Crankshaft hard to turn by hand after rebuild

#1

Allright, here we go again.

I did the big mistake of cleaning a while back my garage, and throwing in a bin all the crankshaft caps in a bucket (from three different engine blocks).

Now, after about a year, I decided to hands on and build one of the blocks. Checked for everything, gasket seal kit, piston rings, rod bearings, metal head gasket, etc, but everything is on a halt now.

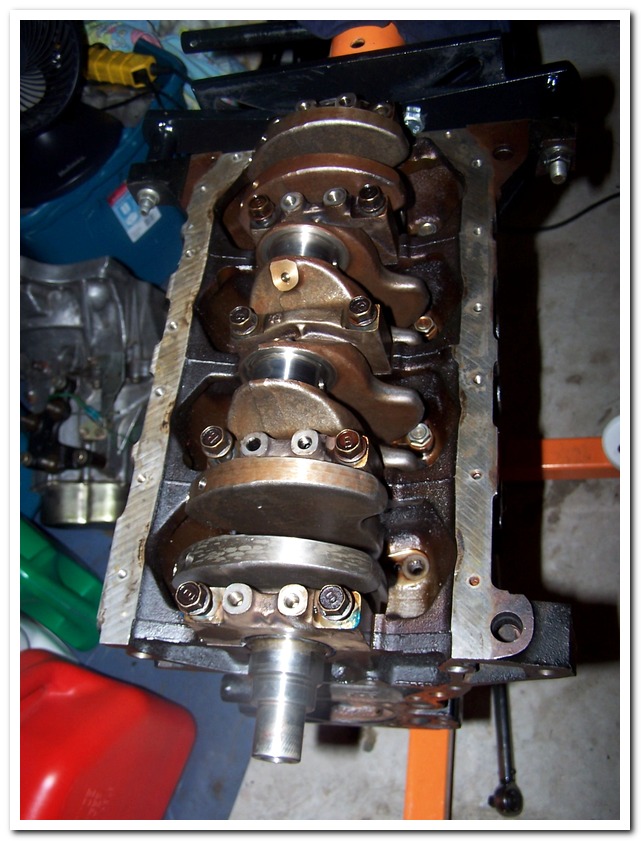

Yesterday I finished installing the crankshaft bearings, crankshaft, thrust washer, etc, and when I torqued everything down in 3 stage sequence to 10 foot of torque, the crank would not rotate. There is nothing else on the block, only the crank, and I recall it should rotate freely with minimal resistance. The bearings are King STD, lubed all moving parts with fresh engine oil, all caps are facing toward the front of the engine, and they are in their corresponding number locations.

Noticing things were not working right, grabbed another crankshaft, and the same deal, very hard to turn by hand, and no crankshaft play at all.

I have one thing, I am not sure if the caps used are from that engine block.

Does the crankshaft caps have to be from that specific engine block?

And if not, Is there an affordable easy way to get it to work?

I heard of inline boring, but not sure if its a good idea or not.

I did the big mistake of cleaning a while back my garage, and throwing in a bin all the crankshaft caps in a bucket (from three different engine blocks).

Now, after about a year, I decided to hands on and build one of the blocks. Checked for everything, gasket seal kit, piston rings, rod bearings, metal head gasket, etc, but everything is on a halt now.

Yesterday I finished installing the crankshaft bearings, crankshaft, thrust washer, etc, and when I torqued everything down in 3 stage sequence to 10 foot of torque, the crank would not rotate. There is nothing else on the block, only the crank, and I recall it should rotate freely with minimal resistance. The bearings are King STD, lubed all moving parts with fresh engine oil, all caps are facing toward the front of the engine, and they are in their corresponding number locations.

Noticing things were not working right, grabbed another crankshaft, and the same deal, very hard to turn by hand, and no crankshaft play at all.

I have one thing, I am not sure if the caps used are from that engine block.

Does the crankshaft caps have to be from that specific engine block?

And if not, Is there an affordable easy way to get it to work?

I heard of inline boring, but not sure if its a good idea or not.

#2

Allright, here we go again.

I did the big mistake of cleaning a while back my garage, and throwing in a bin all the crankshaft caps in a bucket (from three different engine blocks).

Now, after about a year, I decided to hands on and build one of the blocks. Checked for everything, gasket seal kit, piston rings, rod bearings, metal head gasket, etc, but everything is on a halt now.

Yesterday I finished installing the crankshaft bearings, crankshaft, thrust washer, etc, and when I torqued everything down in 3 stage sequence to 10 foot of torque, the crank would not rotate. There is nothing else on the block, only the crank, and I recall it should rotate freely with minimal resistance. The bearings are King STD, lubed all moving parts with fresh engine oil, all caps are facing toward the front of the engine, and they are in their corresponding number locations.

Noticing things were not working right, grabbed another crankshaft, and the same deal, very hard to turn by hand, and no crankshaft play at all.

I have one thing, I am not sure if the caps used are from that engine block.

Does the crankshaft caps have to be from that specific engine block?

Yes.

And if not, Is there an affordable easy way to get it to work?

I heard of inline boring, but not sure if its a good idea or not.

I did the big mistake of cleaning a while back my garage, and throwing in a bin all the crankshaft caps in a bucket (from three different engine blocks).

Now, after about a year, I decided to hands on and build one of the blocks. Checked for everything, gasket seal kit, piston rings, rod bearings, metal head gasket, etc, but everything is on a halt now.

Yesterday I finished installing the crankshaft bearings, crankshaft, thrust washer, etc, and when I torqued everything down in 3 stage sequence to 10 foot of torque, the crank would not rotate. There is nothing else on the block, only the crank, and I recall it should rotate freely with minimal resistance. The bearings are King STD, lubed all moving parts with fresh engine oil, all caps are facing toward the front of the engine, and they are in their corresponding number locations.

Noticing things were not working right, grabbed another crankshaft, and the same deal, very hard to turn by hand, and no crankshaft play at all.

I have one thing, I am not sure if the caps used are from that engine block.

Does the crankshaft caps have to be from that specific engine block?

Yes.

And if not, Is there an affordable easy way to get it to work?

I heard of inline boring, but not sure if its a good idea or not.

#4

If you ever have to use other caps or get them mixed up, you will need to have the block align bored along the crankshaft axis. It is possible some caps may need resizing.

It was an unfortunate mistake, but a problem that can be fixed. I do not recall what it cost me to have it done. When you switch over to main studs, it should be done anyways.

It was an unfortunate mistake, but a problem that can be fixed. I do not recall what it cost me to have it done. When you switch over to main studs, it should be done anyways.

Last edited by miata2fast; 06-22-2013 at 01:44 PM.

#8

I completely dropped the ball on this one. Yesterday I spent around 3 hours reading the manual back to back to see if I was missing anything. Looked everywhere on the block for anything restricting it from moving, surfing the internet until someone posted about the correct caps in another forum. Complete tunnel vision, out of the park, I know...

Oh well, got some extra work, i will fix it though.

Oh well, got some extra work, i will fix it though.

#10

No, I did not.

I have done this before without taking any measurements. I do torque like its suppose to, check for crank play and amount of torque needed to rotate. According to specs it must be no more than 5 pounds of torque to spin freely. Doing the rebuild from a bad machine work done to it a while back.

I have done this before without taking any measurements. I do torque like its suppose to, check for crank play and amount of torque needed to rotate. According to specs it must be no more than 5 pounds of torque to spin freely. Doing the rebuild from a bad machine work done to it a while back.