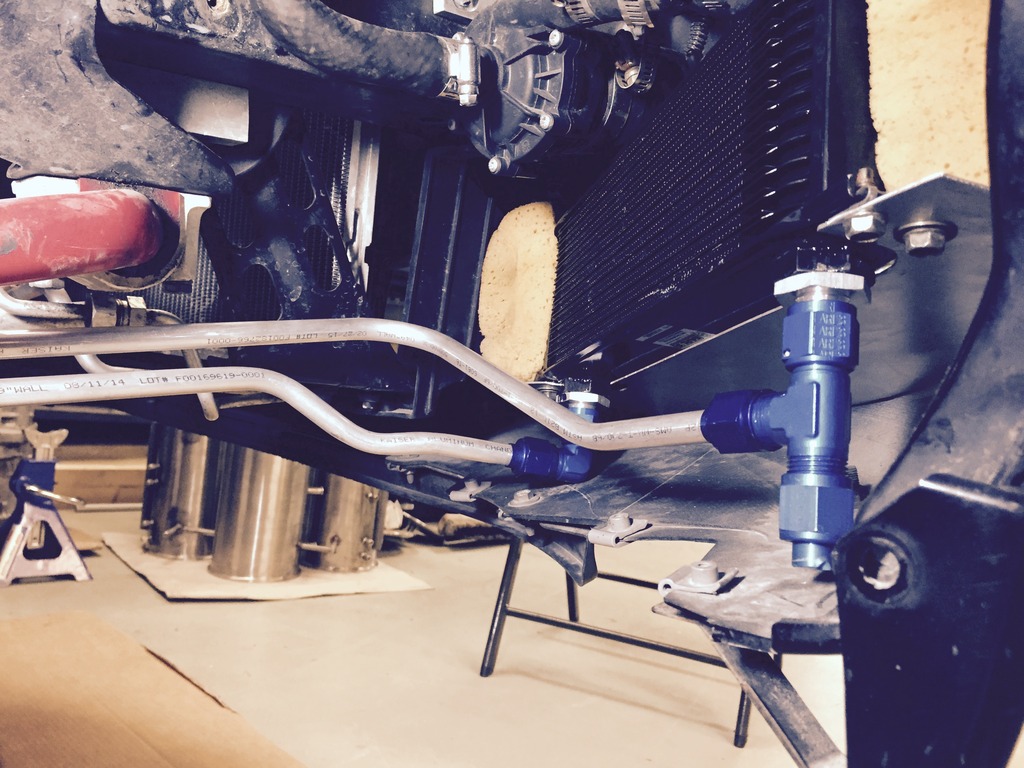

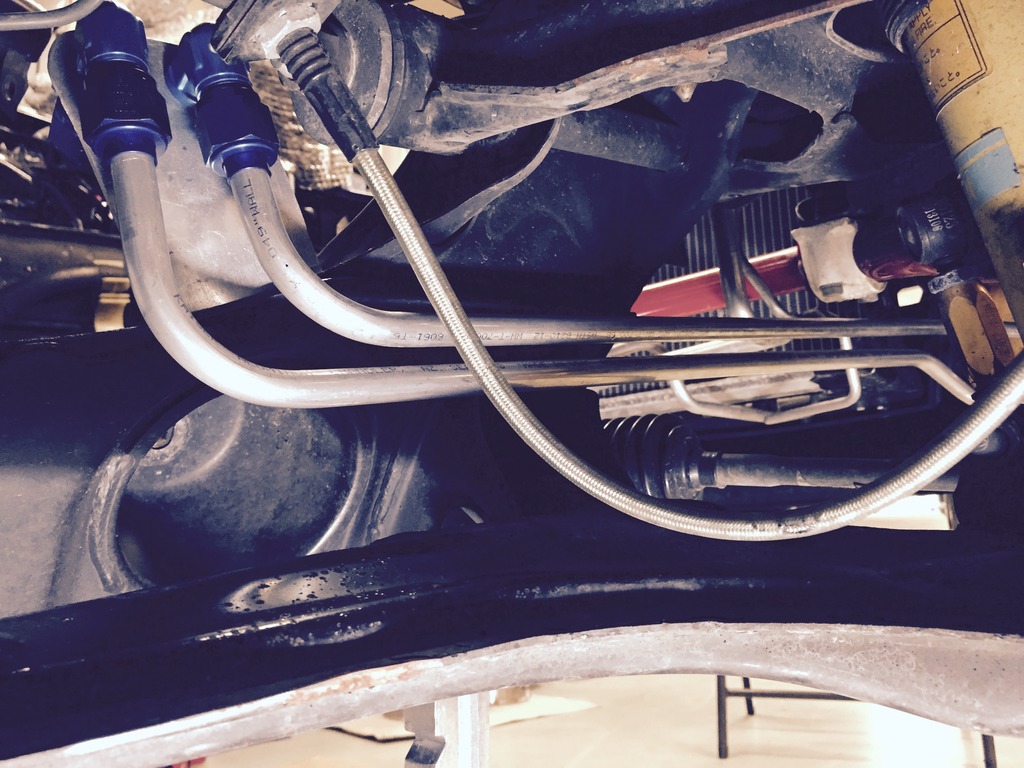

Oil cooler tech

#221

The problem with this is that measuring the temperature of the sump doesn't actually tell you the max temperature, because the sump is a large volume of oil, and the oil that's going into it from the bearings is mixed with the cooler oil that went to the head.

--Ian

#222

Oil degrades due to heat, so in theory you want to know the max temperature the oil has seen so you can decide if you need to change it or not.

The problem with this is that measuring the temperature of the sump doesn't actually tell you the max temperature, because the sump is a large volume of oil, and the oil that's going into it from the bearings is mixed with the cooler oil that went to the head.

--Ian

The problem with this is that measuring the temperature of the sump doesn't actually tell you the max temperature, because the sump is a large volume of oil, and the oil that's going into it from the bearings is mixed with the cooler oil that went to the head.

--Ian

Your idea of measuring oil temp post cooler is the same as measuring engine coolant temp post-radiator instead of after exiting the engine.

#223

Oil is a liquid, not a gas, you're not compressing it.

Oil will get a bit warmer when pumped due to friction, but that's pretty low (low friction is, after all, the main point to having oil).

I suspect it doesn't really matter all that much where you measure it. Personally I change the oil before every track day, because the cost just isn't significant compared to everything else.

--Ian

Oil will get a bit warmer when pumped due to friction, but that's pretty low (low friction is, after all, the main point to having oil).

I suspect it doesn't really matter all that much where you measure it. Personally I change the oil before every track day, because the cost just isn't significant compared to everything else.

--Ian

when you pressurize a liquid it will raise the temperature, I see it all the time using aircraft hydraulic test equipment. they have very large coolers to cool the fluid after it has been "pressurized" to 3000 psi.

Have you seen the large heat exchangers on excavation equipment?

you want to know if you have heated the oil past it's thermal threshold and it will no longer do it's job. the sump is as good as any place, but I plan to put my sensor pre cooler.

what good does knowing what the temp is going to the bearings? If you put a kick *** cooler on and it lowers the oil temp from 350deg to 200deg, you have already smoked the oil. but think everything's great.

#224

SADFab Destructive Testing Engineer

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

<p>Ok, so we want to measure the hottest bit? Hasn't it been reported that temps are hotter right before the filter, than in the pan?</p><p>Going to send this oil change to blackstone and see how it looks.</p><p>What temp does rotella t6 die at, saw a mention of 300, but that sounds high.</p><p>My temps held very stable at 245-255, and oil pressure was still around 60 indicated at full throttle, so I was not too worried. Also my water was 185-190 the whole time.</p>

#225

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,020

Total Cats: 6,588

This debate as to whether the largest contributor to heating of oil is friction in the main and rod bearings vs. transfer from the pistons and cylinder walls is an interesting one.

I've always subscribed to the former theory, albeit without any substantial scientific evidence. Anecdotally, we know that a 100 HP engine operated at sustained high RPM on the track will cook its oil, whereas a 250 HP engine on the street will typically not.

On the other hand, there's a lot of oil, and it acts as a thermal damping mechanism. Thus, the measured oil temperature reflects heat over time. And that 100 HP engine on the track is going to be making 100 HP pretty much continuously, whereas the 250 HP engine on the street is going to be making far less than 100 HP when averaged over a duration of several minutes

That's the conventional wisdom.

It's never made much sense to me. The oil going into the filter was sitting in the oil pan about one second earlier, and it isn't passing through any especially hot areas on its way between the two locations.

I'm not saying it isn't true, merely that I can't see any reason why it wouldn't be false.

SCIENCE!

I've always subscribed to the former theory, albeit without any substantial scientific evidence. Anecdotally, we know that a 100 HP engine operated at sustained high RPM on the track will cook its oil, whereas a 250 HP engine on the street will typically not.

On the other hand, there's a lot of oil, and it acts as a thermal damping mechanism. Thus, the measured oil temperature reflects heat over time. And that 100 HP engine on the track is going to be making 100 HP pretty much continuously, whereas the 250 HP engine on the street is going to be making far less than 100 HP when averaged over a duration of several minutes

It's never made much sense to me. The oil going into the filter was sitting in the oil pan about one second earlier, and it isn't passing through any especially hot areas on its way between the two locations.

I'm not saying it isn't true, merely that I can't see any reason why it wouldn't be false.

SCIENCE!

#227

This debate as to whether the largest contributor to heating of oil is friction in the main and rod bearings vs. transfer from the pistons and cylinder walls is an interesting one.

I've always subscribed to the former theory, albeit without any substantial scientific evidence. Anecdotally, we know that a 100 HP engine operated at sustained high RPM on the track will cook its oil, whereas a 250 HP engine on the street will typically not.

On the other hand, there's a lot of oil, and it acts as a thermal damping mechanism. Thus, the measured oil temperature reflects heat over time. And that 100 HP engine on the track is going to be making 100 HP pretty much continuously, whereas the 250 HP engine on the street is going to be making far less than 100 HP when averaged over a duration of several minutes

I've always subscribed to the former theory, albeit without any substantial scientific evidence. Anecdotally, we know that a 100 HP engine operated at sustained high RPM on the track will cook its oil, whereas a 250 HP engine on the street will typically not.

On the other hand, there's a lot of oil, and it acts as a thermal damping mechanism. Thus, the measured oil temperature reflects heat over time. And that 100 HP engine on the track is going to be making 100 HP pretty much continuously, whereas the 250 HP engine on the street is going to be making far less than 100 HP when averaged over a duration of several minutes

It's never made much sense to me. The oil going into the filter was sitting in the oil pan about one second earlier, and it isn't passing through any especially hot areas on its way between the two locations.

I'm not saying it isn't true, merely that I can't see any reason why it wouldn't be false.

I'm not saying it isn't true, merely that I can't see any reason why it wouldn't be false.

Last edited by hornetball; 09-12-2015 at 02:20 AM.

#228

From personal experience, the aha moment for me was when I was doing high RPM/low MAP fuel tuning on the interstate. In that condition, you're making maybe 20HP to maintain 70mph or so. The oil temperature skyrocketed. Based upon that, bearing friction seems the largest contributor by far.

#229

<p>Ok, so we want to measure the hottest bit? Hasn't it been reported that temps are hotter right before the filter, than in the pan?</p><p>Going to send this oil change to blackstone and see how it looks.</p><p>What temp does rotella t6 die at, saw a mention of 300, but that sounds high.</p><p>My temps held very stable at 245-255, and oil pressure was still around 60 indicated at full throttle, so I was not too worried. Also my water was 185-190 the whole time.</p>

#231

SadFab CEO

iTrader: (3)

Join Date: Sep 2012

Location: your mom's house phoenix, AZ

Posts: 4,560

Total Cats: 1,142

But yes, there is a temp at which an oil will die immediately, probably its flash point or just below, but thats up around 400*. Thats the mechanism that causes turbo "coking".

#232

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,020

Total Cats: 6,588

From personal experience, the aha moment for me was when I was doing high RPM/low MAP fuel tuning on the interstate. In that condition, you're making maybe 20HP to maintain 70mph or so. The oil temperature skyrocketed. Based upon that, bearing friction seems the largest contributor by far.

Our oil pans are finned and oil pan sensors are typically mounted in the periphery where there can be stagnant oil and a temperature gradient. I don't have personal experience measuring in both locations, but I have seen posts to that effect (Mobius provided a link to such a post here: https://www.miataturbo.net/race-prep...4/#post1158693). The typical delta was ~20F. Of course, if you could manage to place your oil pan sensor right by the oil pickup, I would expect that delta to disappear.

Our oil pans are finned and oil pan sensors are typically mounted in the periphery where there can be stagnant oil and a temperature gradient. I don't have personal experience measuring in both locations, but I have seen posts to that effect (Mobius provided a link to such a post here: https://www.miataturbo.net/race-prep...4/#post1158693). The typical delta was ~20F. Of course, if you could manage to place your oil pan sensor right by the oil pickup, I would expect that delta to disappear.

#233

One can speculate all day long but it is just that until one has some real data, I have an 8 channel can egt box that i will use to log the oil temps at various points in the system when i get my car running again. That should give us some good info on what the oil is doing.

The only draw back is that it will be on the street or dyno and not in the track.

The only draw back is that it will be on the street or dyno and not in the track.

#234

Senior Member

iTrader: (1)

Join Date: Sep 2011

Location: Lambertville, NJ

Posts: 1,215

Total Cats: 74

Our oil pans are finned and oil pan sensors are typically mounted in the periphery where there can be stagnant oil and a temperature gradient. I don't have personal experience measuring in both locations, but I have seen posts to that effect (Mobius provided a link to such a post here: https://www.miataturbo.net/race-prep...4/#post1158693). The typical delta was ~20F. Of course, if you could manage to place your oil pan sensor right by the oil pickup, I would expect that delta to disappear.

#235

Boost Pope

iTrader: (8)

Join Date: Sep 2005

Location: Chicago. (The less-murder part.)

Posts: 33,020

Total Cats: 6,588

But unless there's a permanent boundary-layer a half-inch thick all around the inner surface of the oil pan, I can't see why it would be significantly cooler than the oil which has just been sucked up out of the pan and pumped to the filter.

That's the part that bugs me.

Would love to see data from an engine with oil temp sensors installed both in a filter sandwich-plate and in the side of the oil pan.

#236

Cooler than when it came out of the bearings / cylinder walls? Absolutely.

But unless there's a permanent boundary-layer a half-inch thick all around the inner surface of the oil pan, I can't see why it would be significantly cooler than the oil which has just been sucked up out of the pan and pumped to the filter.

That's the part that bugs me.

Would love to see data from an engine with oil temp sensors installed both in a filter sandwich-plate and in the side of the oil pan.

But unless there's a permanent boundary-layer a half-inch thick all around the inner surface of the oil pan, I can't see why it would be significantly cooler than the oil which has just been sucked up out of the pan and pumped to the filter.

That's the part that bugs me.

Would love to see data from an engine with oil temp sensors installed both in a filter sandwich-plate and in the side of the oil pan.

But seriously, even if the oil temp difference was 20 degrees either way (one location cooler than the other) what decision would one make knowing this? I would think oil pan temperature is more important since that's the closest you can measure the oil temp after it exits the bearings. Even if the oil (same/hotter/colder) after another location before you cool it, what would you change?

#238

Former Vendor

Thread Starter

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,099

I like data too.

But seriously, even if the oil temp difference was 20 degrees either way (one location cooler than the other) what decision would one make knowing this? I would think oil pan temperature is more important since that's the closest you can measure the oil temp after it exits the bearings. Even if the oil (same/hotter/colder) after another location before you cool it, what would you change?

But seriously, even if the oil temp difference was 20 degrees either way (one location cooler than the other) what decision would one make knowing this? I would think oil pan temperature is more important since that's the closest you can measure the oil temp after it exits the bearings. Even if the oil (same/hotter/colder) after another location before you cool it, what would you change?

We all drill our pans for turbo drains - drill the other side (as low as possible) for a temp sensor.

#239

SADFab Destructive Testing Engineer

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

If the pan is out then adding a sensor is a no brainer. If you are doing it in the car a sandwich plate is easiest. Knowing the delta between plate and pan would be helpful for those of us with sandwich plates.

#240

That should cover all the bases, regarding the oil temp difference in the pan itself i doubt that there is any significant

temperature difference in the pan regardless of where you measure the tempreature; i have not cc'd the pump gears but would expect the pump to move 5gpm or more at 5k rpm that means that the pan oil cycles through every 10 seconds or so and there are g forces splashing the oil around on top of that so the oil is not just sitting there.