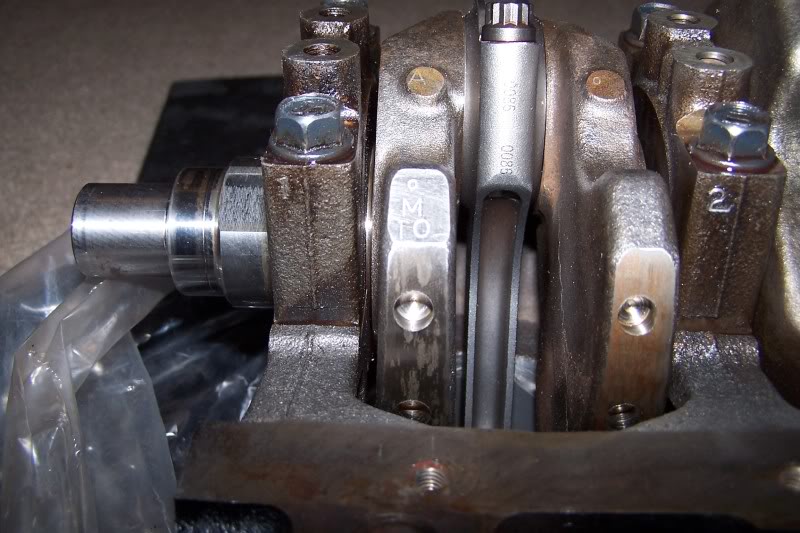

Left engine block with pistons and rods at machine shop

#21

Wirelessly posted

Dover is a machine shop that started doing headwork and they are the only place in town that can machine seats for larger valves which is why i went there but they just recently started boring engines so i can understand why they sent it out for assembly but its not right for them to not disclose info on who.

i talked to a few friends in town that do alot of car stuff and nobody has heard of this place that i know

Dover is a machine shop that started doing headwork and they are the only place in town that can machine seats for larger valves which is why i went there but they just recently started boring engines so i can understand why they sent it out for assembly but its not right for them to not disclose info on who.

i talked to a few friends in town that do alot of car stuff and nobody has heard of this place that i know

#22

Senior Member

Thread Starter

iTrader: (1)

Join Date: Oct 2008

Location: Trailer County

Posts: 531

Total Cats: -18

I took the engine to the machine shop again and talked to the owner one on one, his name is Luis. The difficult thing is he is there half the time and has two other guys Richie who works on cylinder heads and Joe who is front desk customer service.

Joe is clueless about any machine work, etc so if you walk in and see him in Cloud 9 it may give you the perception this shop does not know shyt. I am used to walking into machine shops and the guy at front desk to the one who cleans the toilets all know about valve lapping, forged pistons, main bearing, street lingual like crank walk etc.

Richie he is very good on cylinder heads and can talk to you about it for hours, but dont ask him about plasticing, block balancing, ring gap etc because he as well does not know. The only guru there is the owner on engine blocks, Luis, and he is there half the time, shows up to assemble and then his job is done for the day.

Back to the subject, the owner was waiting for me as I told him I was going over there this afternoon. He could feel the minor movement from the crankshaft, it does have some play. He had a feeler gauge and it had .007" of crankplay. He showed me this computer with a software if I recall called AERA. We went to the main floor and showed me a machine that, according to him, cost him 35,000 and is the only one that does identical cylinder bores by computer. He stated he does not do cranks because he does not have the machine. His main core is cylinder heads and most of his clients are dealers/fleet cars.

My old engine block, the one I bent three rods and the oil pump blew up, had .006" of crankplay (once again on the old crank/engine block). He noticed I was a little hesitant and question his work and that if I felt that way to just leave the other engine block and he would do everything again for free as long as I was satisfied and happy with the work done. On the old engine block I can move the crank a little by hand, it is very minor, maybe the space equal to 2 pages put together.

He showed me the print out showing me he followed the specs shown by the computer which are .0032" to .0111" and that it was good as it has .007" maybe almost .006". He gave me his word the crank will not give me any problems and the job was done by the book. Later he showed me the address of the technician who worked on the block and his phone number and if I felt unsure I could call "Extreme Racing" from the shop.

Here is the kicker... The shop closed when the economy collapsed so he works from home. The guy who worked on the crankshaft and ring gap mainly works with Mustangs. Luis stated the company, Extreme Racing, went out of business because of the economy and not because he is not a good engine builder. At the same time the owner of Dover Cylinder Head machine shop said the only reason he is still making a living is do to the dealers fleet cars.

He said with the .007" crankplay, I have to take in consideration that it has no oil which will make end play much less. Once all other components like flywheel, clutch and everything is in place the crank will have very minimal play.

Thats it for now folks, I will assemble and lets see how much it will last.

Joe is clueless about any machine work, etc so if you walk in and see him in Cloud 9 it may give you the perception this shop does not know shyt. I am used to walking into machine shops and the guy at front desk to the one who cleans the toilets all know about valve lapping, forged pistons, main bearing, street lingual like crank walk etc.

Richie he is very good on cylinder heads and can talk to you about it for hours, but dont ask him about plasticing, block balancing, ring gap etc because he as well does not know. The only guru there is the owner on engine blocks, Luis, and he is there half the time, shows up to assemble and then his job is done for the day.

Back to the subject, the owner was waiting for me as I told him I was going over there this afternoon. He could feel the minor movement from the crankshaft, it does have some play. He had a feeler gauge and it had .007" of crankplay. He showed me this computer with a software if I recall called AERA. We went to the main floor and showed me a machine that, according to him, cost him 35,000 and is the only one that does identical cylinder bores by computer. He stated he does not do cranks because he does not have the machine. His main core is cylinder heads and most of his clients are dealers/fleet cars.

My old engine block, the one I bent three rods and the oil pump blew up, had .006" of crankplay (once again on the old crank/engine block). He noticed I was a little hesitant and question his work and that if I felt that way to just leave the other engine block and he would do everything again for free as long as I was satisfied and happy with the work done. On the old engine block I can move the crank a little by hand, it is very minor, maybe the space equal to 2 pages put together.

He showed me the print out showing me he followed the specs shown by the computer which are .0032" to .0111" and that it was good as it has .007" maybe almost .006". He gave me his word the crank will not give me any problems and the job was done by the book. Later he showed me the address of the technician who worked on the block and his phone number and if I felt unsure I could call "Extreme Racing" from the shop.

Here is the kicker... The shop closed when the economy collapsed so he works from home. The guy who worked on the crankshaft and ring gap mainly works with Mustangs. Luis stated the company, Extreme Racing, went out of business because of the economy and not because he is not a good engine builder. At the same time the owner of Dover Cylinder Head machine shop said the only reason he is still making a living is do to the dealers fleet cars.

He said with the .007" crankplay, I have to take in consideration that it has no oil which will make end play much less. Once all other components like flywheel, clutch and everything is in place the crank will have very minimal play.

Thats it for now folks, I will assemble and lets see how much it will last.

#25

If the engine's disassembled, you can do it with a feeler gauge.

--Ian

#26

Sounds like bullshit.

If you dont leave there feeling good about everything, its bullshit.

Putting all the other stuff on there doesnt change crank play. It will make a **** ton harder to measure witht he added resistance and weight, but the play is still there.

I just say that because I read this entire thread and none of it made me feel good.

If you dont leave there feeling good about everything, its bullshit.

Putting all the other stuff on there doesnt change crank play. It will make a **** ton harder to measure witht he added resistance and weight, but the play is still there.

I just say that because I read this entire thread and none of it made me feel good.

#27

Senior Member

Thread Starter

iTrader: (1)

Join Date: Oct 2008

Location: Trailer County

Posts: 531

Total Cats: -18

I agree.

The next question that arises; How will I know if they really balanced it or not if they took the block to another shop and got no paperwork of each pistons/rod weight.

He did not state anything about how much was removed from each rod, or piston, nothing about the crankshaft, if any material/weight was taken out. At least I look at the crankshaft and does not seem anything was removed to balance it. At no point he stated how much was the gap...

The crankshaft just looks clean.

This is what I am going to do, put a stop on the payment for the $150.00 I got charged for balancing the engine block.

The strange thing is, he states if I feel that the work done does not seem right, to leave the other block and they will redo everything again. One mistake I did was not to mark on some hidden corner if the crankshaft I left was the one they put back.

In a case like this, What can I do in terms of claims?

Note: I paid with credit card.

The next question that arises; How will I know if they really balanced it or not if they took the block to another shop and got no paperwork of each pistons/rod weight.

He did not state anything about how much was removed from each rod, or piston, nothing about the crankshaft, if any material/weight was taken out. At least I look at the crankshaft and does not seem anything was removed to balance it. At no point he stated how much was the gap...

The crankshaft just looks clean.

This is what I am going to do, put a stop on the payment for the $150.00 I got charged for balancing the engine block.

The strange thing is, he states if I feel that the work done does not seem right, to leave the other block and they will redo everything again. One mistake I did was not to mark on some hidden corner if the crankshaft I left was the one they put back.

In a case like this, What can I do in terms of claims?

Note: I paid with credit card.

#30

Senior Member

Thread Starter

iTrader: (1)

Join Date: Oct 2008

Location: Trailer County

Posts: 531

Total Cats: -18

I got charged 150.00 for engine block balancing and not a drop of paperwork or visual proof that it was balanced.

It is impossible all the rods and pistons are the exact same weight and that he did not remove any weight from them.

It is impossible all the rods and pistons are the exact same weight and that he did not remove any weight from them.

#31

Senior Member

Thread Starter

iTrader: (1)

Join Date: Oct 2008

Location: Trailer County

Posts: 531

Total Cats: -18

You know what **** it...

I am done getting ripped off, I will go and be one on one with this ****, will ask the tinest little bit, and if not (as I already talked to the credit scam card company to fix Dys Shyt...

No BS, I will tell him front in his face he is full of shyt, ALL I goyt to do is plan ot mya escape plan, LOL!

I am done getting ripped off, I will go and be one on one with this ****, will ask the tinest little bit, and if not (as I already talked to the credit scam card company to fix Dys Shyt...

No BS, I will tell him front in his face he is full of shyt, ALL I goyt to do is plan ot mya escape plan, LOL!

#33

2 Props,3 Dildos,& 1 Cat

iTrader: (8)

Join Date: Jun 2005

Location: Fake Virginia

Posts: 19,338

Total Cats: 573

You know what **** it...

I am done getting ripped off, I will go and be one on one with this ****, will ask the tinest little bit, and if not (as I already talked to the credit scam card company to fix Dys Shyt...

No BS, I will tell him front in his face he is full of shyt, ALL I goyt to do is plan ot mya escape plan, LOL!

I am done getting ripped off, I will go and be one on one with this ****, will ask the tinest little bit, and if not (as I already talked to the credit scam card company to fix Dys Shyt...

No BS, I will tell him front in his face he is full of shyt, ALL I goyt to do is plan ot mya escape plan, LOL!

#35

Senior Member

Thread Starter

iTrader: (1)

Join Date: Oct 2008

Location: Trailer County

Posts: 531

Total Cats: -18

I find strange those markings on the crankshaft, the letter A, M and a number 10. Although I think its normal on all crankshafts as the other one I got has the A, but not the M nor the number 10.

The forged pistons are 84mm, the chambers from factory are 83mm, How much must be bored for proper clearance? It seems to me the piston is to tight, I have to apply some force to move the crankshaft with all components installed.

Are the clearance the same with 84mm cast pistons compared to forged?

I have heard forged pistons expand and the clearance varies.

#37

Senior Member

Thread Starter

iTrader: (1)

Join Date: Oct 2008

Location: Trailer County

Posts: 531

Total Cats: -18

I just finished talking with the owner.

It turns out they never balanced the block...

I got to go back to the store so I can get a refund of 150.00.

Check this out, I left the block for assembly and the knucleheads left the oil jets out! They had to remove and re-install everything to put back the oil jets.

Honestly, I am going to tear it down, I will buy my own freakin tools and re-measure everything and do it myself.

It turns out they never balanced the block...

I got to go back to the store so I can get a refund of 150.00.

Check this out, I left the block for assembly and the knucleheads left the oil jets out! They had to remove and re-install everything to put back the oil jets.

Honestly, I am going to tear it down, I will buy my own freakin tools and re-measure everything and do it myself.

Last edited by mazpr; 09-07-2010 at 02:03 PM.

#38

The oil jets can be installed without removing anything, unless you meant removing the oil pan/mbsp as 'everything'. Though my engine builder is great, I don't want to give him anymore parts than absolutely necessary. So, for the past two times I have had him assemble the block/crank/pistons and once I get it home, I install the oil jets myself.

--Ferdi

--Ferdi

#39

I really dunno about all this man, I think I'd use the $150 u just saved, and bring the motor as is to a competent place an dhave them recehck everything. let the guy know exactly where your coming from, and that if they are willing to tear apart/check/reassemble and give their stamp of approval--the fault now lies on their backs.

Hopefull u end up spending the same total, but can sleep at night if these people "sign off" on the work that was done

Hopefull u end up spending the same total, but can sleep at night if these people "sign off" on the work that was done