The custom fabrication thread! (Post pics of stuff you have made)

#364

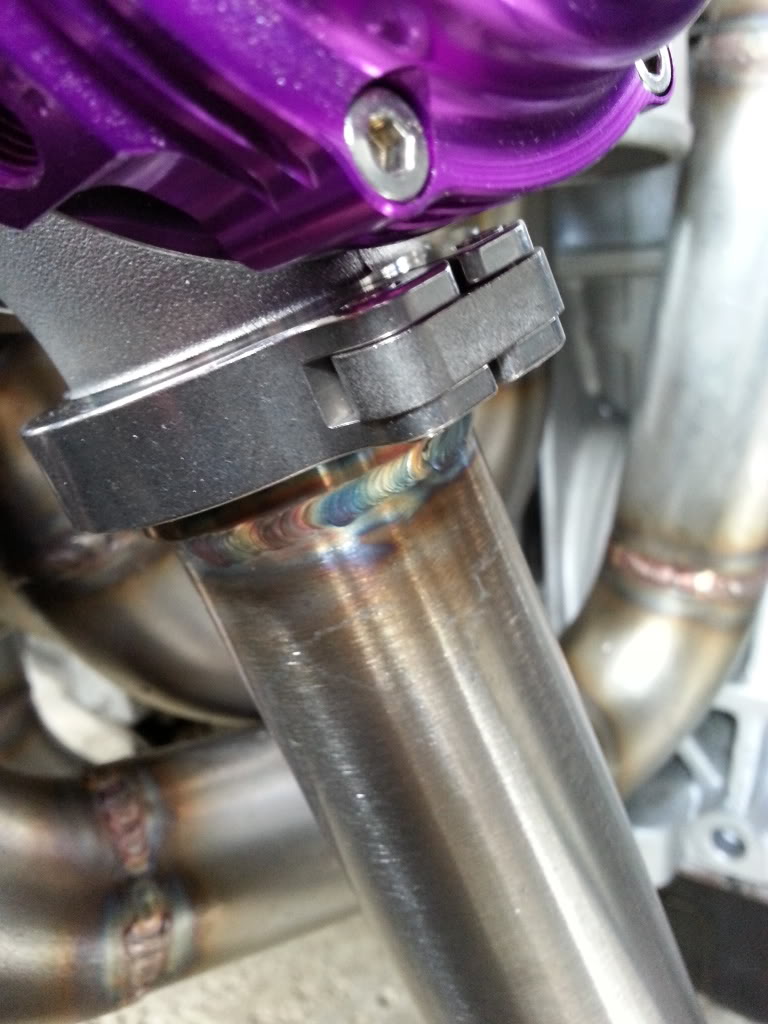

Nothing super impressive but I thought I'd share. Modified my Maxim Works header to better accomidate my Rotrex charger (Yup, bring on the Supercharger hate!  )

)

Then mated it to a 3" catback (essentially made everything from the secondary runners, back) Nice project to learn from and if I were to do it I'd do so many things differently

)

)

Then mated it to a 3" catback (essentially made everything from the secondary runners, back) Nice project to learn from and if I were to do it I'd do so many things differently

#367

Thanks guys,

I know this is mainly a picture thread but a bit of background info:

The header steps from a 2.5" "downpipe" (After the secondaries) and goes into a transition to 3". Within that transition some of the 2.5" protrudes with the idea being similar to an anti-reversion chamber. Not sure if it makes a difference as I have no back-to-back data.

I know this is mainly a picture thread but a bit of background info:

The header steps from a 2.5" "downpipe" (After the secondaries) and goes into a transition to 3". Within that transition some of the 2.5" protrudes with the idea being similar to an anti-reversion chamber. Not sure if it makes a difference as I have no back-to-back data.

#368

Elite Member

iTrader: (8)

Join Date: Dec 2008

Location: Kingston, Ontario

Posts: 2,910

Total Cats: 51

This is why I hate the vibrant elbows.

Checkout the cross sectional wall thickness... My suppliers elbows are way thicker and have the same thickness the whole circumference.

Little pipe welded up today...

Weld closeup...

Checkout the cross sectional wall thickness... My suppliers elbows are way thicker and have the same thickness the whole circumference.

Little pipe welded up today...

Weld closeup...

#369

Just made a couple exhaust hangers for a buddy, he wanted them to clamp on. I heated up the 304 rod with the oxy acetylene torch and hammered it flat on the anvil. We happened to have some 2.5" Al round stock in short sections kicking around so I hammered the bend into it around that.

And then today and I used all of this.

And you know, just made some custom mufflers... out of aluminum.

Yup, made those cores out of perf sheet did that a couple weeks ago.

So remember how I complain about the Dynasty we have. Yeah I'm never going to use pure tungesten in that thing again. All those welds were done with thoriated, 1/16" with a #6 cup. 120Hz, some were done at the balance of 45% that I was using to try to make the pure tungsten work, the rest were done with 60%. And zero weld prep, we didn't have a clean stainless brush in the shop so I figured using the welder to break through the AlOx was better than getting steel all up in the weld. We were also out of acetone.

And then today and I used all of this.

And you know, just made some custom mufflers... out of aluminum.

Yup, made those cores out of perf sheet did that a couple weeks ago.

So remember how I complain about the Dynasty we have. Yeah I'm never going to use pure tungesten in that thing again. All those welds were done with thoriated, 1/16" with a #6 cup. 120Hz, some were done at the balance of 45% that I was using to try to make the pure tungsten work, the rest were done with 60%. And zero weld prep, we didn't have a clean stainless brush in the shop so I figured using the welder to break through the AlOx was better than getting steel all up in the weld. We were also out of acetone.

Last edited by Leafy; 04-28-2013 at 10:10 AM.

#370

Just made a couple exhaust hangers for a buddy, he wanted them to clamp on. I heated up the 304 rod with the oxy acetylene torch and hammered it flat on the anvil. We happened to have some 2.5" Al round stock in short sections kicking around so I hammered the bend into it around that.

And then today and I used all of this.

And you know, just made some custom mufflers... out of aluminum.

Yup, made those cores out of perf sheet did that a couple weeks ago.

So remember how I complain about the Dynasty we have. Yeah I'm never going to use pure tungesten in that thing again. All those welds were done with thoriated, 1/16" with a #6 cup. 120Hz, some were done at the balance of 45% that I was using to try to make the pure tungsten work, the rest were done with 60%. And zero weld prep, we didn't have a clean stainless brush in the shop so I figured using the welder to break through the AlOx was better than getting steel all up in the weld. We were also out of acetone.

And then today and I used all of this.

And you know, just made some custom mufflers... out of aluminum.

Yup, made those cores out of perf sheet did that a couple weeks ago.

So remember how I complain about the Dynasty we have. Yeah I'm never going to use pure tungesten in that thing again. All those welds were done with thoriated, 1/16" with a #6 cup. 120Hz, some were done at the balance of 45% that I was using to try to make the pure tungsten work, the rest were done with 60%. And zero weld prep, we didn't have a clean stainless brush in the shop so I figured using the welder to break through the AlOx was better than getting steel all up in the weld. We were also out of acetone.

#372

Personally I'd say unless you're getting a bead per second you're not going fast enough. Look for the keyhole right before it blows into a hole, that's where you want to dip before it blows into a hole. If you're not getting a keyhole without waiting forever, turn your heat up. I personally don't like the way my welds look unless I blast it and move real fast. If I don't dip on time ill blow a hole in my part to give you an idea. It makes it come out very nice and fast though.

#375

Cpt. Slow

iTrader: (25)

Join Date: Oct 2005

Location: Oregon City, OR

Posts: 14,175

Total Cats: 1,129

That reminds me, I really need to figure out a decent muffler for the N/A track cars around here. They keep burning up their packing with their catless flamethrowers. Custom might be the way to go. What're you using for packing?

#377

Personally I'd say unless you're getting a bead per second you're not going fast enough. Look for the keyhole right before it blows into a hole, that's where you want to dip before it blows into a hole. If you're not getting a keyhole without waiting forever, turn your heat up. I personally don't like the way my welds look unless I blast it and move real fast. If I don't dip on time ill blow a hole in my part to give you an idea. It makes it come out very nice and fast though.

#380

Coming together, got some time to do a little this morning before I had to go.

Muffler tucked RIGHT up and nicely centered. Note that this is still only tacked so the welds (mostly the heat colouration around them) look patchy, thats why.

Not 110% happy with the tip so Im redoing from the muffler outlet back.

I do like how you can JUST see the muffler if you kneel, it looks very OEM.

Whats this we have here? MSM owners will recognise this manifold and heatshield?

BOO :twisted:

Off to the race ceramic coating shop tomorrow.

Dann

Muffler tucked RIGHT up and nicely centered. Note that this is still only tacked so the welds (mostly the heat colouration around them) look patchy, thats why.

Not 110% happy with the tip so Im redoing from the muffler outlet back.

I do like how you can JUST see the muffler if you kneel, it looks very OEM.

Whats this we have here? MSM owners will recognise this manifold and heatshield?

BOO :twisted:

Off to the race ceramic coating shop tomorrow.

Dann