A few unusual parts

#1

This isn't a build thread per se but I thought I'd document a few of the parts I've made for my DIY turbo.

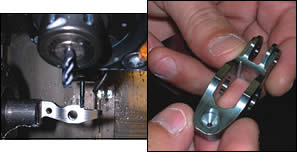

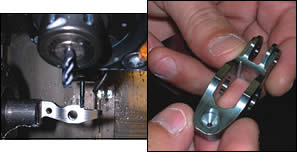

Here's #1:

That's a chunk of 303 stainless milled on my benchtop toy mill. In retrospect I should have used aluminum because this took forever.

Three of the ports are -4 AN O-ring bosses and one is M10x1.0.

In, out, pressure and temperature. Also a mounting location for a knock sensor. The pressure transducer is accurate to a fraction of a PSI and has a 2ms response time. The temperature and knock sensors are Audi parts I had lying around.

In situ. The tubing is 316 .035" wall. I struggled mightly to flare it with my POS Summit Racing flare tool:

After wasting a bunch of ($$) tube I bought a proper tool:

That's a Ridgid 377. It works wonderfully.

More to come.

Here's #1:

That's a chunk of 303 stainless milled on my benchtop toy mill. In retrospect I should have used aluminum because this took forever.

Three of the ports are -4 AN O-ring bosses and one is M10x1.0.

In, out, pressure and temperature. Also a mounting location for a knock sensor. The pressure transducer is accurate to a fraction of a PSI and has a 2ms response time. The temperature and knock sensors are Audi parts I had lying around.

In situ. The tubing is 316 .035" wall. I struggled mightly to flare it with my POS Summit Racing flare tool:

After wasting a bunch of ($$) tube I bought a proper tool:

That's a Ridgid 377. It works wonderfully.

More to come.

Last edited by kday; 07-03-2010 at 01:18 PM.

#6

You know ,when you are a machininst...everything becomes fair game to be made out of indestrucamanium.Is your mill CNC?I miss being able to Program a mill,there is only so much A CNC lathe is capable of producing,My boss will not allow me to set up the Live tooling on our Mazak...some people just dont get it.

(G)

(G)

#8

You know ,when you are a machininst...everything becomes fair game to be made out of indestrucamanium.Is your mill CNC?I miss being able to Program a mill,there is only so much A CNC lathe is capable of producing,My boss will not allow me to set up the Live tooling on our Mazak...some people just dont get it.

(G)

(G)

#10

Elite Member

iTrader: (21)

Join Date: Jun 2007

Location: Rochester, NY

Posts: 6,593

Total Cats: 1,259

Kday, I have the HF micromill, and a 7x14 lathe. Knowing the capabilities of those little machines, I'd say that was pretty good work. I know my machines don't like to cut stainless, or even mild steel.

#14

Originally I was going to make a totally new water pump inlet, with a -16 or -20 AN inlet from the radiator, a -10 from the heater core, and -6 ports for both the oil cooler/warmer and the turbo. I'm getting impatient to get the car on the road though so I took a shorter route:

There is just enough meat on the hose barb boss to tap for 1/4 NPT. I wanted to use a -6 ORB instead but I wasn't sure I'd have enough material to make the O-ring seat. I will use a NPT to male -6 and then a -6 tee to both the oil cooler and the turbo hard lines.

Incidentally these spring loaded tap guides are awesome:

Sorry for the crappy pictures, I forgot how the insanely bright LED work light messes with the camera.

There is just enough meat on the hose barb boss to tap for 1/4 NPT. I wanted to use a -6 ORB instead but I wasn't sure I'd have enough material to make the O-ring seat. I will use a NPT to male -6 and then a -6 tee to both the oil cooler and the turbo hard lines.

Incidentally these spring loaded tap guides are awesome:

Sorry for the crappy pictures, I forgot how the insanely bright LED work light messes with the camera.

#20

Elite Member

iTrader: (9)

Join Date: Jun 2006

Location: Chesterfield, NJ

Posts: 6,892

Total Cats: 399

Very nice stuff! I know how difficult it can be to machine stuff with a chinese tabletop mill. My dad has a Smithy which I'm sure is more rigid than the HF crap and it still chatters like crazy. Nice job on the hardlines too

Tell your boss to get with it! We make these at work in one operation (bar goes in one side, finished part comes out, minus honing & polishing & heattreat) on a live tooling lathe:

Turning Is Optional

Turning Is Optional