Golferluke's Build Thread

#1

So about damn time I did a build thread on my 2000 ls. My goal with this setup was to build the cheapest setup possible that wouldn't hold me back from upgrading later. I also spent about 6 months collecting parts and looking for deals.

So here is a basic list of my setup...

gt2554r: $100 on cl off a ms protege

DIYPNP/ iat and misc bits: $500

lc1 w/ sensor $120 from member

knock off s4 mani: $100 ebay

22" magnaflow: $100 ebay

240sx dp: $120 ebay, $30 to modify

full 3" mandrel bent exhaust w/ flex: $300 local

460cc rx8 injectors: $30 on rx8 forum

DIY COPS: $100 at scrap yard

fmic w/pipes + connectors: $120 (dont remember exact size, I'll try to look it up)

knock off ssqv w/ mount: $40 ebay

**** spectre filter: $20 Autozone

Cheapo boost gauge: hf $20

Total atm: ~ $1700

Thats most of it, I'll update if I think of something else.

As of right now I have stock motor/tranny. Clutch is next, then motor in the spring hopefully. As of right now I'm only doing about 4-5 psi. my clutch is slipping in second/third (oem, only about 15k miles on it) so I should be around 170 hp I think? I don't know, don't really care about hp right now. All I know is I can't go any higher until I replace the clutch. Spool is practically instant right now, I'm making 4-5 by like 2200 rpm. Overall goal is 200 hp, obviously wont happen until after clutch tho.

Ok so on to some pictures and assembly. The whole process took about a week, was on spring break so I dicked around a bit, could have gone faster. Actually assembling the turbo build only took like 2 days max. Just getting the old exhaust out is what took FOREVER! Took like 3 days to get the exhaust out. Lots of pb blaster and cutting with a Wal-Mart grinder. (did I mention I don’t have any real tools?)

Ok so here we go…

Workin on it

Mocking up intercooler

Fmic mounted (more info later on that)

Mocking up turbo placement. Coolant hose behind turbo was no issue at all.

Custom bracket for mounting wastegate

Kris was proud so he signed it. Here is part of the 240 downpipe mentioned earlier. Its actually a nice piece for what I paid for it (and midpipe.) I knew it wouldn’t bolt up but I figured I could make it work with some modifications but it was actually surprisingly close. Not useable but close. The midpipe sits a little bit too low and the flange hits the transmission so the flange was cut off and doing so cut out a few inches of the pipe.

Here is part of the 240 downpipe mentioned earlier. Its actually a nice piece for what I paid for it (and midpipe.) I knew it wouldn’t bolt up but I figured I could make it work with some modifications but it was actually surprisingly close. Not useable but close. The midpipe sits a little bit too low and the flange hits the transmission so the flange was cut off and doing so cut out a few inches of the pipe.

Tacked up for a test fit.

All finished. T25 3” downpipe… $150

Heres the exhaust, its all mandrel bend except the very last bend :( I’ll get that fixed when I get a tip for it

Final product minus washer fluid reservoir and catch can

Heres my catch can I made out of an aluminum water bottle

Here it is mounted

Got bored and made a washer fluid reservoir out of a nos energy drink bottle. Just drilled a hole (harder than you’d think) and attached the pump with clear rtv.

Here it is mounted.

Here is my mbc I put together, havn’t installed it, no need to turn up boost yet.

So here is my idea for a dual stage bc with mbc reliability. Kinda self explanatory, that’s an electrically controlled on off valve. Valve open = IW (currently 4 or 5psi) and valve closed would be whatever the mbc is set at. Plus my jet fighter switch

#2

Copied from my diy thread:

Ok so I’ve seen a few people asking about nb intercooler setups while keeping ac/ps so I figured I’d start a thread on how I did mine. I’m definitely not the first to do this. I actually got the idea from one of 18psi’s builds and I think he got it from someone else. Regardless of whos idea it is, heres how I got it to work on mine. There is a hole behind the driver side headlight. Obviously its too small for a pipe but can easily be expanded to fit a 2.5” i/c pipe. Then its just a 90* into the intercooler. The cold side is fairly straight forward and similar to other year models. Just down and around the radiator.

One issue I did have was mounting the intercooler because of the a/c canister. If I recall correctly my i/c is a 27"X5.5"X2.5" ebay special. I don’t think a 3” would fit.

Ok so heres some pictures. Please go easy on my rusty innards :(

Heres a pic of the i/c

Mocking it up

All mounted up

Heres a picture of the hole placement. I can’t remember if this is the final shape of the hole but pretty close.

Here it is from the front looking through the headlight hole.

Here’s a shot from the top with pipe in place. As you can tell I got a little trigger happy with the grinder, probably didn’t need to be quite that big.

Another picture from the top. Make sure you either round the cut area or do what I did and put a scrap piece of coupler between the pipe and metal. Otherwise it will rub and cut a hole in your pipe.

Here it is from under neath

Where it meets the i/c.

Heres a picture of the hotside pipeing out of the car for reference.

Cold side:

Heres a pic of the cold side piping out of the car for reference.

Side view, this is a good picture of how the intercooler sets up against the canister in front of the condenser and rad. Also after these pics were taken the ic was drilled and tapped for an iat sensor on the cold side.

From the throttle body its just straight down. I had to remove the ducting but I havn’t had any problems (115 heat this summer but I don’t do track days) so if you anticipate problems you’ll need to make custom ducting. Hope this helps.

Ok so I’ve seen a few people asking about nb intercooler setups while keeping ac/ps so I figured I’d start a thread on how I did mine. I’m definitely not the first to do this. I actually got the idea from one of 18psi’s builds and I think he got it from someone else. Regardless of whos idea it is, heres how I got it to work on mine. There is a hole behind the driver side headlight. Obviously its too small for a pipe but can easily be expanded to fit a 2.5” i/c pipe. Then its just a 90* into the intercooler. The cold side is fairly straight forward and similar to other year models. Just down and around the radiator.

One issue I did have was mounting the intercooler because of the a/c canister. If I recall correctly my i/c is a 27"X5.5"X2.5" ebay special. I don’t think a 3” would fit.

Ok so heres some pictures. Please go easy on my rusty innards :(

Heres a pic of the i/c

Mocking it up

All mounted up

Heres a picture of the hole placement. I can’t remember if this is the final shape of the hole but pretty close.

Here it is from the front looking through the headlight hole.

Here’s a shot from the top with pipe in place. As you can tell I got a little trigger happy with the grinder, probably didn’t need to be quite that big.

Another picture from the top. Make sure you either round the cut area or do what I did and put a scrap piece of coupler between the pipe and metal. Otherwise it will rub and cut a hole in your pipe.

Here it is from under neath

Where it meets the i/c.

Heres a picture of the hotside pipeing out of the car for reference.

Cold side:

Heres a pic of the cold side piping out of the car for reference.

Side view, this is a good picture of how the intercooler sets up against the canister in front of the condenser and rad. Also after these pics were taken the ic was drilled and tapped for an iat sensor on the cold side.

From the throttle body its just straight down. I had to remove the ducting but I havn’t had any problems (115 heat this summer but I don’t do track days) so if you anticipate problems you’ll need to make custom ducting. Hope this helps.

Last edited by Golferluke; 08-25-2011 at 08:09 PM.

#4

Almost texted you to let you know I finally made a thread but figure youd find it ha ha. Well honestly I don't know enough about it to tell if the bovs not performing properly being my first turbo car and all but it seems to be the same as when I first put it on, havn't noticed any booost leaks. The manifolds holding up, I think I may have a pinhole leak at the engine flange but I can't see it. Only reason I suspect one is some soot around it. I'm pretty happy its held on this long honestly lol. I'm not sure what I'll do when it goes. I'd like to find a way to brace the new one in a way that doesn't involve me pulling engine mounts out to drill holes. Plus didn't yours break anyways with the brace?

#6

Thanks! Havn't tested it yet. I was thinking today, I think I need to do a boost leak test. I'm getting around 4-5 psi. I was thinking thats what the iw is but isn't that about were people start getting boost leaks? May get bored tomorrow and build one of the dsm vfaq testers. Just curious, should I be attaching the tester to ic piping or the actual inlet on the turbo? I assume attaching it to the turbo would give a better test, but I don't want to screw something up in the turbo. then again considering what the turbo goes through on a daily basis a cold 15psi should be a walk in the park.

#8

I'M BACK!

So I broke my miata this spring. I don't know what happened, was driving home from work and lost a cylinder. No noises or anything, just severely down on power and trying to die. I changed plugs, checked coils no change. It was time to build the engine anyways so just parked it. I don't have a compression checker and never got around to it since, life kind of got in the way.

Shortly after all this I moved back to Missouri, started a new job. Since then I've either had the time and not the money or the money and not the time.

Anyways, now I have a small amount of both and a solid daily, but most of all I FINALLY have a garage. Time to start gathering shiny things. Current power goal is sub 300, just going to get forged rods, arp studs, clutch and refresh seals, bearings, rings etc.

Been scouting out off brand rods, these seem to be the best deal with arp hardware but it doesn't actually say "forged" in the add, just 4340 h beam. 4340 is forged right?

Next what do I need for the engine rebuild? I can't spend alot but at the same time I don't want to destroy my engine. So off the top of my head I'll need a head gasket, vc gasket, rings, main bearings, rod bearings, thrust bearings? valve seals, valve guides, rear main seal, wp has about 10k on it but could probably use a timing belt. What am I forgetting? Questions is which parts do I need to go all out on and what parts just need to be oem spec replacement? Are all multi layered steel head gaskets created equal? Do bearings HAVE to be acl?

Clutch. I don't even know now, ever the first stage of the turbo build I planned on just getting a 6 puck whenever I built the motor and stopped dailying it. Is that a terrible idea? Whats the best clutch/pp options on a budget for mid 300ish tq? As always cheap is king, only time I'll be driving is when I'm out playing so not worried about feel. 949 race clutch isn't going to happen but if the fm stage II really is the best option I could probably swing it.

Not expecting anybody to answer all my questions in one post, any advice is appreciated

Oh yeah almost forgot, I'll definitely have to pick up a 6 speed and probably a different turbo at some point but right now just want to get the motor/clutch figured out.

So I broke my miata this spring. I don't know what happened, was driving home from work and lost a cylinder. No noises or anything, just severely down on power and trying to die. I changed plugs, checked coils no change. It was time to build the engine anyways so just parked it. I don't have a compression checker and never got around to it since, life kind of got in the way.

Shortly after all this I moved back to Missouri, started a new job. Since then I've either had the time and not the money or the money and not the time.

Anyways, now I have a small amount of both and a solid daily, but most of all I FINALLY have a garage. Time to start gathering shiny things. Current power goal is sub 300, just going to get forged rods, arp studs, clutch and refresh seals, bearings, rings etc.

Been scouting out off brand rods, these seem to be the best deal with arp hardware but it doesn't actually say "forged" in the add, just 4340 h beam. 4340 is forged right?

Next what do I need for the engine rebuild? I can't spend alot but at the same time I don't want to destroy my engine. So off the top of my head I'll need a head gasket, vc gasket, rings, main bearings, rod bearings, thrust bearings? valve seals, valve guides, rear main seal, wp has about 10k on it but could probably use a timing belt. What am I forgetting? Questions is which parts do I need to go all out on and what parts just need to be oem spec replacement? Are all multi layered steel head gaskets created equal? Do bearings HAVE to be acl?

Clutch. I don't even know now, ever the first stage of the turbo build I planned on just getting a 6 puck whenever I built the motor and stopped dailying it. Is that a terrible idea? Whats the best clutch/pp options on a budget for mid 300ish tq? As always cheap is king, only time I'll be driving is when I'm out playing so not worried about feel. 949 race clutch isn't going to happen but if the fm stage II really is the best option I could probably swing it.

Not expecting anybody to answer all my questions in one post, any advice is appreciated

Oh yeah almost forgot, I'll definitely have to pick up a 6 speed and probably a different turbo at some point but right now just want to get the motor/clutch figured out.

#9

I went and picked it up from LKQ today... It did come with a slave cyl and I think the connectors (still plastic wrapped)

Problem is it didn't come with the plate that has 4 bolts in it the shifter goes through. I have no idea what its even called let alone where to get one. Anybody have a broken 6 spd I can steal parts off?

This is what I got...

#11

Well it is, kind of. I have a get the car back on the road list, and a stuff I want to upgrade list.

To get the car driving again I have to pull the motor out and go through the engine. Since the motor is coming out, I'm going to do all the things that require having the motor out to do. Manifold is for sure getting replaced, but that's easy and I can do it any time. Going to put funds towards the motor/transmission first. May work out that I replace it before I'm driving again, but not a priority.

To get the car driving again I have to pull the motor out and go through the engine. Since the motor is coming out, I'm going to do all the things that require having the motor out to do. Manifold is for sure getting replaced, but that's easy and I can do it any time. Going to put funds towards the motor/transmission first. May work out that I replace it before I'm driving again, but not a priority.

#12

So I've got a lot of parts coming in this week:

China Rods

Arp head studs

ACL main/rod/thrust bearings

Full gasket/seals kit minus and oil pan

Tie rod ends (rack depower didn't go smoothly lol)

I picked up some 97 pistons on eBay for lower compression ratio. Was waiting on rings to see if I could find some na pistons so I'll go ahead and order those now.

Act pp/ 4 puck

Another member hooked me up with the tranny plate I need

I'm sure I'm forgetting stuff

I dont have an engine hoist right now, waiting on a friend that leant his to someone else so I've been doing everything I can for now. Removed ac/ps (fm depower) and pulled out turbo, manifold, down pipe, intercooler, piping, catch can,radiator, bumper, headlights (considering baking/painting them) drained fluid, took out random crap like overflow bottle and charcoal canister (does that hard line just loop back into a vaccum hose off the im to delete it?)

I'll have more updates this week, not much to take pictures of right now just an emptyish dirty engine bay.

China Rods

Arp head studs

ACL main/rod/thrust bearings

Full gasket/seals kit minus and oil pan

Tie rod ends (rack depower didn't go smoothly lol)

I picked up some 97 pistons on eBay for lower compression ratio. Was waiting on rings to see if I could find some na pistons so I'll go ahead and order those now.

Act pp/ 4 puck

Another member hooked me up with the tranny plate I need

I'm sure I'm forgetting stuff

I dont have an engine hoist right now, waiting on a friend that leant his to someone else so I've been doing everything I can for now. Removed ac/ps (fm depower) and pulled out turbo, manifold, down pipe, intercooler, piping, catch can,radiator, bumper, headlights (considering baking/painting them) drained fluid, took out random crap like overflow bottle and charcoal canister (does that hard line just loop back into a vaccum hose off the im to delete it?)

I'll have more updates this week, not much to take pictures of right now just an emptyish dirty engine bay.

#13

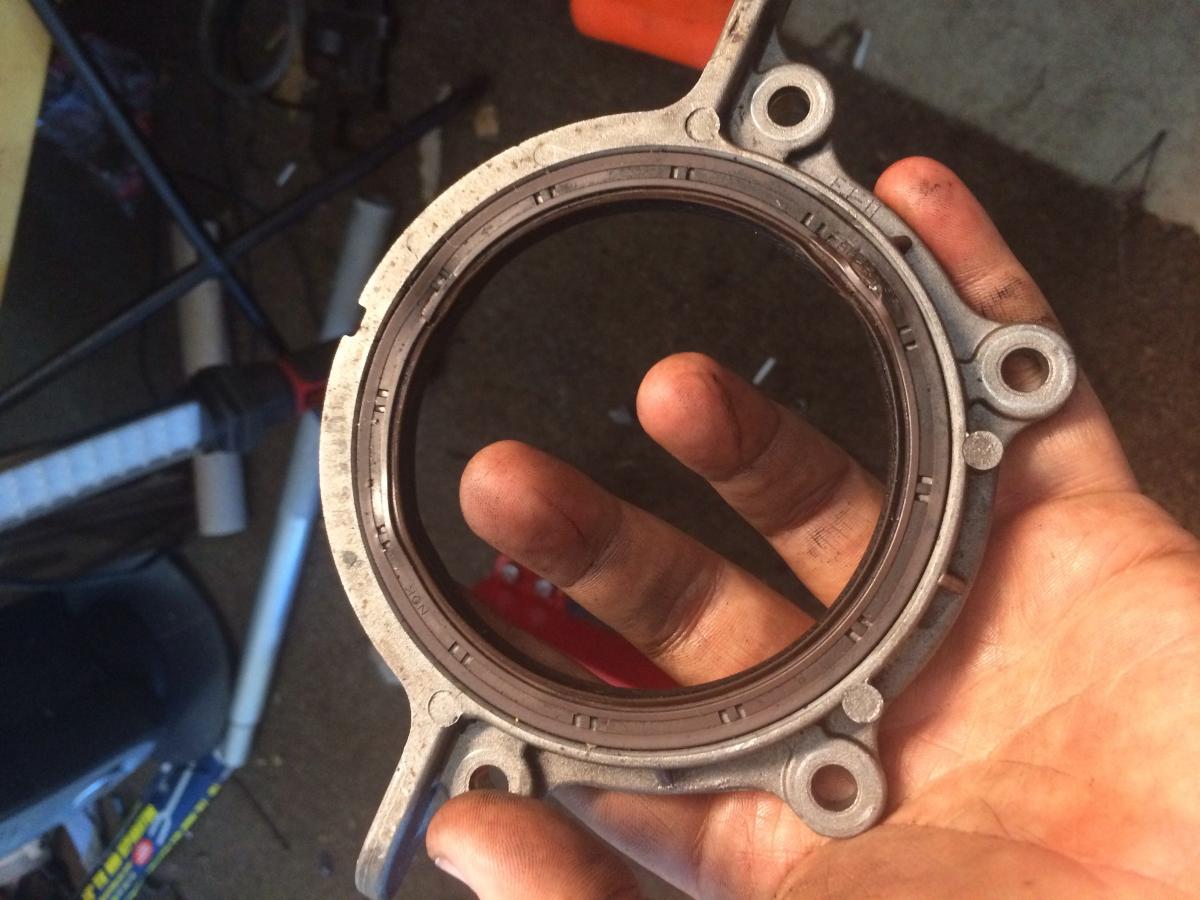

So I've been bad about updating this. Finally got a crane, Motors out, putting the bottem end back together. But I'm having issues with rear main seal. How the **** are you supposed to get this thing out? All the searching I've found are people trying to do it while in the car or something which leads me to believe there's an easy way I'm missing. Please help before I have to resort to

#17

Thanks vlad, yeah lots of ebay. As soon as I get everything back together manifolds first on the list.

I got the tranny piece from a member here so good on that front, still have to figure out how to make the 5spd shifter work, if I can't I'll just pick up a 6 some where but besides that I have all the pieces now, just have to finish putting them together.

Also I guess on the update front I also depowered steering and yanked all the ac bs out. Which reminds me I also need that screw to plug whatever hole leaks when you remove stuff.

Edit:

anybody got a magic solution to getting carbon off valves? Don't have a brass wheel to grind em :( I heard soaking in kerosene?

I got the tranny piece from a member here so good on that front, still have to figure out how to make the 5spd shifter work, if I can't I'll just pick up a 6 some where but besides that I have all the pieces now, just have to finish putting them together.

Also I guess on the update front I also depowered steering and yanked all the ac bs out. Which reminds me I also need that screw to plug whatever hole leaks when you remove stuff.

Edit:

anybody got a magic solution to getting carbon off valves? Don't have a brass wheel to grind em :( I heard soaking in kerosene?

Last edited by Golferluke; 03-13-2014 at 09:32 PM.

#18

Holy crap, either this guys smoking something or my wheels are going up for sale tonight lol! Speed Star Racing Wheel Rims Integral S1 SSR Rims Wheel 5x114 3 17 9 0J 38 | eBay

After 8 hours working on it today the motors back together finally, timings done, pulleys etc. Not sure how to torque the crankshaft bolt out of the car though (no fm tool) so I'll probably just wait on that until its in and I can put it in gear or something. Still lacking intake mani, injectors, im brace, alternator water pipe that goes next to block and finally the tranny/starter.

Speaking of I guess I didn't buy a gasket for that, I should be fine with rtv right? Now that I think about it should I use paper gaskets for anything in the motor?

Anyways I'll get that stuff done tomorrow probably, its starting to look like an engine again, beginning to see a light at the end of the tunnel finally...

After 8 hours working on it today the motors back together finally, timings done, pulleys etc. Not sure how to torque the crankshaft bolt out of the car though (no fm tool) so I'll probably just wait on that until its in and I can put it in gear or something. Still lacking intake mani, injectors, im brace, alternator water pipe that goes next to block and finally the tranny/starter.

Speaking of I guess I didn't buy a gasket for that, I should be fine with rtv right? Now that I think about it should I use paper gaskets for anything in the motor?

Anyways I'll get that stuff done tomorrow probably, its starting to look like an engine again, beginning to see a light at the end of the tunnel finally...

How's the mani holding up? Ever bother to brace it any? How's the ebay bov? I'm thinking about ordering one of those to replace my real ssqv since its old and leaking some.

How's the mani holding up? Ever bother to brace it any? How's the ebay bov? I'm thinking about ordering one of those to replace my real ssqv since its old and leaking some.