ARP head stud torque for a Miata.

#21

Elite Member

Thread Starter

Join Date: Jul 2005

Location: Anacortes, WA

Posts: 2,478

Total Cats: 144

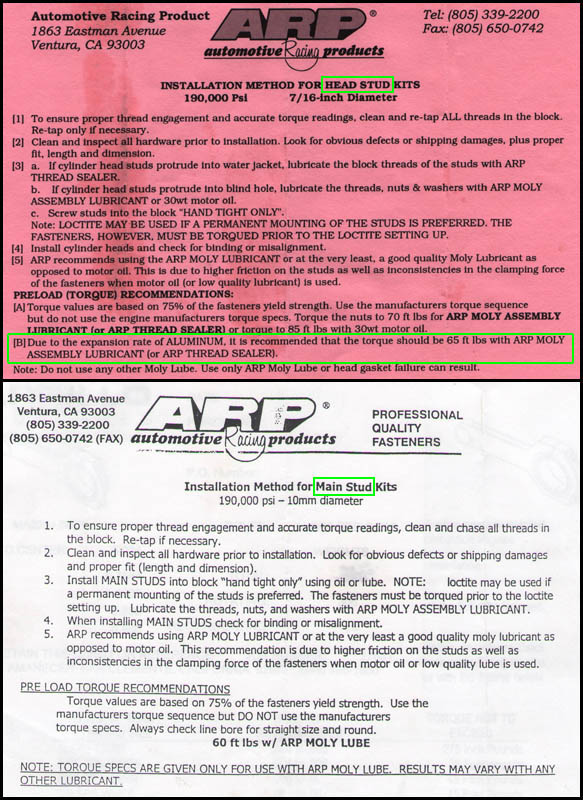

There is a chart on the back of the box that has generic recommended torque values for 3 different material strength fasteners based on fastener diameter. They don't even tell you what material strength the fasteners that comes in the box are.

Again I have never seen a documented torque value for ARP head studs on a Miata. Go searching on line and you find wildly varying answers that dont seem right.

Bob

#23

Elite Member

Thread Starter

Join Date: Jul 2005

Location: Anacortes, WA

Posts: 2,478

Total Cats: 144

None of my boxes I got ever came with that sheet. Maybe mine were Chinese knock offs or something from Ebay but the box says made in the USA. The threads in the block are 11mmX1.5 not 7/16" but I just verified the nut end is indeed 7/16X20 didn’t realize that before.

The back of the box says 63 ft-lbs for a 7/16 size stud and 71 ft-lbs for an 11mm stud.

And I can verify using the 70 or 85 lb values in the [A] part also shown on your sheet will yield the aluminum head with heat cycles and 85 lbs will likely turn your head into a paper weight. 65 Is probably more than necessary but OK I guess and it wouldn’t surprise me if it produced nearly double the stock clamp force> ~15,000 lbs of force per stud by there chart and the area under the washers is pretty small to apply that much force on aluminum especially when it heats up and expands more than the bolt does further increasing the clamp. I can also varify that 48 to 50 ft-lbs has no issues holding more than 300 hp.

Bob

#25

The lower torque (48, IIRC) is what the original engineer at ARP came up with when we worked with them to build a correct Miata stud kit that was an exact fit. He was basing it on stud diameter, head thickness and OE torque values. That guy is gone now and nobody at ARP since then has ever agreed with the low number. But we have used it for a long time without issues and the original guy seemed to spend the time to study the application. YMMV. ARP is pretty funny sometimes, they'll send a box where none of the nuts are threaded or sometimes the studs. Seems to only happen when we ship overseas...

#26

Elite Member

Thread Starter

Join Date: Jul 2005

Location: Anacortes, WA

Posts: 2,478

Total Cats: 144

The lower torque (48, IIRC) is what the original engineer at ARP came up with when we worked with them to build a correct Miata stud kit that was an exact fit. He was basing it on stud diameter, head thickness and OE torque values. That guy is gone now and nobody at ARP since then has ever agreed with the low number. But we have used it for a long time without issues and the original guy seemed to spend the time to study the application. YMMV. ARP is pretty funny sometimes, they'll send a box where none of the nuts are threaded or sometimes the studs. Seems to only happen when we ship overseas...

Bob

#28

I was questioning this as well as I noticed the difference between OEM and ARP torque values. I meant to retorque them as ppl told me I should go w/ ARP's specs (which I have on the box somewhere) but never got around to it.

Are the ARPs re-usable? Say since I torqued them down already and have gone through numerous heat cycles... I would like to loosen them, and start over to re-torque (especially since I don't remember what I tq'd them to)... would this be okay? Stock 1.6L... I threw on the ARPs "just cause."

Are the ARPs re-usable? Say since I torqued them down already and have gone through numerous heat cycles... I would like to loosen them, and start over to re-torque (especially since I don't remember what I tq'd them to)... would this be okay? Stock 1.6L... I threw on the ARPs "just cause."

#30

Are the ARPs re-usable? Say since I torqued them down already and have gone through numerous heat cycles... I would like to loosen them, and start over to re-torque (especially since I don't remember what I tq'd them to)... would this be okay? Stock 1.6L... I threw on the ARPs "just cause."

You have to check the stud with a micrometer (clamp it down on the non-threaded part and run it down the length of the stud) to ensure it didn't stretch and inspect it at the base of the threads (where they start on each end) visually. Those are the places that will stretch and generally they don't unless there is a mechanical failure (disconnected piston hits the head, blown head gasket).

#31

Elite Member

Thread Starter

Join Date: Jul 2005

Location: Anacortes, WA

Posts: 2,478

Total Cats: 144

I was questioning this as well as I noticed the difference between OEM and ARP torque values. I meant to retorque them as ppl told me I should go w/ ARP's specs (which I have on the box somewhere) but never got around to it.

Are the ARPs re-usable? Say since I torqued them down already and have gone through numerous heat cycles... I would like to loosen them, and start over to re-torque (especially since I don't remember what I tq'd them to)... would this be okay? Stock 1.6L... I threw on the ARPs "just cause."

Are the ARPs re-usable? Say since I torqued them down already and have gone through numerous heat cycles... I would like to loosen them, and start over to re-torque (especially since I don't remember what I tq'd them to)... would this be okay? Stock 1.6L... I threw on the ARPs "just cause."

I suspect what happens if they are over torqed is the head starts to yield due to contact forces under the washers first. And that is another thing. ARP supply smaller OD hardened washers than OE so they will actually yield the head at a lower clamp force than OE as the contact pressure under the washer is higher. I have been tossing the ARP washers and using the OE ones to reduce this problem. So what happens is you torque them up near the point the head wants to yield and a few heat cycles the head yields a bit under the washers so stress and clamp force is reduced. This causes a reduction in clamp force, again this is bad.

Bob

#32

Elite Member

iTrader: (2)

Join Date: May 2007

Location: Cromwell, Connecticut

Posts: 2,604

Total Cats: 16

Hmm. I have to double check the sheet mine came with and maybe that will jog my memory. I believe the first time I put the head on I torqued to 65-70 ftlbs ... but I had the head off at one point and probably followed the "using 30 wt " torque of 85 !!!!

I will do a lot less next time.

I haven't had any issues yet.

I will do a lot less next time.

I haven't had any issues yet.

#33

Elite Member

Thread Starter

Join Date: Jul 2005

Location: Anacortes, WA

Posts: 2,478

Total Cats: 144

Hmm. I have to double check the sheet mine came with and maybe that will jog my memory. I believe the first time I put the head on I torqued to 65-70 ftlbs ... but I had the head off at one point and probably followed the "using 30 wt " torque of 85 !!!!

I will do a lot less next time.

I haven't had any issues yet.

I will do a lot less next time.

I haven't had any issues yet.

Bob

#37

Former Vendor

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,099

FYI, I ordered two sets of studs for a couple of cars at the shop this week. Just opened the first box to install them and the instructions say 80 ft.lbs with ARP Ultra-Torque fastener lube.

I will be torquing to 65ft.lbs.

I will be torquing to 65ft.lbs.

#38

Torquing the studs to 65 ft-lbs puts about 740lb of axial load in the bolts, or slightly less using the lube on the threads. (this assumes 0.15 friction factor, but with the lube it's in the range of 0.11-0.17 from what I can tell) I'm not sure what the stock bolts are shooting for or if they're torque to yield bolts, so it's hard to compare. The 48ft-lb torque produces about 550lb of load in the bolt using the same friction assumption as above.

#40

Elite Member

Thread Starter

Join Date: Jul 2005

Location: Anacortes, WA

Posts: 2,478

Total Cats: 144

Torquing the studs to 65 ft-lbs puts about 740lb of axial load in the bolts, or slightly less using the lube on the threads. (this assumes 0.15 friction factor, but with the lube it's in the range of 0.11-0.17 from what I can tell) I'm not sure what the stock bolts are shooting for or if they're torque to yield bolts, so it's hard to compare. The 48ft-lb torque produces about 550lb of load in the bolt using the same friction assumption as above.

Need to calculate the area under the washer and see if it is enough pressure to yield the aluminum head Id guess the material would yield at about 41,000 psi cold for the cast aluminum head. As the head gets hot the clamp load increases and yeald occurs at a lower level. ARP studs also have smaller OD washers than stock which isnt helping things.

quick guesses I come up with .291 for area makes 2543 psi. shouldnt yield when tightened to 65 FT-lbs. bit more involved to look at effects of thermal expansion. The head will wan't to grow a lot more than the bolts when things get hot.

Bob

Last edited by bbundy; 01-21-2011 at 06:42 PM.