The custom fabrication thread! (Post pics of stuff you have made)

#983

SADFab Destructive Testing Engineer

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

My version of seans bead roller. Timed myself, took less than 7 minutes to make this (which included digging the welder out of my parts pile and finding my **** set of vice grips) haha:

#984

Here is my first attempt at MIG welding. Aluminum is a completely different beast, hats off to you folk that can lay down dimes. It took me four hours to make 16 small welds.

Initial results were....suboptimal

Last weld of the day, slightly less shitty.

In my quest to just get the goddamn aluminum to stick together, I neglected to tack everything up first, then proceeded to put a ton of heat into the welds. You can see the frames are warped by about an inch at the top.

So I ended up adjusting the cedar planking to compensate. Not really noticeable from the outside.

Any ideas on how I can the the aluminum to look rusty like the steel? Paint seems to be the only option I've seen so far.

Initial results were....suboptimal

Last weld of the day, slightly less shitty.

In my quest to just get the goddamn aluminum to stick together, I neglected to tack everything up first, then proceeded to put a ton of heat into the welds. You can see the frames are warped by about an inch at the top.

So I ended up adjusting the cedar planking to compensate. Not really noticeable from the outside.

Any ideas on how I can the the aluminum to look rusty like the steel? Paint seems to be the only option I've seen so far.

#986

Elite Member

iTrader: (5)

Join Date: Oct 2011

Location: Detroit (the part with no rules or laws)

Posts: 5,677

Total Cats: 800

Not true at all.

My last job at the fab shop we did it all the time. Way more than using the tig.

At my current job the boys in the fab shop ONLY use mig for aluminum...

It's pretty common.

My last job at the fab shop we did it all the time. Way more than using the tig.

At my current job the boys in the fab shop ONLY use mig for aluminum...

It's pretty common.

#988

Elite Member

iTrader: (8)

Join Date: Dec 2008

Location: Kingston, Ontario

Posts: 2,910

Total Cats: 51

its common and has the traits of mig welding. its not as precise and not as clean.... but its much much faster when compared to TIG welding.

its used in a lot of process type stuff- some MIG welders are pretty trick now... more than your basic on/off welders.

M

its used in a lot of process type stuff- some MIG welders are pretty trick now... more than your basic on/off welders.

M

#991

Fab related

Dual flow meter arrived today so I can finally back purge stuff.

My bench, longevity 200sx & wp-9 torch

A transition I did for a friends R33 gtr for a 4" mid pipe. Port guys damaged the Apexi mid pipe taking it off the boat, it connects a Nismo cow pipe to the 95mm part of the Apexi exhaust

Dual flow meter arrived today so I can finally back purge stuff.

My bench, longevity 200sx & wp-9 torch

A transition I did for a friends R33 gtr for a 4" mid pipe. Port guys damaged the Apexi mid pipe taking it off the boat, it connects a Nismo cow pipe to the 95mm part of the Apexi exhaust

#996

Elite Member

iTrader: (9)

Join Date: Jun 2006

Location: Chesterfield, NJ

Posts: 6,893

Total Cats: 399

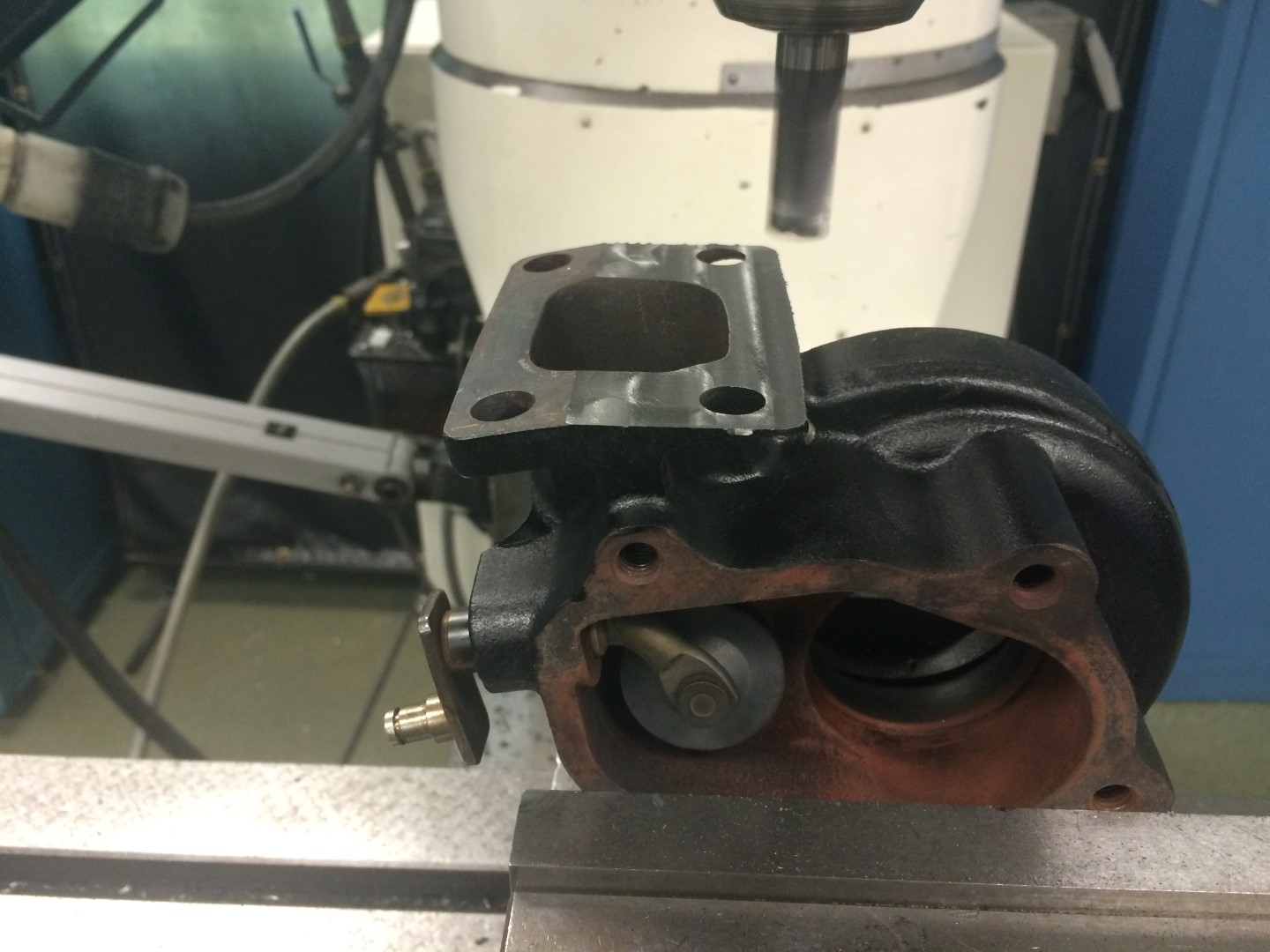

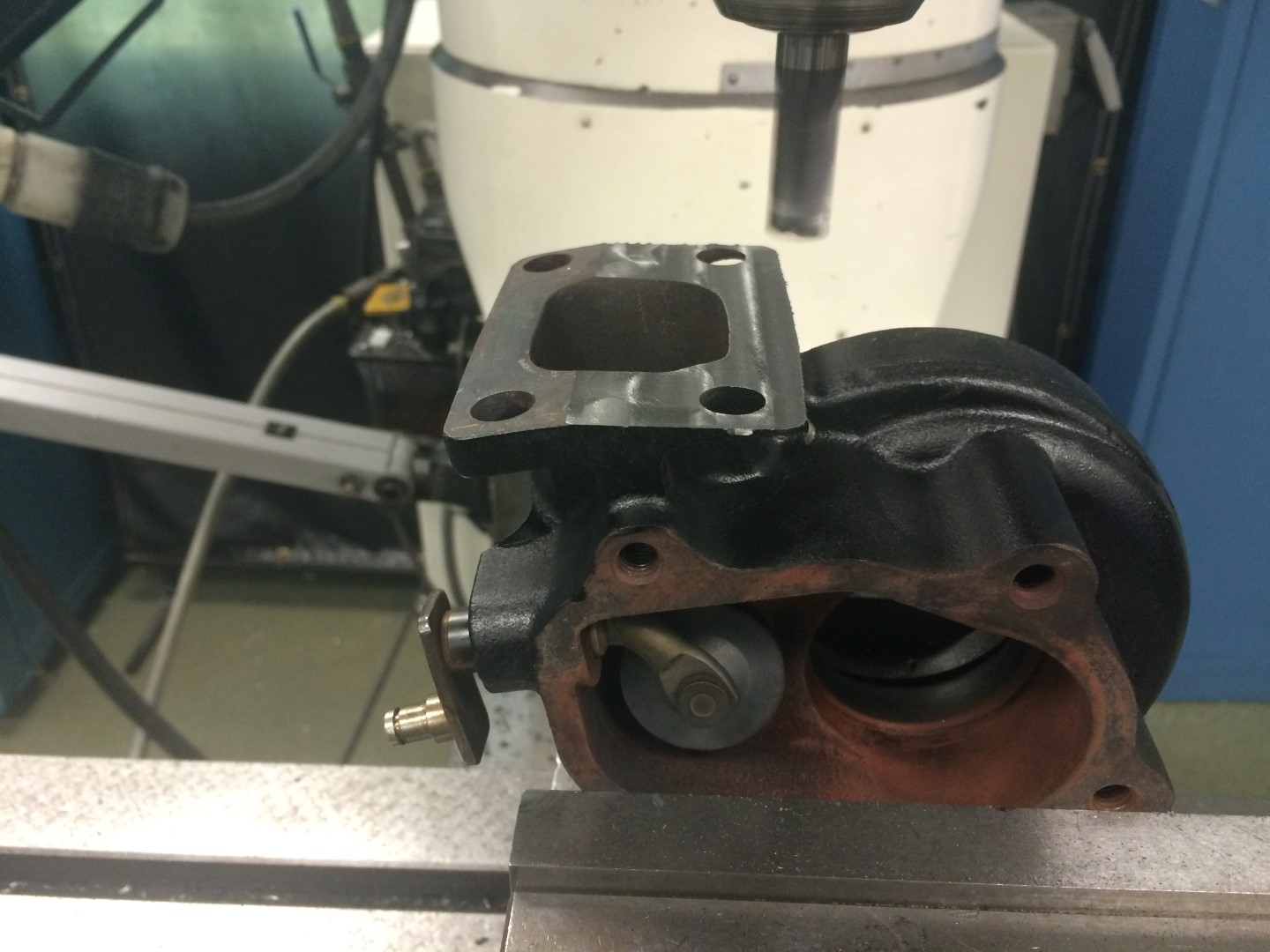

I'm getting creative with an old turbo I bought from you Lars. Lets see how quickly it does(n't) spool with 2.5l.

At lunch I'll see if I can attach some unknown, probably leaded, mild steel to cast iron.

At lunch I'll see if I can attach some unknown, probably leaded, mild steel to cast iron.

#999

Elite Member

iTrader: (9)

Join Date: Jun 2006

Location: Chesterfield, NJ

Posts: 6,893

Total Cats: 399

Swapping springs in one EWG is enough.

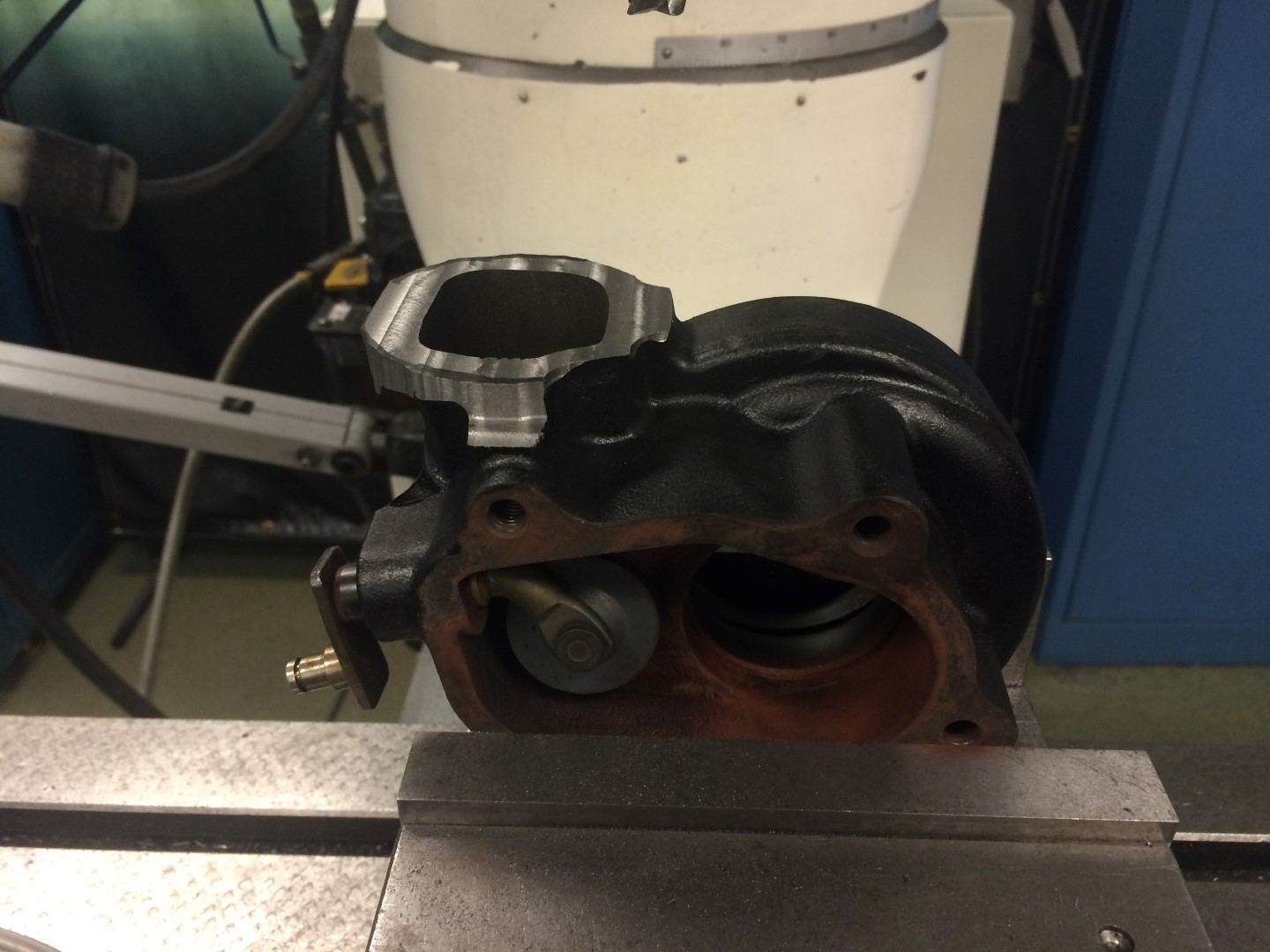

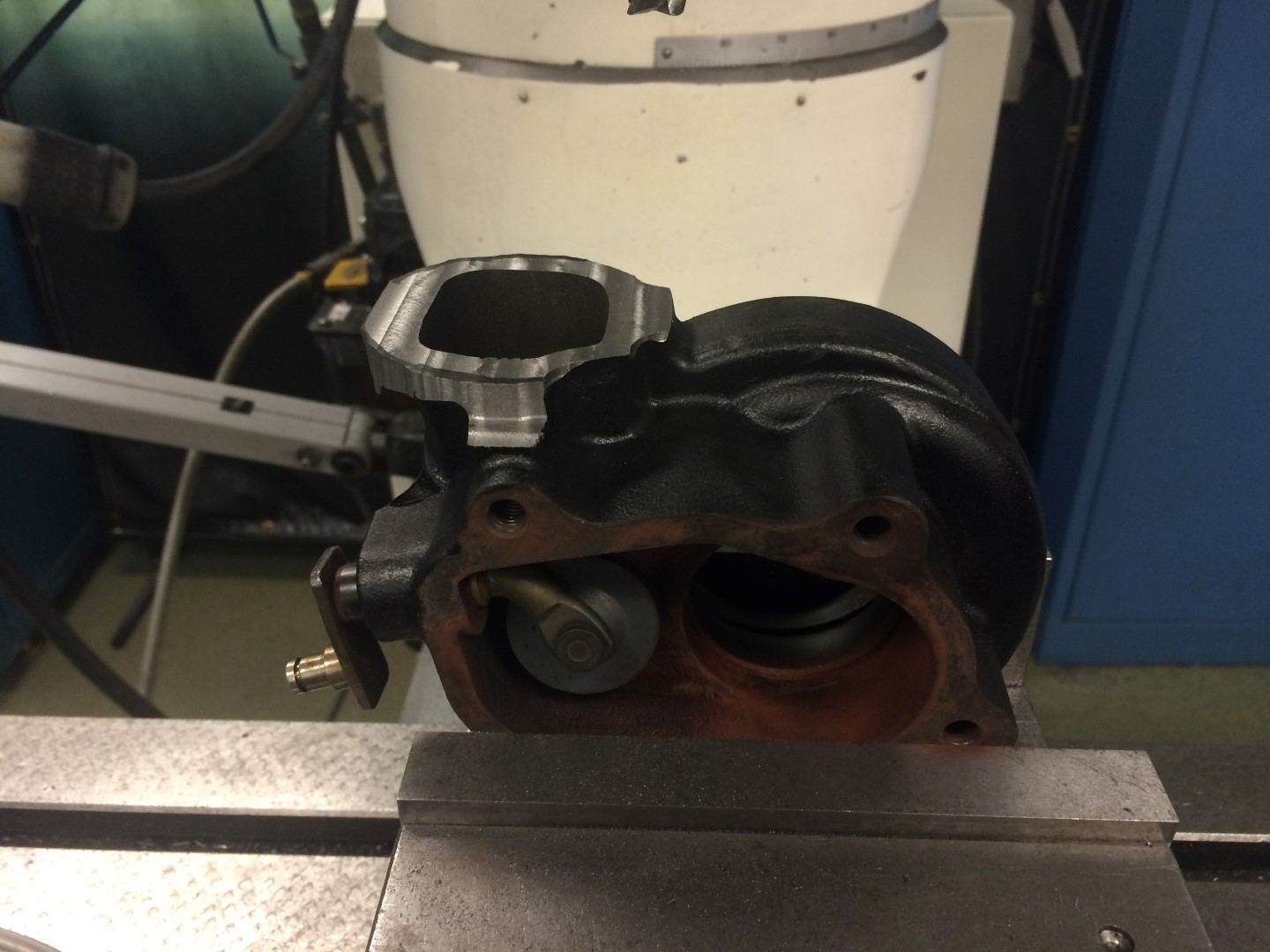

So it took a little while to choose a filler rod. I ended up using 309, with ~45min @500F preheat and shutting off the oven and letting it cool itself done post heat. So far there's no cracks. There's some silicon bronze and a few other material tacks mixed in there.

So here's a chinese "EMUSA GT28" turbo direct swap for a Precision vband turbine. hehe

So it took a little while to choose a filler rod. I ended up using 309, with ~45min @500F preheat and shutting off the oven and letting it cool itself done post heat. So far there's no cracks. There's some silicon bronze and a few other material tacks mixed in there.

So here's a chinese "EMUSA GT28" turbo direct swap for a Precision vband turbine. hehe