[carnage] Savington throws a rod, hilarity ensues

#43

Elite Member

iTrader: (21)

Join Date: Jun 2006

Location: Point Pleasant, NJ

Posts: 2,957

Total Cats: 2

**** man, another. Sorry to hear it Sav. As far as 99 into 94 its basically a direct swap. I think people mentioned all the necessary changes you'll have to do.

Both CLT sensors from your 94 need to go into the 99 head, the small one on the driver side is for your cluster gauge. The sensor on the back of the 99 head is 3 wire because it's 2 sensors in one, it combines the sensor for the ecu and the one for the gauge. Put your 2 wire sensor from 94 in there

Source a real oil pressure gauge for the 99 block or make sue your existing one didnt get fuxored.

The longer oil feed since you lose the driver side port.

Alternator your got.

Use 94 throttle body and your will have to do something fancy with the throttle cable as it will be too long. either make a custom bracket or you have to wrap the cable around to the next hole.

VICs - i didnt bother and I am not gonna bother when I do my 99 swap on my daily any day now.

Use CAS from 94.

**** EGR.

Both CLT sensors from your 94 need to go into the 99 head, the small one on the driver side is for your cluster gauge. The sensor on the back of the 99 head is 3 wire because it's 2 sensors in one, it combines the sensor for the ecu and the one for the gauge. Put your 2 wire sensor from 94 in there

Source a real oil pressure gauge for the 99 block or make sue your existing one didnt get fuxored.

The longer oil feed since you lose the driver side port.

Alternator your got.

Use 94 throttle body and your will have to do something fancy with the throttle cable as it will be too long. either make a custom bracket or you have to wrap the cable around to the next hole.

VICs - i didnt bother and I am not gonna bother when I do my 99 swap on my daily any day now.

Use CAS from 94.

**** EGR.

#46

Tour de Franzia

iTrader: (6)

Join Date: Jun 2006

Location: Republic of Dallas

Posts: 29,085

Total Cats: 375

do the reroute now, and call begi for a new intake pipe. Your IAC settings will be different but you can copy mine, gut the vics **** and plug the holes with jb-weld, kill the EGR, and cut the valve cover so you can check timing on the fly.

What about the throttle cable mount?

I'm interested to see what happens to power, torque, and your spark table with the 9.5:1 compression.

What about the throttle cable mount?

I'm interested to see what happens to power, torque, and your spark table with the 9.5:1 compression.

#50

Elite Member

iTrader: (1)

Join Date: Feb 2008

Location: Birmingham Alabama

Posts: 7,930

Total Cats: 45

You dont mess around dude, already out. I guess I could be fast if I had a decent place to work on them. Id be willing to bet that auto engine has seen less stress than a manuel may have. Good luck on the build. Seeing your old engines history makes me feel a bit better. Mine isnt nearly as high of mileage (1200 miles

) and probably wont see more than a few HPDE's in its lifetime, so Im not too worried.

) and probably wont see more than a few HPDE's in its lifetime, so Im not too worried.

#52

Former Vendor

Thread Starter

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,099

The more I think about it, the more I never want to deal with this again.

Can anyone give me a reason not to do the following:

-Get the new 99 motor, pull the head and pan, remove pistons and rods

-Have a bung welded into the pan for the oil drain (if I have the motor out, may as well)

-Replace ONLY THE RODS with Belfab/ETD rods

-Put pistons/new rods back into the motor with no ring/hone work at all (96k on them right now)

-Install my billet OPGs (I have them, may as well throw them in)

-Size new main bearings, install

-ARP hardware, fresh head gasket, spacerless coolant reroute, new timing belt/water pump

Realistically, I have no 300whp aspirations. I'll eventually do a basic water injection setup and max the 2554R out completely, but I like the spool of this turbo and the largest I'll ever go is a 2560 if I do change. I don't think I need pistons; rods are the only thing I NEED to change, and OPGs are a paid-for safety item.

I have neither the time nor the money to do a full build right now. The rods are $400ish, everything else should bring the total to around $700 including the water pump and timing belt. Reusing the pistons and rings lets me save 99% of the machining costs, and they don't really need to be changed anyway.

Can anyone give me a reason not to do the following:

-Get the new 99 motor, pull the head and pan, remove pistons and rods

-Have a bung welded into the pan for the oil drain (if I have the motor out, may as well)

-Replace ONLY THE RODS with Belfab/ETD rods

-Put pistons/new rods back into the motor with no ring/hone work at all (96k on them right now)

-Install my billet OPGs (I have them, may as well throw them in)

-Size new main bearings, install

-ARP hardware, fresh head gasket, spacerless coolant reroute, new timing belt/water pump

Realistically, I have no 300whp aspirations. I'll eventually do a basic water injection setup and max the 2554R out completely, but I like the spool of this turbo and the largest I'll ever go is a 2560 if I do change. I don't think I need pistons; rods are the only thing I NEED to change, and OPGs are a paid-for safety item.

I have neither the time nor the money to do a full build right now. The rods are $400ish, everything else should bring the total to around $700 including the water pump and timing belt. Reusing the pistons and rings lets me save 99% of the machining costs, and they don't really need to be changed anyway.

#53

If you swap the rods, some people advocate a quick diy hone job and fresh factory rings. Just make sure the gap in the rings are big enuf for turbo work.

With a very careful diy hone you don't need to hot tank the block.

IIRC the better diy hone tool is the one with the bottle brush look (as opposed to the 3 long stones).

ARP hardware isn't a must IMO - how many have seen fastener failures in a miata with <300 hp and <7500 RPM?

#54

Elite Member

iTrader: (1)

Join Date: Feb 2008

Location: Birmingham Alabama

Posts: 7,930

Total Cats: 45

The more I think about it, the more I never want to deal with this again.

Can anyone give me a reason not to do the following:

-Get the new 99 motor, pull the head and pan, remove pistons and rods

-Have a bung welded into the pan for the oil drain (if I have the motor out, may as well)

-Replace ONLY THE RODS with Belfab/ETD rods

-Put pistons/new rods back into the motor with no ring/hone work at all (96k on them right now)

-Install my billet OPGs (I have them, may as well throw them in)

-Size new main bearings, install

-ARP hardware, fresh head gasket, spacerless coolant reroute, new timing belt/water pump

Realistically, I have no 300whp aspirations. I'll eventually do a basic water injection setup and max the 2554R out completely, but I like the spool of this turbo and the largest I'll ever go is a 2560 if I do change. I don't think I need pistons; rods are the only thing I NEED to change, and OPGs are a paid-for safety item.

I have neither the time nor the money to do a full build right now. The rods are $400ish, everything else should bring the total to around $700 including the water pump and timing belt. Reusing the pistons and rings lets me save 99% of the machining costs, and they don't really need to be changed anyway.

Can anyone give me a reason not to do the following:

-Get the new 99 motor, pull the head and pan, remove pistons and rods

-Have a bung welded into the pan for the oil drain (if I have the motor out, may as well)

-Replace ONLY THE RODS with Belfab/ETD rods

-Put pistons/new rods back into the motor with no ring/hone work at all (96k on them right now)

-Install my billet OPGs (I have them, may as well throw them in)

-Size new main bearings, install

-ARP hardware, fresh head gasket, spacerless coolant reroute, new timing belt/water pump

Realistically, I have no 300whp aspirations. I'll eventually do a basic water injection setup and max the 2554R out completely, but I like the spool of this turbo and the largest I'll ever go is a 2560 if I do change. I don't think I need pistons; rods are the only thing I NEED to change, and OPGs are a paid-for safety item.

I have neither the time nor the money to do a full build right now. The rods are $400ish, everything else should bring the total to around $700 including the water pump and timing belt. Reusing the pistons and rings lets me save 99% of the machining costs, and they don't really need to be changed anyway.

^n/m. For sure try and find a bottle hone. I used one of the standard stone hones and found it to be a pain in the ***. I used to have a bottle hone (the ones that look like a round wire brush with ***** on the ends of the wires) but lost it apparently. I couldnt make the hone I used go all the way to the bottom of the bore, and I kept chipping stones by going too deep and hitting the castings in the crankcase under the cylinders. Plus with a stone type of hone you cant go all the way out of the cylinder and back in while keeping it spinning like you can a bottle hone, which leads to the crosshatch having curves from where you stopped and restarted up and down the bore.

And why not just hone and spray it off with a cleaner and a high pressure hose. Of course you would have to remove the oil pressure sending unit and the other little stuff attached to the block first, but thats not a huge task.

#58

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,019

Total Cats: 6,587

Like Jason said, I'm liking the idea of a quick hone and new stock rings. While the rings are off, it'll give you a chance to better inspect the pistons, clean up the oil holes and ring lands, etc. I can't imagine that a shop would charge you more than $72.50 to run a hone down the bores. Since the block itself is completely torn-down at that point, go ahead and hot-tank it, clean out the oil galleys, etc. No point in not doing it, etc?

VICS, as has been mentioned, is a no-brainer. Set up a relay output on your MS and use that to drive the VICS. It's a simple RPM based on/off system even in stock form. Looks like it should be on between 3,500 and 5,600 RPM: https://www.miataturbo.net/forum/t20742/

VICS, as has been mentioned, is a no-brainer. Set up a relay output on your MS and use that to drive the VICS. It's a simple RPM based on/off system even in stock form. Looks like it should be on between 3,500 and 5,600 RPM: https://www.miataturbo.net/forum/t20742/

#59

Senior Member

iTrader: (2)

Join Date: May 2005

Location: Edmonton Ab, Canada

Posts: 1,202

Total Cats: 21

Honestly I would just drop in the stock motor and run it.

Once you start ******* around with replacing this and doing that you end up sinking in more time and money than you wanted too.

When is the track day? How much time do you really have?

Once you start ******* around with replacing this and doing that you end up sinking in more time and money than you wanted too.

When is the track day? How much time do you really have?

#60

Elite Member

iTrader: (15)

Join Date: Dec 2007

Location: San Antonio, Texas

Posts: 4,847

Total Cats: 27

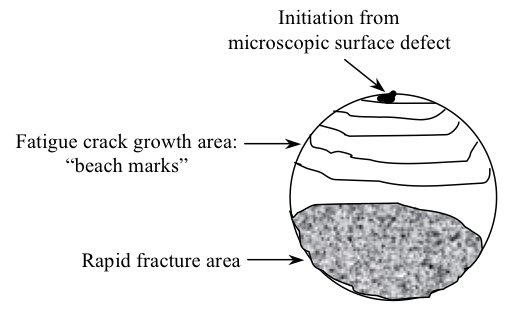

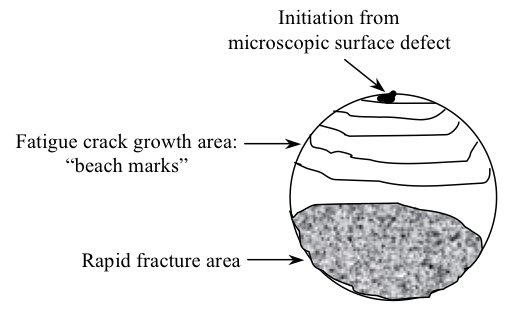

If it is a fatigue failure you will see markings on the broken ends of the rods like this

Look for the initiation site, then the 'beach marks' or striations leading out from there, then the catastrophic failure area which is rough looking. I could not look for this on my rod because the broken ends were so beat to **** it would have not been visible.

Personally I think pulling motors is a PIA so I would take the time and beef up the bottom end with Belfab rods, with new rings and bearings while you are in there. Then the billet oil pump gears like you mentioned. It is more money, and more time, and maybe you will miss your track day, but it will be done and should last a lot longer if you turn up the power. I think it is pretty well established at this point that the rods are the weak link

Look for the initiation site, then the 'beach marks' or striations leading out from there, then the catastrophic failure area which is rough looking. I could not look for this on my rod because the broken ends were so beat to **** it would have not been visible.

Personally I think pulling motors is a PIA so I would take the time and beef up the bottom end with Belfab rods, with new rings and bearings while you are in there. Then the billet oil pump gears like you mentioned. It is more money, and more time, and maybe you will miss your track day, but it will be done and should last a lot longer if you turn up the power. I think it is pretty well established at this point that the rods are the weak link

Last edited by ZX-Tex; 03-03-2009 at 10:33 AM.