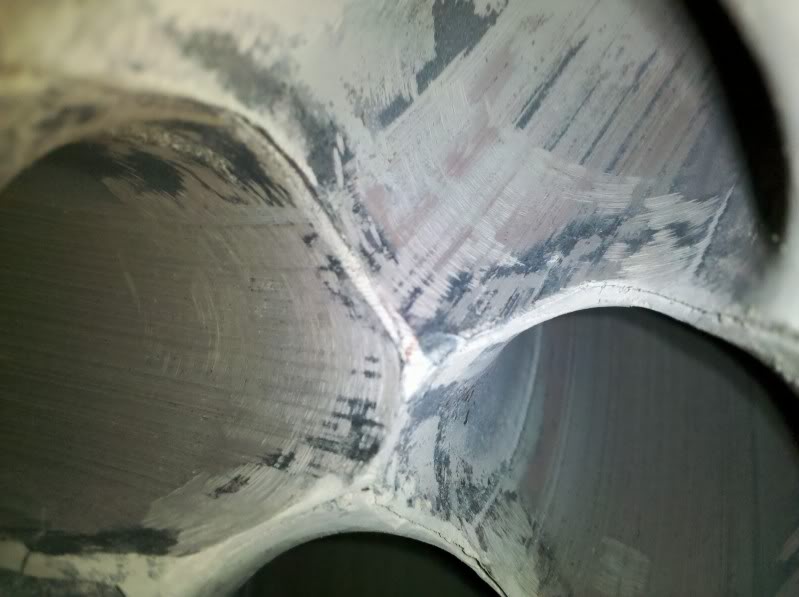

SS Exhaust Mani Cracked In Half

#1

While driving today the pipe going to my external waste gate on my Greddy JDM SS manifold split in half. Tomorrow im going to take it all off and get pictures, but It should be fine just getting it re welded right?

Any ideas to what would cause this? The flange from the turbo to the manifold is above to turbo and the WG is VTA. Could it have been caused somehow by the weight of it hanging down, or maybe a faulty waste gate somehow?

What would Jesus do if he didnt want to buy a new manifold?

Any ideas to what would cause this? The flange from the turbo to the manifold is above to turbo and the WG is VTA. Could it have been caused somehow by the weight of it hanging down, or maybe a faulty waste gate somehow?

What would Jesus do if he didnt want to buy a new manifold?

#2

Former Vendor

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,099

As far as I'm aware, GReddy never made a tubular stainless manifold. You probably have a cheap eBay manifold. You can re-weld it but it will just continuously break - it needs to be replaced with a quality piece.

This is why Tim stopped doing VTA wastegates, BTW - the wastegate dump acts as a huge tuning fork and rips the wastegate off the manifold from harmonics. Blending it into the exhaust supports it from the other end and erases those issues.

This is why Tim stopped doing VTA wastegates, BTW - the wastegate dump acts as a huge tuning fork and rips the wastegate off the manifold from harmonics. Blending it into the exhaust supports it from the other end and erases those issues.

#3

From what ive gathered in research, they made a small run of tubular SS manifolds only for the JDM that were never sold in the states. Addressed this in another thread.

I would think that putting a bracket between the body and the WG/Exhaust would be a No-No because of vibrations and all, but has anyone had success doing one between the engine block its self and the WG/Turbo? Or would the body mount work If i also installed rigid engine mounts or something like that?

I would think that putting a bracket between the body and the WG/Exhaust would be a No-No because of vibrations and all, but has anyone had success doing one between the engine block its self and the WG/Turbo? Or would the body mount work If i also installed rigid engine mounts or something like that?

#5

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,022

Total Cats: 6,590

Or would the body mount work If i also installed rigid engine mounts or something like that?

#6

So I'm gonna get it in a shop this week and get it re welded. Looks like it just wasn't the best weld when it was re worked from a side mount to a top mount. Theeres also a few other hair line cracks that ill get fixed as well. I have to check clearance of the block but I want to get a brace welded in between the flange and where the repair is going to be for a little more support.

#7

Another thing, while its all out I'm rebuilding the turbo and re doing the oil feed and drain. Aren't one of the two plugs in the first picture a factory oil feed that will work for the turbo? Another thing I need to get is the flange for the drain line that'll let me use an an line instead of the slip fit hose.

#9

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,022

Total Cats: 6,590

Example of the parts I used: http://www.anplumbing.com/shop/index...p=&dept=Banjos

The other fitting is a coolant port, which is where the factory coolant feed to the turbo was. So if you have a W/C turbo, you can pick up water for it at that location.

I will say that that's about the cleverest location for an EWG I think I have ever seen on a Miata manifold. It violates Corky's Third Law a bit, but definitely a very ingenious solution to the packaging dilemma.

Thread

Thread Starter

Forum

Replies

Last Post

StratoBlue1109

Miata parts for sale/trade

21

09-30-2018 01:09 PM