All your electronic are belong to us: TIN WHISKERS

#1

Elite Member

Thread Starter

iTrader: (7)

Join Date: Jul 2009

Location: Jackson, MS

Posts: 7,388

Total Cats: 474

So I've been reading up on tin whiskers, and WHAT THE HELL.

All of your modern electronics made with lead-free solder will probably last 10-15 years at most* before tin whiskers start producing shorts and errors. In the early days of electronic circuitry, the tin whisker phenomenon was observed but not understood, but a switch to leaded solder fixed the problem.

As environmental concerns reduced the use of leaded solder (and consumer electronics were again made with lead-free solder), the mysterious menace returned: tin whiskers.

http://en.wikipedia.org/wiki/Whisker_(metallurgy)

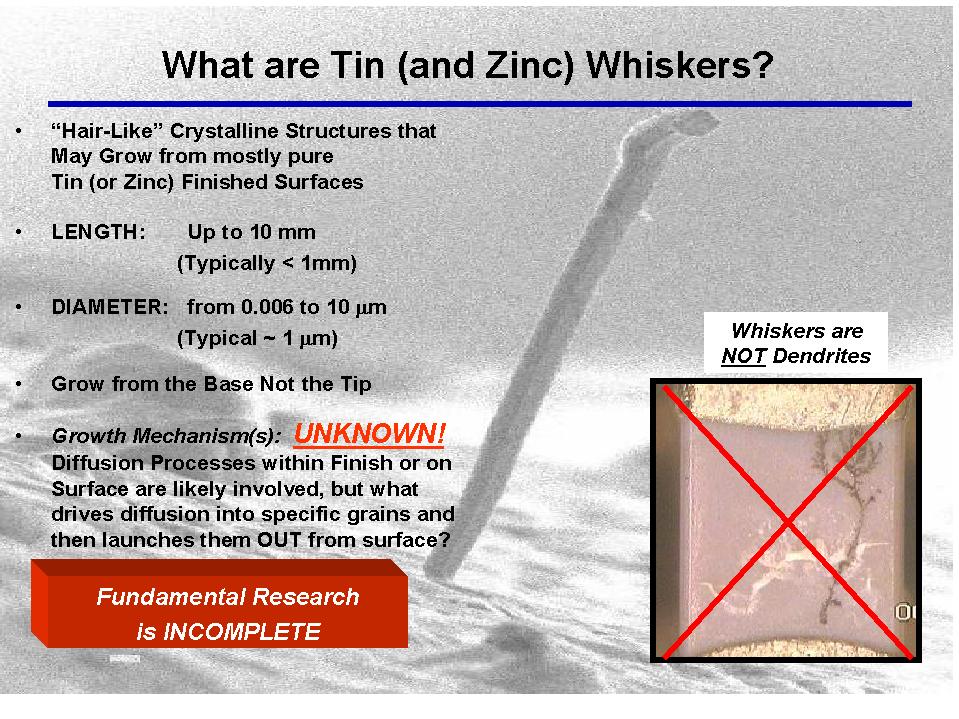

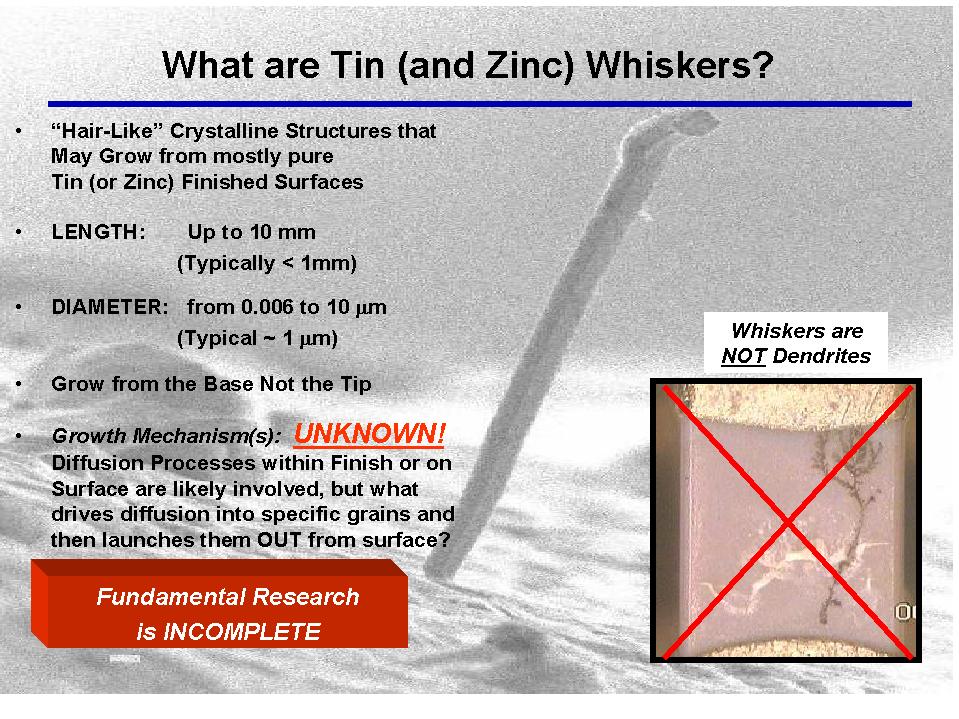

Basic Info on Tin Whiskers

Not only is it going to KILL your iPod, we don't even understand how it works. We know that it happens, but we don't know how or why. Actually, "how" and "why" are redundant questions with modern reductionist scientific method, but I digress.

What shall be done about the tin whisker menace?

*Granted, all of your consumer electronics are obsolete 3 times over by the time tin whiskers finally kills them, but whatever.

All of your modern electronics made with lead-free solder will probably last 10-15 years at most* before tin whiskers start producing shorts and errors. In the early days of electronic circuitry, the tin whisker phenomenon was observed but not understood, but a switch to leaded solder fixed the problem.

As environmental concerns reduced the use of leaded solder (and consumer electronics were again made with lead-free solder), the mysterious menace returned: tin whiskers.

http://en.wikipedia.org/wiki/Whisker_(metallurgy)

Basic Info on Tin Whiskers

Not only is it going to KILL your iPod, we don't even understand how it works. We know that it happens, but we don't know how or why. Actually, "how" and "why" are redundant questions with modern reductionist scientific method, but I digress.

What shall be done about the tin whisker menace?

*Granted, all of your consumer electronics are obsolete 3 times over by the time tin whiskers finally kills them, but whatever.

#2

I work with a guy from IBM who was involved with some in-depth studies from a few decades ago so I'm aware of the problem.

The electronics lead scare and subsequent lead bannage was based on a flawed study. Try undoing *any* enviro-related regs that were justified by bad science....

When lead-free solder was first introduced, there were a lot of failures as the industry had to re-learn how to solder properly. Lots of folks predicted that there would be long-term reliability problems even after that initial learning phase. In our lab, the stuff is banned from being used in prototypes, because hand soldering with the unleaded stuff produces unreliable joints and overheated parts.

The electronics lead scare and subsequent lead bannage was based on a flawed study. Try undoing *any* enviro-related regs that were justified by bad science....

When lead-free solder was first introduced, there were a lot of failures as the industry had to re-learn how to solder properly. Lots of folks predicted that there would be long-term reliability problems even after that initial learning phase. In our lab, the stuff is banned from being used in prototypes, because hand soldering with the unleaded stuff produces unreliable joints and overheated parts.

#8

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,022

Total Cats: 6,589

The ROHS transition has been kind of a pain in the *** for us in the electronics-manufacturing industry.

There were some initial yield problems, but nothing too severe. And while we've been lead-free for about six years now, we haven't seen much in the way of abnormal whiskering.

The biggest annoyance is simply with servicing lead-free boards on the bench. Lead-free solder is, quite frankly, a pain in the *** to deal with as compared to 63/37. At first, the company was pretty strict about declaring that we had to stock (and use) lead free solder for all bench repairs, but they've long since stopped paying attention. We now have a box full of lead-free solder in the storage locker, and have gone back to the old stuff at the bench.

Fortunately, it's not illegal to make or sell conventional leaded solder, and I haven't heard anything that makes me believe this will change any time soon. The price has gone up a bit, but you can still buy it just as easily as ever from Fry's / Radioshack / Mouser / etc.

Sidebar: You have a lot of electronic devices older than ten years in your life. Your microwave oven, the clock-radio beside your bed, the amplifier in the cable TV line that's just outside your house (and the dozen or so like it between you and the headend), the dimmers / fan-speed-controls in your walls, most of the underlying infrastructure of the internet, the keycard entry system where you work, the phones and PBX in your office, your garage-door opener and its associated remote, the cash register at the place where you buy your pony-related plush collectables, etc...

There were some initial yield problems, but nothing too severe. And while we've been lead-free for about six years now, we haven't seen much in the way of abnormal whiskering.

The biggest annoyance is simply with servicing lead-free boards on the bench. Lead-free solder is, quite frankly, a pain in the *** to deal with as compared to 63/37. At first, the company was pretty strict about declaring that we had to stock (and use) lead free solder for all bench repairs, but they've long since stopped paying attention. We now have a box full of lead-free solder in the storage locker, and have gone back to the old stuff at the bench.

Fortunately, it's not illegal to make or sell conventional leaded solder, and I haven't heard anything that makes me believe this will change any time soon. The price has gone up a bit, but you can still buy it just as easily as ever from Fry's / Radioshack / Mouser / etc.

Sidebar: You have a lot of electronic devices older than ten years in your life. Your microwave oven, the clock-radio beside your bed, the amplifier in the cable TV line that's just outside your house (and the dozen or so like it between you and the headend), the dimmers / fan-speed-controls in your walls, most of the underlying infrastructure of the internet, the keycard entry system where you work, the phones and PBX in your office, your garage-door opener and its associated remote, the cash register at the place where you buy your pony-related plush collectables, etc...

#10

Oh well.

#11

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,022

Total Cats: 6,589

You guys weren't exempt?

What's a typical service lifetime for a commercial jet? Yes, I know it's expressed in hours and cycles, but in real-world terms, 30 years?

The Military folks push their stuff a lot longer than that. Whole lotta military jets older than the crews that are flying them. They stopped building the B52 in 1962, so the very youngest of those planes is 51 years old.

In my world (broadcast equipment), 20 years is pretty common for studio gear, and transmitters are expected to last 30+ years, operating at full power 24/7.

What's a typical service lifetime for a commercial jet? Yes, I know it's expressed in hours and cycles, but in real-world terms, 30 years?

The Military folks push their stuff a lot longer than that. Whole lotta military jets older than the crews that are flying them. They stopped building the B52 in 1962, so the very youngest of those planes is 51 years old.

In my world (broadcast equipment), 20 years is pretty common for studio gear, and transmitters are expected to last 30+ years, operating at full power 24/7.

#12

Doesn't matter. When the non-ROHS part goes end of life, you either have to swag what you might use for the next 20 years and make a lifetime buy or you change the design to use the ROHS part (and recertify). The manufacture of basic electronic componenents is driven by consumer equipment, not by the miniscule volume of avionics/military. Design cycles for consumer equipment is measured in months to 2 years, not in decades.

#13

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,022

Total Cats: 6,589

I've no idea what FAA certs have to say on the subject, but it's been my personal experience that RoHS-compliant parts seem to be entirely compatible with conventional leaded-solder processes, regardless of whether you're doing wave, reflow, or hand-placement. We don't even flux them differently.

#14

Our issue is that when we replace ROHS with non-ROHS (even if the part is otherwise identical -- think basic resistors/capacitors), we have "changed" the design as far as the FAA b'crats are concerned. It's maddening.

The other fun part is when the MBAs that run the joint (and don't have the slightest clue) decide that you're holding too much inventory and sell off the lifetime buys.

Even though my focus is software, I still get to deal with this on a seemingly weekly basis.

The other fun part is when the MBAs that run the joint (and don't have the slightest clue) decide that you're holding too much inventory and sell off the lifetime buys.

Even though my focus is software, I still get to deal with this on a seemingly weekly basis.

Thread

Thread Starter

Forum

Replies

Last Post

Zaphod

MEGAsquirt

47

10-26-2018 11:00 PM

Braineack

Cars for sale/trade

3

09-04-2015 02:12 PM