DIY manifold

#321

Sorry for the very late response. Probably made in the exact same factory so I wouldn't sweat the Grizzly vs HF issue. Go with the HF. At the time there was no local HF store and I was in Springfield MO a lot for work and the Grizzly showroom/warehouse is there and the price was about the same. I've had mine for 8-10 years.

#330

Elite Member

iTrader: (37)

Join Date: Apr 2010

Location: Very NorCal

Posts: 10,441

Total Cats: 1,899

Interesting.

I'd be worried about torquing a bolt down and having the coating chip out from under the head. I called them literally yesterday to ask about this and they couldn't give me a decent response. I probably got a sales guy.

How did they do masking off through holes and threaded holes? I'm guessing no coating on the sealing surfaces or inside the manifold & housing?

I'd be worried about torquing a bolt down and having the coating chip out from under the head. I called them literally yesterday to ask about this and they couldn't give me a decent response. I probably got a sales guy.

How did they do masking off through holes and threaded holes? I'm guessing no coating on the sealing surfaces or inside the manifold & housing?

#333

Thanks. Trying to cram the EFR in a low mount is not something I want to try again, at least not with a 4" long collector. Its not even the length that is the problem, its the diameter of the compressor housing and the location of the wastegate actuator. What does worry me is that my thermal simulations of this manifold show it either trying to tuck the turbo closer to the block or just twist it forward depending on how I setup the conditions. So I might end up with turbo hit block, but only if hot. It'll only be hitting the webbing where the AC bracket mounts, which I'm sure is safe to grind out.

#336

Yeah, when I was trying to make a 3.5" down pipe fit I was like "How the **** did fae do this?!" and then I was like "This must what all the sawall jokes are from." lol. I think though I'm going to need to cut the little tab off my tranny thats right near the down pipe to prevent it from rattling against it. And I'm still trying to figure out how exactly I want to do the rest of the exhaust, I have my mufflers, resonators, and I know how they'll be laid out. I just need to figure out how I want to do the mounts.

Doap, white is the only color option. And I dont care what it looks like, racecar parts.

Doap, white is the only color option. And I dont care what it looks like, racecar parts.

#337

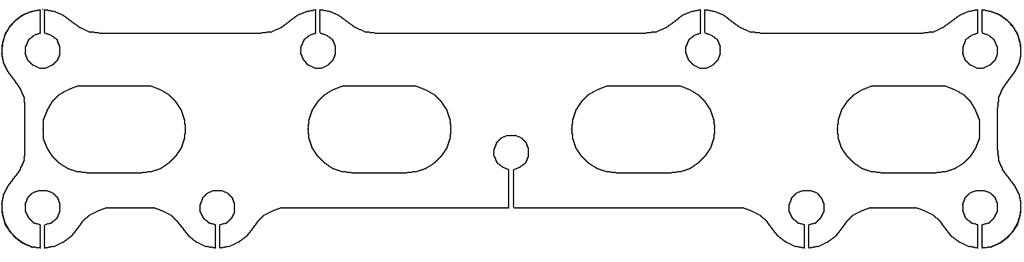

Has any one got a drawing for a 1.6 exhaust flange?

(I would like to compare dimensions before fail cutting my sketch.)

edit: searched more

https://www.miataturbo.net/diy-turbo...25/#post911749

(I would like to compare dimensions before fail cutting my sketch.)

edit: searched more

https://www.miataturbo.net/diy-turbo...25/#post911749

Last edited by sturovo; 05-07-2013 at 03:51 AM. Reason: searched some more

#340

Elite Member

iTrader: (8)

Join Date: Dec 2008

Location: Kingston, Ontario

Posts: 2,910

Total Cats: 51

Look at the head itself and see where you can leave material. It wont add cost to cutting the flange and having a little more meat on the head flange will help both with welding and even torque over the flange once your done and tighten it down. If its laser cut the extra girth in the flange will keep warping down too.

Cut the overlay flange you just posted.

Cut the overlay flange you just posted.

Dimensions all over the place.

Dimensions all over the place.