trying to hunt down - if anyone could lend me a hand with this or just bounce ideas, it'd be much appreciated. I can't get a valid VSS signal from HPTuners - it reads 158mph (0xFF, 255kmh == 158mph). This is a blocking issue for getting the car registered once the exhaust is finished (will need mileage to get the OBDII readiness set). I think it's because my E39a ECM is from an automatic, and despite changing the transmission type in HPTuners. I think the bits are missing. From what I understand - HPTuners just modifies bits, doesn't install new ones. From what I've grok'd from other forums, this is the failure mode when the Transmission Control Module is missing.

The VSS sensor appears to be a hall type, based on A. it makes sense and B. power, ground, and signal wires from the harness. If anyone has their transmission on the ground and could yank the sensor out, count and take a shot of the teeth, and stick something ferrous to see if the teeth are magnetic - it'd be a huge help.

I've poured over the wiring diagrams a dozen times now to verify my inputs. To further complicate things, the alldatadiy diagrams do not match the VSS input pin from the acdelco site (X1 43 vs X2 8). I went so far as to tap the VSS wire with my scope and snag a trace with the car in 5th while idling, but it doesn't look valid. I *think* the VSS pin must have a software-enabled pullup that I'm lacking - if only I had a 10k resistor at my shop I could have verified at the time.

Doesn't help that there's a lot of noise. Either that, or my VSS is busted. I might snag a sensor from rockauto and try it out on the bench.

The other way to fix this is to have someone with GM's tech2 reflash the ECM. I talked briefly with a service manager at a dealership who said they could reflash for $110 - which I'm sure is the price of a stock reflash (insert VIN, push bits out). I wish could have talked directly to a tech. Since I think HPTuners hashes their credits based on the VIN, and I think Tech2 is mostly-automated (input VIN, database lookup for options to program, flash bits). I might be better off snagging another Camaro ECM from a junkyard and burning another 2 hptuner credits on disabling VATS - and then I have 2 (sorta) working ECM's.

Oh - and here's a (mostly complete) picture of the engine bay. Just need to lick this VSS problem then I can finish wrapping the harnesses.

#119

Man I wish I could help you and I have been thinking a good deal about how I will get the VSS to send to the new speedo gauge and send to the ECU. I guess there is a chance the ECU will not need the signal but if it does I doubt I will be able to send to both with the same sensor without creating interference. Wonder if Sean can help out or if 99LFX has his licked.

#120

No PPF brace - I figure that Mazda spent considerable engineering effort in designing it, and all those calculations go out the window when you shove another power plant, subframe, and crossmember in.

Apologies for not posting up the wiring - I've been very busy. Resurrected our tow vehicle that's been sitting for 3 years, dealing with leaking diesel and glow plug wires grounding against the frame. Ultimately, dropped the car off at the exhaust shop today.

I've got a major issue I'm trying to hunt down - if anyone could lend me a hand with this or just bounce ideas, it'd be much appreciated. I can't get a valid VSS signal from HPTuners - it reads 158mph (0xFF, 255kmh == 158mph). This is a blocking issue for getting the car registered once the exhaust is finished (will need mileage to get the OBDII readiness set). I think it's because my E39a ECM is from an automatic, and despite changing the transmission type in HPTuners. I think the bits are missing. From what I understand - HPTuners just modifies bits, doesn't install new ones. From what I've grok'd from other forums, this is the failure mode when the Transmission Control Module is missing.

The VSS sensor appears to be a hall type, based on A. it makes sense and B. power, ground, and signal wires from the harness. If anyone has their transmission on the ground and could yank the sensor out, count and take a shot of the teeth, and stick something ferrous to see if the teeth are magnetic - it'd be a huge help.

I've poured over the wiring diagrams a dozen times now to verify my inputs. To further complicate things, the alldatadiy diagrams do not match the VSS input pin from the acdelco site (X1 43 vs X2 8). I went so far as to tap the VSS wire with my scope and snag a trace with the car in 5th while idling, but it doesn't look valid. I *think* the VSS pin must have a software-enabled pullup that I'm lacking - if only I had a 10k resistor at my shop I could have verified at the time.

Doesn't help that there's a lot of noise. Either that, or my VSS is busted. I might snag a sensor from rockauto and try it out on the bench.

The other way to fix this is to have someone with GM's tech2 reflash the ECM. I talked briefly with a service manager at a dealership who said they could reflash for $110 - which I'm sure is the price of a stock reflash (insert VIN, push bits out). I wish could have talked directly to a tech. Since I think HPTuners hashes their credits based on the VIN, and I think Tech2 is mostly-automated (input VIN, database lookup for options to program, flash bits). I might be better off snagging another Camaro ECM from a junkyard and burning another 2 hptuner credits on disabling VATS - and then I have 2 (sorta) working ECM's.

Oh - and here's a (mostly complete) picture of the engine bay. Just need to lick this VSS problem then I can finish wrapping the harnesses.

Apologies for not posting up the wiring - I've been very busy. Resurrected our tow vehicle that's been sitting for 3 years, dealing with leaking diesel and glow plug wires grounding against the frame. Ultimately, dropped the car off at the exhaust shop today.

I've got a major issue I'm trying to hunt down - if anyone could lend me a hand with this or just bounce ideas, it'd be much appreciated. I can't get a valid VSS signal from HPTuners - it reads 158mph (0xFF, 255kmh == 158mph). This is a blocking issue for getting the car registered once the exhaust is finished (will need mileage to get the OBDII readiness set). I think it's because my E39a ECM is from an automatic, and despite changing the transmission type in HPTuners. I think the bits are missing. From what I understand - HPTuners just modifies bits, doesn't install new ones. From what I've grok'd from other forums, this is the failure mode when the Transmission Control Module is missing.

The VSS sensor appears to be a hall type, based on A. it makes sense and B. power, ground, and signal wires from the harness. If anyone has their transmission on the ground and could yank the sensor out, count and take a shot of the teeth, and stick something ferrous to see if the teeth are magnetic - it'd be a huge help.

I've poured over the wiring diagrams a dozen times now to verify my inputs. To further complicate things, the alldatadiy diagrams do not match the VSS input pin from the acdelco site (X1 43 vs X2 8). I went so far as to tap the VSS wire with my scope and snag a trace with the car in 5th while idling, but it doesn't look valid. I *think* the VSS pin must have a software-enabled pullup that I'm lacking - if only I had a 10k resistor at my shop I could have verified at the time.

Doesn't help that there's a lot of noise. Either that, or my VSS is busted. I might snag a sensor from rockauto and try it out on the bench.

The other way to fix this is to have someone with GM's tech2 reflash the ECM. I talked briefly with a service manager at a dealership who said they could reflash for $110 - which I'm sure is the price of a stock reflash (insert VIN, push bits out). I wish could have talked directly to a tech. Since I think HPTuners hashes their credits based on the VIN, and I think Tech2 is mostly-automated (input VIN, database lookup for options to program, flash bits). I might be better off snagging another Camaro ECM from a junkyard and burning another 2 hptuner credits on disabling VATS - and then I have 2 (sorta) working ECM's.

Oh - and here's a (mostly complete) picture of the engine bay. Just need to lick this VSS problem then I can finish wrapping the harnesses.