Effects of a restrictor plate

#1

Junior Member

Thread Starter

iTrader: (2)

Join Date: Oct 2007

Location: Louisville, KY

Posts: 445

Total Cats: 15

I'm build a FP autocross car and am required to run a 46mm restrictor within 4in of the turbo compressor.

Engine specs as follows:

2004 MSM block, head, and cams

11:1

+1 intake valves

+2 exhaust valves

EFR 6758

Here's the rule regarding the 46mm restrictor....

2. Induction systems must have a restrictor on the inlet side. This restrictor

orifice must not be more than 4.0” (10.2 cm) from the compressor

inlet and must maintain the specified diameter for at least ½

2015 SCCA® National Solo® Rules — 125

17. Prepared

inch (0.50”, 12.7 mm). Induction system restrictors may be located

within or be integral to the compressor housing, provided that all

dimensional requirements of 17.10.C.2 are maintained. All inducted

air must pass through this restrictor. The diameter for the restrictor

shall be as follows (unless specified otherwise in Appendix A):

a. XP: No restrictor required

b. CP: 52 mm (2.047”) restrictor

c. FP: 46 mm (1.811”) restrictor

I'm questioning ideal intercooler piping size and throttle body. What would you recommend for pipping given this limitation?

Is there any benefit to stepping up the I/C exit pipe and using a larger (skunk2 or similar) throttle body given the intake limitations?

Engine specs as follows:

2004 MSM block, head, and cams

11:1

+1 intake valves

+2 exhaust valves

EFR 6758

Here's the rule regarding the 46mm restrictor....

2. Induction systems must have a restrictor on the inlet side. This restrictor

orifice must not be more than 4.0” (10.2 cm) from the compressor

inlet and must maintain the specified diameter for at least ½

2015 SCCA® National Solo® Rules — 125

17. Prepared

inch (0.50”, 12.7 mm). Induction system restrictors may be located

within or be integral to the compressor housing, provided that all

dimensional requirements of 17.10.C.2 are maintained. All inducted

air must pass through this restrictor. The diameter for the restrictor

shall be as follows (unless specified otherwise in Appendix A):

a. XP: No restrictor required

b. CP: 52 mm (2.047”) restrictor

c. FP: 46 mm (1.811”) restrictor

I'm questioning ideal intercooler piping size and throttle body. What would you recommend for pipping given this limitation?

Is there any benefit to stepping up the I/C exit pipe and using a larger (skunk2 or similar) throttle body given the intake limitations?

#2

Senior Member

iTrader: (1)

Join Date: Dec 2010

Location: Farmington Hills, MI

Posts: 1,218

Total Cats: 175

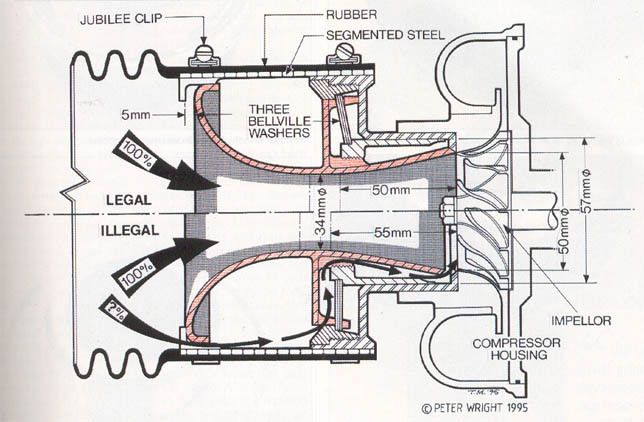

I wouldn't think you'd need to focus on the size post compressor, given that the intake restrictor is 45mm (1.811"). That is your bottleneck, because the throttle body is 52mm. I would focus your attention on using the best flowing restrictor possible. CFD would be ideal to maximize flow, but in general, around a 7 degree draft angle entering and exiting the restrictor with as smooth transitions as possible. Route your intake with a giant filter on a velocity stack, going into a smooth flowing restrictor.

The EFR outlet is also 2", which tells me two things. If a step up to 2.5" was worth it, BW would've made the outlet 2.5". 2" is already larger than the restrictor, so as long as the IC piping isn't super complex, has bad gaps at couplers, etc, that's not going to be a bottleneck.

My experience comes from designing FSAE intakes with 19mm restrictors.

The EFR outlet is also 2", which tells me two things. If a step up to 2.5" was worth it, BW would've made the outlet 2.5". 2" is already larger than the restrictor, so as long as the IC piping isn't super complex, has bad gaps at couplers, etc, that's not going to be a bottleneck.

My experience comes from designing FSAE intakes with 19mm restrictors.

#3

I would assume you're building this to be as competitive as possible. So you'll be running enough boost that the restrictor limits your flow as soon as the turbo can make enough boost to hit choke flow on the restrictor.

I don't think bigger than 2.5" intercooler pipe would benefit your much. The air speed is just not that fast, thus the pressure drop will be very low.

If anything, I'd be designing everything to spool as fast as possible given you said it's for autocross. So perhaps even smaller or shorter piping for faster spool.

I don't think bigger than 2.5" intercooler pipe would benefit your much. The air speed is just not that fast, thus the pressure drop will be very low.

If anything, I'd be designing everything to spool as fast as possible given you said it's for autocross. So perhaps even smaller or shorter piping for faster spool.

#4

Senior Member

iTrader: (1)

Join Date: Dec 2010

Location: Farmington Hills, MI

Posts: 1,218

Total Cats: 175

It's been a while since I've done restrictor stuff, but I'm now remembering how large our plenums were. It may be beneficial to use larger intake piping to increase volume. This won't affect throttle response, because it's pre-throttle. You're essentially boosting a "reserve tank" that once the throttle is opened up will allow more air to be ready to pass through the intake manifold.

When we were naturally aspirated, we didn't have the boost to pressurize a pre-throttle reserve plenum, so our plenum was post throttle. We dealt with throttle response with a properly torque based engine calibration. Using a plenum that was about 10 times larger than the engine displacement (on a 1 cylinder) net a peak power of about 155 hp/L at the crank, likely a record for FSAE.

In our turbo application, we used a stock bike throttle that bolted to the head (super small throttled volume, great injector angle), and ran a relatively long tube from compressor to throttle. We were limited by diameter, and couldn't use excessively long routing, so we packaged the turbo far away from the intake port. This setup is essentially the best of both worlds, as the turbo is charging the pre-throttle air, but doesn't affect engine torque until the throttle is opened. We ended up making about 170 hp/L with huge torque increases across the whole RPM range. You essentially want to hit choked flow as soon as possible, and hold that power until redline.

When we were naturally aspirated, we didn't have the boost to pressurize a pre-throttle reserve plenum, so our plenum was post throttle. We dealt with throttle response with a properly torque based engine calibration. Using a plenum that was about 10 times larger than the engine displacement (on a 1 cylinder) net a peak power of about 155 hp/L at the crank, likely a record for FSAE.

In our turbo application, we used a stock bike throttle that bolted to the head (super small throttled volume, great injector angle), and ran a relatively long tube from compressor to throttle. We were limited by diameter, and couldn't use excessively long routing, so we packaged the turbo far away from the intake port. This setup is essentially the best of both worlds, as the turbo is charging the pre-throttle air, but doesn't affect engine torque until the throttle is opened. We ended up making about 170 hp/L with huge torque increases across the whole RPM range. You essentially want to hit choked flow as soon as possible, and hold that power until redline.

#5

Former Vendor

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,099

Does standard restrictor theory even apply when you're talking about a 46mm orifice feeding a turbo with a ~54mm inducer? I wonder if the pressure drop across the orifice ends up being similar to running the car at altitude.

#6

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,019

Total Cats: 6,587

I would think so. All the restrictor is going to do is increase the effective pressure ratio for a given mass-flow. Size the turbo accordingly.

#7

SADFab Destructive Testing Engineer

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

Based on no math at all I would have my restrictor exactly 4" from the compressor, with smooth angles going to and from the restrictor. Velocity stack in and like a smooth transition to 54mm over the 4 inches.

About the post turbo size. If I were running XP I would have full antilag and my turbo would never be not at or near full boost. So intake piping would theoretically be irrelevant because it would always be at full boost.

Theoretically.

About the post turbo size. If I were running XP I would have full antilag and my turbo would never be not at or near full boost. So intake piping would theoretically be irrelevant because it would always be at full boost.

Theoretically.

#12

Basically you're in 80's rally car turf right here. Optimally your restrictor would be built into the compressor cover and the compressor wheel designed specifically for the restrictor. Now since you arent like audi your best bet is to look up what FSAE teams have published about maximizing airflow through the restrictor and copy it. I think they gotten to using more or less straight tapers at specific angles though maybe something more modern has come out. I think its like 14° on the inlet and 7° on the outlet or something like that.

Thread

Thread Starter

Forum

Replies

Last Post

hustler

Race Prep

17

03-26-2012 03:06 PM

zoomin

DIY Turbo Discussion

9

11-30-2009 04:13 PM

anarchyx34

DIY Turbo Discussion

4

11-25-2009 09:36 AM

thesnowboarder

DIY Turbo Discussion

17

05-21-2008 07:19 PM