cam cover blowby flow and crankcase pressure, tiny hole modification

#61

I did this as well, but with a -10 AN line. Yep, dont put it back together without scrubbers in there or you'll fill the catch can up in 1 auto-x run.

But for the love of god use pure copper scrubbers and not plastic or copper coated steel. The normal brand of "the good stuff" for pure copper scrubbers is chore boy.

One think I couldnt figure when I had this apart is, how does the 2nd chamber drain if the chamber's cover is sealed? The center chamber is easy, it just goes out the inlet, but the 2nd chamber would need to either travel upwards up that hole we're drilling out, or go out into the catch can.

But for the love of god use pure copper scrubbers and not plastic or copper coated steel. The normal brand of "the good stuff" for pure copper scrubbers is chore boy.

One think I couldnt figure when I had this apart is, how does the 2nd chamber drain if the chamber's cover is sealed? The center chamber is easy, it just goes out the inlet, but the 2nd chamber would need to either travel upwards up that hole we're drilling out, or go out into the catch can.

#62

mkturbo.com

iTrader: (24)

Join Date: May 2006

Location: Charleston SC

Posts: 15,176

Total Cats: 1,680

On my VVT head I have -8an lines I believe coming off. I removed all the scrubbers and cut the metal seals in half to just cover where the AN fittings are. Since then I have had zero oil in my catch cans.

#66

Savington, did you eventually make ports at the top of the valve cover as you planned?

Shuiend, how is your half baffle setup working out for you?

Blindbox2334's photos of the protege vc looks like it might be a pretty good setup as the PCV port is way at the front of the cover, and the case vent doesn't pick up oil from the back right but the center. This might eliminate the worry about oil pooling up under hard left hand corners, right?

I have a spare valve cover that I am considering having AN fittings welded to. But after re-reviewing this thread I wonder if there was a consensus on what works well

Shuiend, how is your half baffle setup working out for you?

Blindbox2334's photos of the protege vc looks like it might be a pretty good setup as the PCV port is way at the front of the cover, and the case vent doesn't pick up oil from the back right but the center. This might eliminate the worry about oil pooling up under hard left hand corners, right?

I have a spare valve cover that I am considering having AN fittings welded to. But after re-reviewing this thread I wonder if there was a consensus on what works well

#67

mkturbo.com

iTrader: (24)

Join Date: May 2006

Location: Charleston SC

Posts: 15,176

Total Cats: 1,680

Well for the bit that my car ran after I switched to half baffles it worked great and there was no more oil in either of my 2 catch cans. BUT I don't have a ton of miles on it, have had the motor down twice since the switch due to oil problems.

#68

I've got the half baffles and a 1/2" hole going to the center baffle, with Scotch-Brite to catch the oil vapors. It still doesn't seem to be enough.

The "baffling" thing is that I'm still getting an oil leak. At first I thought was the turbo oil return at the pan. But then when I opened the hood this time I had oil all over the passenger firewall. It's only a guess, but a vacuum plug popped off from the intake manifold--facing forward--and the excess oil from the valve cover shot out of the vacuum port and right into the fan...my fan it tilted forward at about 45 degrees. I lost that "OH ****" feeling when I pressed the "go" pedal too, as my 10psi boost probably dropped to about 3psi.

edit--the theory is that oil mist is being sucked out of the valve cover and into the intake. There, it's being shot out of the vacuum line right into the fan, or into the engine where it's fouling my plugs.

BTW, I'm running full baffles with 7/16" hole on the exhaust side and 1/2 baffles on the intake side.

The plan--rig up a vented oil catch can tomorrow, with lines coming from both valve cover holes.

Does that sound crazy, or should I look somewhere else? The goal--a fun Laguna Seca weekend without the need to open the hood.

The "baffling" thing is that I'm still getting an oil leak. At first I thought was the turbo oil return at the pan. But then when I opened the hood this time I had oil all over the passenger firewall. It's only a guess, but a vacuum plug popped off from the intake manifold--facing forward--and the excess oil from the valve cover shot out of the vacuum port and right into the fan...my fan it tilted forward at about 45 degrees. I lost that "OH ****" feeling when I pressed the "go" pedal too, as my 10psi boost probably dropped to about 3psi.

edit--the theory is that oil mist is being sucked out of the valve cover and into the intake. There, it's being shot out of the vacuum line right into the fan, or into the engine where it's fouling my plugs.

BTW, I'm running full baffles with 7/16" hole on the exhaust side and 1/2 baffles on the intake side.

The plan--rig up a vented oil catch can tomorrow, with lines coming from both valve cover holes.

Does that sound crazy, or should I look somewhere else? The goal--a fun Laguna Seca weekend without the need to open the hood.

Last edited by cordycord; 09-02-2014 at 11:19 PM. Reason: clarification

#69

I'm running atmospheric vent on boths ports currently and it's helped a LOT with preventing oil from blowing past my turbo seals. I had some smoking because the turbo couldn't drain with the PCV still in place.

(Leak down test tomorrow)

I imagine that you'd still need to worry about that oil pooling and dumping out of the passenger side during hard sustained left handers.

Thats why I was wondering if Sav ended up plugging his ports and welding some fittings up top to reduce the amount of fluid pushing through the lines versus just vapors

(Leak down test tomorrow)

I imagine that you'd still need to worry about that oil pooling and dumping out of the passenger side during hard sustained left handers.

Thats why I was wondering if Sav ended up plugging his ports and welding some fittings up top to reduce the amount of fluid pushing through the lines versus just vapors

#70

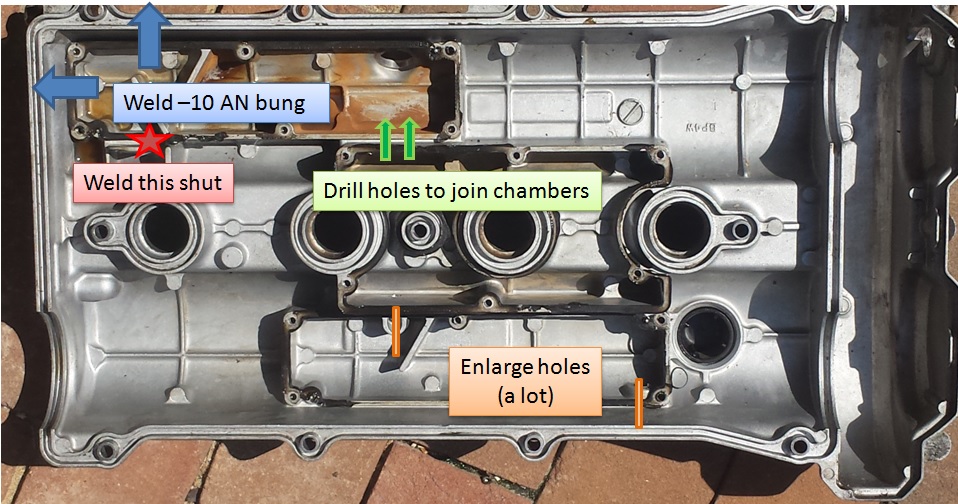

This is what I was thinking about.

First off, blocking the chamber inlet on the passenger side as hustler had pointed out in another thread, this is where the oil feed is for the head and oil might pool up on this side while taking sustained left-handers.

Instead, a port would be welded at either of the blue arrows, still utilizing the 'baffle' from factory, but grabbing positive pressure from the central chamber via holes drilled.

Obviously as everyone has done already in the thread, the enlarging of the holes on the driver side to help accommodate evacuation of gases.

I don't know if the stock PCV port would be utilized or plugged but it may render the rear baffled port useless as the restriction would be the holes drilled in green.

Just an idea. You can pick up an extra driver side baffle cover from dealer for about $15 which fits on the passenger side if welding that corner shut.

First off, blocking the chamber inlet on the passenger side as hustler had pointed out in another thread, this is where the oil feed is for the head and oil might pool up on this side while taking sustained left-handers.

Instead, a port would be welded at either of the blue arrows, still utilizing the 'baffle' from factory, but grabbing positive pressure from the central chamber via holes drilled.

Obviously as everyone has done already in the thread, the enlarging of the holes on the driver side to help accommodate evacuation of gases.

I don't know if the stock PCV port would be utilized or plugged but it may render the rear baffled port useless as the restriction would be the holes drilled in green.

Just an idea. You can pick up an extra driver side baffle cover from dealer for about $15 which fits on the passenger side if welding that corner shut.

Last edited by psyber_0ptix; 09-04-2014 at 06:00 PM.

#71

I only had the day to try and get this done before Laguna Seca, so here's what I did:

--tapped PCV valve outlet and added fitting with barb

--added vented oil catch can to firewall

--rerouted Valve cover vents (2) to the catch can

I've already messed around with the valve cover (center hole bigger, cut PCV plate, add Scotch-brite mesh), so we'll see how it works.

The funny thing is that during the first start-up/test, there seemed to be far less oil sptting from the exhaust, but for the first time I started to see some white smoke. Holy crap. Has this been masked by the venting problem? One problem ends and another begins?

--tapped PCV valve outlet and added fitting with barb

--added vented oil catch can to firewall

--rerouted Valve cover vents (2) to the catch can

I've already messed around with the valve cover (center hole bigger, cut PCV plate, add Scotch-brite mesh), so we'll see how it works.

The funny thing is that during the first start-up/test, there seemed to be far less oil sptting from the exhaust, but for the first time I started to see some white smoke. Holy crap. Has this been masked by the venting problem? One problem ends and another begins?

#72

mkturbo.com

iTrader: (24)

Join Date: May 2006

Location: Charleston SC

Posts: 15,176

Total Cats: 1,680

I've got the half baffles and a 1/2" hole going to the center baffle, with Scotch-Brite to catch the oil vapors. It still doesn't seem to be enough.

The "baffling" thing is that I'm still getting an oil leak. At first I thought was the turbo oil return at the pan. But then when I opened the hood this time I had oil all over the passenger firewall. It's only a guess, but a vacuum plug popped off from the intake manifold--facing forward--and the excess oil from the valve cover shot out of the vacuum port and right into the fan...my fan it tilted forward at about 45 degrees. I lost that "OH ****" feeling when I pressed the "go" pedal too, as my 10psi boost probably dropped to about 3psi.

edit--the theory is that oil mist is being sucked out of the valve cover and into the intake. There, it's being shot out of the vacuum line right into the fan, or into the engine where it's fouling my plugs.

BTW, I'm running full baffles with 7/16" hole on the exhaust side and 1/2 baffles on the intake side.

The plan--rig up a vented oil catch can tomorrow, with lines coming from both valve cover holes.

Does that sound crazy, or should I look somewhere else? The goal--a fun Laguna Seca weekend without the need to open the hood.

The "baffling" thing is that I'm still getting an oil leak. At first I thought was the turbo oil return at the pan. But then when I opened the hood this time I had oil all over the passenger firewall. It's only a guess, but a vacuum plug popped off from the intake manifold--facing forward--and the excess oil from the valve cover shot out of the vacuum port and right into the fan...my fan it tilted forward at about 45 degrees. I lost that "OH ****" feeling when I pressed the "go" pedal too, as my 10psi boost probably dropped to about 3psi.

edit--the theory is that oil mist is being sucked out of the valve cover and into the intake. There, it's being shot out of the vacuum line right into the fan, or into the engine where it's fouling my plugs.

BTW, I'm running full baffles with 7/16" hole on the exhaust side and 1/2 baffles on the intake side.

The plan--rig up a vented oil catch can tomorrow, with lines coming from both valve cover holes.

Does that sound crazy, or should I look somewhere else? The goal--a fun Laguna Seca weekend without the need to open the hood.

#73

I'll try that when I get back from Laguna SECA. We drove the car from the track to lunch (at the wharf), just to see what kind of smoke colors we were going to get from the exhaust. Black, white, more white (panic), more black, and then not much of anything. Coming back from lunch the smoke was barely noticeable. We'll see what happens tomorrow at the track...

#74

I have been reading this thread trying to figure out what to do on my car, after building the engine and installing a DYI turbo it started to get oil on the intake through the PCV system, i did not have a drop of oil coming from the the PCV in to the intake.

I then deleted the PCV and welded bungs on both vents, routed hoses to a catch can and the oil is now coming from the exhaust side vent and not from the PCV hose.

After thinking of how the system works i realized that the bulk of the oil going to the exhaust side vent gets separated and sent back to the engine in the center chamber, a small percentage makes it to the chamber on top of the exhaust cam.

My big question was, where did the oil go before when i had the PCV hooked up that it was not leaking out of that vent?

Well i think that the answer is that any oil that makes it to the seccond chamber gets sucked back out into the center chamber where it can drain back into the engine by negative presure generated by the PCV when it operates.

This answers the question asked earlier on this thread of why is the connecting hole between chambers going from the bottom of the exhaust chamber to the top of the center chamber.

I think that my next experiment will be to put back the PCV with a sealed in line oil separator that has a metered orifice on the drain line with a check valve that drains oil to the sump when in boost and alows the PCV to work normally on part throttle and leave the stock exhaust vent separator.

Will see if this works.

I then deleted the PCV and welded bungs on both vents, routed hoses to a catch can and the oil is now coming from the exhaust side vent and not from the PCV hose.

After thinking of how the system works i realized that the bulk of the oil going to the exhaust side vent gets separated and sent back to the engine in the center chamber, a small percentage makes it to the chamber on top of the exhaust cam.

My big question was, where did the oil go before when i had the PCV hooked up that it was not leaking out of that vent?

Well i think that the answer is that any oil that makes it to the seccond chamber gets sucked back out into the center chamber where it can drain back into the engine by negative presure generated by the PCV when it operates.

This answers the question asked earlier on this thread of why is the connecting hole between chambers going from the bottom of the exhaust chamber to the top of the center chamber.

I think that my next experiment will be to put back the PCV with a sealed in line oil separator that has a metered orifice on the drain line with a check valve that drains oil to the sump when in boost and alows the PCV to work normally on part throttle and leave the stock exhaust vent separator.

Will see if this works.

#76

The intake side vents through the PCV and will vent when the car is on light throttle when there is vacuum on the IM it will close on boost but some tend to leak on high boost cars pressurizing the crankase further and making the exhaust side vent flow more air that it can separate and flow causing oil coming out the vent and even blowing seals on extreme cases.

#77

This issue has been the focus of the last two weeks, and my Saturday at Laguna Seca. CRAP!

To summarize the problem, the hole that returns oil from the valve cover to the crank case doesn't work when the crank case is pressurized. Crank pressure is usually caused by the "blow by" pressure of combustion that escapes around the piston rings into the crank case. Turbos and old engines exacerbate this issue.

The pressure is so high that oil that is supposed to return to the crank case via gravity is blown back into the valve cover from the crank pressure. What to do?

The current solutions have included:

--add copper mesh to convert oil vapor to liquid so it will drain back down the tube

--remove the center baffle

--open the breather hole at the valve cover

--add a catch can that routed from both valve cover outlets

--allofit

I'm pretty sure my problem was "terminal" by the time I'd even gotten to the track, so "allofit" wouldn't have worked anyway. MT.net member (Marlon? I'm terrible with names) showed me his immaculate turbo setup with methane injection, and told me he'd had the same issues.

His solution was the catch can with routing from both ports. The big difference with his solution was that he basically said that the stock baffle system needs to be sealed to work. In other words, he took off all three plates, cleaned, and then resealed the whole shebang with high temp gasket sealer.

Hey, my tests all ended in failure but I thought I'd forward something that seemed to work. Also, if you're looking for a grand bargain in catch cans, look no further than this Asian wonder:

Black Aluminum Oil Reservoir Catch Can Tank with Breather Filter | eBay

To summarize the problem, the hole that returns oil from the valve cover to the crank case doesn't work when the crank case is pressurized. Crank pressure is usually caused by the "blow by" pressure of combustion that escapes around the piston rings into the crank case. Turbos and old engines exacerbate this issue.

The pressure is so high that oil that is supposed to return to the crank case via gravity is blown back into the valve cover from the crank pressure. What to do?

The current solutions have included:

--add copper mesh to convert oil vapor to liquid so it will drain back down the tube

--remove the center baffle

--open the breather hole at the valve cover

--add a catch can that routed from both valve cover outlets

--allofit

I'm pretty sure my problem was "terminal" by the time I'd even gotten to the track, so "allofit" wouldn't have worked anyway. MT.net member (Marlon? I'm terrible with names) showed me his immaculate turbo setup with methane injection, and told me he'd had the same issues.

His solution was the catch can with routing from both ports. The big difference with his solution was that he basically said that the stock baffle system needs to be sealed to work. In other words, he took off all three plates, cleaned, and then resealed the whole shebang with high temp gasket sealer.

Hey, my tests all ended in failure but I thought I'd forward something that seemed to work. Also, if you're looking for a grand bargain in catch cans, look no further than this Asian wonder:

Black Aluminum Oil Reservoir Catch Can Tank with Breather Filter | eBay

Last edited by cordycord; 09-08-2014 at 01:11 AM. Reason: typo's

#78

mkturbo.com

iTrader: (24)

Join Date: May 2006

Location: Charleston SC

Posts: 15,176

Total Cats: 1,680

This issue has been the focus of the last two weeks, and my Saturday at Laguna Seca. CRAP!

To summarize the problem, the hole that returns oil from the valve cover to the crank case doesn't work when the crank case is pressurized. Crank pressure is usually caused by the "blow by" pressure of combustion that escapes around the piston rings into the crank case. Turbos and old engines exacerbate this issue.

The pressure is so high that oil that is supposed to return to the crank case via gravity is blown back into the valve cover from the crank pressure. What to do?

The current solutions have included:

--add copper mesh to convert oil vapor to liquid so it will drain back down the tube

--remove the center baffle

--open the breather hole at the valve cover

--add a catch can that routed from both valve cover outlets

--allofit

I'm pretty sure my problem was "terminal" by the time I'd even gotten to the track, so "allofit" wouldn't have worked anyway. MT.net member (Marlon? I'm terrible with names) showed me his immaculate turbo setup with methane injection, and told me he'd had the same issues.

His solution was the catch can with routing from both ports. The big difference with his solution was that he basically said that the stock baffle system needs to be sealed to work. In other words, he took off all three plates, cleaned, and then resealed the whole shebang with high temp gasket sealer.

Hey, my tests all ended in failure but I thought I'd forward something that seemed to work. Also, if you're looking for a grand bargain in catch cans, look no further than this Asian wonder:

Black Aluminum Oil Reservoir Catch Can Tank with Breather Filter | eBay

To summarize the problem, the hole that returns oil from the valve cover to the crank case doesn't work when the crank case is pressurized. Crank pressure is usually caused by the "blow by" pressure of combustion that escapes around the piston rings into the crank case. Turbos and old engines exacerbate this issue.

The pressure is so high that oil that is supposed to return to the crank case via gravity is blown back into the valve cover from the crank pressure. What to do?

The current solutions have included:

--add copper mesh to convert oil vapor to liquid so it will drain back down the tube

--remove the center baffle

--open the breather hole at the valve cover

--add a catch can that routed from both valve cover outlets

--allofit

I'm pretty sure my problem was "terminal" by the time I'd even gotten to the track, so "allofit" wouldn't have worked anyway. MT.net member (Marlon? I'm terrible with names) showed me his immaculate turbo setup with methane injection, and told me he'd had the same issues.

His solution was the catch can with routing from both ports. The big difference with his solution was that he basically said that the stock baffle system needs to be sealed to work. In other words, he took off all three plates, cleaned, and then resealed the whole shebang with high temp gasket sealer.

Hey, my tests all ended in failure but I thought I'd forward something that seemed to work. Also, if you're looking for a grand bargain in catch cans, look no further than this Asian wonder:

Black Aluminum Oil Reservoir Catch Can Tank with Breather Filter | eBay

#79

So my results can't really be used to guide a group solution, but Marlon's solution that works at the track (all three baffles glued on, catch can) can be added to the mix.

#80

I've got the half baffles and a 1/2" hole going to the center baffle, with Scotch-Brite to catch the oil vapors. It still doesn't seem to be enough.

The "baffling" thing is that I'm still getting an oil leak. At first I thought was the turbo oil return at the pan. But then when I opened the hood this time I had oil all over the passenger firewall. It's only a guess, but a vacuum plug popped off from the intake manifold--facing forward--and the excess oil from the valve cover shot out of the vacuum port and right into the fan...my fan it tilted forward at about 45 degrees. I lost that "OH ****" feeling when I pressed the "go" pedal too, as my 10psi boost probably dropped to about 3psi.

edit--the theory is that oil mist is being sucked out of the valve cover and into the intake. There, it's being shot out of the vacuum line right into the fan, or into the engine where it's fouling my plugs.

BTW, I'm running full baffles with 7/16" hole on the exhaust side and 1/2 baffles on the intake side.

The plan--rig up a vented oil catch can tomorrow, with lines coming from both valve cover holes.

Does that sound crazy, or should I look somewhere else? The goal--a fun Laguna Seca weekend without the need to open the hood.

The "baffling" thing is that I'm still getting an oil leak. At first I thought was the turbo oil return at the pan. But then when I opened the hood this time I had oil all over the passenger firewall. It's only a guess, but a vacuum plug popped off from the intake manifold--facing forward--and the excess oil from the valve cover shot out of the vacuum port and right into the fan...my fan it tilted forward at about 45 degrees. I lost that "OH ****" feeling when I pressed the "go" pedal too, as my 10psi boost probably dropped to about 3psi.

edit--the theory is that oil mist is being sucked out of the valve cover and into the intake. There, it's being shot out of the vacuum line right into the fan, or into the engine where it's fouling my plugs.

BTW, I'm running full baffles with 7/16" hole on the exhaust side and 1/2 baffles on the intake side.

The plan--rig up a vented oil catch can tomorrow, with lines coming from both valve cover holes.

Does that sound crazy, or should I look somewhere else? The goal--a fun Laguna Seca weekend without the need to open the hood.