In Soviet Russia car build YOU!

#1023

You might have enough length on that nipple under the rubber hose to flare and put an AN fitting directly on it. Like a male to male fitting. Would require you getting a 37* flare tool. if you didnt already have one. Or if they make a compression fitting in that size that goes directly to AN that would be an option too.

#1025

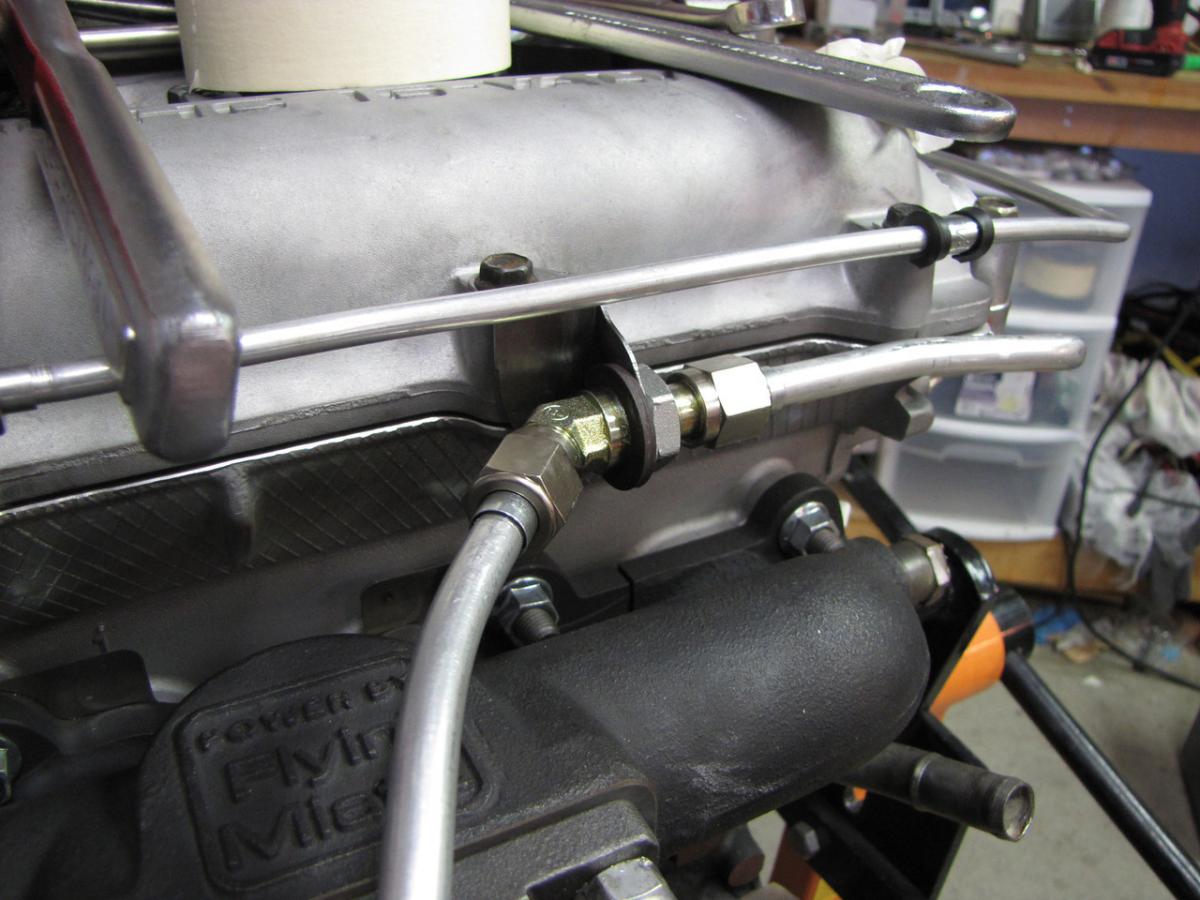

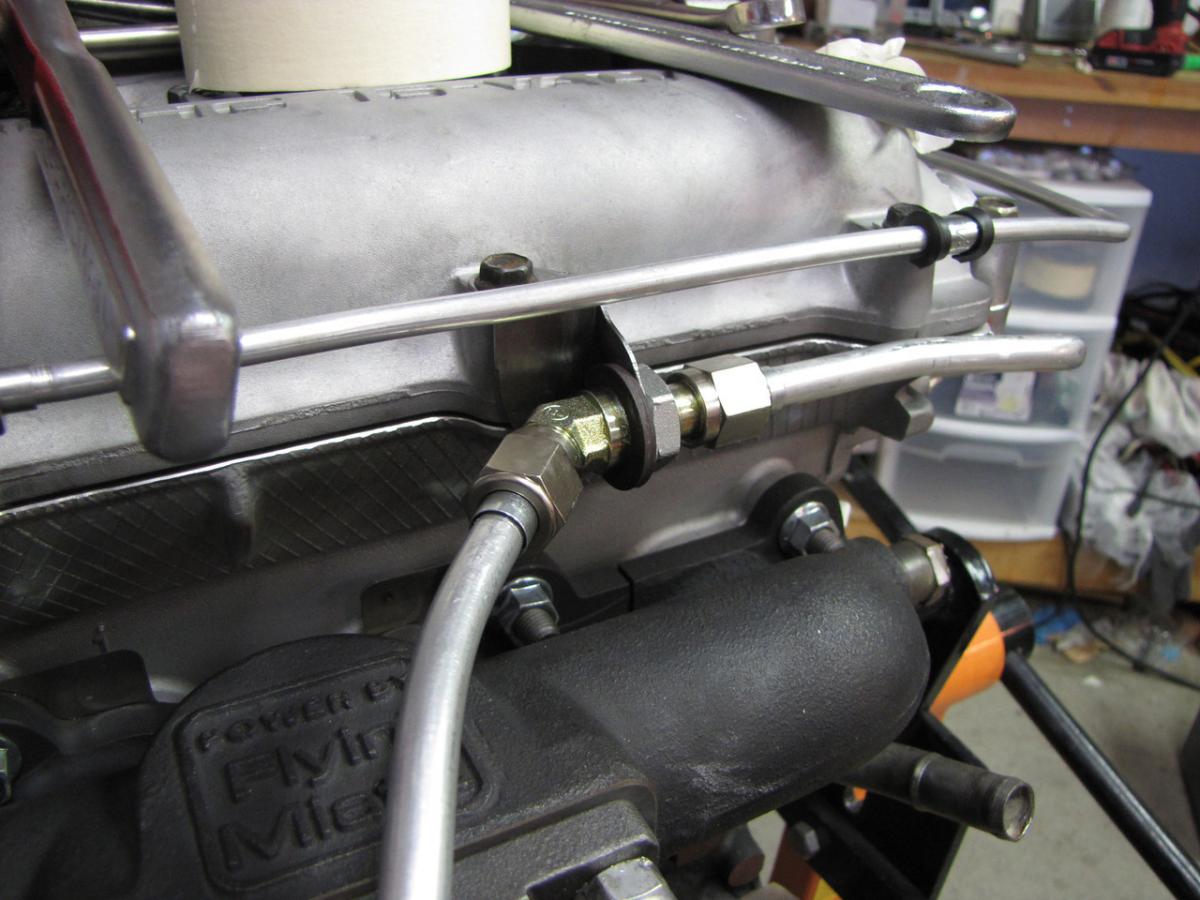

Yeah - after trying to come up with clever ways to put another cludge over the factory cludge of stealing even more oil from the pressure sender... I just figured why not take it up here?

I had to do some VVT oil feed rerouting (i.e. bending OEM hardline), I forget why - I think it's from my 'turned a 1.6l water neck on the lathe because I didn't know about the kia part' coolant reroute.

I *do* get a slight ticking on startup - I'm thinking either because I monkied up the VVT mechanism by installing the low pressure lock pin thing in backwards when I first installed it (caught it before I started it but not before the cam went slamming around a few times during the timing processes) or just loose valves or the fact I have a small, known leak at the VVT hard line to valve cover feed (back there) which I think I just need to MAN on and/or get new washers.

Anyway, the point is, yeah so far it works great. SUPER liking the hardlines, my oil return is one too. Built little braces for everything and have extra break points so it's easy to work on.

Put a big old banjo in my front water outlet plate and used it to feed water to turbo....

This set up is 100-million-billion times better than FM's water feed/return - the the turbo clocked correctly and the return path being close to monotonically rising, the water really just runs through the turbo after shut down. Before it would gurgle super loudly every ten of 15 seconds, now it's like a bubbling brook - and Garret's own research shows that keeps the peak bearing temps down over 100 degrees. My $300 china turbo will live forever!

I had to do some VVT oil feed rerouting (i.e. bending OEM hardline), I forget why - I think it's from my 'turned a 1.6l water neck on the lathe because I didn't know about the kia part' coolant reroute.

I *do* get a slight ticking on startup - I'm thinking either because I monkied up the VVT mechanism by installing the low pressure lock pin thing in backwards when I first installed it (caught it before I started it but not before the cam went slamming around a few times during the timing processes) or just loose valves or the fact I have a small, known leak at the VVT hard line to valve cover feed (back there) which I think I just need to MAN on and/or get new washers.

Anyway, the point is, yeah so far it works great. SUPER liking the hardlines, my oil return is one too. Built little braces for everything and have extra break points so it's easy to work on.

Put a big old banjo in my front water outlet plate and used it to feed water to turbo....

This set up is 100-million-billion times better than FM's water feed/return - the the turbo clocked correctly and the return path being close to monotonically rising, the water really just runs through the turbo after shut down. Before it would gurgle super loudly every ten of 15 seconds, now it's like a bubbling brook - and Garret's own research shows that keeps the peak bearing temps down over 100 degrees. My $300 china turbo will live forever!

#1029

I'll post more pics, but I haven't fully updated it (see below)

In the mean time, existing pics here: 2012 hardlines for China 2871 - AbeFM's Photos

Bad news: I've had one crack! I put a huge loop in the turbo water feed to make room for wrenches - this was all done out of the car so I thought I'd have more trouble than I did. It was obvious (that big loop you see) was just flapping in the breeze and I was being optimistic.

The new routing is much shorted and goes nearly immediately to the support brace I put in. I'm debating making the brace a 3D structure as was the water return support. That thing isn't going anywhere, whereas I'm a little worried about the water feed leaking. The oil feed supports were just some sub $1 supports I got at home depot or something. The oil return is how a hard line too (another never ending source of trouble for me), much lighter weight and whatnot. It was getting just a big hard to bend even in alum.

All that said - I'm really happy with the hard lines. I basically lived my life 1-2 weeks of "running car" at a time with the FM stuff - either the water lines were bursting/cooking, or the turbo studs were breaking. After putting in bigger, high grade studs and now with these lines, my life is complete. The car just runs and I'm very happy with it.

All in all, it was the same $$$ as buying FM's some metal, some rubber kit, and now I have enough left over junk to make more... And remaking anything due to design changes costs me like $0.79 a foot, so I've no complaints. Will edit post and add pics of redone water feed hard line soon.

#1030

Redone Tube: Turbo Hardline Water Feed Redo - AbeFM's Photos

Any minute now my phone will actually upload these pics and you can check it out. :-(

Any minute now my phone will actually upload these pics and you can check it out. :-(

#1033

So, I was hoping to weld in a fitting, and it turned out not to look good - but tapping worked well.

So far the worst issue with my whole set up is that I can't seem to keep the motor warm in very cold weather - I think the water feed to the turbo (which dumps to the radiator) and it's aluminum lines cools stuff too much. Happy with it though.

Totally need a new thread, this is supposed to be about people drooling over the sweet BW setup. :-)

Why not? Not more VVT?

So far the worst issue with my whole set up is that I can't seem to keep the motor warm in very cold weather - I think the water feed to the turbo (which dumps to the radiator) and it's aluminum lines cools stuff too much. Happy with it though.

Totally need a new thread, this is supposed to be about people drooling over the sweet BW setup. :-)

Why not? Not more VVT?

#1034

Elite Member

Thread Starter

iTrader: (10)

Join Date: Jan 2010

Location: VA

Posts: 3,493

Total Cats: 268

Today, I was driving to my parents house. Punched it in 4th, started spinning wheels as usual. Rear end stepped out and I wasn't able to quite hold it - as result hit the curb pretty hard.

As result I now have about 10* rear toe-in and rear wheel is missing 3/4 of the outer rim (lol). I limped to my parents garage and left the car there - won't know full extent of damage until later this week.

I, luckly, have the whole rear suspension/subframe from the other 91 car I parted - so this should be an easy fix, especially if it's just the control arms. I really hope the shock is ok (it should be).

Lesson learned, don't dick around in stupid powered car with no traction control on UHP summer tires in sub-freezing temperatures.

Edit: its not clear from the picture, but the damage is JUST to the wheel/suspension. The body appears to be unharmed - it's just really dirty.

As result I now have about 10* rear toe-in and rear wheel is missing 3/4 of the outer rim (lol). I limped to my parents garage and left the car there - won't know full extent of damage until later this week.

I, luckly, have the whole rear suspension/subframe from the other 91 car I parted - so this should be an easy fix, especially if it's just the control arms. I really hope the shock is ok (it should be).

Lesson learned, don't dick around in stupid powered car with no traction control on UHP summer tires in sub-freezing temperatures.

Edit: its not clear from the picture, but the damage is JUST to the wheel/suspension. The body appears to be unharmed - it's just really dirty.

#1036

Elite Member

Thread Starter

iTrader: (10)

Join Date: Jan 2010

Location: VA

Posts: 3,493

Total Cats: 268

I busted a 6ul too!

https://www.miataturbo.net/wheels-ti...what-do-59920/

In fact, Lars is already getting that one

I got very lucky that I only bent a $104 wheel and will just need a $100 alignment plus like $16 in mounting/balancing fees @ walmart.

https://www.miataturbo.net/wheels-ti...what-do-59920/

In fact, Lars is already getting that one

I got very lucky that I only bent a $104 wheel and will just need a $100 alignment plus like $16 in mounting/balancing fees @ walmart.

#1038

Anyway, you could totally put a T somewhere in the line. I kinda wonder about oil draining out of the VVT tube into the turbo when the motor's not running....

As result I now have about 10* rear toe-in and rear wheel is missing 3/4 of the outer rim (lol).

I did something similar to my car some years back, only my wheels, while cheap, are out of production. Had to scour the earth to find just one, paid a bunch for it too. Pretty irritating.

I've been toying with building some traction control into my car someday.... Anyway, glad you and the car are alright.

#1039

FM sells the pre made line and the adapter fittings. Sure you could source it somewhere, but it was easier to order it done already. Just need to modify the line for the fittings. I'll be using a T fitting at the block. One line will go to the VVT, one for the turbo oil feed, and one for oil pressure. Told that's how they do it for VVT FMII setups without issue. Does make the turbo oil feed line long, but aren't they sorta all

#1040

mkturbo.com

iTrader: (24)

Join Date: May 2006

Location: Charleston SC

Posts: 15,176

Total Cats: 1,680

Today, I was driving to my parents house. Punched it in 4th, started spinning wheels as usual. Rear end stepped out and I wasn't able to quite hold it - as result hit the curb pretty hard.

As result I now have about 10* rear toe-in and rear wheel is missing 3/4 of the outer rim (lol). I limped to my parents garage and left the car there - won't know full extent of damage until later this week.

I, luckly, have the whole rear suspension/subframe from the other 91 car I parted - so this should be an easy fix, especially if it's just the control arms. I really hope the shock is ok (it should be).

Lesson learned, don't dick around in stupid powered car with no traction control on UHP summer tires in sub-freezing temperatures.

Edit: its not clear from the picture, but the damage is JUST to the wheel/suspension. The body appears to be unharmed - it's just really dirty.

As result I now have about 10* rear toe-in and rear wheel is missing 3/4 of the outer rim (lol). I limped to my parents garage and left the car there - won't know full extent of damage until later this week.

I, luckly, have the whole rear suspension/subframe from the other 91 car I parted - so this should be an easy fix, especially if it's just the control arms. I really hope the shock is ok (it should be).

Lesson learned, don't dick around in stupid powered car with no traction control on UHP summer tires in sub-freezing temperatures.

Edit: its not clear from the picture, but the damage is JUST to the wheel/suspension. The body appears to be unharmed - it's just really dirty.

Huh. Who makes that? I like it a lot better. Actually, I don't even think you really need a banjo at the bottom, just thread right into it. May upgrade my setup someday to something like that.

Anyway, you could totally put a T somewhere in the line. I kinda wonder about oil draining out of the VVT tube into the turbo when the motor's not running....

He's just trying to sell his smaller turbo.....

Think of all the weight you saved!

I did something similar to my car some years back, only my wheels, while cheap, are out of production. Had to scour the earth to find just one, paid a bunch for it too. Pretty irritating.

I've been toying with building some traction control into my car someday.... Anyway, glad you and the car are alright.

Anyway, you could totally put a T somewhere in the line. I kinda wonder about oil draining out of the VVT tube into the turbo when the motor's not running....

He's just trying to sell his smaller turbo.....

Think of all the weight you saved!

I did something similar to my car some years back, only my wheels, while cheap, are out of production. Had to scour the earth to find just one, paid a bunch for it too. Pretty irritating.

I've been toying with building some traction control into my car someday.... Anyway, glad you and the car are alright.