Managing heat with a flat underbody

#81

I've been thinking about buying some square steel tubing that's the same height as the pinch welds and welding it along the back side of the pinch under the car. Would make the entire length of the pinch weld a solid jacking point and I'd never again have to worry about folding it over. It would also be easy to drill and tap a bunch of M6 holes in it for mounting flat underbody panels...

#82

jpreston, please post photos if you do that. My rockers are rusting out and the area around the jacking points has completely collapsed so I'm looking at ways to rebuild them like you are talking about. I had wondered about welding angle iron down the side but your idea of square tubing could work better as it avoids the "folding pinchweld" syndrome entirely and makes the jacking point(s) flat.

Thomas

Thomas

#83

Supporting Vendor

Thread Starter

iTrader: (3)

Join Date: Jul 2006

Location: San Diego

Posts: 3,303

Total Cats: 1,216

Sounds like a lot of extra weight. I would do just a 12" or so section along the front and rear of the pinch weld - give yourself a reinforced section but don't run it the full length, that would be almost 10 ft. of steel for both sides.

-Ryan

-Ryan

#85

Supporting Vendor

Thread Starter

iTrader: (3)

Join Date: Jul 2006

Location: San Diego

Posts: 3,303

Total Cats: 1,216

On the angle iron welded behind pinch weld subject, I weighed a 4'x4' sheet of 11 gauge (1/8") steel today - 75 lbs. Yikes. Not that there's any need for a big sheet of that stuff to be used on our cars, but it reinforced the knowledge I already had that steel is heavy! And therefore it should be added in very tiny amounts and only where absolutely necessary.

Thanks.

The ABS is 1/8" thick. I consider this a prototype, made from cheap ABS. ($50 for the whole 4x8 sheet) to get the shape, mounting and testing done. I will probably remake the panel itself down the road with either Fire/heat-resistant ABS (2x the cost of regular) or Alumalite.

The diffuser is made primarily from 0.050" 5052 aluminum, but I used 0.040" in a few places where there was no need for thicker material to cut weight slightly.

-Ryan

The ABS is 1/8" thick. I consider this a prototype, made from cheap ABS. ($50 for the whole 4x8 sheet) to get the shape, mounting and testing done. I will probably remake the panel itself down the road with either Fire/heat-resistant ABS (2x the cost of regular) or Alumalite.

The diffuser is made primarily from 0.050" 5052 aluminum, but I used 0.040" in a few places where there was no need for thicker material to cut weight slightly.

-Ryan

#86

Supporting Vendor

Thread Starter

iTrader: (3)

Join Date: Jul 2006

Location: San Diego

Posts: 3,303

Total Cats: 1,216

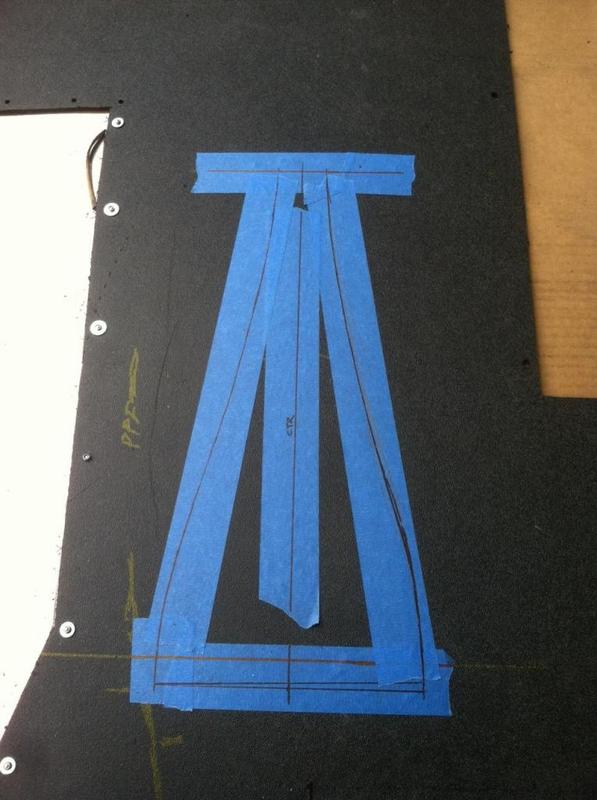

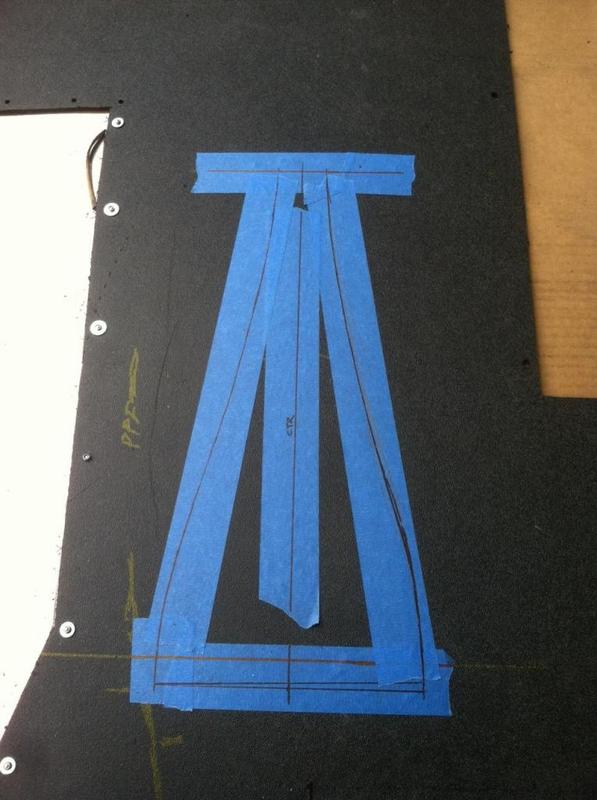

On the original topic of this thread, here is what I'm almost done with as the for-now solution. This NACA duct sits to the right of the PPF, and the diverting panel behind it will angle the air through two of the big holes in the PPF right at the driveshaft U-joint/front of differential. I could have placed it on the other side and avoided the PPF, but placed on this side, the direction of airflow should push radiant heat from the exhaust away from the differential rather than towards it.

I am not making one of these for the tranny - partly because its position and size makes it much harder to supply cold air to, and partly because the Torsen is ~$600 while the tranny is ~$150, so I'm putting my efforts first into the diff.

-Ryan

I am not making one of these for the tranny - partly because its position and size makes it much harder to supply cold air to, and partly because the Torsen is ~$600 while the tranny is ~$150, so I'm putting my efforts first into the diff.

-Ryan

#89

Elite Member

iTrader: (2)

Join Date: May 2008

Location: Portland, Oregon

Posts: 3,468

Total Cats: 365

Yes.

The flat underbody enhances the effectiveness of both the front spoiler and the diffuser. Done right, the entire underbody effectively becomes part of the rear diffuser, and the downforce created by the diffuser moves forward underneath the car (not as rear biased).

The flat underbody enhances the effectiveness of both the front spoiler and the diffuser. Done right, the entire underbody effectively becomes part of the rear diffuser, and the downforce created by the diffuser moves forward underneath the car (not as rear biased).

#90

Yes.

The flat underbody enhances the effectiveness of both the front spoiler and the diffuser. Done right, the entire underbody effectively becomes part of the rear diffuser, and the downforce created by the diffuser moves forward underneath the car (not as rear biased).

Competition Car Aerodynamics: A Practical Handbook

The flat underbody enhances the effectiveness of both the front spoiler and the diffuser. Done right, the entire underbody effectively becomes part of the rear diffuser, and the downforce created by the diffuser moves forward underneath the car (not as rear biased).

Competition Car Aerodynamics: A Practical Handbook

Very interesting to say the least.

#91

Supporting Vendor

Thread Starter

iTrader: (3)

Join Date: Jul 2006

Location: San Diego

Posts: 3,303

Total Cats: 1,216

It's definitely not the first time it's been done on a miata, although it's definitely not common. I'm just talking about it/sharing pics of it a good deal more than most of those who have done it. Why? Because those cars (and mine) are used for competitions, and usually you don't want to give away your designs and secrets.

I'm on the fence about this - on one hand I don't want the next guy in Super Mod to have it too easy - just copy what I've gone through the hard work to develop, but on the other hand I want to see Miatas as a whole get faster and faster, help in some small way by contributing to the collective so to speak to further our community and help us all spank "faster" cars, so for now I am sharing

Just got home from Auto Club Speedway. Won Super Mod by 2 seconds.

ABS is the wrong material for this. It's still on the car, and I ran with it all day, but it has begun to get wavy from the exhaust heat, so I will soon be making Version 2.0 with probably alumalite.

-Ryan

I'm on the fence about this - on one hand I don't want the next guy in Super Mod to have it too easy - just copy what I've gone through the hard work to develop, but on the other hand I want to see Miatas as a whole get faster and faster, help in some small way by contributing to the collective so to speak to further our community and help us all spank "faster" cars, so for now I am sharing

Just got home from Auto Club Speedway. Won Super Mod by 2 seconds.

ABS is the wrong material for this. It's still on the car, and I ran with it all day, but it has begun to get wavy from the exhaust heat, so I will soon be making Version 2.0 with probably alumalite.

-Ryan

#93

It's definitely not the first time it's been done on a miata, although it's definitely not common. I'm just talking about it/sharing pics of it a good deal more than most of those who have done it. Why? Because those cars (and mine) are used for competitions, and usually you don't want to give away your designs and secrets.

I'm on the fence about this - on one hand I don't want the next guy in Super Mod to have it too easy - just copy what I've gone through the hard work to develop, but on the other hand I want to see Miatas as a whole get faster and faster, help in some small way by contributing to the collective so to speak to further our community and help us all spank "faster" cars, so for now I am sharing

Just got home from Auto Club Speedway. Won Super Mod by 2 seconds.

ABS is the wrong material for this. It's still on the car, and I ran with it all day, but it has begun to get wavy from the exhaust heat, so I will soon be making Version 2.0 with probably alumalite.

-Ryan

I'm on the fence about this - on one hand I don't want the next guy in Super Mod to have it too easy - just copy what I've gone through the hard work to develop, but on the other hand I want to see Miatas as a whole get faster and faster, help in some small way by contributing to the collective so to speak to further our community and help us all spank "faster" cars, so for now I am sharing

Just got home from Auto Club Speedway. Won Super Mod by 2 seconds.

ABS is the wrong material for this. It's still on the car, and I ran with it all day, but it has begun to get wavy from the exhaust heat, so I will soon be making Version 2.0 with probably alumalite.

-Ryan

#94

Ryan, Your hard work has paid off! Congrats on the win-- entering at 135, was the banking enough for you to hit your Vmax or were speeds still climbing before the L-hander?

At what part? I am guessing closer to the turbo since you added an aluminum piece under the piping right by the diff?

I had plastic (coroplast) to test things out (still haven't made anything else since, just testing) and it is millimeters from the resonator (close to the diff) and has not deformed in any way.

However, by the tranny, it caused issues on the downpipe portion before the catalytic converter-- this is only an an N/A car.

I had plastic (coroplast) to test things out (still haven't made anything else since, just testing) and it is millimeters from the resonator (close to the diff) and has not deformed in any way.

However, by the tranny, it caused issues on the downpipe portion before the catalytic converter-- this is only an an N/A car.

#95

Elite Member

iTrader: (14)

Join Date: Sep 2009

Location: Birmingham, AL

Posts: 2,101

Total Cats: 180

I was also thinking of using alumalite (worked great as a splitter), but will probably use a combination of both sheet aluminum and alumalite - use the sheet alum over the exhaust as I would think the plastic core of the lite would melt, like your ABS.

#96

Supporting Vendor

Thread Starter

iTrader: (3)

Join Date: Jul 2006

Location: San Diego

Posts: 3,303

Total Cats: 1,216

Speed was still climbing when I turned into the banked turn at which point I eased off the throttle.

We know the factory speedometers can be pretty off... but along the straight I would glance down, see the tach in 5th gear at about 6800 and climbing towards the red 7000, the speedo needle at about 132-133 climbing up, and after that quick glance I would have just enough time to bring my eyes back up, take a breath, (speed and rpm still climbing), look through the turn, and then turn in. So I don't know the exact rpm and speed I hit before easing off on turn-in. I just plugged my gearing and tire size into FM's speed calculator and it says that at 6800 is 139 mph, 7000 rpm is 143. We also know the stock tach can be innacurate, but if my tach is anywhere near accurate, my speedometer may have been under-estimating my speed actually.

I need to get some form of GPS speed readings...

At what part? I am guessing closer to the turbo since you added an aluminum piece under the piping right by the diff?

I had plastic (coroplast) to test things out (still haven't made anything else since, just testing) and it is millimeters from the resonator (close to the diff) and has not deformed in any way.

However, by the tranny, it caused issues on the downpipe portion before the catalytic converter-- this is only an an N/A car.

I had plastic (coroplast) to test things out (still haven't made anything else since, just testing) and it is millimeters from the resonator (close to the diff) and has not deformed in any way.

However, by the tranny, it caused issues on the downpipe portion before the catalytic converter-- this is only an an N/A car.

-Ryan

#98

Supporting Vendor

Thread Starter

iTrader: (3)

Join Date: Jul 2006

Location: San Diego

Posts: 3,303

Total Cats: 1,216

I can weigh both to see but I would bet that per square foot, 1/4" thick alumalite is the same weight or lighter than 0.050" aluminum.

-Ryan

#100

Supporting Vendor

Thread Starter

iTrader: (3)

Join Date: Jul 2006

Location: San Diego

Posts: 3,303

Total Cats: 1,216

-Ryan