Hi from a rotary/roadrace nut.

#1

Hm, don't think I ever did one of these.

So hi, I'm Dan, I'm a 30-something engineer. Been going racing with my dad (mostly him driving) in RX-7s since about '02, now he's moved over to an NC prepped for SCCA T4 (CAI, suspension package, Hoosiers, little else) and I'm looking at sharing the car starting this year. Of course, since there's a massive pile of rotary parts leftover, I'm prepping a '94 from a bare shell for SCCA STU - which is a splitter/airdam/wing, Hoosiers, engine swap allowed plus big brakes class (I can get into more details but whatever). The "normal" Miata solution is a Mazdaspeed flogged to within an inch of the turbo's life (either stock turbos or small replacements are allowed - IHI VF30, GT2554R, some K03 and restrictors are required) but I've wanted to do a 13B in a Miata for years, so what the hell.

I'm working on ... a lot of details and supporting equipment so it's not a short term project, and quite frankly I figure I'm better off learning to drive on comparatively stock NC. Coming from a test engineering background (and learning from crewing for my dad) I'm not satisfied with most DAQ solutions so I'm working on rolling my own (seriously, I don't want to shell out for a race grade DAQ that will do 50-some channels) I'm doing aluminum castings for fun, working on the second version of my DIY shock dyno, flowbench adapters for rotary parts... yes, I am a nut.

So hi, I'm Dan, I'm a 30-something engineer. Been going racing with my dad (mostly him driving) in RX-7s since about '02, now he's moved over to an NC prepped for SCCA T4 (CAI, suspension package, Hoosiers, little else) and I'm looking at sharing the car starting this year. Of course, since there's a massive pile of rotary parts leftover, I'm prepping a '94 from a bare shell for SCCA STU - which is a splitter/airdam/wing, Hoosiers, engine swap allowed plus big brakes class (I can get into more details but whatever). The "normal" Miata solution is a Mazdaspeed flogged to within an inch of the turbo's life (either stock turbos or small replacements are allowed - IHI VF30, GT2554R, some K03 and restrictors are required) but I've wanted to do a 13B in a Miata for years, so what the hell.

I'm working on ... a lot of details and supporting equipment so it's not a short term project, and quite frankly I figure I'm better off learning to drive on comparatively stock NC. Coming from a test engineering background (and learning from crewing for my dad) I'm not satisfied with most DAQ solutions so I'm working on rolling my own (seriously, I don't want to shell out for a race grade DAQ that will do 50-some channels) I'm doing aluminum castings for fun, working on the second version of my DIY shock dyno, flowbench adapters for rotary parts... yes, I am a nut.

#2

I'm bored, have some pictures!

Dad's workshop - visible is one of the welders, the Locost frame, the lathe, and the mill is off to the right.

Spare car shells. I think we're at about a dozen 1st gen RX-7s and assorted lesser cars. The parts Miata is back there too.

3d printed intake manifold for a 13B to an Arcticat snowmobile throttle body for the Locost. Not usable as is; it's a pattern for investment casting.

The foundry!

Shift **** I did for a secret santa this year.

The last proper EP RX-7 build we did. Got wrecked though, oops.

The new project shell. Yeah, needs a bit of work.

Dad's workshop - visible is one of the welders, the Locost frame, the lathe, and the mill is off to the right.

Spare car shells. I think we're at about a dozen 1st gen RX-7s and assorted lesser cars. The parts Miata is back there too.

3d printed intake manifold for a 13B to an Arcticat snowmobile throttle body for the Locost. Not usable as is; it's a pattern for investment casting.

The foundry!

Shift **** I did for a secret santa this year.

The last proper EP RX-7 build we did. Got wrecked though, oops.

The new project shell. Yeah, needs a bit of work.

#4

Oh yeah, and a doing-the-math time on my thinking... turbo Miatas have done well in the class (Marc Hoover being one example) though SCCA has sort of tried to dial things back a bit. SCCA doesn't do things like NASA (where it seems like a lot of you guys run) so they don't believe in dynos, performance balancing is done by stuff that can be teched with a teardown. Turbos in the class are restrictor size vs weight, and RWD/AWD takes a 2mm penalty... so long story short, you can run 2525 pounds (with driver) with a 32mm restrictor, 2675 for a 33mm restrictor, and so on if you want an even piggier car. On Garrett's rally potato map, they call a 34mm restrictor 28 lb/min, so I figure a 32mm one is around 25 lb/min.

Now, with pretty open engine rules and antilag, I figure it would be possible to have a broad as hell powerband and a lot of midrange torque, throw a T5 in and avoid shifting much... but that's not a cheap engine build and it's only a ballpark, what, 210-220hp at the wheels on a 2525 pound car? And probably treating turbos as wear items.

In contrast, I know I can do at least 210whp with a 13B with parts I have sitting around and no development whatsoever, probably more with development, and a streetport 13B is allowed to run at 2300 pounds. Yes yes, narrower powerband, but transmission options are more or less wide open in the class (sequentials have a weight penalty) and naturally aspirated rotaries have pretty good longevity in roadrace duty. And I have the parts.

Now, with pretty open engine rules and antilag, I figure it would be possible to have a broad as hell powerband and a lot of midrange torque, throw a T5 in and avoid shifting much... but that's not a cheap engine build and it's only a ballpark, what, 210-220hp at the wheels on a 2525 pound car? And probably treating turbos as wear items.

In contrast, I know I can do at least 210whp with a 13B with parts I have sitting around and no development whatsoever, probably more with development, and a streetport 13B is allowed to run at 2300 pounds. Yes yes, narrower powerband, but transmission options are more or less wide open in the class (sequentials have a weight penalty) and naturally aspirated rotaries have pretty good longevity in roadrace duty. And I have the parts.

#5

So, I don't know if it's normal to do stuff here or if I should post a build thread... I may do that anyway, but later. Is it weird to do a build thread when most of the stuff I'm building at this point is infrastructure to build the car? Serious question.

As I mentioned in the OP, I'm a test engineer, and I'm actually working in the R&D arm of a small engine company. So I've had a bunch of exposure to engine dynos in the last couple years, and before that exposure to high powered Labview based DAQ systems. And the other week I sorta stopped, peered at one of the engine dynos, and said to myself, "hey wait, I could build that."

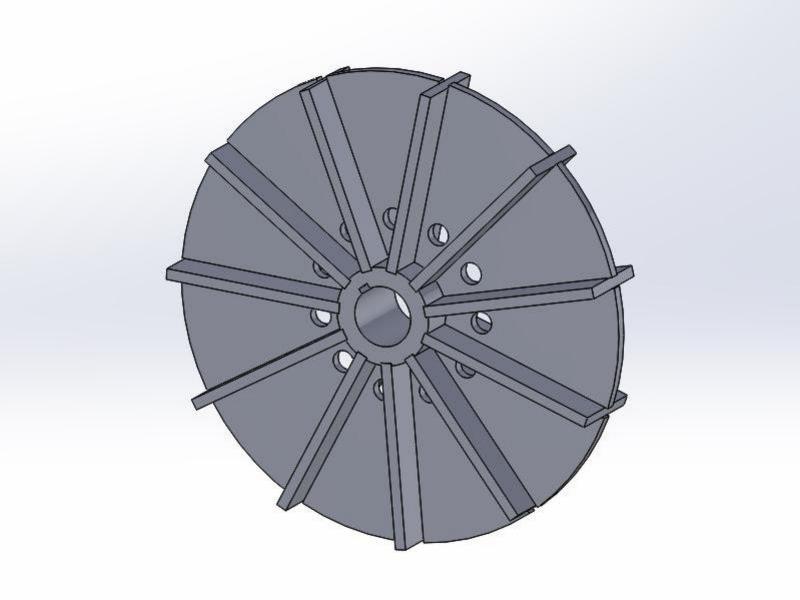

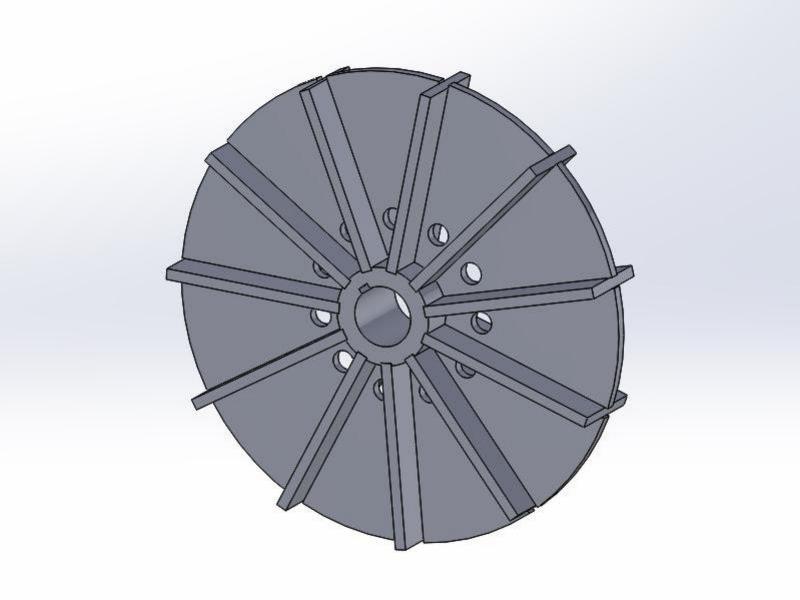

OK, that's not strictly true. At work we're using AC motor dynos, which can motor the engines and hold them at very specific RPMs very easily, regenerate power back into the grid, etc - that's expensive, especially to have practical power dissipation for useful engines. But water brakes are nice and simple - I have a friend who found a surplus Stuska and built it with manual control and all, and he has zero background in test stuff. So a few hours in solidworks and I have this.

So that's the impeller side for a water brake, in this case designed to be a weldment out of 1/4" plate. Comparing sizing, commercially available units this big will dissipate about 600ft/lbs of torque - assuming "backyard DIY" inefficiencies, it still should be plenty for the first round of what I have in mind. I'm speccing the bearings and seals for 15k RPM to give myself a bit of leeway. No, it almost definitely won't do 600ft/lbs and 15k RPM at the same time.

Data side, I picked up a PCIe based Labview card off ebay - 16 analog inputs at about a million samples per second, 2 analog outputs, and 24 digital IO ports. So that should be able to do about anything I have in mind given the right signal conditioning, up to and including combustion pressure monitoring if I get the right sensors. Now, I'd need a different sort of setup to do load cells or thermocouples directly into the DAQ or steppers on the output side, but I'm not too bothered about having a bit of extra circuitry. Need to build a PC for it obviously. The intent is to have automatic load control and throttle control, be able to program in RPM sweeps or... quite frankly a bunch of functions. I mean, if I sit down to write it, there's no reason Labview can't talk to a Megasquirt in the same way Tunerstudio does, and you guys can probably put together some of the implications from that.

Anyway, I mentioned "nut" in the title of the OP, and I want to make it clear that I'm not kidding.

As I mentioned in the OP, I'm a test engineer, and I'm actually working in the R&D arm of a small engine company. So I've had a bunch of exposure to engine dynos in the last couple years, and before that exposure to high powered Labview based DAQ systems. And the other week I sorta stopped, peered at one of the engine dynos, and said to myself, "hey wait, I could build that."

OK, that's not strictly true. At work we're using AC motor dynos, which can motor the engines and hold them at very specific RPMs very easily, regenerate power back into the grid, etc - that's expensive, especially to have practical power dissipation for useful engines. But water brakes are nice and simple - I have a friend who found a surplus Stuska and built it with manual control and all, and he has zero background in test stuff. So a few hours in solidworks and I have this.

So that's the impeller side for a water brake, in this case designed to be a weldment out of 1/4" plate. Comparing sizing, commercially available units this big will dissipate about 600ft/lbs of torque - assuming "backyard DIY" inefficiencies, it still should be plenty for the first round of what I have in mind. I'm speccing the bearings and seals for 15k RPM to give myself a bit of leeway. No, it almost definitely won't do 600ft/lbs and 15k RPM at the same time.

Data side, I picked up a PCIe based Labview card off ebay - 16 analog inputs at about a million samples per second, 2 analog outputs, and 24 digital IO ports. So that should be able to do about anything I have in mind given the right signal conditioning, up to and including combustion pressure monitoring if I get the right sensors. Now, I'd need a different sort of setup to do load cells or thermocouples directly into the DAQ or steppers on the output side, but I'm not too bothered about having a bit of extra circuitry. Need to build a PC for it obviously. The intent is to have automatic load control and throttle control, be able to program in RPM sweeps or... quite frankly a bunch of functions. I mean, if I sit down to write it, there's no reason Labview can't talk to a Megasquirt in the same way Tunerstudio does, and you guys can probably put together some of the implications from that.

Anyway, I mentioned "nut" in the title of the OP, and I want to make it clear that I'm not kidding.