Turbine outlet studs + Downpipe Q's

#1

Junior Member

Thread Starter

iTrader: (10)

Join Date: Jun 2011

Location: Detroit Burbs

Posts: 299

Total Cats: 3

OK, did a search, and there is alot of talk about manifold studs. I couldn't find anyone talking about turbine outlet studs.

I just bought a used GT2560R from an S14 240SX SR20. There are a few turbine outlet studs missing.

I also just bought a used BEGI 1.8L log manifold, and an older BEGI downpipe. Based on how the BEGI downpipe bolts up to the turbine housing the few remaining studs in the housing could be another 5mm longer for better nut engagement.

Luckily, it appears that the BEGI manifold I bought came with the TSE Inconel stud kit already installed. Although one of the studs has some of it's threads worn off (vibration??).

So, what is the hot ticket for turbine outlet studs?

-Standard black oxide coated steel studs and nuts?

-CAD coated steel studs?

-Stainless studs and nuts??

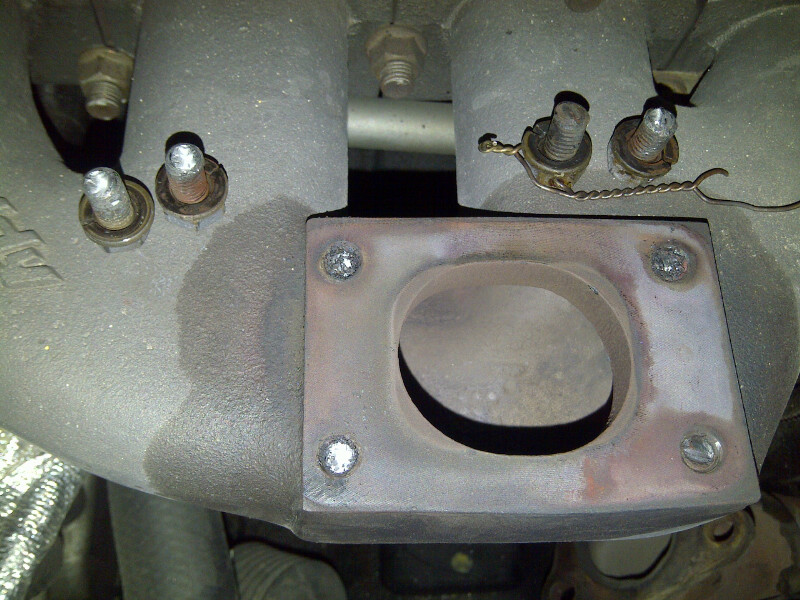

Another question about the downpipe- it looks like this:

So, it doesn't have a divorced wastegate feed. Or really any sort of special provision for the wastegate.

I could:

-Add a divorced wastegate tube (say 1.5"), but that is alot of cutting and welding, and may cause me boost creep issues.

OR

-Add a kickout piece of tubing for better wastegate flow. A little easier to do, and won't require me to mockup in the car. Kinda like this:

OR

-Say **** it and slap it on as-is?

I just bought a used GT2560R from an S14 240SX SR20. There are a few turbine outlet studs missing.

I also just bought a used BEGI 1.8L log manifold, and an older BEGI downpipe. Based on how the BEGI downpipe bolts up to the turbine housing the few remaining studs in the housing could be another 5mm longer for better nut engagement.

Luckily, it appears that the BEGI manifold I bought came with the TSE Inconel stud kit already installed. Although one of the studs has some of it's threads worn off (vibration??).

So, what is the hot ticket for turbine outlet studs?

-Standard black oxide coated steel studs and nuts?

-CAD coated steel studs?

-Stainless studs and nuts??

Another question about the downpipe- it looks like this:

So, it doesn't have a divorced wastegate feed. Or really any sort of special provision for the wastegate.

I could:

-Add a divorced wastegate tube (say 1.5"), but that is alot of cutting and welding, and may cause me boost creep issues.

OR

-Add a kickout piece of tubing for better wastegate flow. A little easier to do, and won't require me to mockup in the car. Kinda like this:

OR

-Say **** it and slap it on as-is?

#2

Moderator

iTrader: (12)

Join Date: Nov 2008

Location: Tampa, Florida

Posts: 20,646

Total Cats: 3,009

Second part first, **** it.

Now for the first part. It would be best to get inconel studs and resbond for the turbine outlet to downpipe connection because they will also stretch, crack, loosen, etc over time. If Trackspeed doesn't have them in the smaller size (m8x1.5) you can get them from Full Race. Resbond is available pretty cheap from McMaster Carr.

Now for the first part. It would be best to get inconel studs and resbond for the turbine outlet to downpipe connection because they will also stretch, crack, loosen, etc over time. If Trackspeed doesn't have them in the smaller size (m8x1.5) you can get them from Full Race. Resbond is available pretty cheap from McMaster Carr.

#4

Junior Member

Thread Starter

iTrader: (10)

Join Date: Jun 2011

Location: Detroit Burbs

Posts: 299

Total Cats: 3

I search for Resbond on Mcmaster site and come up with nothing. I see they have something called high temperature pipe sealants and threadlocker.

Part number 7604A56 @ $31.18 per 4 Oz. bottle.

"Make strong, secure bonds even in extreme temperatures. These no-drip liquid adhesives withstand temperatures from -300° to +2100°F and resist oil, fuel, acids, and alkalies. They form an electrically resistant bond on metal and ceramic threads. Seals can be broken using hand tools. Begin to harden in 24 hours; reach full strength in 2-3 days. Come in 4-oz. bottles. These products are compliant under all state VOC rules in effect on October 1, 2008.

Green penetrates fine openings, such as for set, adjustment, and instrumentation screws. Fills spaces up to 0.003".

Blue prevents loosening from vibration for medium-sized fasteners, pipe threads, and bearings. Fills spaces up to 0.005".

Red provides high-strength bonds for studs and large fasteners, bolts, and pipe threads. Fills spaces up to 0.01".

Is this the stuff?

Part number 7604A56 @ $31.18 per 4 Oz. bottle.

"Make strong, secure bonds even in extreme temperatures. These no-drip liquid adhesives withstand temperatures from -300° to +2100°F and resist oil, fuel, acids, and alkalies. They form an electrically resistant bond on metal and ceramic threads. Seals can be broken using hand tools. Begin to harden in 24 hours; reach full strength in 2-3 days. Come in 4-oz. bottles. These products are compliant under all state VOC rules in effect on October 1, 2008.

Green penetrates fine openings, such as for set, adjustment, and instrumentation screws. Fills spaces up to 0.003".

Blue prevents loosening from vibration for medium-sized fasteners, pipe threads, and bearings. Fills spaces up to 0.005".

Red provides high-strength bonds for studs and large fasteners, bolts, and pipe threads. Fills spaces up to 0.01".

Is this the stuff?

#5

Junior Member

Thread Starter

iTrader: (10)

Join Date: Jun 2011

Location: Detroit Burbs

Posts: 299

Total Cats: 3

Also, the Full Race Inconel studs come in a pack of 4, and I would need 5 for the turbine outlet. They also don't mention a stud length, so not sure if they would fit the downpipe or not.

Pack of 4 for $50. Would need 2.

Full-Race T25 Turbo M8 Stud Hardware Kit - Full-Race.com

Pack of 4 for $50. Would need 2.

Full-Race T25 Turbo M8 Stud Hardware Kit - Full-Race.com

#7

The turbo to downpipe area sees MUCH less heat than the manifold to turbo area. That's the point of a turbine after all. Convert heat and pressure to mechanical work.

I recently did a teardown after 1.5 years and 15,000 miles of aggressive, windy-road daily driving (cherry-red turbo every night). On my initial build, I cheaped out and put in mild-steel bolts safetied with Inconel wire. Here's the ugliness in the manifold to turbo area on my teardown:

TSE's studs are in there now.

What was interesting is that the same bolts used in the turbo to downpipe area were fine. They were still tight and came out without drama. The only issue there was that the zinc coating had burned off.

In the interest of belt and suspenders, I've upgraded these to Inconel as well. I was able to find some Nissan OEM Inconel bolts in M8x1.25. At $3.50 per bolt, they were pretty darn cheap for black-oxide Inconel. Wrote about them here:

https://www.miataturbo.net/engine-pe...e-bolts-68918/

A word about bolt material. We use Inconel for two reasons. The first (obviously) is that Inconel retains its strength at high temperatures. The second (less obvious) is that Inconel's thermal expansion coefficient is a near perfect match for mild steel and iron. There are some SS alloys that have excellent strength at high temperatures. However, the thermal expansion coefficient for typical SS is quite a bit higher than mild steel or iron. Keep that in mind if you are considering SS.

I recently did a teardown after 1.5 years and 15,000 miles of aggressive, windy-road daily driving (cherry-red turbo every night). On my initial build, I cheaped out and put in mild-steel bolts safetied with Inconel wire. Here's the ugliness in the manifold to turbo area on my teardown:

TSE's studs are in there now.

What was interesting is that the same bolts used in the turbo to downpipe area were fine. They were still tight and came out without drama. The only issue there was that the zinc coating had burned off.

In the interest of belt and suspenders, I've upgraded these to Inconel as well. I was able to find some Nissan OEM Inconel bolts in M8x1.25. At $3.50 per bolt, they were pretty darn cheap for black-oxide Inconel. Wrote about them here:

https://www.miataturbo.net/engine-pe...e-bolts-68918/

A word about bolt material. We use Inconel for two reasons. The first (obviously) is that Inconel retains its strength at high temperatures. The second (less obvious) is that Inconel's thermal expansion coefficient is a near perfect match for mild steel and iron. There are some SS alloys that have excellent strength at high temperatures. However, the thermal expansion coefficient for typical SS is quite a bit higher than mild steel or iron. Keep that in mind if you are considering SS.

#8

Junior Member

Thread Starter

iTrader: (10)

Join Date: Jun 2011

Location: Detroit Burbs

Posts: 299

Total Cats: 3

Good find on the cheap inconel bolts. Unfortunately, it looks like they won't work for my application. The downpipe flange is 22mm, leaving only 5mm of thread engagement. Looks like the general rule of thumb is 1.5 x D for thread engagement in cast iron, so 12mm in this case. Bummer.

I'm still not sure how long the Full-Race stuff is. Anyone know?

I'm still not sure how long the Full-Race stuff is. Anyone know?

#9

Junior Member

Thread Starter

iTrader: (10)

Join Date: Jun 2011

Location: Detroit Burbs

Posts: 299

Total Cats: 3

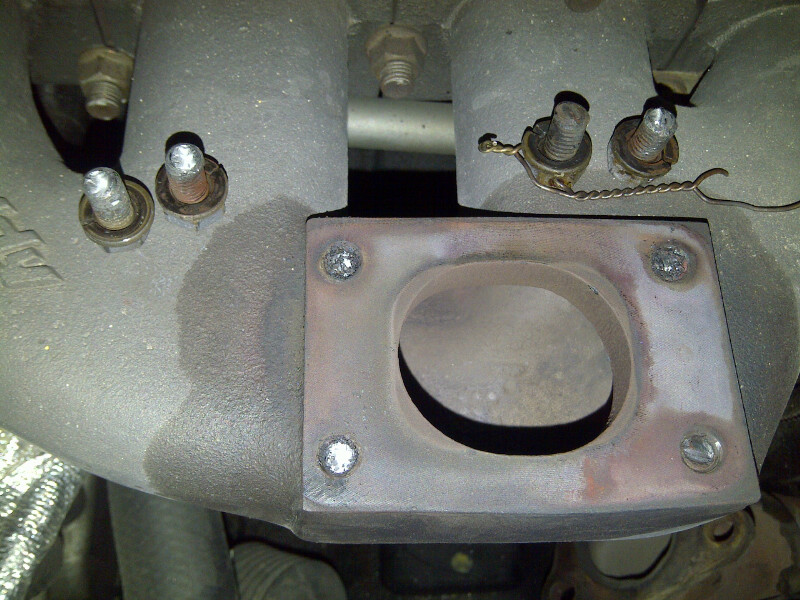

So, here's a pic of my BEGI manifold with the TSE studs in it. I just bought this used, so have no history on it. But, two of the studs have the threads worn away. Also, most of the studs can be turned by hand like about 10-20 degrees, so will probably need some new resbond.

#10

A286 is a well-known heat resistant stainless alloy (often used to join jet engine sections together). It has a high thermal expansion coefficient vis-a-vis your nearly 1" thick downpipe flange. You want to make sure you use a metal gasket to handle the mismatch. You'll also want a nut that offers a positive locking feature (like Stage-8 or a metal locknut).

Another option in A286 . . . you can find A286 bolts of various lengths pretty reasonably from industrial suppliers (search on A286 and they'll pop up). These usually have allen heads and can be drilled for safety wire. Obviously, you have to have enough clearance to tighten the allen head. It looks like that might be a challenge on one of your downpipe bolts.

Are the studs only worn in the turbo flange area or does the thread damage extend into the nut area?

Another option in A286 . . . you can find A286 bolts of various lengths pretty reasonably from industrial suppliers (search on A286 and they'll pop up). These usually have allen heads and can be drilled for safety wire. Obviously, you have to have enough clearance to tighten the allen head. It looks like that might be a challenge on one of your downpipe bolts.

Are the studs only worn in the turbo flange area or does the thread damage extend into the nut area?

#11

Junior Member

Thread Starter

iTrader: (10)

Join Date: Jun 2011

Location: Detroit Burbs

Posts: 299

Total Cats: 3

I can't seem to find anyone that sells metric A286 bolts. Looks like there is a MIL-SPEC for close tolerance Metric, pre-drilled for safety wire (NA0045), but I can't seem to find a website selling them. MIL-SPEC = hard to find and really expensive.

The threads that are worn away on my TSE studs all should be below the nut engagement portion. Makes me wonder how they got worn away though - I assume the studs came loose on the car, and vibration wore away the stud. Not a good sign for a good sealing robust setup.

The threads that are worn away on my TSE studs all should be below the nut engagement portion. Makes me wonder how they got worn away though - I assume the studs came loose on the car, and vibration wore away the stud. Not a good sign for a good sealing robust setup.

#15

Junior Member

Thread Starter

iTrader: (10)

Join Date: Jun 2011

Location: Detroit Burbs

Posts: 299

Total Cats: 3

Well, I just heard back from Full-Race about their 8mm turbo studs. Apparently they are only 40mm in length, and are also out of stock. Bummer.

22mm flange thickness + 1mm gasket + 7mm M8 nut height = 30mm stackup. So, only 10mm of thread engagement into the turbine housing, which wouldn't bottom out the stud on the shoulder. Maybe this is OK with Resbond, but seems pretty marginal. Also less than the 1.5 x D thread engagement rule of thumb for cast iron.

Anyone know where to buy some longer inconel or A286 studs?

22mm flange thickness + 1mm gasket + 7mm M8 nut height = 30mm stackup. So, only 10mm of thread engagement into the turbine housing, which wouldn't bottom out the stud on the shoulder. Maybe this is OK with Resbond, but seems pretty marginal. Also less than the 1.5 x D thread engagement rule of thumb for cast iron.

Anyone know where to buy some longer inconel or A286 studs?

#16

You could try these guys. They claim to have A286 in stock in M8 socket head bolts. Haven't tried them myself.

Sockethead Cap Screws | Ocean State Stainless, Inc.

Sockethead Cap Screws | Ocean State Stainless, Inc.

#18

Here's the ugliness in the manifold to turbo area on my teardown:

TSE's studs are in there now.

What was interesting is that the same bolts used in the turbo to downpipe area were fine... I've upgraded these to Inconel as well. I was able to find some Nissan OEM Inconel bolts in M8x1.25.

TSE's studs are in there now.

What was interesting is that the same bolts used in the turbo to downpipe area were fine... I've upgraded these to Inconel as well. I was able to find some Nissan OEM Inconel bolts in M8x1.25.

Also thank you for the post of your unfortunate street driven manifold stud situation. I've been trying to cost-benefit balance my street/some autox car for the regular steel studs (already have them) vs TSE inco studs on a begi mani and your post has helped make it a little clearer.

How much did it run you to remove the broken studs?

#19

Anyone tried something like this?

ARP 400-8012 Stainless Steel Exhaust Manifold Kit 8x Studs/Yokes/ Nuts

Curious if they would be any good for the turbine to downpipe connection.

ARP 400-8012 Stainless Steel Exhaust Manifold Kit 8x Studs/Yokes/ Nuts

Curious if they would be any good for the turbine to downpipe connection.

#20

Removing the studs wasn't a big deal because the manifold was being drilled and tapped to go from M8 to M10. So, essentially "free."