ITT: Injector Timing table tuning

#21

Former Vendor

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,099

Probably true. Leaving fuel on the valve means it's not deposited until the next event, but it does still make it eventually. Perhaps it's the improvement in mixture homogeneity that creates the richer AFRs.

#24

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,019

Total Cats: 6,587

And if they're in the form of large droplets rather than a fine spray, some portion of them will fail to become part of a homogenous air /fuel mixture, and then will either combust too late I the cycle for optimum efficiency, or will not combust completely and will exit the engine as unburned HC.

#25

1. The injector timing tables, the numbers are in crank degrees, right? I think so but just making sure.

2. What is the reference? If I put a "0" in my table, when does it spray the fuel?

#26

A few points:

Sweeping injection timing at part load will only tell you if you've gone too far, too early or too late, by looking at how smooth the engine is running. You can't narrow it down to optimum within that remaining range without an emissions analyzer (even something from a smog test station will do, doesn't need to be lab grade) or cylinder pressure sensors.

Injection timing very much affects combustion efficiency under some conditions but you can't calculate that without hydrocarbon, carbon monoxide concentration, oxygen concentration, and lower heating value of the fuel (its energy content measured by a fuel lab or some assumed value). I have a spreadsheet I use to calculate it.

For home use, figure out what makes it run worse and stay away from values like that (duh).

You can tell if the injection timing is going in the wrong direction as you sweep because the hydrocarbons go up, indicating unburned fuel, while o2 and CO concentration increases, indicating poor mixing.

I specifically don't tune with VE analyze/autotune at all for any reason on any platform or EMS.

Sweeping injection timing at part load will only tell you if you've gone too far, too early or too late, by looking at how smooth the engine is running. You can't narrow it down to optimum within that remaining range without an emissions analyzer (even something from a smog test station will do, doesn't need to be lab grade) or cylinder pressure sensors.

Injection timing very much affects combustion efficiency under some conditions but you can't calculate that without hydrocarbon, carbon monoxide concentration, oxygen concentration, and lower heating value of the fuel (its energy content measured by a fuel lab or some assumed value). I have a spreadsheet I use to calculate it.

For home use, figure out what makes it run worse and stay away from values like that (duh).

You can tell if the injection timing is going in the wrong direction as you sweep because the hydrocarbons go up, indicating unburned fuel, while o2 and CO concentration increases, indicating poor mixing.

I specifically don't tune with VE analyze/autotune at all for any reason on any platform or EMS.

#27

Ok let me ask a couple dumb questions, but this is a thread about injector timing tables so why not for clarity. I don't know some of this thus I've never messed with it.

1. The injector timing tables, the numbers are in crank degrees, right? I think so but just making sure.

2. What is the reference? If I put a "0" in my table, when does it spray the fuel?

1. The injector timing tables, the numbers are in crank degrees, right? I think so but just making sure.

2. What is the reference? If I put a "0" in my table, when does it spray the fuel?

If you put 0 in there, the injection will end at TDC firing. The injection will start, in terms of crank angle, based on the duty cycle. 40% duty cycle is 720 × 0.4 , which is 288 degrees. So your start is roughly 288 btdc and your end is TDC.

The tricky thing is that this is port injection. When the intake valve closes, the fuel will stay in the port until the next cycle. So if the intake valve closes with stock non vvt timing, that's about 130 deg btdc. 288 - 130 means that 158 degrees of injection went into an open valve and the rest stayed in the port wall until the valve opened the next time.

#29

They are crank angle degrees btdc firing, same units as spark timing table.

If you put 0 in there, the injection will end at TDC firing. The injection will start, in terms of crank angle, based on the duty cycle. 40% duty cycle is 720 × 0.4 , which is 288 degrees. So your start is roughly 288 btdc and your end is TDC.

The tricky thing is that this is port injection. When the intake valve closes, the fuel will stay in the port until the next cycle. So if the intake valve closes with stock non vvt timing, that's about 130 deg btdc. 288 - 130 means that 158 degrees of injection went into an open valve and the rest stayed in the port wall until the valve opened the next time.

If you put 0 in there, the injection will end at TDC firing. The injection will start, in terms of crank angle, based on the duty cycle. 40% duty cycle is 720 × 0.4 , which is 288 degrees. So your start is roughly 288 btdc and your end is TDC.

The tricky thing is that this is port injection. When the intake valve closes, the fuel will stay in the port until the next cycle. So if the intake valve closes with stock non vvt timing, that's about 130 deg btdc. 288 - 130 means that 158 degrees of injection went into an open valve and the rest stayed in the port wall until the valve opened the next time.

Ok...

So, I would think that for low-load, low-pulsewidth conditions, you would want to spray the fuel when the velocity of the charge flowing through the port is the highest. This would give the fuel the best-chance to get sucked into the cylinder. So if you know your at say, 10% duty cycle, so that's 72* of spray, you'd want to design your table at that load so that it resulted in the injection occurring during maximum port velocity. Does this seem right? So basically in the "middle" of the intake valves being open, that's when it would spray.

As the duty cycle ramps up, there will be a point where you can no longer injection ONLY when the valve is open, as that window will be too-short. So in this case, the question is, when is the best time to inject? I would think if you had to spray fuel at a closed valve, do it right-before the valve is about to open. Thus the injector will basically shut-off right as the intake valve is shutting. How does this sound? This would minimize the time that fuel sprays at a closed valve before the valve opens.

Thoughts? This makes sense to me, but I dunno, I've never tuned any of this before.

#30

^ that's one way of doing it but it depends on head design.

The fundamental question at part load is, does the engine want open valve or closed valve injection? That is, do you set the EOI before the intake valve opens (375 btdc like we've been saying) or something during the intake stroke, say 180 to 350. At full load your duty cycle gets higher.

If you get on a loading dyno and lock speed at cruising rpm and adjust MAP with throttle, you can see where the injection timing affects it. It's especially noticeable as you try to run leaner in cruise or idle at a lower stock like speed.

What's your idle speed and afr? Try to run it like stock. If you are even 50 rpm above stock idle speed the engine becomes less sensitive. Idling like stock is hard to do even with stock cams.

The fundamental question at part load is, does the engine want open valve or closed valve injection? That is, do you set the EOI before the intake valve opens (375 btdc like we've been saying) or something during the intake stroke, say 180 to 350. At full load your duty cycle gets higher.

If you get on a loading dyno and lock speed at cruising rpm and adjust MAP with throttle, you can see where the injection timing affects it. It's especially noticeable as you try to run leaner in cruise or idle at a lower stock like speed.

What's your idle speed and afr? Try to run it like stock. If you are even 50 rpm above stock idle speed the engine becomes less sensitive. Idling like stock is hard to do even with stock cams.

#31

Mines at 850rpm. I think stock is within 50rpm, and on the tach it looks exactly like stock. I'll double check what the factory specified idle is on an MSM.

What really confused me is that going from 0-460 didn't appear to do much, if anything.

AFR would take a tiny dip or a tiny jump, but within a couple seconds would come right back down to target. I thought doing such a drastic sweep would result in some serious changes.

I now see that this whole procedure will likely result in such small changes overall that it won't be fast or easy to dial in, and in fact a pain in the rear. I guess worst case I'll just set it to 360.

I did PM DIYautotune to chime in, I'm still really curious about why their numbers are so different.

What really confused me is that going from 0-460 didn't appear to do much, if anything.

AFR would take a tiny dip or a tiny jump, but within a couple seconds would come right back down to target. I thought doing such a drastic sweep would result in some serious changes.

I now see that this whole procedure will likely result in such small changes overall that it won't be fast or easy to dial in, and in fact a pain in the rear. I guess worst case I'll just set it to 360.

I did PM DIYautotune to chime in, I'm still really curious about why their numbers are so different.

#32

Boost Czar

iTrader: (62)

Join Date: May 2005

Location: Chantilly, VA

Posts: 79,490

Total Cats: 4,079

So the way DIY has their table set up it is spraying the fuel REALLY late right?

Wouldn't that cause lean tip in, and then lots of fuel sucked from walls and basically wasted?

Wouldn't that cause lean tip in, and then lots of fuel sucked from walls and basically wasted?

IIRC the injector timing table is inputted as BDTC. As far as I can tell, a 90° end-of-squirt would finish injecting VERY early on.

it makes me wonder why DIY uses that map, since that makes me think it would be injecting on the compression stroke?

I forgot A LOT of this. One huge test could be switching from end-of-squirt to begin-of-squirt, just to see the effect on AFRs when you inject during the intake opening, vs. completely before.

Last edited by Braineack; 06-30-2015 at 07:38 AM.

#33

Boost Czar

iTrader: (62)

Join Date: May 2005

Location: Chantilly, VA

Posts: 79,490

Total Cats: 4,079

I'm here to learn too.

But I will say the reason rich = good, is because it means if you make a change to your injector timing table and the AFR shows a richer reading, that means the combustion efficiency just improved, and you burned more of the available oxygen, thus less oxygen, and it reads richer. That's all I've got right now....

But I will say the reason rich = good, is because it means if you make a change to your injector timing table and the AFR shows a richer reading, that means the combustion efficiency just improved, and you burned more of the available oxygen, thus less oxygen, and it reads richer. That's all I've got right now....

Does this link still work?

https://dl.dropboxusercontent.com/u/...ming_v3.0.xlsx

#34

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,019

Total Cats: 6,587

And before that they used carburetors.

In the 70s and 80s, a lot of German cars (including all Porsches) used continuous mechanical injection- nozzles located where port fuel injectors would be on a modern car, which sprayed continuously at variable pressure regardless of whether the intake valve was open or not.

All of these solutions worked reasonably well. Timed port injection is better, and direct injection is better yet, but we're getting to a point where the gains in both performance and emissions are getting quite small for each advance in technology.

#35

did you not read my post where i wrote: 360° vs 90°?

IIRC the injector timing table is inputted as BDTC. As far as I can tell, a 90° end-of-squirt would finish injecting VERY early on.

it makes me wonder why DIY uses that map, since that makes me think it would be injecting on the compression stroke?

IIRC the injector timing table is inputted as BDTC. As far as I can tell, a 90° end-of-squirt would finish injecting VERY early on.

it makes me wonder why DIY uses that map, since that makes me think it would be injecting on the compression stroke?

Meaning 0 is right before BTDC and 720* is at the beginning?

What you're saying is contradicting what argh7x is saying.

How is it that we have code and yet no one knows what it actually does?

Let's define some things. In the injector timing map, would 0 = beginning or end? Since it's calculated from 720* wouldn't it be the end. And 360* the middle. And 720* the very beginning?

I can't believe how unclear all this crap is.

#36

Boost Czar

iTrader: (62)

Join Date: May 2005

Location: Chantilly, VA

Posts: 79,490

Total Cats: 4,079

it wouldn't be MS if things were clear from the start.

i honestly am very rusty and im trying to remember everything I forgot 5 years ago.

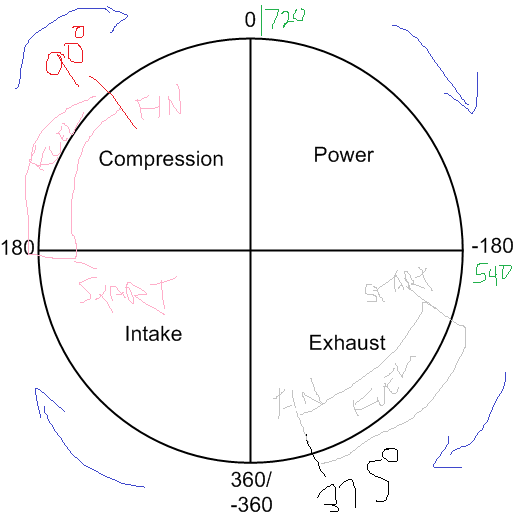

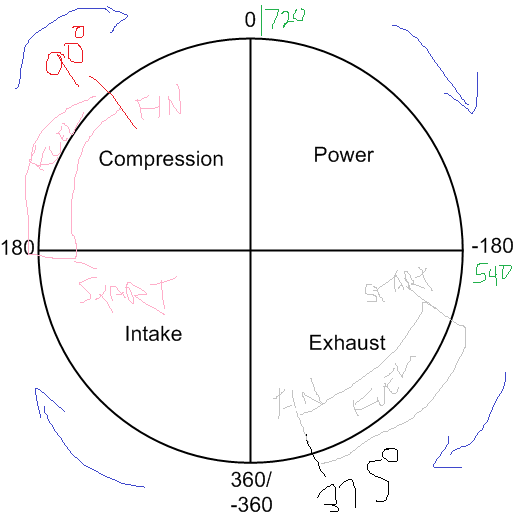

this is the way I understand it [end-of-squirt]:

i honestly am very rusty and im trying to remember everything I forgot 5 years ago.

this is the way I understand it [end-of-squirt]:

Last edited by Braineack; 06-26-2015 at 11:49 AM.

#37

SADFab Destructive Testing Engineer

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

<p>Because having code means nothing. Understanding it is the hard part. Here is the sequential fuel code. I'll dig into it some more but for other to look at if they want to:</p><p>Also, no code option for formating? wtf mt.net</p><p>Here are the relevant bits of code:</p><p>This looks up the inj_timing from the table:</p><p><a href="http://imgur.com/7an6Ls9" target="_blank"><img src="https://www.miataturbo.net/attachment.php?attachmentid=142716&dateline=14 35334320" border="0" alt="" /></a></p><p>Here is where it gets </p><p>Then this is where it looks at which squirt option you have (Beginning, middle end), then from what I can tell does the following.</p><p>If beginning of squirt it uses the fuel_angle calculated above from the lookup table.</p><p>If middle of squirt it uses the pw divided by two and then some math.</p><p>And if end of squirt the fuel angle is just set to the pulse width and some math.</p><p><a href="http://imgur.com/uk9u9NY" target="_blank"><img src="https://www.miataturbo.net/attachment.php?attachmentid=142717&dateline=14 35334320" border="0" alt="" /></a></p><p>Now here is where I had to stop for now because I really have to **** (ate some gnarly mexican food last night) but I'll dig some more soon. This is where the injection event is actually created.</p><p><a href="http://imgur.com/fQ58atk" target="_blank"><img src="https://www.miataturbo.net/attachment.php?attachmentid=142718&dateline=14 35334320" border="0" alt="" /></a></p><p>And this is where it is fired off</p><p><a href="http://imgur.com/XP0Coqx" target="_blank"><img src="https://www.miataturbo.net/attachment.php?attachmentid=142719&dateline=14 35334320" border="0" alt="" /></a></p><p>This was 10 minutes of digging. Someone who actually knows the code better could answer faster.</p>

#39

That diagram is correct. The crank angle distance between start and finish depends on the duty cycle. 10 percent duty would be 72 degrees etc.

Your intake valve is going to open around 360 and close after 180, more like 150. Vvt makes the intake valve close earlier (150 becomes 160 with 10 degrees cam advance). It makes the valve open earlier as well, so 360 becomes 370.

Your intake valve is going to open around 360 and close after 180, more like 150. Vvt makes the intake valve close earlier (150 becomes 160 with 10 degrees cam advance). It makes the valve open earlier as well, so 360 becomes 370.