Please not another crankcase ventilation thread.

#145

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,026

Total Cats: 6,592

Our basement also contains a huge tape / film vault, parking spaces for nine news vans, and a mysterious pipe coming out of the wall which scares me.

Sidebar: I've never liked how the manufacturers of all industrial engines apply a uniform spray of paint over the entire finished assembly, including all the wiring harnesses, hoses, filters, sensors, bolts, etc. It looks sloppy to me, like what you'd expect of a $300 rebuilt VW engine from Sears (back when they sold such things), as opposed to a brand new top-of-the-line engine costing well over $100k.

They all seem to do it, even Merc:

#148

Moderator

iTrader: (12)

Join Date: Nov 2008

Location: Tampa, Florida

Posts: 20,652

Total Cats: 3,011

Welp. It's 3.3 times larger than the Miata engine and runs 16.3:1 to 17:1 compression ratio and 15 to 40 lbs of boost. If it were to be maxxed out at 2800 rpm (probably runs steady under a load at 2100 rpm as a generator), it would make as much volume of air as a Miata engine running 9200 rpm (or 6,930rpm in Miata volume at 2100rpm under a full load). Does the singular breather hose extra large to you? Do you see an air inlet?

And since when are race teams running PCV valves? Please cite examples. They run vacuum pumps to reduce air pressure in the crankcase on certain types of race engines, yes. They do not run PCV valves, which only function when the engine is not under a load and making any significant blow-by. Arguing vacuum pumps and PCV valves at the same time is not the answer. They are two different devices for two different purposes. Vacuum pumps are for horsepower and PCV valves are for the EPA.

And since when are race teams running PCV valves? Please cite examples. They run vacuum pumps to reduce air pressure in the crankcase on certain types of race engines, yes. They do not run PCV valves, which only function when the engine is not under a load and making any significant blow-by. Arguing vacuum pumps and PCV valves at the same time is not the answer. They are two different devices for two different purposes. Vacuum pumps are for horsepower and PCV valves are for the EPA.

#149

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,026

Total Cats: 6,592

There are really two separate issues which I can see here:

One is the fact that there are some blowby gasses which need to be dealt with so that they do not cause the crankcase to become pressurized.

The other is that it is beneficial to purge the crankcase of all manner of random stuff floating around airborne inside of it, such as moisture and combustion byproducts. Actually purging the crankcase of said things is different from just allowing them to escape under their own pressure, and presupposes the use of a means of active ventilation, eg: the forced withdrawl of "foul" air, with a means provided for the replenishment of the same volume of fresh air.

Not making any assertions here, just speculating.

?

While I've never noticed its running speed (we measure alternator frequency, not crank RPM), most gennys I've come across run at either 1,800 or 3,600 RPM, and I assume this one is the

Last edited by Joe Perez; 11-09-2015 at 11:55 PM.

#150

...

Sidebar: I've never liked how the manufacturers of all industrial engines apply a uniform spray of paint over the entire finished assembly, including all the wiring harnesses, hoses, filters, sensors, bolts, etc. It looks sloppy to me, like what you'd expect of a $300 rebuilt VW engine from Sears (back when they sold such things), as opposed to a brand new top-of-the-line engine costing well over $100k.

They all seem to do it, even Merc:...

Sidebar: I've never liked how the manufacturers of all industrial engines apply a uniform spray of paint over the entire finished assembly, including all the wiring harnesses, hoses, filters, sensors, bolts, etc. It looks sloppy to me, like what you'd expect of a $300 rebuilt VW engine from Sears (back when they sold such things), as opposed to a brand new top-of-the-line engine costing well over $100k.

They all seem to do it, even Merc:...

Also PCV valves drop coolant temps, raise efficiency, increase fuel economy, slow fatigue life, reverse wear, and eliminate shaft play from the turbo if any is present.

#151

And since when are race teams running PCV valves? Please cite examples. They run vacuum pumps Dry sumps to reduce air pressure in the crankcase on certain types of race engines, yes. They do not run PCV valves, which only function when the engine is not under a load and making any significant blow-by. Arguing vacuum pumps and PCV valves at the same time is not the answer. They are two different devices for two different purposes. Vacuum pumps are for horsepower and PCV valves are for the EPA.

__________________

OG Racing

Your Source For Motorsports Safety Equipment

WWW.OGRACING.COM

800.934.9112

703.430.3303

info@ogracing.com

OG Racing

Your Source For Motorsports Safety Equipment

WWW.OGRACING.COM

800.934.9112

703.430.3303

info@ogracing.com

#152

Moderator

iTrader: (12)

Join Date: Nov 2008

Location: Tampa, Florida

Posts: 20,652

Total Cats: 3,011

That engine won't turn over 3,000 under its own power unless something is very wrong. If you have a phototach you can see what it is actually running.

Side note - I find it interesting the radiator is set up to vent the hot air into the room, unless the fan is set up to blow the other way. That could make for a hot room in a couple of hours. Kinda like how Joe P. heats his apartment...

Side note - I find it interesting the radiator is set up to vent the hot air into the room, unless the fan is set up to blow the other way. That could make for a hot room in a couple of hours. Kinda like how Joe P. heats his apartment...

#153

Moderator

iTrader: (12)

Join Date: Nov 2008

Location: Tampa, Florida

Posts: 20,652

Total Cats: 3,011

#154

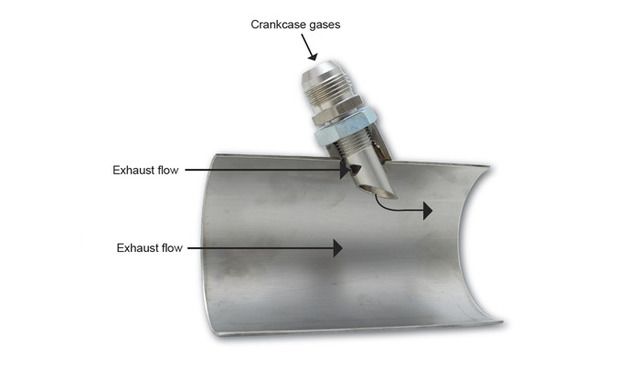

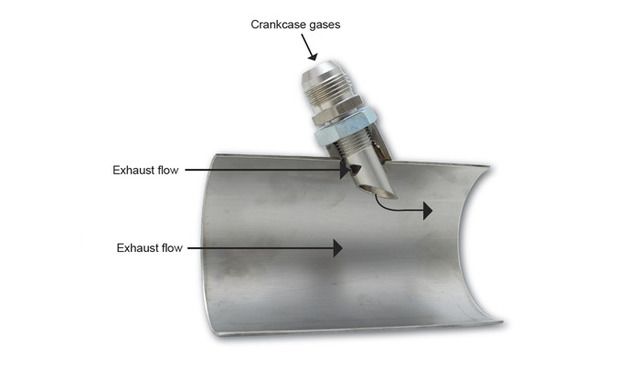

i did a little experiment that involves the vibrant crank case evacuation kit. remember i have a ls1 and i can listen to drag racers tricks with a little more confidence.

i removed the pcv off my engine due to a ton of oil that gets dumped into the intake. i replaced it with a Joes-racing-dry-sump-catch-can. after driving around with it, i noticed the catch can would vent off some really nasty smells and fill the cab with blow by/exhaust. so i went looking for an alternate arrangement. i found on yellow bullet (drag forum) that guys where using the crank case evacuation kits to pull a vacuum. i don't care about the added hp of having a crankcase under vacuum. I just wanted the blow by to be vented somewhere not under my hood, i gave it a shot.

i welded the kit into my headers, added a check valve, and tested it. it pulled a large vacuum under deceleration. it pulled about 5 in of vac. worried i had too much back pressure i moved the kit and plumbed it 12" away from the exhaust tip. behind the muffler. same thing 5in under deceleration. under idle and driving around it would pull between 1 and .5 in. seeing the vac i felt confident that the air was moving the the correct direction and was happy to test it out on a track.

I took the car out to Daytona this weekend. thing worked great, fumes where gone. the only problem was the line was so long it filled up with oil. coming out of turn 5 i blew 1/2qt of oil threw my exhaust. huge bellow of smoke and got blacked flagged. i had to go back to the old catch can to finish my runs. i'm going to add an oil air separator and continue using the evac kit.

i removed the pcv off my engine due to a ton of oil that gets dumped into the intake. i replaced it with a Joes-racing-dry-sump-catch-can. after driving around with it, i noticed the catch can would vent off some really nasty smells and fill the cab with blow by/exhaust. so i went looking for an alternate arrangement. i found on yellow bullet (drag forum) that guys where using the crank case evacuation kits to pull a vacuum. i don't care about the added hp of having a crankcase under vacuum. I just wanted the blow by to be vented somewhere not under my hood, i gave it a shot.

i welded the kit into my headers, added a check valve, and tested it. it pulled a large vacuum under deceleration. it pulled about 5 in of vac. worried i had too much back pressure i moved the kit and plumbed it 12" away from the exhaust tip. behind the muffler. same thing 5in under deceleration. under idle and driving around it would pull between 1 and .5 in. seeing the vac i felt confident that the air was moving the the correct direction and was happy to test it out on a track.

I took the car out to Daytona this weekend. thing worked great, fumes where gone. the only problem was the line was so long it filled up with oil. coming out of turn 5 i blew 1/2qt of oil threw my exhaust. huge bellow of smoke and got blacked flagged. i had to go back to the old catch can to finish my runs. i'm going to add an oil air separator and continue using the evac kit.

#155

I have a LS1 so my system is a little different. i disconnected the PCV system and threw it away. i then ran the lines off the valve cover into the vibrant system, with a check valve. I plugged up the old intake PCV lines.

__________________

OG Racing

Your Source For Motorsports Safety Equipment

WWW.OGRACING.COM

800.934.9112

703.430.3303

info@ogracing.com

OG Racing

Your Source For Motorsports Safety Equipment

WWW.OGRACING.COM

800.934.9112

703.430.3303

info@ogracing.com

Last edited by OGRacing; 11-09-2015 at 05:08 PM.

#156

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,026

Total Cats: 6,592

That engine won't turn over 3,000 under its own power unless something is very wrong. If you have a phototach you can see what it is actually running.

Side note - I find it interesting the radiator is set up to vent the hot air into the room, unless the fan is set up to blow the other way. That could make for a hot room in a couple of hours. Kinda like how Joe P. heats his apartment...

Side note - I find it interesting the radiator is set up to vent the hot air into the room, unless the fan is set up to blow the other way. That could make for a hot room in a couple of hours. Kinda like how Joe P. heats his apartment...

I assume this one is running at 1,800, which I think is what I said.

The whole room is VTA. All of our generators are set up this way, including the one up on the 79th floor of the Empire State Building. One side of the radiator is ducted directly to the outside of the building, and then there's a louvered window of roughly equal size beside it. Doesn't really matter which way it's set up, aside from the fact that if the radiator is set to exhaust warm air into the room, the exhaust louvers will open up by themselves when it's in operation, which removes a potential failure point. Heat is kind of irrelevant- even with hearing protection it's difficult to be in the same room when it's running.

Fun fact: during the blackout of '65, it was discovered that the fuel transfer pump, which brings diesel up from street level to the tank on the 79th floor, was not powered by the generator.

Last edited by Joe Perez; 11-09-2015 at 06:51 PM.

#157

Welp. It's 3.3 times larger than the Miata engine and runs 16.3:1 to 17:1 compression ratio and 15 to 40 lbs of boost. If it were to be maxxed out at 2800 rpm (probably runs steady under a load at 2100 rpm as a generator), it would make as much volume of air as a Miata engine running 9200 rpm (or 6,930rpm in Miata volume at 2100rpm under a full load). Does the singular breather hose extra large to you? Do you see an air inlet?

And since when are race teams running PCV valves? Please cite examples. They run vacuum pumps to reduce air pressure in the crankcase on certain types of race engines, yes. They do not run PCV valves, which only function when the engine is not under a load and making any significant blow-by. Arguing vacuum pumps and PCV valves at the same time is not the answer. They are two different devices for two different purposes. Vacuum pumps are for horsepower and PCV valves are for the EPA.

And since when are race teams running PCV valves? Please cite examples. They run vacuum pumps to reduce air pressure in the crankcase on certain types of race engines, yes. They do not run PCV valves, which only function when the engine is not under a load and making any significant blow-by. Arguing vacuum pumps and PCV valves at the same time is not the answer. They are two different devices for two different purposes. Vacuum pumps are for horsepower and PCV valves are for the EPA.

Its been awhile since we lived on a boat in the Bahamas for 10 years and I forgot, but Joe is right that Gens run at 1800 or 3600 rpm to achieve 60hz. The old Onans used to run at 3600 but that was along time ago, our Northern lights ran at 1800 and as far as I know all the later ones do too, much less noise. I would be surprised if a stationary gen diesel running at 1800 sees very high turbo psi, even so they are running much better ring setup on the pistons then our little 1mm thick moly rings.

#158

Cue Deezums calling Caterpillar engineers "stupid" for it being VTA instead of sucking the oil vapor and contaminants into the engine to make hard carbon deposits on the valves and pistons.

"But how does it breathe in fresh air?"

It doesn't. It is an artificial construct to say that it needs to. What it does need is to be able to release the operational blow-by pressure from the crankcase so that the seals are not pushed out.

And that Cummins in the other post is a 5.9. One version of that particular series occasionally had problems with leaky timing cover seals. Its breather tube is on the side on the pushrod cover and hangs down behind the little blue hoses. There is no inlet for "fresh air."

"But how does it breathe in fresh air?"

It doesn't. It is an artificial construct to say that it needs to. What it does need is to be able to release the operational blow-by pressure from the crankcase so that the seals are not pushed out.

And that Cummins in the other post is a 5.9. One version of that particular series occasionally had problems with leaky timing cover seals. Its breather tube is on the side on the pushrod cover and hangs down behind the little blue hoses. There is no inlet for "fresh air."

This is a turbodiesel meant to run a fixed RPM.

Where, exactly, dear six, is the intake vacuum to come from?

#159

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,026

Total Cats: 6,592

From the restrictor plate between the compressor inlet and the air filter.

(I keed, I keed...)

But seriously, if you can design an air filter which prevents any sort of vacuum from emerging in the intake pipe while the engine is running at full-tilt-boogie, I can get you a rather lucrative job.

(I keed, I keed...)

But seriously, if you can design an air filter which prevents any sort of vacuum from emerging in the intake pipe while the engine is running at full-tilt-boogie, I can get you a rather lucrative job.