Weld repair cylinder head?

#1

Elite Member

Thread Starter

Join Date: Jul 2005

Location: Anacortes, WA

Posts: 2,478

Total Cats: 144

Well after nearly 4 years on one motor a cascade of failures and errors caused me to detonate the motor to death. Blew a hole in a piston.

CAQS failure caused extreme advance somehow. Knock sensor went flaky and my 02 sensor has been flaky for a while but I’ve been running open loop. Failure occurred approaching 140mph on the front straight at Pacific Raceway.

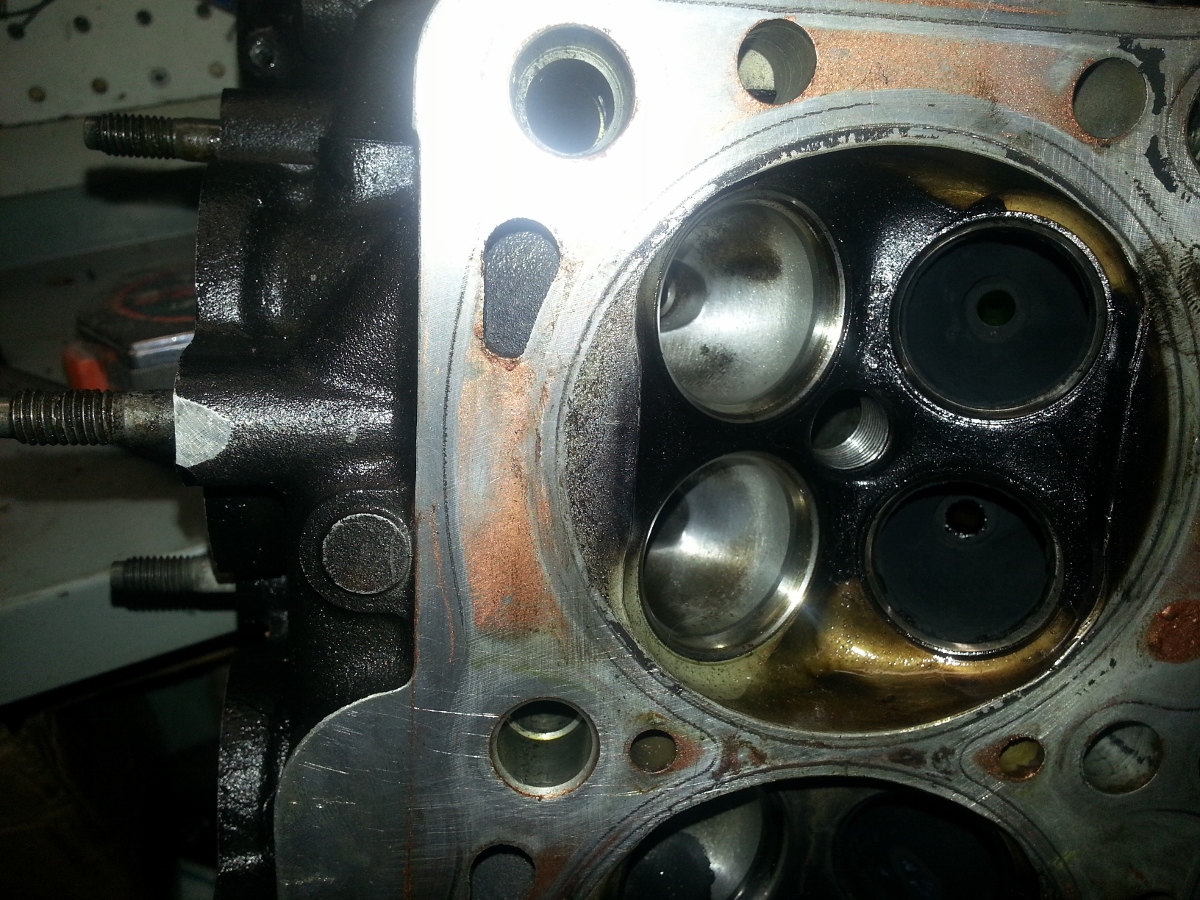

I rebuilt the bottom end and it seems to be running fine but under full load I’m pressurizing the coolant somehow. Head is flat gasket shows no leaks but the combustion chamber on the head definitely took a lot of abuse. The only thing I can figure is there is a crack somewhere here where I’m seeing the detonation marks going into the water jacket.

Currently bolting on a stock head with the stiffer valve springs moved over. But I’m wondering if this fully ported head is salvageable and if it is worth doing. Some searching shows some pretty extreme weld repair and re-construction of combustion chambers. Seems like if it is cracked here it wouldn’t be too hard to groove the crack out and fill with weld and re-finish.

CAQS failure caused extreme advance somehow. Knock sensor went flaky and my 02 sensor has been flaky for a while but I’ve been running open loop. Failure occurred approaching 140mph on the front straight at Pacific Raceway.

I rebuilt the bottom end and it seems to be running fine but under full load I’m pressurizing the coolant somehow. Head is flat gasket shows no leaks but the combustion chamber on the head definitely took a lot of abuse. The only thing I can figure is there is a crack somewhere here where I’m seeing the detonation marks going into the water jacket.

Currently bolting on a stock head with the stiffer valve springs moved over. But I’m wondering if this fully ported head is salvageable and if it is worth doing. Some searching shows some pretty extreme weld repair and re-construction of combustion chambers. Seems like if it is cracked here it wouldn’t be too hard to groove the crack out and fill with weld and re-finish.

#5

The Harley guys weld and reshape the combustion chamber. I have never heard of one failing. That mean it can be done. On the other hand every time I have something aluminum welded it twists and needs to be flattened again. Once that area is welded I bet there would need to be a good chunk of material removed to make the surface flat. I bet you're already at ideal CC specs now so that's not good.

In your shoes I would start over with a fresh head. I know its a shame to say goodby to good port work but sometimes that happens. Consider it a chance to make improvements based on current knowledge. VVT? Cams? CNC?

In your shoes I would start over with a fresh head. I know its a shame to say goodby to good port work but sometimes that happens. Consider it a chance to make improvements based on current knowledge. VVT? Cams? CNC?

#6

Cracks can be tough to find and it might take a few tries (weld, reshape, test) before it can hold pressure.

I'm lucky that my builder sees all his jobs as babies and the repair of this damage was just new parts from my end.

https://www.miataturbo.net/engine-pe...28/#post885540

Get the head tested and the leaks figured out first, unless you see an opportunity to improve on the porting/flow/profile from starting over/CNC, if so put the junk out for sale and never look back.

I'm lucky that my builder sees all his jobs as babies and the repair of this damage was just new parts from my end.

https://www.miataturbo.net/engine-pe...28/#post885540

Get the head tested and the leaks figured out first, unless you see an opportunity to improve on the porting/flow/profile from starting over/CNC, if so put the junk out for sale and never look back.

#8

I have heard of a lot of VW TDI people doing this because of the relative scarcity of OEM TDI heads.

TDI Cylinder Heads - TDIClub Forums

TDI Cylinder Heads - TDIClub Forums

#9

There are 2 aspects of the repair as I see it - Mechanical and water / combustion area sealing.

Its quite possible in addition to visible surface cracks, that the head has been distorted from detonation / excess pressure. So, I'd carefully check every machined face for flat and straightness - cylinder head/block face, intake and exhaust manifold surfaces. In addition to machined surface cracks and flatness, check cam bore alignment.

If all looks good, welding the cracks and refacing is an option. Again checking for welding induced distortion (especially the cam bore alignment) before machining.

To seal any small water leaks Bar's Leak products seem to work. Bar's Leaks & Rislone - Premium Automotive Chemicals

The actual product used was the HD Pelletized version. http://barsproducts.com/catalog/view...top-leak-plt11

Water leaking cure - Racing friends have used this product for excessively ported NA heads that seeped water into intake the ports (porous cast iron).

The process they used: leaking head was bolted to a spare block with a working block heater, rad hoses looped together to complete the water circuit, water pump powered by a small 110v AC motor using the vbelt, filled block and head with water and bar's leak. Block heater and water pump motor plugged in and left running over night. By morning no apparent leaking remained. (Your experience may vary depending on the location and crack repair success). Water flushed out, head ready to go with no apparent leaks. Ran several seasons with this approach.

I have also used Bar's Leak as a temporary repair on a road car with good success. 61 MGA head gasket water leak to exterior of engine (25 yr old gasket corroded).

Its quite possible in addition to visible surface cracks, that the head has been distorted from detonation / excess pressure. So, I'd carefully check every machined face for flat and straightness - cylinder head/block face, intake and exhaust manifold surfaces. In addition to machined surface cracks and flatness, check cam bore alignment.

If all looks good, welding the cracks and refacing is an option. Again checking for welding induced distortion (especially the cam bore alignment) before machining.

To seal any small water leaks Bar's Leak products seem to work. Bar's Leaks & Rislone - Premium Automotive Chemicals

The actual product used was the HD Pelletized version. http://barsproducts.com/catalog/view...top-leak-plt11

Water leaking cure - Racing friends have used this product for excessively ported NA heads that seeped water into intake the ports (porous cast iron).

The process they used: leaking head was bolted to a spare block with a working block heater, rad hoses looped together to complete the water circuit, water pump powered by a small 110v AC motor using the vbelt, filled block and head with water and bar's leak. Block heater and water pump motor plugged in and left running over night. By morning no apparent leaking remained. (Your experience may vary depending on the location and crack repair success). Water flushed out, head ready to go with no apparent leaks. Ran several seasons with this approach.

I have also used Bar's Leak as a temporary repair on a road car with good success. 61 MGA head gasket water leak to exterior of engine (25 yr old gasket corroded).

Last edited by 99Racer; 08-26-2014 at 09:52 AM.

#10

Elite Member

Thread Starter

Join Date: Jul 2005

Location: Anacortes, WA

Posts: 2,478

Total Cats: 144

There are 2 aspects of the repair as I see it - Mechanical and water / combustion area sealing.

Its quite possible in addition to visible surface cracks, that the head has been distorted from detonation / excess pressure. So, I'd carefully check every machined face for flat and straightness - cylinder head/block face, intake and exhaust manifold surfaces. In addition to machined surface cracks and flatness, check cam bore alignment.

If all looks good, welding the cracks and refacing is an option. Again checking for welding induced distortion (especially the cam bore alignment) before machining.

To seal any small water leaks Bar's Leak products seem to work. Bar's Leaks & Rislone - Premium Automotive Chemicals

The actual product used was the HD Pelletized version. Pelletized Heavy Duty Stop Leak (p/n PLT11) | Products | Bar's Leaks & Rislone - Premium Automotive Chemicals

Water leaking cure - Racing friends have used this product for excessively ported NA heads that seeped water into intake the ports (porous cast iron).

The process they used: leaking head was bolted to a spare block with a working block heater, rad hoses looped together to complete the water circuit, water pump powered by a small 110v AC motor using the vbelt, filled block and head with water and bar's leak. Block heater and water pump motor plugged in and left running over night. By morning no apparent leaking remained. (Your experience may vary depending on the location and crack repair success). Water flushed out, head ready to go with no apparent leaks. Ran several seasons with this approach.

I have also used Bar's Leak as a temporary repair on a road car with good success. 61 MGA head gasket water leak to exterior of engine (25 yr old gasket corroded).

Its quite possible in addition to visible surface cracks, that the head has been distorted from detonation / excess pressure. So, I'd carefully check every machined face for flat and straightness - cylinder head/block face, intake and exhaust manifold surfaces. In addition to machined surface cracks and flatness, check cam bore alignment.

If all looks good, welding the cracks and refacing is an option. Again checking for welding induced distortion (especially the cam bore alignment) before machining.

To seal any small water leaks Bar's Leak products seem to work. Bar's Leaks & Rislone - Premium Automotive Chemicals

The actual product used was the HD Pelletized version. Pelletized Heavy Duty Stop Leak (p/n PLT11) | Products | Bar's Leaks & Rislone - Premium Automotive Chemicals

Water leaking cure - Racing friends have used this product for excessively ported NA heads that seeped water into intake the ports (porous cast iron).

The process they used: leaking head was bolted to a spare block with a working block heater, rad hoses looped together to complete the water circuit, water pump powered by a small 110v AC motor using the vbelt, filled block and head with water and bar's leak. Block heater and water pump motor plugged in and left running over night. By morning no apparent leaking remained. (Your experience may vary depending on the location and crack repair success). Water flushed out, head ready to go with no apparent leaks. Ran several seasons with this approach.

I have also used Bar's Leak as a temporary repair on a road car with good success. 61 MGA head gasket water leak to exterior of engine (25 yr old gasket corroded).

#11

Agreed. Fix in a bottle will not hold combustion pressures... manifold possibly.

No answers… just more questions.

I have a hard time seeing anything like carbon tracks or grooves in the chamber or head surface to believe there is a seriously large crack. Where should I be looking? The peppering on the chamber appears to be bits of piston & ring debris and/or pre ignition to me.

Why do you believe there was a sufficiently large combustion chamber to water path to cause cooling system pressurization? Air bubbling out the rad cap running on idle? That’s a classic head gasket symptom.

At the time of failure, did you see a large cloud of steam out the exhaust pipe or was it water dumped out onto the track through the loose/missing frost plug burning off the exterior of the exhaust pipe?

Also, if the combustion pressure was making it into the cooling system, I would have expected the rad cap to open releasing large volumes of 20 psi water (rad cap release pressure) into the overflow tank – Was it full / overflowing?

Is it possible the sequence of events was: Freeze plug fell out of the head, cooling was compromised then the first piston to be overheated due to lack of water melted? What did the other piston look like?

Other factors you identify related to engine control (such as open loop fueling) may have added to the overheating…

It’s also interesting that the failure point is directly over the piston pin. Is it possible the oil control ring failed followed by the compression rings then a burn track through the ring lands?

Sorry for not being much help by providing answers instead of questions…

No answers… just more questions.

I have a hard time seeing anything like carbon tracks or grooves in the chamber or head surface to believe there is a seriously large crack. Where should I be looking? The peppering on the chamber appears to be bits of piston & ring debris and/or pre ignition to me.

Why do you believe there was a sufficiently large combustion chamber to water path to cause cooling system pressurization? Air bubbling out the rad cap running on idle? That’s a classic head gasket symptom.

At the time of failure, did you see a large cloud of steam out the exhaust pipe or was it water dumped out onto the track through the loose/missing frost plug burning off the exterior of the exhaust pipe?

Also, if the combustion pressure was making it into the cooling system, I would have expected the rad cap to open releasing large volumes of 20 psi water (rad cap release pressure) into the overflow tank – Was it full / overflowing?

Is it possible the sequence of events was: Freeze plug fell out of the head, cooling was compromised then the first piston to be overheated due to lack of water melted? What did the other piston look like?

Other factors you identify related to engine control (such as open loop fueling) may have added to the overheating…

It’s also interesting that the failure point is directly over the piston pin. Is it possible the oil control ring failed followed by the compression rings then a burn track through the ring lands?

Sorry for not being much help by providing answers instead of questions…

#12

I'd first send it in for a full cleaning just to get a good look at what you're working with before bothering braining around it much.

I'll try to remember tomorrow, but i have a head currently bolted to another one of my projects with some gnarly looking cracks that turned out to not be a big deal, but it has also had some welding repair elsewhere. I'm going to trust it to fairly lofty power numbers. I'll try to post pics tomorrow.

I'll try to remember tomorrow, but i have a head currently bolted to another one of my projects with some gnarly looking cracks that turned out to not be a big deal, but it has also had some welding repair elsewhere. I'm going to trust it to fairly lofty power numbers. I'll try to post pics tomorrow.

#14

I may be blind... i don't even see any cracks in that head.

Here's a kinda shitty picture of what i was talking about.

Easier to see in the bottom panel, but i have a crack running from spark plug to exhaust valve. Same thing on another chamber.

I was told it was repairable for not an obscene amount of money, but as the head was still sealing just fine, it was suggested that i just leave it.

Then, that head was shipped to me. And this happened:

Was welded back on, ground flat, and we're rolling.

Here's a kinda shitty picture of what i was talking about.

Easier to see in the bottom panel, but i have a crack running from spark plug to exhaust valve. Same thing on another chamber.

I was told it was repairable for not an obscene amount of money, but as the head was still sealing just fine, it was suggested that i just leave it.

Then, that head was shipped to me. And this happened:

Was welded back on, ground flat, and we're rolling.

#16

Elite Member

Thread Starter

Join Date: Jul 2005

Location: Anacortes, WA

Posts: 2,478

Total Cats: 144

Agreed. Fix in a bottle will not hold combustion pressures... manifold possibly.

No answers… just more questions.

I have a hard time seeing anything like carbon tracks or grooves in the chamber or head surface to believe there is a seriously large crack. Where should I be looking? The peppering on the chamber appears to be bits of piston & ring debris and/or pre ignition to me.

Why do you believe there was a sufficiently large combustion chamber to water path to cause cooling system pressurization? Air bubbling out the rad cap running on idle? That’s a classic head gasket symptom.

At the time of failure, did you see a large cloud of steam out the exhaust pipe or was it water dumped out onto the track through the loose/missing frost plug burning off the exterior of the exhaust pipe?

Also, if the combustion pressure was making it into the cooling system, I would have expected the rad cap to open releasing large volumes of 20 psi water (rad cap release pressure) into the overflow tank – Was it full / overflowing?

Is it possible the sequence of events was: Freeze plug fell out of the head, cooling was compromised then the first piston to be overheated due to lack of water melted? What did the other piston look like?

Other factors you identify related to engine control (such as open loop fueling) may have added to the overheating…

It’s also interesting that the failure point is directly over the piston pin. Is it possible the oil control ring failed followed by the compression rings then a burn track through the ring lands?

Sorry for not being much help by providing answers instead of questions…

No answers… just more questions.

I have a hard time seeing anything like carbon tracks or grooves in the chamber or head surface to believe there is a seriously large crack. Where should I be looking? The peppering on the chamber appears to be bits of piston & ring debris and/or pre ignition to me.

Why do you believe there was a sufficiently large combustion chamber to water path to cause cooling system pressurization? Air bubbling out the rad cap running on idle? That’s a classic head gasket symptom.

At the time of failure, did you see a large cloud of steam out the exhaust pipe or was it water dumped out onto the track through the loose/missing frost plug burning off the exterior of the exhaust pipe?

Also, if the combustion pressure was making it into the cooling system, I would have expected the rad cap to open releasing large volumes of 20 psi water (rad cap release pressure) into the overflow tank – Was it full / overflowing?

Is it possible the sequence of events was: Freeze plug fell out of the head, cooling was compromised then the first piston to be overheated due to lack of water melted? What did the other piston look like?

Other factors you identify related to engine control (such as open loop fueling) may have added to the overheating…

It’s also interesting that the failure point is directly over the piston pin. Is it possible the oil control ring failed followed by the compression rings then a burn track through the ring lands?

Sorry for not being much help by providing answers instead of questions…

1) Cam angle sensor failure. I had a cam angel sensor failure I’m running a 36-2 crank trigger but use an NA cam sensor for the sync signal. When it failed I noted timing would go to Zero advance intermittently on data logs when it lost signal, it would misfire, and occasionally fire only on the exhaust stroke. It would look fine if I did a trigger test while cranking with the Hydra but failed at higher RPM and under load.

2) I replaced the cam sensor. And had to reset base timing in the hydra. Somehow I think I re-loaded an older map at some point and the timing got advanced ~ 4-6 degrees. I discovered this when I temporarily installed a stock internal backup motor and could not even mechanically adjust the working NA cam sensor I was using retarded enough. Had to re-set base timing in the hydra again from where I had it when initial failure occurred to get it back in range.

3) Knock sensor appears to have quit working. I’m getting almost no signal out of it. Just some electrical background noise. Whenever I got knock before the check engine light gets triggered in the hydra shines in my face to say hay dumbass the car is knocking. This time I got no check engine light for excessive knock.

4) O2 sensor quit working a while ago but I never trust those things anyway to auto tune or to have any authority over fuel while driving in anger anyway. I run open loop.

Electrical devices hate me and my mechanical stuff!

#17

So... I'm guessing the sequence of events failure sequence was:

1) Frost plug fell out of head at front of engine. Local overheating at cylinder head in area of cylinders 1 & 2.

2) Head casting went "a little soft"... Not enough to loose compression or have obvious large water leaking at low load BUT enough that the head studs were no longer clamping at the same level as previously.

3) under heavy load, with the head studs no longer providing the same clamping force, there was leakage past the head gasket fire seal into the water ways.

4) secondary failure noted as water loss / pressure in water system under high load (when the combustion pressures lift the head enough to provide a leakage path to the water jacket.

Other electrical factors potentially causing pre ignition / detonation contributed to high cylinder pressures and head lifting off the block. (agreed - electrical problems are the source of all evil).

Did you retorque the head after the frost plug fell out? Possibly you noticed if some head studs were a little less tight than the others?

I suspect you may be looking at refacing the head also.

Hope this helps....

1) Frost plug fell out of head at front of engine. Local overheating at cylinder head in area of cylinders 1 & 2.

2) Head casting went "a little soft"... Not enough to loose compression or have obvious large water leaking at low load BUT enough that the head studs were no longer clamping at the same level as previously.

3) under heavy load, with the head studs no longer providing the same clamping force, there was leakage past the head gasket fire seal into the water ways.

4) secondary failure noted as water loss / pressure in water system under high load (when the combustion pressures lift the head enough to provide a leakage path to the water jacket.

Other electrical factors potentially causing pre ignition / detonation contributed to high cylinder pressures and head lifting off the block. (agreed - electrical problems are the source of all evil).

Did you retorque the head after the frost plug fell out? Possibly you noticed if some head studs were a little less tight than the others?

I suspect you may be looking at refacing the head also.

Hope this helps....

#18

Elite Member

Thread Starter

Join Date: Jul 2005

Location: Anacortes, WA

Posts: 2,478

Total Cats: 144

So... I'm guessing the sequence of events failure sequence was:

1) Frost plug fell out of head at front of engine. Local overheating at cylinder head in area of cylinders 1 & 2.

2) Head casting went "a little soft"... Not enough to loose compression or have obvious large water leaking at low load BUT enough that the head studs were no longer clamping at the same level as previously.

3) under heavy load, with the head studs no longer providing the same clamping force, there was leakage past the head gasket fire seal into the water ways.

4) secondary failure noted as water loss / pressure in water system under high load (when the combustion pressures lift the head enough to provide a leakage path to the water jacket.

Other electrical factors potentially causing pre ignition / detonation contributed to high cylinder pressures and head lifting off the block. (agreed - electrical problems are the source of all evil).

Did you retorque the head after the frost plug fell out? Possibly you noticed if some head studs were a little less tight than the others?

I suspect you may be looking at refacing the head also.

Hope this helps....

1) Frost plug fell out of head at front of engine. Local overheating at cylinder head in area of cylinders 1 & 2.

2) Head casting went "a little soft"... Not enough to loose compression or have obvious large water leaking at low load BUT enough that the head studs were no longer clamping at the same level as previously.

3) under heavy load, with the head studs no longer providing the same clamping force, there was leakage past the head gasket fire seal into the water ways.

4) secondary failure noted as water loss / pressure in water system under high load (when the combustion pressures lift the head enough to provide a leakage path to the water jacket.

Other electrical factors potentially causing pre ignition / detonation contributed to high cylinder pressures and head lifting off the block. (agreed - electrical problems are the source of all evil).

Did you retorque the head after the frost plug fell out? Possibly you noticed if some head studs were a little less tight than the others?

I suspect you may be looking at refacing the head also.

Hope this helps....

The freeze plug never came out or did I loose any coolant when the carnage to the piston and head happend.

The freeze plug poped out after I tried to re-use the head after rebuilding the bottom end.

#19

Elite Member

Thread Starter

Join Date: Jul 2005

Location: Anacortes, WA

Posts: 2,478

Total Cats: 144

A couple pictures that illustrate the internal geometry of the head. There is only about 3/16" of flat sheet shaped aluminum separating the combustion chamber from the coolant in the portion of the combustion chamber where there is noticeable material Damage. Visual inspection can't confirm there is in fact crack here because the surface is roughed up so bad but based on what is happening I am highly suspect.

#20

I've used a dye penetrant called SpotCheck before to find a crack in an Aluminium head.

It's a two part spray that has a dye and developer. You spray the dye onto the head first then clean it off, then you spray a developer that pull the dye out of the crack if there is one. It's easy to use but a bit expensive and a little hard to find. You might be able to find it locally at a welding supply store or a Grainger.

It's a two part spray that has a dye and developer. You spray the dye onto the head first then clean it off, then you spray a developer that pull the dye out of the crack if there is one. It's easy to use but a bit expensive and a little hard to find. You might be able to find it locally at a welding supply store or a Grainger.

Thread

Thread Starter

Forum

Replies

Last Post