Over The Radiator Intercooler Setup 99 NB

#25

two reasons to like over the rad.

A) safer for tubing, really nothing exposed to road hazards (cept for the IC but thats always the case)

B) less connections, mine is 4 couplings total (yes you can do it around the rad, but its harder longer)

C) more effcient, less pressure loss

D) less likely to absorb heat from engine

A) safer for tubing, really nothing exposed to road hazards (cept for the IC but thats always the case)

B) less connections, mine is 4 couplings total (yes you can do it around the rad, but its harder longer)

C) more effcient, less pressure loss

D) less likely to absorb heat from engine

A) Never heard of anyone putting a hole in a intercooler pipe from road debris.

B) My around the radiator setup had only 4 couplers (compressor outlet to pipe, pipe to i/c, i/c to pipe, pipe to t/b.

C) Maybe, but probably not noticeable in the real world

D) Maybe, but probably not noticeable in the real world

#26

A) ive seen people dent piping (greater pressure drop)

B) Right but its easier with less places to weld (like i said its possible but harder and longer) Whats with people not reading posts?

C) Look up WOT old setup (and its for sure, measurable yes)

D) Not according to BEGI/FM (why FM switch to the silicon tubing supposedly)

B) Right but its easier with less places to weld (like i said its possible but harder and longer) Whats with people not reading posts?

C) Look up WOT old setup (and its for sure, measurable yes)

D) Not according to BEGI/FM (why FM switch to the silicon tubing supposedly)

#31

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,292

Total Cats: 475

Your setup looks nice. I'm aiming for something similar, but with a smaller blower (damn it boy that bitch is big!)

#33

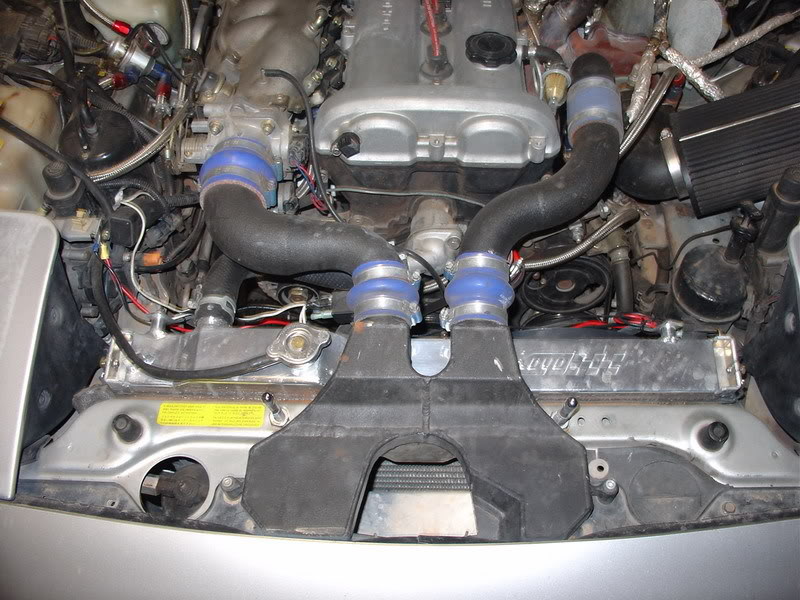

Here's the setup Corky built for me. He designed it for use with the hood latch but I use hood pins.

Having had this one for several years, I personally would recommend the approach Corky now uses on his kits. The aluminum tube exiting down from the compressor and then entering the intercooler on the driver's side of the intercooler actually sheds approx 10-12 degrees of temperature from the compressed air before it even reaches the intercooler.

FWIW.

Having had this one for several years, I personally would recommend the approach Corky now uses on his kits. The aluminum tube exiting down from the compressor and then entering the intercooler on the driver's side of the intercooler actually sheds approx 10-12 degrees of temperature from the compressed air before it even reaches the intercooler.

FWIW.

#35

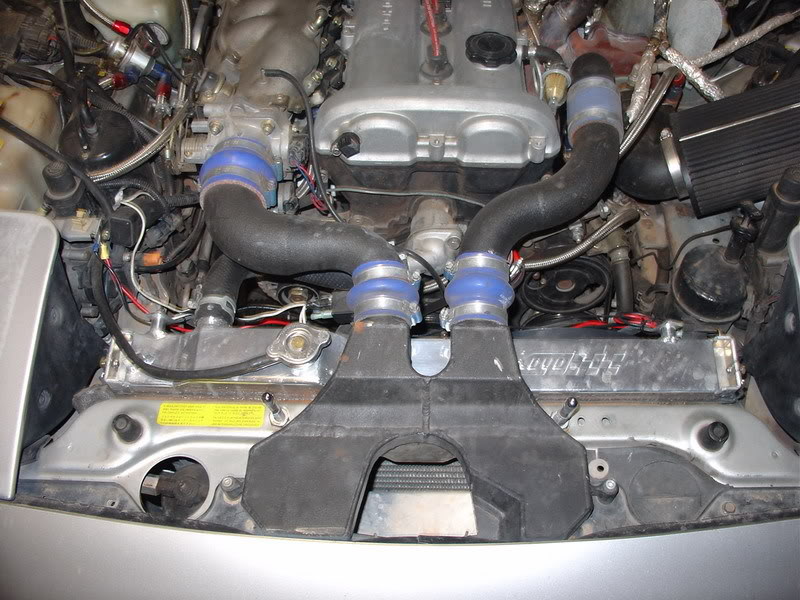

You may find that that intercooler is too wide. Measure the distance between the rad supports and make sure that the intercooler outlets will clear in between.

I chose a narrower intercooler that lines up real well with the width between the turbo and throttle body making it reall easy to fabricate the pipes.

Here'e mine:

I chose a narrower intercooler that lines up real well with the width between the turbo and throttle body making it reall easy to fabricate the pipes.

Here'e mine:

#36

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,292

Total Cats: 475

yea IC will put the pipes going up where the current readiator supports are. That's not a problem though, as I'll have to make new ones anyway to move the radiator back. I need a good size IC so going smaller isn't gonna happen.

Thread

Thread Starter

Forum

Replies

Last Post