DIY manifold

#285

mkturbo.com

iTrader: (24)

Join Date: May 2006

Location: Charleston SC

Posts: 15,177

Total Cats: 1,681

Zabac had them for sale and I picked them up. They are mild steal flanges. My first few manifolds will be made of mild steal, then once I actually get some more practice on stainless I will switch to making manifolds and downpipes in that.

#288

mkturbo.com

iTrader: (24)

Join Date: May 2006

Location: Charleston SC

Posts: 15,177

Total Cats: 1,681

Basically what WittyWorks said is my big thing. If the price on the groupbuy pieces is a good bit cheaper then ordering one from him or the other vendors I will probably pick up some. If it is about the same I will probably wait till I am ready to build an actual manifold.

#289

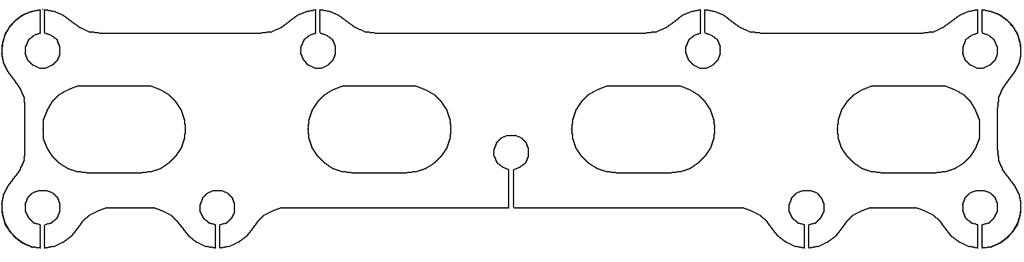

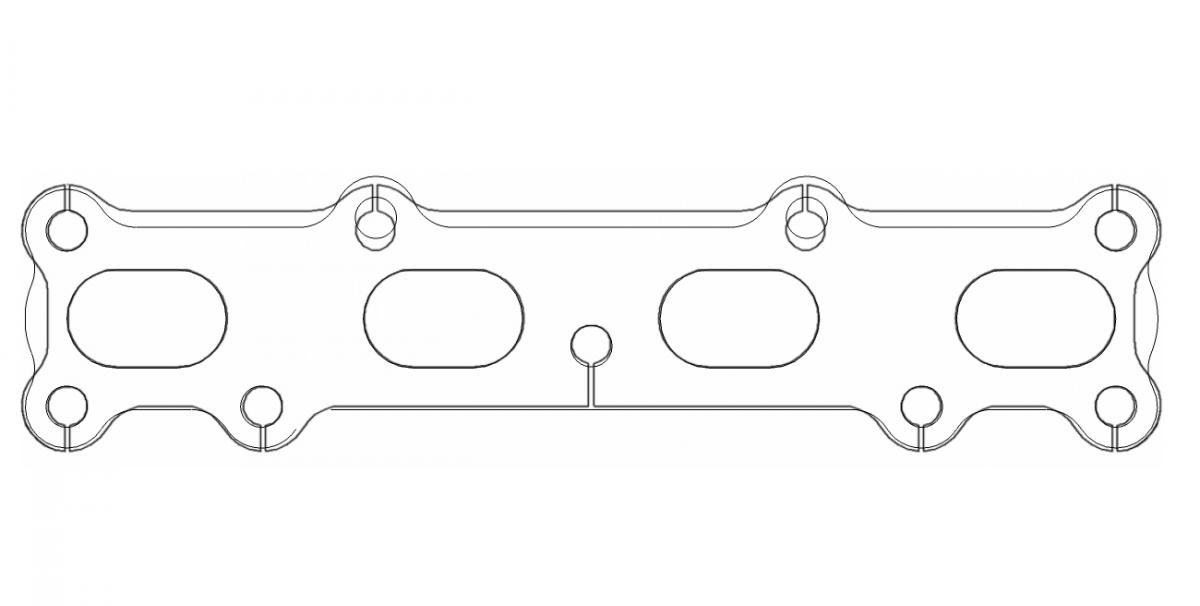

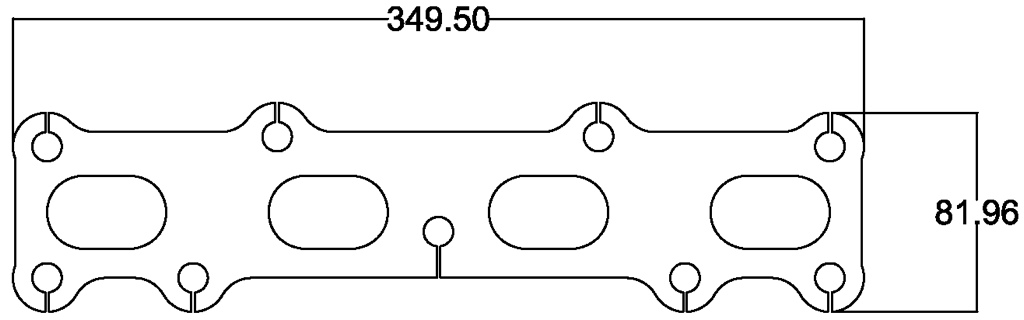

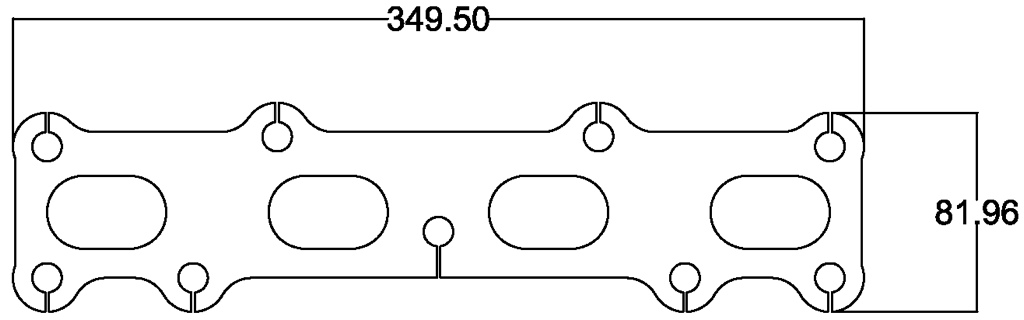

The top bolt hole positions for port 2 and 3 may need some adjustment? Usually there is a 4.1mm vertical offset where as this drawing shows them as being in a straight line?

Also the width of material at the outside edges of port 1and 4 could be increased? (Other flange dwgs use 12.7mm width.)

Last edited by sturovo; 02-20-2013 at 02:19 AM.

#290

Sturovo,

Thanks for the good catch, you are correct on both counts I had it marked on the gasket but failed to offset the two top center bolt holes on the drawing.

I would have noticed the problems on the thin gauge steel part that am getting made just to check for problems like this, but it is best to start with the proper dimensions in the first place.

Thanks again

Thanks for the good catch, you are correct on both counts I had it marked on the gasket but failed to offset the two top center bolt holes on the drawing.

I would have noticed the problems on the thin gauge steel part that am getting made just to check for problems like this, but it is best to start with the proper dimensions in the first place.

Thanks again

#291

Elite Member

iTrader: (37)

Join Date: Apr 2010

Location: Very NorCal

Posts: 10,441

Total Cats: 1,899

I need a saw to cut tubes and elbows with. I already own the obligatory sawzall, what would you guys recommend for something a little more... precise? Part numbers or links get you props. I'm cutting mild steel if that helps.

- OR -

You can also tell me what to avoid as well. Example: Sawzall

- OR -

You can also tell me what to avoid as well. Example: Sawzall

#293

Cpt. Slow

iTrader: (25)

Join Date: Oct 2005

Location: Oregon City, OR

Posts: 14,181

Total Cats: 1,131

As much as we joke about the sawzall, I don't think you should actually use it for anything that needs precision.

I.E. My pipe and canvas car cover collapsed on my miata during a snow storm, I would have used a sawzall when no measurement or straightness is needed.

For pipe, I prefer an angle grinder, however as my fabrication skills get better, I get more and more annoyed when my cuts have slight angles, etc.

A chop saw would solve this, once with an adjustable vise base. Unfortunately, even HF units are $400.

I.E. My pipe and canvas car cover collapsed on my miata during a snow storm, I would have used a sawzall when no measurement or straightness is needed.

For pipe, I prefer an angle grinder, however as my fabrication skills get better, I get more and more annoyed when my cuts have slight angles, etc.

A chop saw would solve this, once with an adjustable vise base. Unfortunately, even HF units are $400.

#294

You can cheat this. Put the piece in the vice and set it up so your cut is perfect if you hold the shield on the angle grinder up against it. With some finess you can get nearly as straight as a chop saw with a lower chance of nailing yourself in the ***** with a hot piece of steel, or 8" grinding disk fragments to the chest.

#296

I have both a chop saw and a horizontal bandsaw. I love the band saw over the chop saw, its not as messy. Also my bandsaw has a better vise than my chop saw and the chop saw fiber disc wears out a lot quicker than the bandsaw blade. Even cutting stainless the bandsaw blade lasts longer(alot longer running coolant). I have a 4x6 Craftex which from what i have seen in pictures and stats is the equivalent of the 4x6 that Grizzly.com sells.

#300

mkturbo.com

iTrader: (24)

Join Date: May 2006

Location: Charleston SC

Posts: 15,177

Total Cats: 1,681

So looking online it seems that the Grizzy 4x6 bandsaw looks exactly the same as the HF 4x6 band saw. Any reason why in the future I should decide to spend an extra $150 to go with the Grizzly one over the HF one?