Learning to Weld

#1

Hey everyone,

Tried to find an answer to my question but didn't seem to find much, so I'll ask you smart people. I'm interested in learning to weld solely for my car projects. Not trying to make a career out of welding, just want to be more self sufficient and experiment with making cool things. I.E welding intercooler piping, tabs for mounting things, heatshield, stuff like that. Things I've had to make out of thinner material I could bend that sometimes don't fit correctly because it was all I had to work with. Is it worth it to go to school to learn or is it something I could safely practice over time, using youtube videos or whatever? The only local school is through a university and its about 8k for the course over 8 months. I work full time and don't know when the classes would take place but I could make it work if it would be that much better. 8k seems like a bit much for the time being since its only a hobby and that money could be put into the car. Ideally I would start with MIG to get the basics and eventually move to TIG.

I'm open to any wisdom or advice. Tell me if its a waste of time, worth the money, I could learn it slowly with practice, whatever!

Thanks!

Tried to find an answer to my question but didn't seem to find much, so I'll ask you smart people. I'm interested in learning to weld solely for my car projects. Not trying to make a career out of welding, just want to be more self sufficient and experiment with making cool things. I.E welding intercooler piping, tabs for mounting things, heatshield, stuff like that. Things I've had to make out of thinner material I could bend that sometimes don't fit correctly because it was all I had to work with. Is it worth it to go to school to learn or is it something I could safely practice over time, using youtube videos or whatever? The only local school is through a university and its about 8k for the course over 8 months. I work full time and don't know when the classes would take place but I could make it work if it would be that much better. 8k seems like a bit much for the time being since its only a hobby and that money could be put into the car. Ideally I would start with MIG to get the basics and eventually move to TIG.

I'm open to any wisdom or advice. Tell me if its a waste of time, worth the money, I could learn it slowly with practice, whatever!

Thanks!

#3

+1 to what bahurd said. I taught myself to weld after watching maybe an hour of youtube then spending the weekend practicing on scrap steel. I started on a flux cord Lincoln welder i got for less than $100 then got a stick welder and practiced that. Now that my work has a big tig i practiced at work on my lunch brakes and stuff welding pipe and more scrap in my spare time until i got decent. You can figure out most of what you need to know from youtube and welding forums the rest is just practice and lots of it.

#4

Great to hear guys! Thanks so much for the input, I really appreciate it! Makes me feel a lot better about it being possible without the classes. I figure for the money spent on the class, I could buy a welder and A LOT of material to practice with. I'll have to do some research on a good starting unit. Hopefully I could find one used but there isn't much on craigslist up here.

#5

I have 3 "welding " schools near my house. I see a lot of local kids getting screwed out of money and learn nothing.

NOTHING beats practice. follow the advice above, post pictures of your work, and we can help advise from there. I could make a simple diagram that could help speed things up too. I should do that.

NOTHING beats practice. follow the advice above, post pictures of your work, and we can help advise from there. I could make a simple diagram that could help speed things up too. I should do that.

#6

Get an Alphatig 200x for $700 and upgrade the foot pedal for an additional $100. Get some scrap steal and aluminum and then start laying beads. Any chance you get, more beads... beads on top of beads. In between laying beads watch youtube videos (weld.com, weldingtipsandtricks and kevin caron). The things that don't make sense initially will start to click and you'll be decent before you know it. Welding is 100% a time based scale of improvement.

#7

Elite Member

iTrader: (15)

Join Date: Jan 2007

Location: Murfreesboro,TN

Posts: 2,041

Total Cats: 265

I have 3 "welding " schools near my house. I see a lot of local kids getting screwed out of money and learn nothing.

NOTHING beats practice. follow the advice above, post pictures of your work, and we can help advise from there. I could make a simple diagram that could help speed things up too. I should do that.

NOTHING beats practice. follow the advice above, post pictures of your work, and we can help advise from there. I could make a simple diagram that could help speed things up too. I should do that.

#9

Most schools dont focus on teaching anything. They just show you---- and ask you to repeat. Thats not learning. and yeah, I vetted a lot of candidates prior to wasting time with an interview. They rarely pass even the most basic skills test.

OP- Mig is absolutely the most versatile welding, a little less pretty and cannot do thin (less than 1/8") aluminum.

TIG will do pretty much anything, but the learning curve is steep. real steep. and tall. steep and tall. also more of a pain in the *** for quick small jobs. some people are 100% not capable of learning it.

Really look close at a multi purpose machine with 200 amps. Buy once- cry once.

OP- Mig is absolutely the most versatile welding, a little less pretty and cannot do thin (less than 1/8") aluminum.

TIG will do pretty much anything, but the learning curve is steep. real steep. and tall. steep and tall. also more of a pain in the *** for quick small jobs. some people are 100% not capable of learning it.

Really look close at a multi purpose machine with 200 amps. Buy once- cry once.

#10

OP- I have zero hands on experiance with this welder but all the local pipeline guys seem to really like it and say it is bombproof.

Razorweld - Suppliers of Razorweld & Razorcut Mig Welders, Tig Welder, Plasma Cutters, Gas Cutting Equipment, supplies and parts for your welding machines

We also just got this at work for one of the service trucks and it is a nice unit but i feel the tig function is lacking

https://www.millerwelds.com/equipmen...YaAhyzEALw_wcB

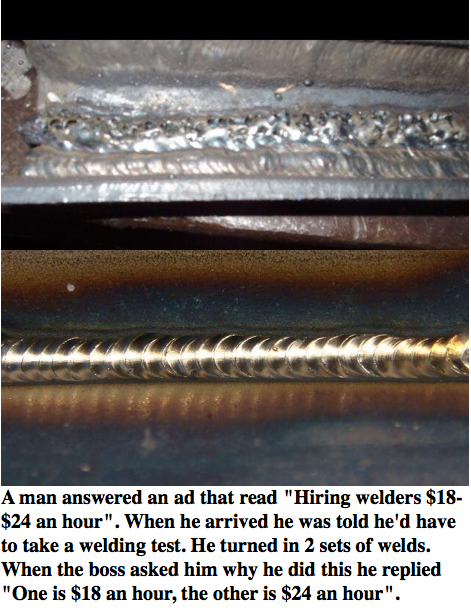

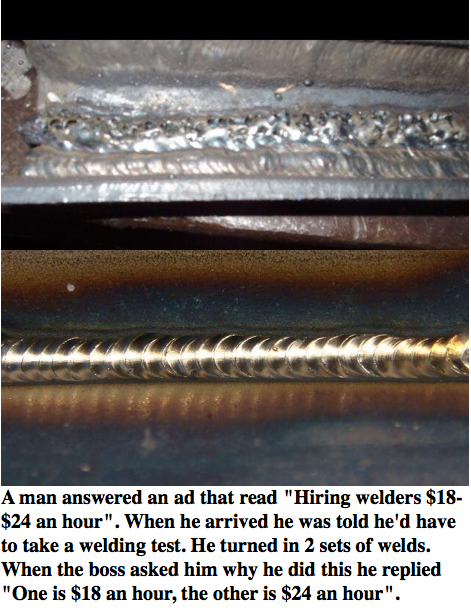

Your post reminded me of this.

Razorweld - Suppliers of Razorweld & Razorcut Mig Welders, Tig Welder, Plasma Cutters, Gas Cutting Equipment, supplies and parts for your welding machines

We also just got this at work for one of the service trucks and it is a nice unit but i feel the tig function is lacking

https://www.millerwelds.com/equipmen...YaAhyzEALw_wcB

Your post reminded me of this.

#11

Elite Member

iTrader: (5)

Join Date: Oct 2011

Location: Detroit (the part with no rules or laws)

Posts: 5,677

Total Cats: 800

When I went through the welding program to get my certificate I found it to be VERY good.

Though, it could be because of my geological location and a teacher who kind of cared.

Now the school is going to have 10% welding classes 90% other classes with the program. You SHOULD just be able to take the welding classes.

I highly recommend this. But check it out first. Also, if you only went for 1 or 2 weeks my school would refund your money if you stopped.

If this isn't an option just buy a cheap machine / machines and watch YouTube videos. Really, practice is what will make you better.

Though, it could be because of my geological location and a teacher who kind of cared.

Now the school is going to have 10% welding classes 90% other classes with the program. You SHOULD just be able to take the welding classes.

I highly recommend this. But check it out first. Also, if you only went for 1 or 2 weeks my school would refund your money if you stopped.

If this isn't an option just buy a cheap machine / machines and watch YouTube videos. Really, practice is what will make you better.

#12

Another here that learned thru YouTube and just getting hands-on. Make mistakes and learn from it. I am still far from being accomplished and am still learning.

Mig was the easiest for me learn. I bought an Alpha tig recently and have been practicing alum and for funsies tried stick. Lol....stick is something after learning the other cleaner methods first.

Mig was the easiest for me learn. I bought an Alpha tig recently and have been practicing alum and for funsies tried stick. Lol....stick is something after learning the other cleaner methods first.

#13

The wealth of knowledge here is so incredible! Thanks for all of the input. For the time being it seems I'm going to look at the youtube, practice route. My wife is in grad school at the moment, so this seems the most practical. Later schooling could always be an option if I wanted to get certified it seems. Now I just gotta convince her to let me get a welder in the near future lol.

Feel free to keep giving advice or wisdom! Hopefully others will get some insight as well as me and welding might not seem so elusive.

Feel free to keep giving advice or wisdom! Hopefully others will get some insight as well as me and welding might not seem so elusive.

#14

Former Vendor

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,099

Youtube + seat time here. I took a welding class in college that taught me almost nothing - the most valuable thing I got from it was the seat time behind the gun/torch.

Youtube has been hugely helpful, particularly Weld.com's channel and Welding Tips and Tricks. Arguably the most valuable info they give you is the machine settings. If those are wrong, you'll never actually learn anything, because you'll be fighting those settings the entire time without knowing it. Get the settings right and you'll actually get good real-time feedback from the welds as your technique improves. Once you have the basics, and you know specific things you want to work on, just look for videos on those specific things. Repeat ad nauseum.

As far as equipment goes, I have a Miller autoset MIG and a Lincoln TIG, both 200A machines. I spent a little less on the pair of boxes than I would have spent on a full AC/DC dual-process machine, but I have a feeling that the price on those machines is going to come down pretty quickly. I also bought the MIG 4 years ago and the TIG 18mos ago, which smoothed out the bumps to my wallet.

If you have zero welding experience, I would buy an autoset MIG box from whichever company makes it in the color you like the most (red, blue, or green). Learn to weld mild steel on that, get some half-decent gear, and get the hang of things. Focus on the basics, things like torch angle, arc length, gas flow rates, travel speed, etc. Once you have a good grasp on that, get a TIG machine and start the whole process over again. More gear (TIG gloves, tungsten grinder, torch parts), more settings to play with, more basics to learn (filler material and size).

If you buy used, be aware that "previous owner" applies to welders too. I got my MIG from someone who did not treat it nicely, and I always assumed that all the issues I had were my own doing. Turns out a trashed gun tip and clogged nozzles don't do you any favors. I've finally rebuilt the entire gun at this point and that welder works far better than when I first bought it. I bought my TIG box brand new at a trade show and it was a much smoother experience.

Youtube has been hugely helpful, particularly Weld.com's channel and Welding Tips and Tricks. Arguably the most valuable info they give you is the machine settings. If those are wrong, you'll never actually learn anything, because you'll be fighting those settings the entire time without knowing it. Get the settings right and you'll actually get good real-time feedback from the welds as your technique improves. Once you have the basics, and you know specific things you want to work on, just look for videos on those specific things. Repeat ad nauseum.

As far as equipment goes, I have a Miller autoset MIG and a Lincoln TIG, both 200A machines. I spent a little less on the pair of boxes than I would have spent on a full AC/DC dual-process machine, but I have a feeling that the price on those machines is going to come down pretty quickly. I also bought the MIG 4 years ago and the TIG 18mos ago, which smoothed out the bumps to my wallet.

If you have zero welding experience, I would buy an autoset MIG box from whichever company makes it in the color you like the most (red, blue, or green). Learn to weld mild steel on that, get some half-decent gear, and get the hang of things. Focus on the basics, things like torch angle, arc length, gas flow rates, travel speed, etc. Once you have a good grasp on that, get a TIG machine and start the whole process over again. More gear (TIG gloves, tungsten grinder, torch parts), more settings to play with, more basics to learn (filler material and size).

If you buy used, be aware that "previous owner" applies to welders too. I got my MIG from someone who did not treat it nicely, and I always assumed that all the issues I had were my own doing. Turns out a trashed gun tip and clogged nozzles don't do you any favors. I've finally rebuilt the entire gun at this point and that welder works far better than when I first bought it. I bought my TIG box brand new at a trade show and it was a much smoother experience.

#16

I'm actually looking at buying a TIG and learning to weld myself simply because in the past year, the amount of money I've paid for some guy to do random aluminum welding could have easily paid for a machine but I've always been intimidated until I got a a cheapie $100 flux wire fed welder and started to just stick stuff together and now it doesn't seem so intimidating anymore.

I'll probably buy a Harbor Freight Vulcan protig 200 or omni 220 unit just because its a 1 year return policy .. so I have options in case my need changes. Just my 2c.

I'll probably buy a Harbor Freight Vulcan protig 200 or omni 220 unit just because its a 1 year return policy .. so I have options in case my need changes. Just my 2c.

#17

I'm actually looking at buying a TIG and learning to weld myself simply because in the past year, the amount of money I've paid for some guy to do random aluminum welding could have easily paid for a machine but I've always been intimidated until I got a a cheapie $100 flux wire fed welder and started to just stick stuff together and now it doesn't seem so intimidating anymore.

I'll probably buy a Harbor Freight Vulcan protig 200 or omni 220 unit just because its a 1 year return policy .. so I have options in case my need changes. Just my 2c.

I'll probably buy a Harbor Freight Vulcan protig 200 or omni 220 unit just because its a 1 year return policy .. so I have options in case my need changes. Just my 2c.

Fab work is crazy expensive. My Alpha tig has paid for itself multiple times now in the money I've saved doing my own fab work.

#18

I wouldn't even call it fab work. For example getting 2 bung welded onto my oil pan after I cleaned the pan, drilled the hole, wire brushed the area around the hole so he could have a clean weld surface and it still cost $80. Same thing with some slightly more complicated brackets for aero was $200. Yeah, that's motivation for me to learn to weld right there.

#19

I wouldn't even call it fab work. For example getting 2 bung welded onto my oil pan after I cleaned the pan, drilled the hole, wire brushed the area around the hole so he could have a clean weld surface and it still cost $80. Same thing with some slightly more complicated brackets for aero was $200. Yeah, that's motivation for me to learn to weld right there.

Its all fun and nice to weld your buddies fuel rail for cheap, until you realize that the Chinese bung is made of some **** mixture of aluminum and it just pops and spatters and pin holes. suddenly you spent 2 hrs to make 50 bucks. back out electric and consumables, and the job just cost you 10 bucks.