Pitt's 09-10 FSAE car!

#1

Elite Member

Thread Starter

iTrader: (12)

Join Date: Jan 2007

Location: Hermosa Beach, CA

Posts: 2,573

Total Cats: 12

Well guys we have been gearing up for another year of FSAE, and I figured why not make a thread here... plus I miss my miata which is back home haha.

Anyway we got 22ed out of ~120 last year at Detroit, and that was with barely any testing with the honda 600rr engine we just switched to that year (which meant a HUGE bog at ~9k rpm, it was such a bitch...).

This year we got some more money too, so I came up with the idea of switching to Motec... which is iffy ($6k for the ecu and PDM!!) but may happen (would be awesome as the Performance Electronics we use now is.. well its just ok).

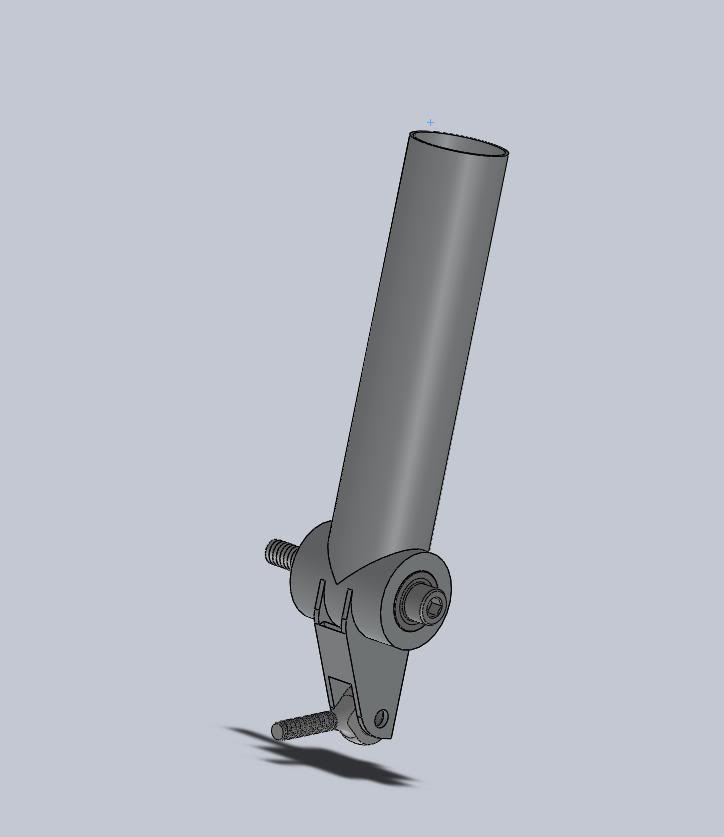

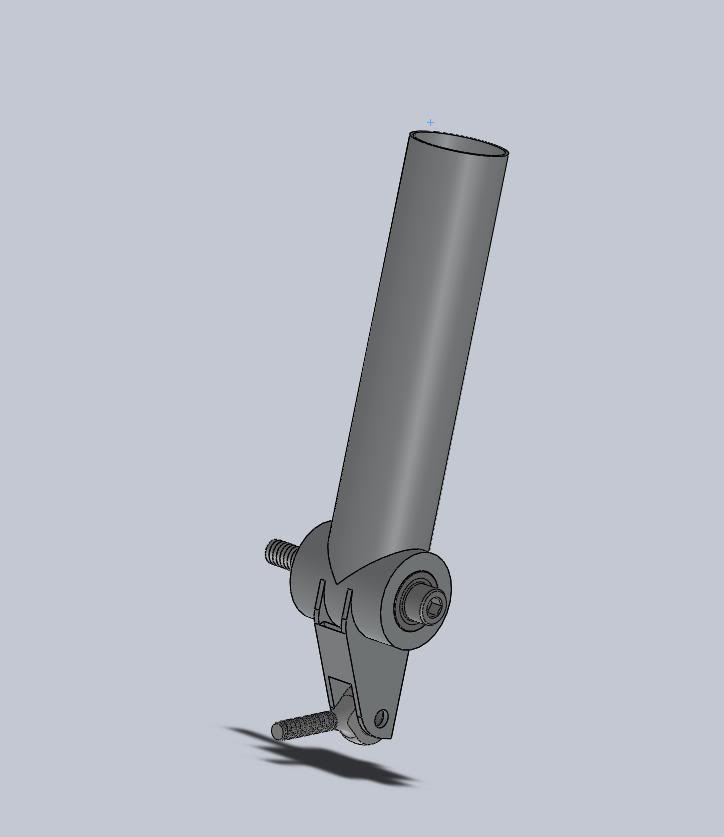

But I did just finish the shifter design... I was tasked to make a lever shifter this year as the mechanical paddle one from last year dident work well...

I think it came out well. Now I gotta work on some bodywork, which is a bitch to do in solidworks just because i dont know where to start haha.

Oh I am going to be doing a project, its going to be a electric linear solenoid that will shift, using push buttons on the steering wheel and interfacing with the ECU. Should be sweet.

Anyway we got 22ed out of ~120 last year at Detroit, and that was with barely any testing with the honda 600rr engine we just switched to that year (which meant a HUGE bog at ~9k rpm, it was such a bitch...).

This year we got some more money too, so I came up with the idea of switching to Motec... which is iffy ($6k for the ecu and PDM!!) but may happen (would be awesome as the Performance Electronics we use now is.. well its just ok).

But I did just finish the shifter design... I was tasked to make a lever shifter this year as the mechanical paddle one from last year dident work well...

I think it came out well. Now I gotta work on some bodywork, which is a bitch to do in solidworks just because i dont know where to start haha.

Oh I am going to be doing a project, its going to be a electric linear solenoid that will shift, using push buttons on the steering wheel and interfacing with the ECU. Should be sweet.

#2

I miss designing machines, I need to start using solidworks again pronto before I forget it all. Shifter looks good, what material do you plan to use?

I was going to ask a few more questions to spike design ideas but realized you're using the honda 600 and none of them applied any longer.

Good luck with the body work.

I was going to ask a few more questions to spike design ideas but realized you're using the honda 600 and none of them applied any longer.

Good luck with the body work.

#3

We never bothered with actually DESIGNING bodywork. We just mocked it up and went from there. Much of this was due to the fact that other design changes dictated bodywork changes, so we'd wait until we were reasonably sure that everything was final externally and then cut-n-fit from there. Then again I don't think we ever bothered designing a shifter, either. Maybe that's why **** was always breaking.

I will say that we wound up briefly experimenting with paddles and then dumping them because they were more of a pain in the *** than they were worth. Will that shifter be getting a hand clutch, or are you sticking with a foot clutch? Hand clutch allows the footwell to be redesigned more efficiently.

MoTec makes good stuff, but for the price, well, it better be damn good stuff. Microsquirt is much, much more cost effective.

Personally I think the biggest problem you're fighting is sticking with a 4-cylinder engine. Weight and packaging are a royal pain in the ***, lack of torque on tight courses is a pain in the ***, the whole thing is a pain in the ***. Then again, when you rip the restrictor off of a retired car and really let it scream...

I will say that we wound up briefly experimenting with paddles and then dumping them because they were more of a pain in the *** than they were worth. Will that shifter be getting a hand clutch, or are you sticking with a foot clutch? Hand clutch allows the footwell to be redesigned more efficiently.

MoTec makes good stuff, but for the price, well, it better be damn good stuff. Microsquirt is much, much more cost effective.

Personally I think the biggest problem you're fighting is sticking with a 4-cylinder engine. Weight and packaging are a royal pain in the ***, lack of torque on tight courses is a pain in the ***, the whole thing is a pain in the ***. Then again, when you rip the restrictor off of a retired car and really let it scream...

#4

Elite Member

Thread Starter

iTrader: (12)

Join Date: Jan 2007

Location: Hermosa Beach, CA

Posts: 2,573

Total Cats: 12

We never bothered with actually DESIGNING bodywork. We just mocked it up and went from there. Much of this was due to the fact that other design changes dictated bodywork changes, so we'd wait until we were reasonably sure that everything was final externally and then cut-n-fit from there. Then again I don't think we ever bothered designing a shifter, either. Maybe that's why **** was always breaking.

I will say that we wound up briefly experimenting with paddles and then dumping them because they were more of a pain in the *** than they were worth. Will that shifter be getting a hand clutch, or are you sticking with a foot clutch? Hand clutch allows the footwell to be redesigned more efficiently.

MoTec makes good stuff, but for the price, well, it better be damn good stuff. Microsquirt is much, much more cost effective.

Personally I think the biggest problem you're fighting is sticking with a 4-cylinder engine. Weight and packaging are a royal pain in the ***, lack of torque on tight courses is a pain in the ***, the whole thing is a pain in the ***. Then again, when you rip the restrictor off of a retired car and really let it scream...

I will say that we wound up briefly experimenting with paddles and then dumping them because they were more of a pain in the *** than they were worth. Will that shifter be getting a hand clutch, or are you sticking with a foot clutch? Hand clutch allows the footwell to be redesigned more efficiently.

MoTec makes good stuff, but for the price, well, it better be damn good stuff. Microsquirt is much, much more cost effective.

Personally I think the biggest problem you're fighting is sticking with a 4-cylinder engine. Weight and packaging are a royal pain in the ***, lack of torque on tight courses is a pain in the ***, the whole thing is a pain in the ***. Then again, when you rip the restrictor off of a retired car and really let it scream...

The shifter is going to be made of alum. for weight. We will problaly stick with a foot clutch for simplicity this year.

I personally love the 4 cylinder, the power and sound is sick

#5

The problem with unrestricted running is that you wind up with way more power than the wheelbase allows you to safely use. It's all fun and games until somebody hits something and the combination of impact force and sub strap cause their voice to be permanently higher.

Aluminum makes the most sense. Just make up 2-3 spares for when some bonehead breaks and/or bends it. The normal cause of such bending/breaking is hanging onto it and using it to brace yourself when driving.

Foot clutch has advantages and disadvantages. Most typically cited advantage is that it's what you used last year and therefore it's the easiest to reproduce. Nothing wrong with that, if you don't hold over at least some of the stuff, you'll never get anything done. Downside is that little stuff often gets lost amid a sea of big stuff.

I wanted to love the 4-cylinders, we were using R6 motors. Not just the sound and power, but the amount of money we'd sunk into developing headers, intakes, tuning and everything went straight out the window with the decision to go to a single cylinder, not to mention that the pile of spare parts became essentially useless. Alas, the pros and cons were made and the decision was made to go to the 450 single cylinder. I don't think they've looked back since.

Best of luck with everything and please keep me/us updated. If there's anything you're curious about I'd be happy to chime in with what we found. I've discovered from talking to other teams over the years, alumni from before I participated and people still on the team after I'd graduated, the same stuff tends to come up over and over and over. Granted, things change over the years and what was a good idea/decision then isn't necessarily a good idea/decision now, but there were/are plenty of things that were tried and failed and don't need to be tried again.

Aluminum makes the most sense. Just make up 2-3 spares for when some bonehead breaks and/or bends it. The normal cause of such bending/breaking is hanging onto it and using it to brace yourself when driving.

Foot clutch has advantages and disadvantages. Most typically cited advantage is that it's what you used last year and therefore it's the easiest to reproduce. Nothing wrong with that, if you don't hold over at least some of the stuff, you'll never get anything done. Downside is that little stuff often gets lost amid a sea of big stuff.

I wanted to love the 4-cylinders, we were using R6 motors. Not just the sound and power, but the amount of money we'd sunk into developing headers, intakes, tuning and everything went straight out the window with the decision to go to a single cylinder, not to mention that the pile of spare parts became essentially useless. Alas, the pros and cons were made and the decision was made to go to the 450 single cylinder. I don't think they've looked back since.

Best of luck with everything and please keep me/us updated. If there's anything you're curious about I'd be happy to chime in with what we found. I've discovered from talking to other teams over the years, alumni from before I participated and people still on the team after I'd graduated, the same stuff tends to come up over and over and over. Granted, things change over the years and what was a good idea/decision then isn't necessarily a good idea/decision now, but there were/are plenty of things that were tried and failed and don't need to be tried again.

#6

We did this last year, and you are going to bend the **** out of it and it will be a sloppy dick after your first outing with it. Think about it, how many OEM or aftermarket automotive shifters do you see out there? There is a reason for that.

We are rigging up the jig table tonight, and hopefully I will have some pictures of our progress by the weekend.

Last year was ok for us. Our car was poorly planned out, and we didn't have enough time for testing before, but we actually didn't do too bad in the dynamic events. We didn't finish the endurance due to one of the halfshafts sliding out of the diff and taking us out five laps in. We were hauling ***, overtaking cars here and there, those five laps though.

#7

Elite Member

Thread Starter

iTrader: (12)

Join Date: Jan 2007

Location: Hermosa Beach, CA

Posts: 2,573

Total Cats: 12

Also, freaking great news at the meeting tonight, 95% chance we are going to get an engine dyno!!! Woot, tuning will be awesome now, but that does mean no motec for this year. I think the dyno is a better choice tho!

#8

What did your design look like last year? Ill keep that in mind.

Also, freaking great news at the meeting tonight, 95% chance we are going to get an engine dyno!!! Woot, tuning will be awesome now, but that does mean no motec for this year. I think the dyno is a better choice tho!

Also, freaking great news at the meeting tonight, 95% chance we are going to get an engine dyno!!! Woot, tuning will be awesome now, but that does mean no motec for this year. I think the dyno is a better choice tho!

We have an engine dyno at our shop, but not really allowed to use it. One of our bigger sponsors in Superchips, who let us use their chassis dyno. We also used the PE last year, and I have NOTHING good to say about that system. I believe we are switching to Haltech this year, but that is pending a donation by one of the member's family.

#9

Elite Member

Thread Starter

iTrader: (12)

Join Date: Jan 2007

Location: Hermosa Beach, CA

Posts: 2,573

Total Cats: 12

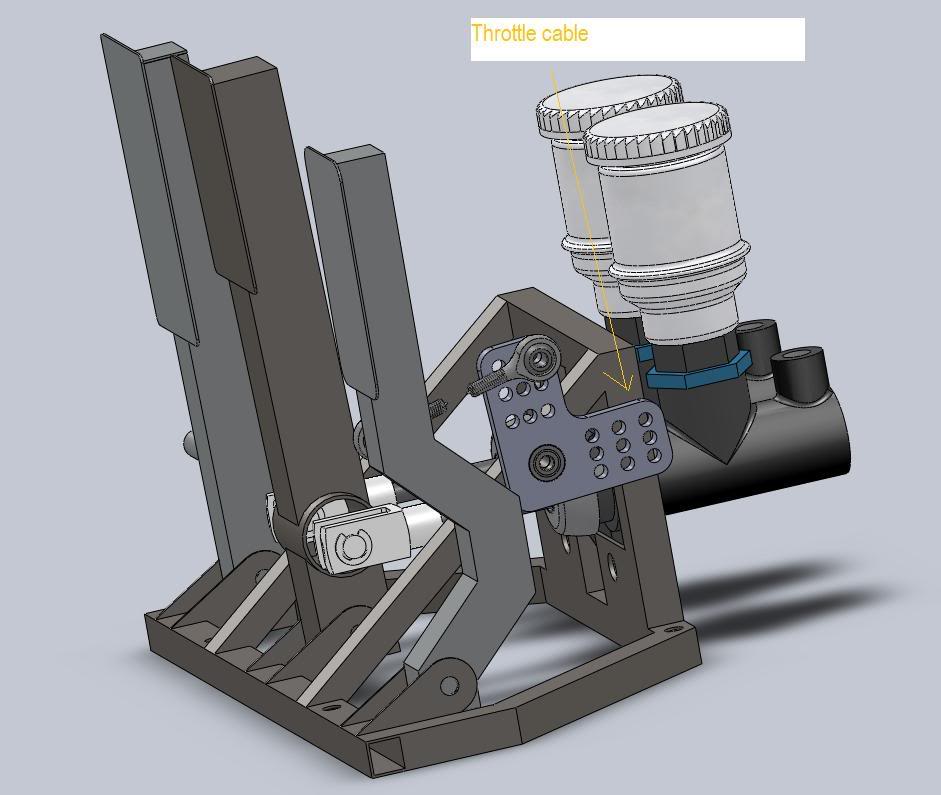

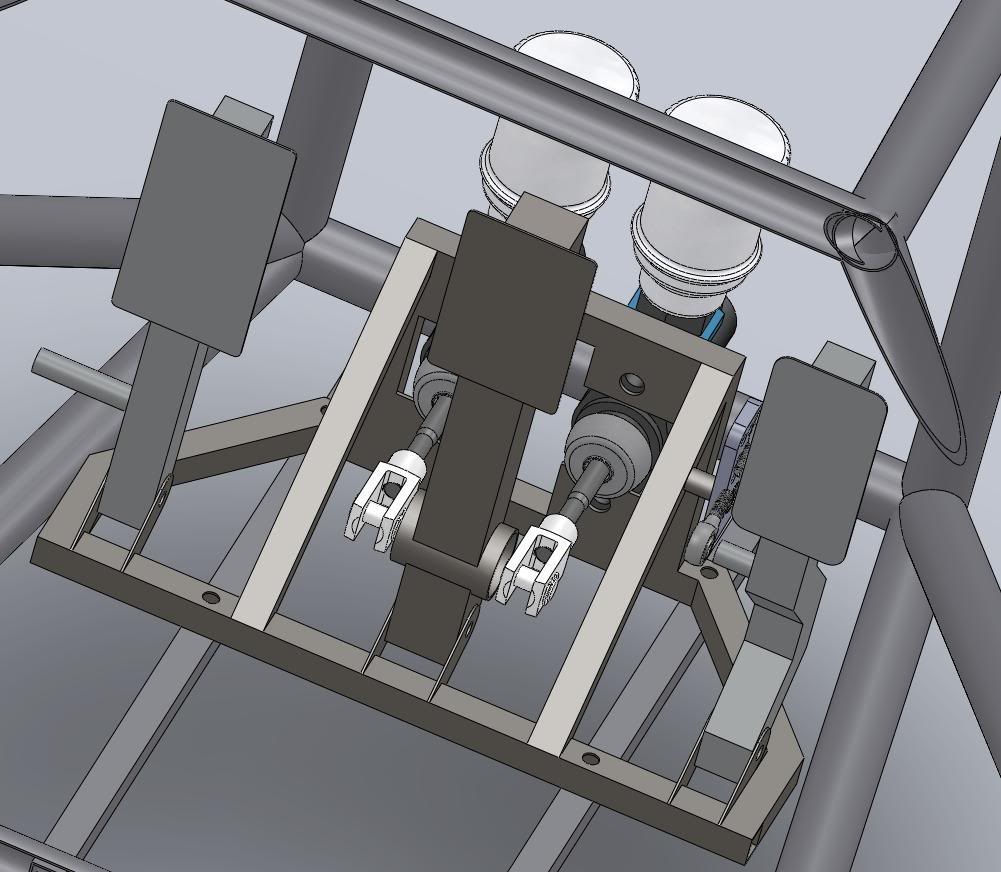

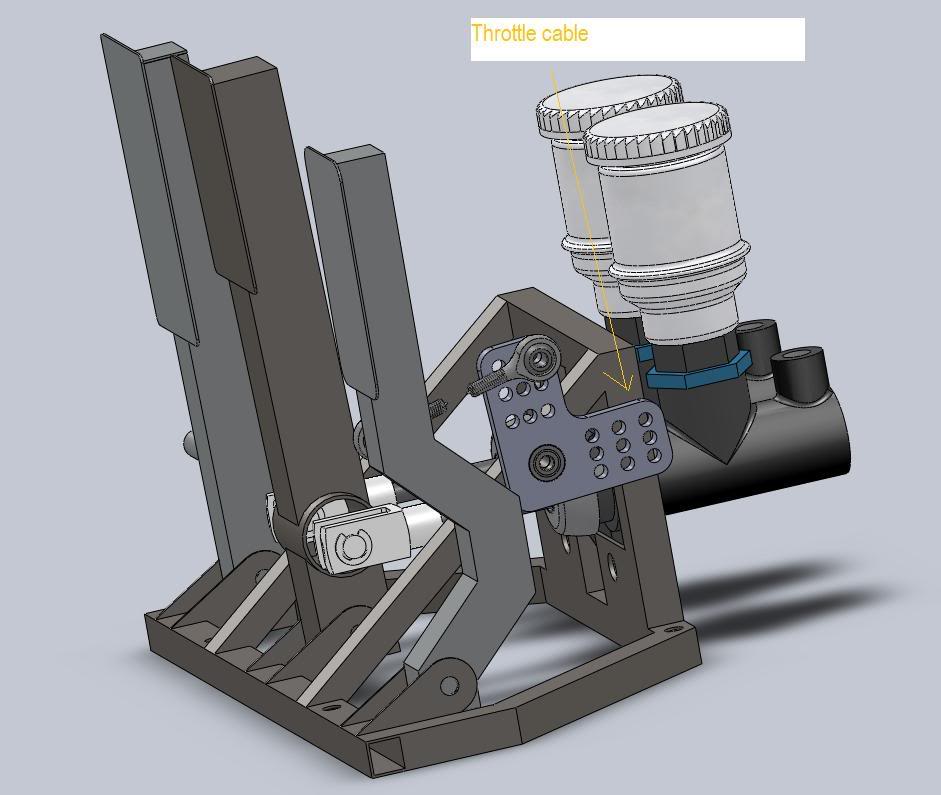

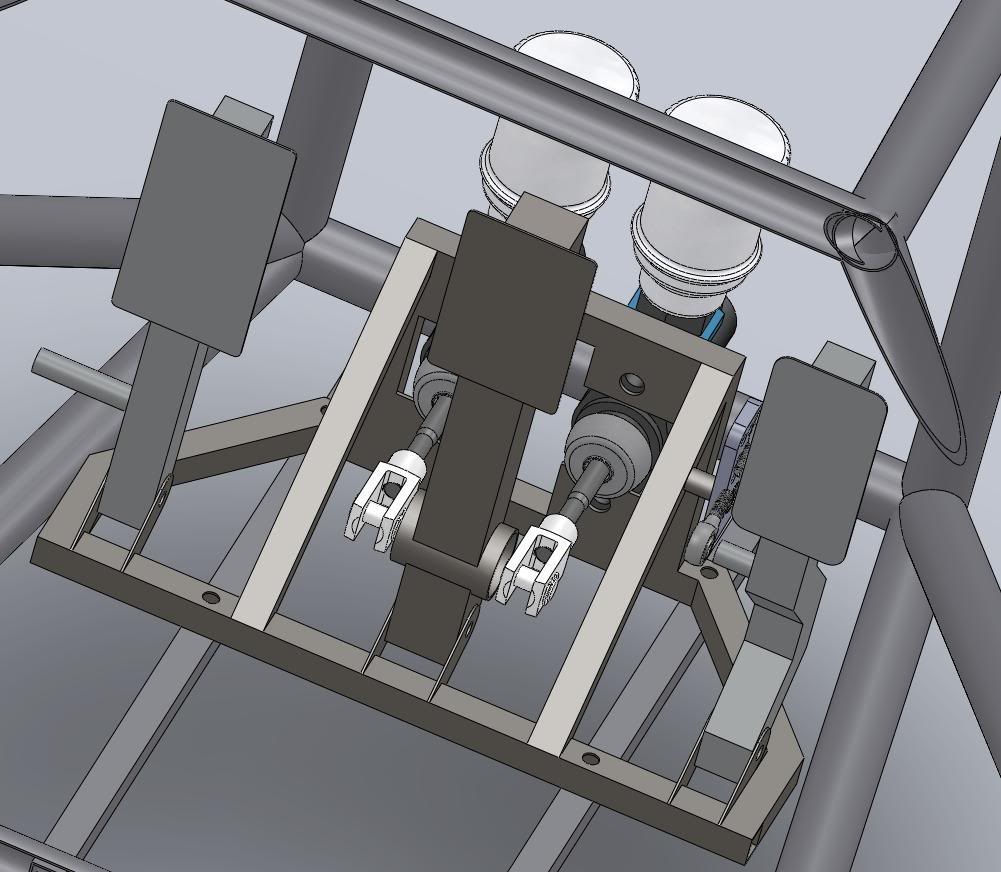

Well, I am trying to finish up the pedal box, here is what I got so far. I stole the adjustable throttle from tilton, dunno if it will be used or not. Thought it was a cool idea tho haha.

#14

It looks like pretty much every other FSAE car pedalbox using floor-mounted pedals. Are you saying that you have a better plan, or are you just trying to toss out comments that are marginally above worthless to boost your post count without being called out on it?

Edit- Since it's a cable clutch and not hydraulic, the pedal box is somewhat simpler than others, upon further thought. So basically STFU.

It comes out to around 3.35 lbs in solidworks.

That's not too shabby. Are you making it adjustable?

Edit- Since it's a cable clutch and not hydraulic, the pedal box is somewhat simpler than others, upon further thought. So basically STFU.

Originally Posted by cardriverx

It comes out to around 3.35 lbs in solidworks.

#16

It looks like pretty much every other FSAE car pedalbox using floor-mounted pedals. Are you saying that you have a better plan, or are you just trying to toss out comments that are marginally above worthless to boost your post count without being called out on it?

Edit- Since it's a cable clutch and not hydraulic, the pedal box is somewhat simpler than others, upon further thought. So basically STFU.

That's not too shabby. Are you making it adjustable?

Edit- Since it's a cable clutch and not hydraulic, the pedal box is somewhat simpler than others, upon further thought. So basically STFU.

That's not too shabby. Are you making it adjustable?

1.) Using a hand clutch seems like it'd be a huge deal to learn to drive around, but it's actually not much a learning curve at all. Our (UAHunstville's) last hand clutch weighed 2 lbs less than the foot clutch/ extra cable length/ extra bracing on the pedal box. We played with air/ linear actuator clutch actuation for a while, but, while launches were perfect every time, you had to spend 20 minutes explaining how to operate the thing to every freshman who wanted to drive the car. Replacing clutches in the car gets old REALLY fast.

2.) Why use that turn buckle/ adjuster plate assembly? Why not put a pin on the side throttle pedal like you did with the pin that pulls the clutch cable in your current design?

3.) I like to use box tube for the bottom tubes in the foot box. This allows you to make the pedal box adjustable for driver leg length/ preference very easily with a few simple square brackets and aircraft push pins. In the 'production' drawings for the design report, you would logically just have a series of adjustment holes a set distance apart, but we actually had a set of holes for each driver. Our car fit both a 6'4" 185 lb driver and a 5'6" 165 lb driver (me) at competition with only the 4 push pins in the pedal box and a seat pad swap. Actually, our electronics guy drove the car more than anyone, and he was 6'2" and every bit of 325... He just pulled the seat pad entirely and ran the pedals all the way out.

#17

Elite Member

Thread Starter

iTrader: (12)

Join Date: Jan 2007

Location: Hermosa Beach, CA

Posts: 2,573

Total Cats: 12

The adjuster plate is an idea I had to allow for an adjustable throttle throw/pedal to cable ratio. Plus it makes cable mounting simple. I took the idea from some baller tilton box.

It will be adjustable using pins when all is said and done.

We thought about making a hand clutch, then figured it would be too hard to learn (aka in an emergency you are used to mashing the clutch with your left foot, not pulling a lever).

It will be adjustable using pins when all is said and done.

We thought about making a hand clutch, then figured it would be too hard to learn (aka in an emergency you are used to mashing the clutch with your left foot, not pulling a lever).

#18

We actually had a guy go 'two feet in' in a panic situation, hit the only two pedals in the foot box and push the fronts/ spin the rears all the way across a parking lot into a fence post. He had no business being in the car in the first place, though. In hind sight, i would still go with a two pedal arrangement, and just not let morons drive the car. Having enough room to move your feet around the foot box is SOOOOO nice in the endurance event.

#19

Elite Member

Thread Starter

iTrader: (12)

Join Date: Jan 2007

Location: Hermosa Beach, CA

Posts: 2,573

Total Cats: 12

We actually had a guy go 'two feet in' in a panic situation, hit the only two pedals in the foot box and push the fronts/ spin the rears all the way across a parking lot into a fence post. He had no business being in the car in the first place, though. In hind sight, i would still go with a two pedal arrangement, and just not let morons drive the car. Having enough room to move your feet around the foot box is SOOOOO nice in the endurance event.