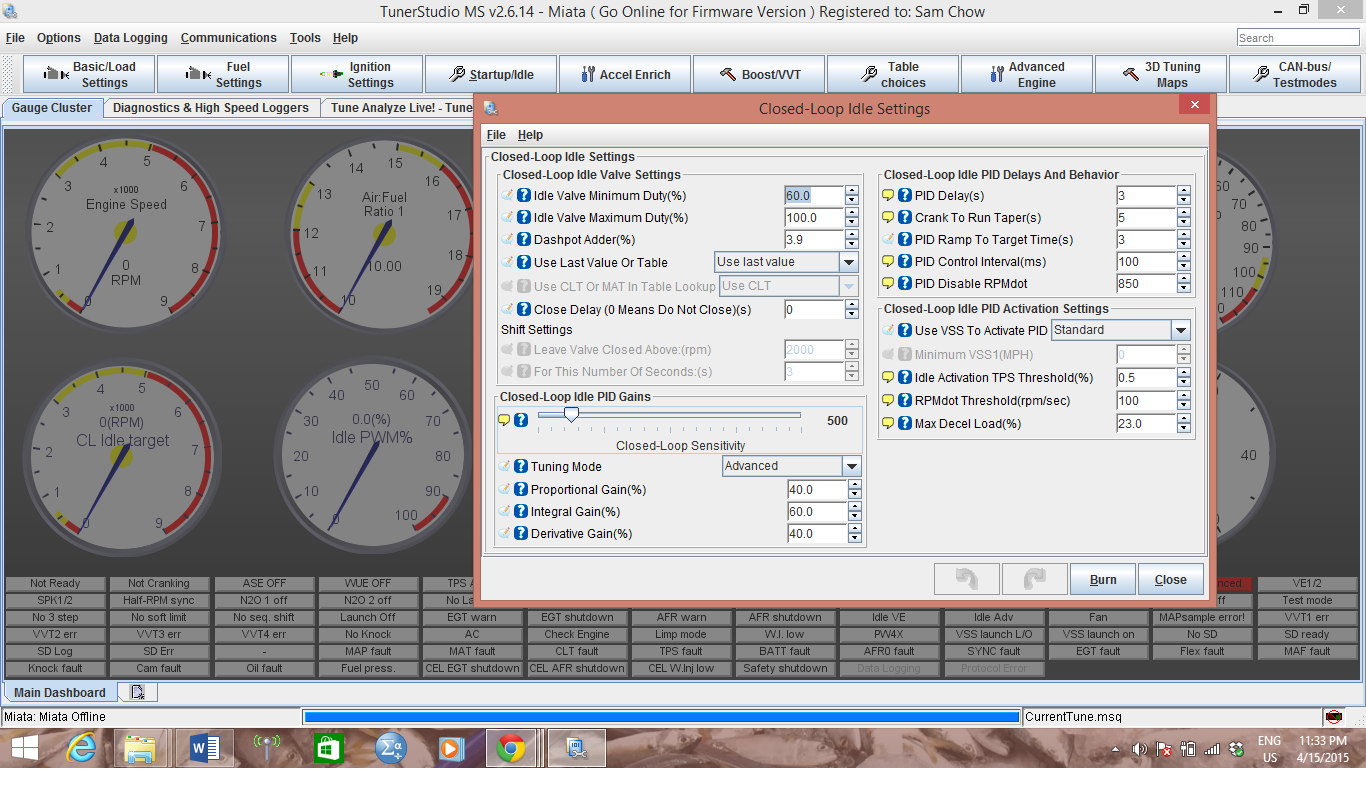

Idle valve min/max duty %

#21

I have mine totally closed. You use the PWM closed duty percent to simulate the screw, more or less. It should be possible to tune all the RPM drops out, but you can't ever tune that screw more closed and a high idle sure is annoying.

If you have the rest of the car tuned to catch and return low RPMs with timing or fuel it's exceptionally hard to stall the car even if the rpms drop below 700rpm.

If you have the rest of the car tuned to catch and return low RPMs with timing or fuel it's exceptionally hard to stall the car even if the rpms drop below 700rpm.

#22

I have mine totally closed. You use the PWM closed duty percent to simulate the screw, more or less. It should be possible to tune all the RPM drops out, but you can't ever tune that screw more closed and a high idle sure is annoying.

If you have the rest of the car tuned to catch and return low RPMs with timing or fuel it's exceptionally hard to stall the car even if the rpms drop below 700rpm.

If you have the rest of the car tuned to catch and return low RPMs with timing or fuel it's exceptionally hard to stall the car even if the rpms drop below 700rpm.

I'll try this when I get home today.

The other thing that was suggested was to disconnect my idle valve. What does this accomplish? Is it just testing whether my car can run solely based on the idle screw? -- my understanding was that the idle screw adjusted the idle valve to a permanent position (open-- close) then the computer fine tunes it from there.

Thanks for all the help guys.. Turbo is being installed this weekend.. Hopefully I can flush out the rest of my MS3 issues before then.

#24

The other thing that was suggested was to disconnect my idle valve. What does this accomplish? Is it just testing whether my car can run solely based on the idle screw? -- my understanding was that the idle screw adjusted the idle valve to a permanent position (open-- close) then the computer fine tunes it from there.

Adjusting the warm idle using the screw sets the idle air baseline (mechanically, unaffected by PWM gremlins), and then the idle control valve can raise the idle from there.

The idle screw is nothing more than a needle bleed valve, very unconnected to anything else than it's own air channel.

This is an NB right?

The idle screw is on top of the intake near the TB, the idle air valve is hanging below the TB (you can see it's air channel rectangular openings before/after the throttle plate). Two parallel air paths passing air around the closed throttle plate.

#25

The problem with setting idle via the screw is you've now set your minimum idle in those exact conditions. If your PWM valve is also totally closed at that position, you might get high idle if the weather changes.

If your idle settings are correct when you enter closed loop you should be a few hundred rpm above your target, the valve can then close to bring it where it needs to be but it should not entirely close (close as in reaching your minimum idle duty%.) That little buffer room lets the idle compensate electrical loads and weather a lot better.

If your idle settings are correct when you enter closed loop you should be a few hundred rpm above your target, the valve can then close to bring it where it needs to be but it should not entirely close (close as in reaching your minimum idle duty%.) That little buffer room lets the idle compensate electrical loads and weather a lot better.

#27

Disconnecting the valve will have it closed, regardless of how flawed your MS is.

Adjusting the warm idle using the screw sets the idle air baseline (mechanically, unaffected by PWM gremlins), and then the idle control valve can raise the idle from there.

The idle screw is nothing more than a needle bleed valve, very unconnected to anything else than it's own air channel.

This is an NB right?

The idle screw is on top of the intake near the TB, the idle air valve is hanging below the TB (you can see it's air channel rectangular openings before/after the throttle plate). Two parallel air paths passing air around the closed throttle plate.

Adjusting the warm idle using the screw sets the idle air baseline (mechanically, unaffected by PWM gremlins), and then the idle control valve can raise the idle from there.

The idle screw is nothing more than a needle bleed valve, very unconnected to anything else than it's own air channel.

This is an NB right?

The idle screw is on top of the intake near the TB, the idle air valve is hanging below the TB (you can see it's air channel rectangular openings before/after the throttle plate). Two parallel air paths passing air around the closed throttle plate.

I'm trying to do everything I can to rule out the fact that my MS3 might be defective (I do not want to send it in for warranty- $$).

#28

After that you have a know baseline where you calmly can figure out the duty cycle where you valve start to opens.

You might want to close it a little to lower the unassisted idle for low altitude and colder weather, but that can wait.

But you have already done this according to #1, your unassisted idle is 750rpm.

How non-damaged idle valve deals with high %dc through a funky circuit someone else might be able to answer.

#29

You set your idle screw to the position where it gives you the idle you want without additional air through the IAC valve (achieved by disconnecting it).

After that you have a know baseline where you calmly can figure out the duty cycle where you valve start to opens.

You might want to close it a little to lower the unassisted idle for low altitude and colder weather, but that can wait.

But you have already done this according to #1, your unassisted idle is 750rpm.

How non-damaged idle valve deals with high %dc through a funky circuit someone else might be able to answer.

After that you have a know baseline where you calmly can figure out the duty cycle where you valve start to opens.

You might want to close it a little to lower the unassisted idle for low altitude and colder weather, but that can wait.

But you have already done this according to #1, your unassisted idle is 750rpm.

How non-damaged idle valve deals with high %dc through a funky circuit someone else might be able to answer.

After disconnecting it, I adjust the screw to hit 850RPM. Then I connect the valve back on and test valve settings to get my min/max.

That makes sense to me. Thanks for the advice. I'll report back once I get the results.

#30

Does MS3 not have idle valve test mode? What exactly is the problem? Is 75-100% not the correct values for a NB?

I don't know how this can be so complicated. Put it in test mode, set it at 100%, change numbers. Does the idle react? Then the valve works, everything to do with your idle dipping is just poor fuel or spark tuning.

Messing with the idle bleed air screw will screw with all the idle settings you work to figure out and tune. You should never touch the screw after you start tuning closed loop, unless you want to tune it again.

I don't know how this can be so complicated. Put it in test mode, set it at 100%, change numbers. Does the idle react? Then the valve works, everything to do with your idle dipping is just poor fuel or spark tuning.

Messing with the idle bleed air screw will screw with all the idle settings you work to figure out and tune. You should never touch the screw after you start tuning closed loop, unless you want to tune it again.

#32

Does MS3 not have idle valve test mode? What exactly is the problem? Is 75-100% not the correct values for a NB?

I don't know how this can be so complicated. Put it in test mode, set it at 100%, change numbers. Does the idle react? Then the valve works, everything to do with your idle dipping is just poor fuel or spark tuning.

Messing with the idle bleed air screw will screw with all the idle settings you work to figure out and tune. You should never touch the screw after you start tuning closed loop, unless you want to tune it again.

I don't know how this can be so complicated. Put it in test mode, set it at 100%, change numbers. Does the idle react? Then the valve works, everything to do with your idle dipping is just poor fuel or spark tuning.

Messing with the idle bleed air screw will screw with all the idle settings you work to figure out and tune. You should never touch the screw after you start tuning closed loop, unless you want to tune it again.

#33

18-65 is a massive range, I don't really see that being necessary unless you plan to idle the car over 2K for some reason. If you have enough valve to start the car, and you have little enough valve to idle ~850 I wouldn't worry about it. In my case, 10% is around 1k in extra idle...

If anything you might check the idle valve frequency to make sure it matches everyone else.

If anything you might check the idle valve frequency to make sure it matches everyone else.

#34

18-65 is a massive range, I don't really see that being necessary unless you plan to idle the car over 2K for some reason. If you have enough valve to start the car, and you have little enough valve to idle ~850 I wouldn't worry about it. In my case, 10% is around 1k in extra idle...

If anything you might check the idle valve frequency to make sure it matches everyone else.

If anything you might check the idle valve frequency to make sure it matches everyone else.

My new problem is that SOMETIMES when I lift my foot off the throttle, the RPMS come to settle at 1300RPM before CL kicks in. After CL kicks in, it drops it to the designated RPM. However, this is happening infrequently and there doesn't appear to be a pattern to this madness. I just spent the last 30 minutes driving around to try to trigger this event, and nothing. Also, sometimes my RPMs skyrocket to 3-4k RPM and my CL settings are locked out since my MAP is so low. I had to readjust my map way below my idle so this doesn't occur.

I tried logging this behavior but it seems like the idle valve behaves when TS is logging. I thought I understood what the idle valve did but now I'm just confused as to how PWM duty/idle valve work together. It makes sense to me that before CL is activated, the car should idle at whatever RPM the valve screw is set to (for me: 1300 RPM). However, the last 30 mins of driving would return the RPMs to 850-900 after lifting my foot from the throttle even BEFORE my CL kicks in.

**Although I set my minimum PWM duty to %60, under valve test mode, the valve reacts at around 75% up to 100% (possibly more..)

Last edited by Chowcow; 04-16-2015 at 01:36 AM.

#35

So I was able to log the raising RPM issue after throttle release. The log shows that as I'm driving, the PWM sits at 83.5%. As soon as I lift the throttle, my PWM jumps to 91% and sticks there for a few seconds (this is around 3000 RPM and basically drives the car itself). Once CL idle kicks in, the RPMs begin to move down towards target.

What causes the idle valve to pop open?

What causes the idle valve to pop open?

#37

I'm not sure that lowering my valve from 100% to say, 95 would help. If the car likes to pop it back to 91% when driving, how would dropping the max to higher than 91% help? -- I might be missing a bit of information on how the idle valve works, so if I'm wrong, feel free to correct me.

).

).