99 Sport eBay turbo build

#121

Elite Member

Thread Starter

iTrader: (1)

Join Date: Mar 2014

Location: Jacksonville, FL

Posts: 1,552

Total Cats: 196

do i need to seal the threads on said npt fitting on the charge pipe after i screw on the fitting? if so what product is recommended?

I tapped a 3/8" npt hole for the GM IAT sensor, and screwed it into the pipe right after the intercooler, and i put permatex thread sealer, but this stuff is like paste and doesnt harden after a few days, i touched it and its still a paste, so no idea how its supposed to seal the threads.

#124

#125

What does the hive mind think about this sort of nonsense: Silicone Port System

Were you thinking to put this on the cold side piping just as it left the intercooler? Just looking at it there could be a sensor depth issue since this would have to go from 1/2" to 3/8". It would be cool if they made it in 3/8" without the adaptor.

#126

I think best bet for AIT is threaded straight into the intercooler end tank. If it's a cheap cast unit, which it probably is with all this talk, there's plenty of meat there to tap.

If I were trying to be efficient and cheap I would drill and tap 1/8npt right into the turbo compressor outlet. I used steel intercooler pipes and just welded a nut to the cold side, drilled and tapped to 1/8 npt. Only reason I went through the trouble is I wanted to switch the EBC valve off entirely for low power without dealing with pressure drop. You should be able to braze a nut to the pipe, would work fine if you did.

I'm not fond of the silicone thing, so many more leak points and they mention JB weld in the directions.

If I were trying to be efficient and cheap I would drill and tap 1/8npt right into the turbo compressor outlet. I used steel intercooler pipes and just welded a nut to the cold side, drilled and tapped to 1/8 npt. Only reason I went through the trouble is I wanted to switch the EBC valve off entirely for low power without dealing with pressure drop. You should be able to braze a nut to the pipe, would work fine if you did.

I'm not fond of the silicone thing, so many more leak points and they mention JB weld in the directions.

#127

I think best bet for AIT is threaded straight into the intercooler end tank. If it's a cheap cast unit, which it probably is with all this talk, there's plenty of meat there to tap.

If I were trying to be efficient and cheap I would drill and tap 1/8npt right into the turbo compressor outlet. I used steel intercooler pipes and just welded a nut to the cold side, drilled and tapped to 1/8 npt. Only reason I went through the trouble is I wanted to switch the EBC valve off entirely for low power without dealing with pressure drop. You should be able to braze a nut to the pipe, would work fine if you did.

I'm not fond of the silicone thing, so many more leak points and they mention JB weld in the directions.

If I were trying to be efficient and cheap I would drill and tap 1/8npt right into the turbo compressor outlet. I used steel intercooler pipes and just welded a nut to the cold side, drilled and tapped to 1/8 npt. Only reason I went through the trouble is I wanted to switch the EBC valve off entirely for low power without dealing with pressure drop. You should be able to braze a nut to the pipe, would work fine if you did.

I'm not fond of the silicone thing, so many more leak points and they mention JB weld in the directions.

#128

Elite Member

Thread Starter

iTrader: (1)

Join Date: Mar 2014

Location: Jacksonville, FL

Posts: 1,552

Total Cats: 196

Ok. This is going to sound silly, but bear with my noobness.

Car is running great, pulls strong.

I want to take it to the dyno, and have it tuned by myself....

But being the noob that i am, i never been to a dyno, nor tuned at a dyno.

Without DET cans, i will leave my timing map alone, and tune only fuel. correct?

So when at the dyno, i just have to do a bunch autotune runs, with different throttle inputs and basically hit all the cells on the map yes?

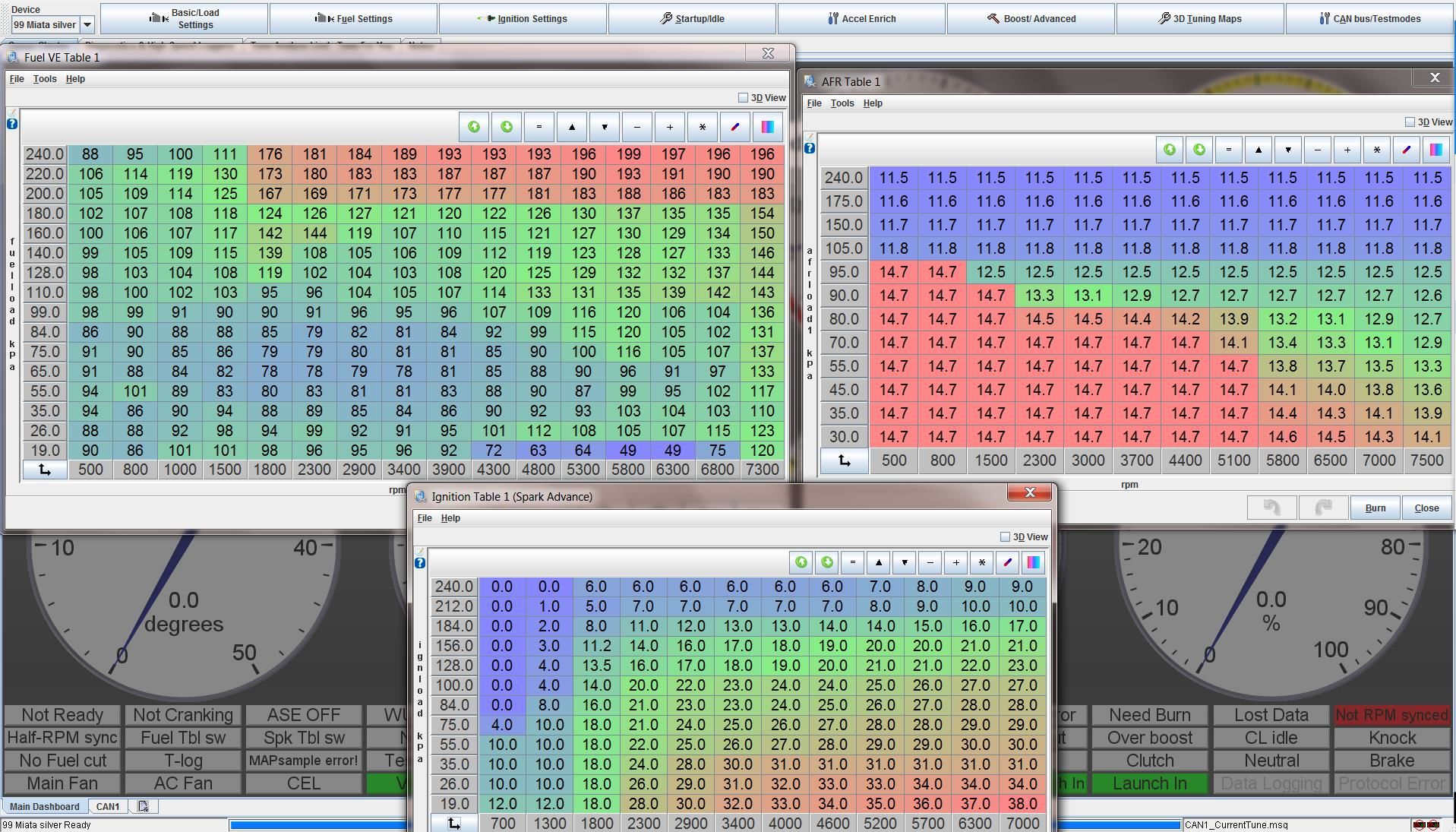

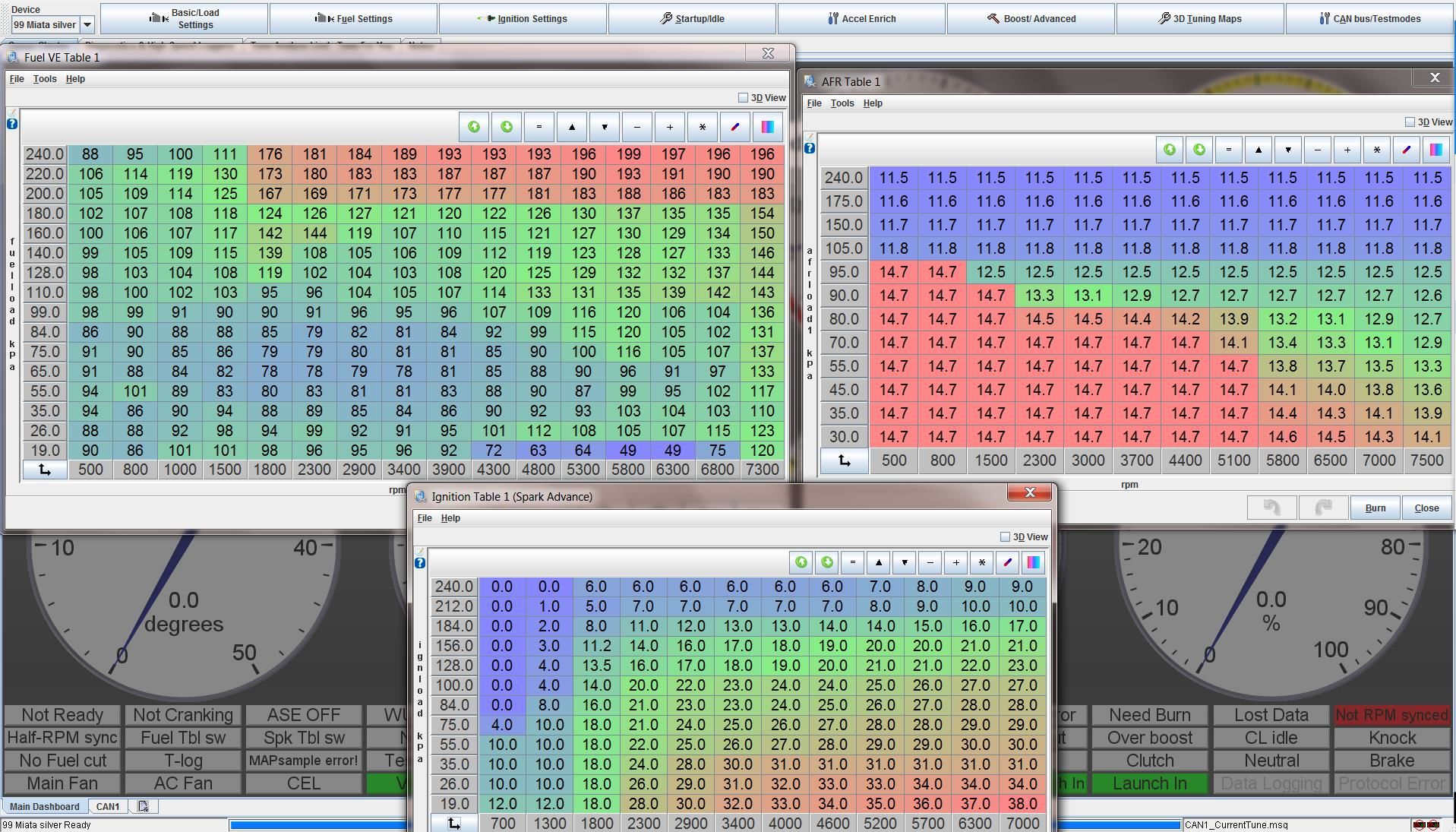

here are my maps, let me know if you see anything odd. (VE map over 180kpa is stupid rich, as i have not hit those cells yet to autotune).

99 miata stock engine. i will be tuning 10-12 psi.

Car is running great, pulls strong.

I want to take it to the dyno, and have it tuned by myself....

But being the noob that i am, i never been to a dyno, nor tuned at a dyno.

Without DET cans, i will leave my timing map alone, and tune only fuel. correct?

So when at the dyno, i just have to do a bunch autotune runs, with different throttle inputs and basically hit all the cells on the map yes?

here are my maps, let me know if you see anything odd. (VE map over 180kpa is stupid rich, as i have not hit those cells yet to autotune).

99 miata stock engine. i will be tuning 10-12 psi.

#130

Elite Member

Thread Starter

iTrader: (1)

Join Date: Mar 2014

Location: Jacksonville, FL

Posts: 1,552

Total Cats: 196

If im on small road, i can do a 1-7k 4th gear pull, but then the speed limit is low and i am way way over it.

Then if i go on a hwy with 70 limit, i cant slow down to 1.5k rpm to do a full rpm sweep pull.

so a dyno is a rolling road, where i can take my time and hit all the cells correct?

basically i dont want to get run over or arrested.

#131

Senior Member

iTrader: (1)

Join Date: Dec 2010

Location: Farmington Hills, MI

Posts: 1,218

Total Cats: 175

Autotuning on a dyno sounds silly. Just drive it! If you really want to do tuning on a dyno, then get/make some det cans and tune spark. But with autotune, tuning fuel on a dyno is just a waste of money and time. If you want to dyno for numbers, then autotune fuel on the street, and do a pull on the dyno while datalogging to verify AFR.

Also, you can lean out AFR in the 105-150 kpa range. You could make your 95 kpa row around 13.0, keep your 175 row at 11.6, and interpolate in between.

Also, you can lean out AFR in the 105-150 kpa range. You could make your 95 kpa row around 13.0, keep your 175 row at 11.6, and interpolate in between.

#132

Senior Member

iTrader: (1)

Join Date: Dec 2010

Location: Farmington Hills, MI

Posts: 1,218

Total Cats: 175

ive been autotuning it myself for 3 month's already. but i am having trouble finding enough road or time on the road to hit every cell reliably with constant throttle from 1k to 7k rpm.

If im on small road, i can do a 1-7k 4th gear pull, but then the speed limit is low and i am way way over it.

Then if i go on a hwy with 70 limit, i cant slow down to 1.5k rpm to do a full rpm sweep pull.

so a dyno is a rolling road, where i can take my time and hit all the cells correct?

basically i dont want to get run over or arrested.

If im on small road, i can do a 1-7k 4th gear pull, but then the speed limit is low and i am way way over it.

Then if i go on a hwy with 70 limit, i cant slow down to 1.5k rpm to do a full rpm sweep pull.

so a dyno is a rolling road, where i can take my time and hit all the cells correct?

basically i dont want to get run over or arrested.

Ideally, the fuel map will be perfectly linear, in both rpm and map. This isn't exactly true in reality, but it's close. So after you autotune, pull up your VE map and a 3D tuning map of the VE map and start interpolating. Never interpolate more than 4x4 or 5x5 or so cells at a time, because there may actually be humps in the map. But, notice trends in how VE changes with rpm and map, and apply that to the cells you didn't quite hit. This has gotten me close enough for a near spot on VE map. Sometimes I will autotune, smooth and interpolate, then autotune again, then smooth again.

#133

Elite Member

Thread Starter

iTrader: (1)

Join Date: Mar 2014

Location: Jacksonville, FL

Posts: 1,552

Total Cats: 196

If my base map is driveable, I can hit enough cells to get a good tune in 10 minutes or so. It's pretty easy to find a highway on ramp with a right turn leading up to it. Stick it in 3rd gear at 2500 rpm or so and get up to redline. That should be around 75 mph. Then in 3rd gear, play around with the throttle to hit the mid range of map, then stick it in 4th and continue.

Ideally, the fuel map will be perfectly linear, in both rpm and map. This isn't exactly true in reality, but it's close. So after you autotune, pull up your VE map and a 3D tuning map of the VE map and start interpolating. Never interpolate more than 4x4 or 5x5 or so cells at a time, because there may actually be humps in the map. But, notice trends in how VE changes with rpm and map, and apply that to the cells you didn't quite hit. This has gotten me close enough for a near spot on VE map. Sometimes I will autotune, smooth and interpolate, then autotune again, then smooth again.

Ideally, the fuel map will be perfectly linear, in both rpm and map. This isn't exactly true in reality, but it's close. So after you autotune, pull up your VE map and a 3D tuning map of the VE map and start interpolating. Never interpolate more than 4x4 or 5x5 or so cells at a time, because there may actually be humps in the map. But, notice trends in how VE changes with rpm and map, and apply that to the cells you didn't quite hit. This has gotten me close enough for a near spot on VE map. Sometimes I will autotune, smooth and interpolate, then autotune again, then smooth again.

ok. more road tuning, and then ill do 3 dyno pulls just to get numbers. its $75 here for 3 pulls.

im curious to see what it makes at 10 and 12psi.

#135

Elite Member

Thread Starter

iTrader: (1)

Join Date: Mar 2014

Location: Jacksonville, FL

Posts: 1,552

Total Cats: 196

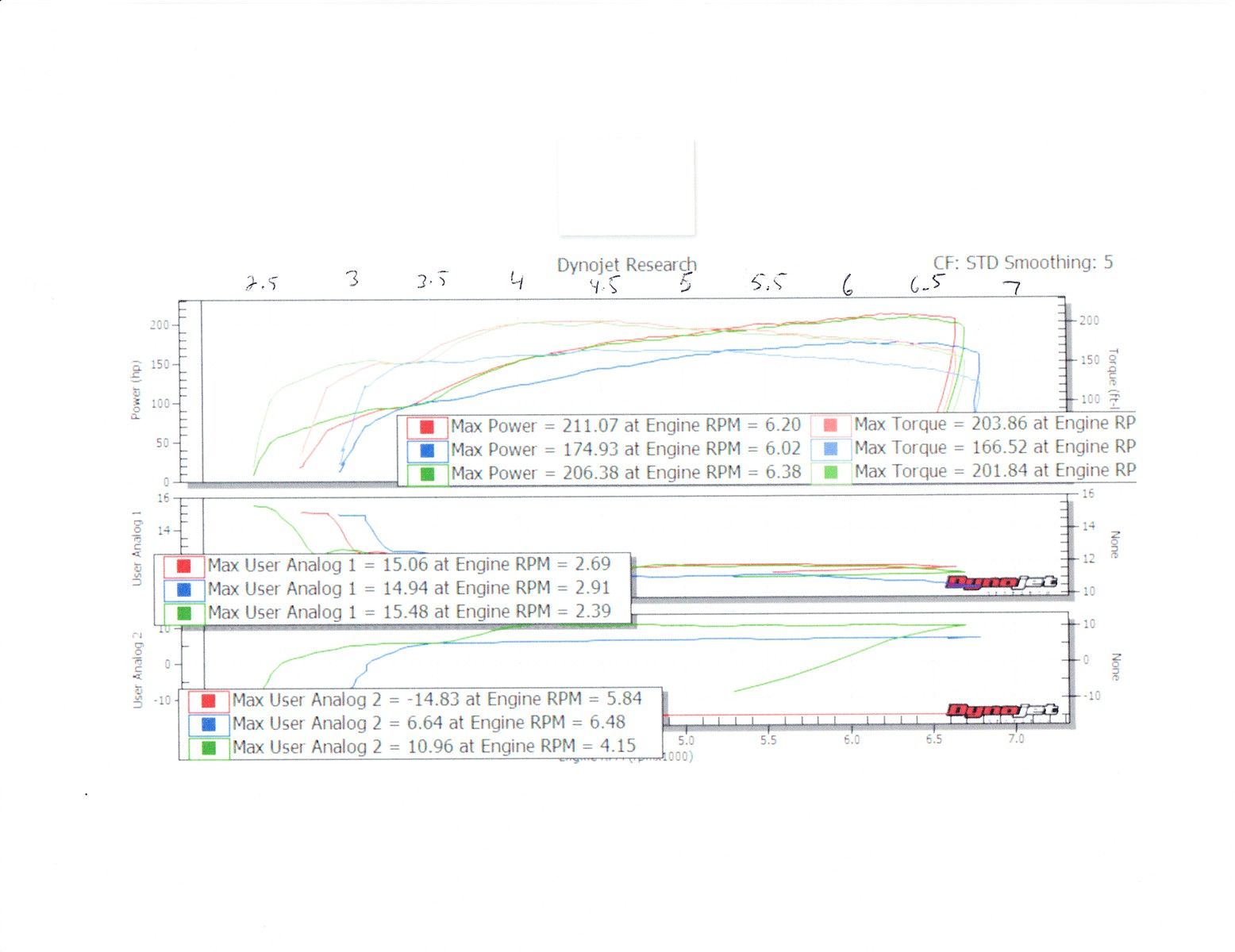

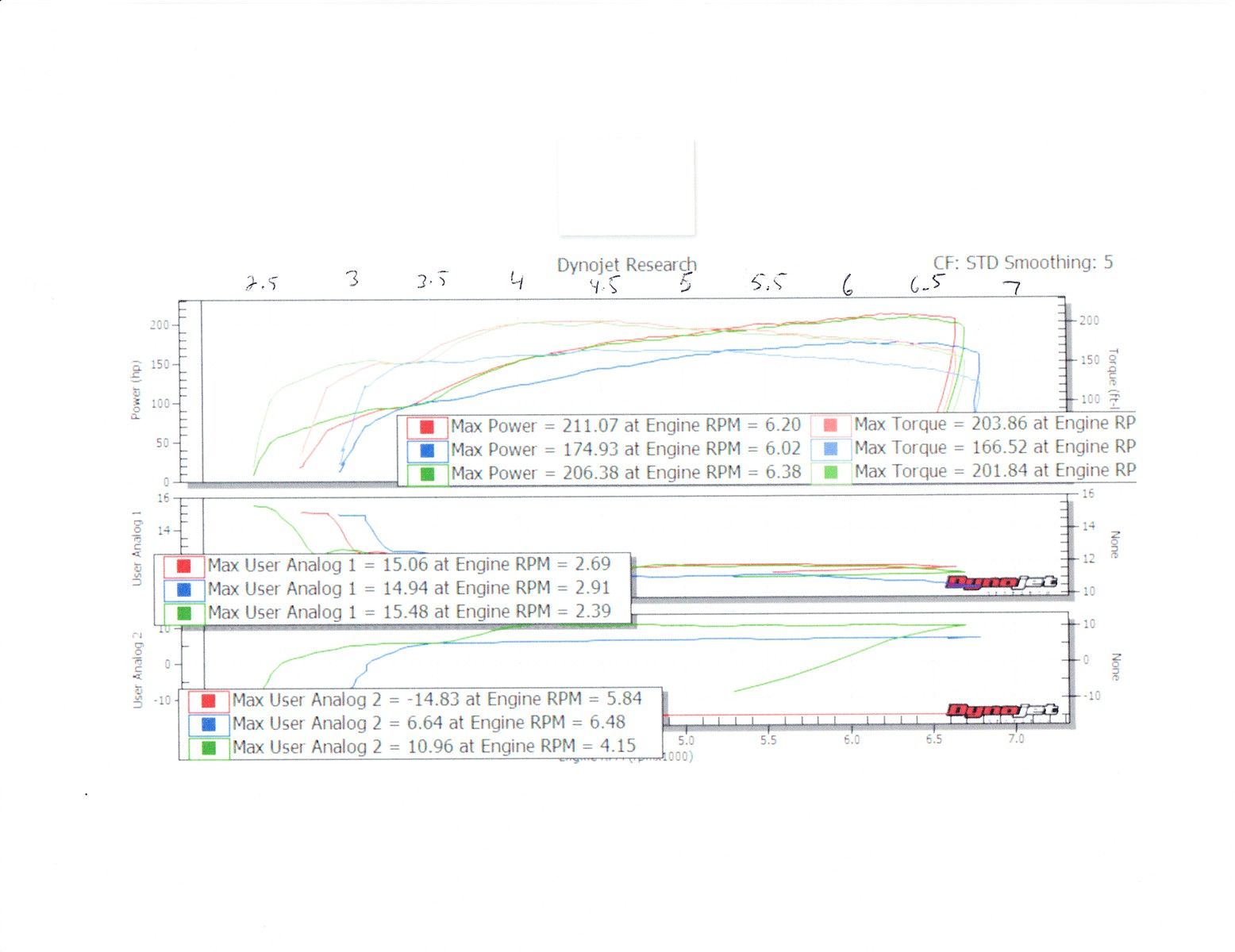

so, went to the dyno. a little disappointing. i was hoping to make 220-230whp.

Did 3 pulls:

Waste-gate only: 6-7 psi. 174HP 166TQ - Not bad for wg only.

EBC 40% Duty cycle: 10-11psi 206HP 201TQ - I was hoping for 220hp or so.

EBC 46% Duty cycle: 11-12psi 211HP 203TQ - I was hoping for 230hp :(

Logs attached. you can see my maps and timing 5 posts up.

Im just using the base timing map that came from Rev with my MS2E, you think i need more timing to make moar power?

Let me know what you think, and if i should have made moar powwaaa.

Did 3 pulls:

Waste-gate only: 6-7 psi. 174HP 166TQ - Not bad for wg only.

EBC 40% Duty cycle: 10-11psi 206HP 201TQ - I was hoping for 220hp or so.

EBC 46% Duty cycle: 11-12psi 211HP 203TQ - I was hoping for 230hp :(

Logs attached. you can see my maps and timing 5 posts up.

Im just using the base timing map that came from Rev with my MS2E, you think i need more timing to make moar power?

Let me know what you think, and if i should have made moar powwaaa.

#137

Elite Member

Thread Starter

iTrader: (1)

Join Date: Mar 2014

Location: Jacksonville, FL

Posts: 1,552

Total Cats: 196

Went to the drag strip last night. fun times. met another turbo miata owner and we were racing neck to neck the whole night.

He did beat me at the end though 0.1 sec faster.

Im a noob at drag racing, and could not get a good off the line start.

Ran into a problem with the car that i had once before, after about 8 runs, the car started idling high, for no reason. it would idle at 2.5k rpm, and if i gas it it would stay at 3k rpm idling.

PWM came down to my normal 5.1%, but idle was still 2.5k rpm.

i am attaching a log of the high idle. plz help.

He did beat me at the end though 0.1 sec faster.

Im a noob at drag racing, and could not get a good off the line start.

Ran into a problem with the car that i had once before, after about 8 runs, the car started idling high, for no reason. it would idle at 2.5k rpm, and if i gas it it would stay at 3k rpm idling.

PWM came down to my normal 5.1%, but idle was still 2.5k rpm.

i am attaching a log of the high idle. plz help.

#140

Elite Member

Thread Starter

iTrader: (1)

Join Date: Mar 2014

Location: Jacksonville, FL

Posts: 1,552

Total Cats: 196

when i was playing with the percentages, 5.1% is what it took to get my idle to idle at 950rpm, anything higher and idle was higher...