Aidan's loose oily bunghole actually runs a track lap

#8563

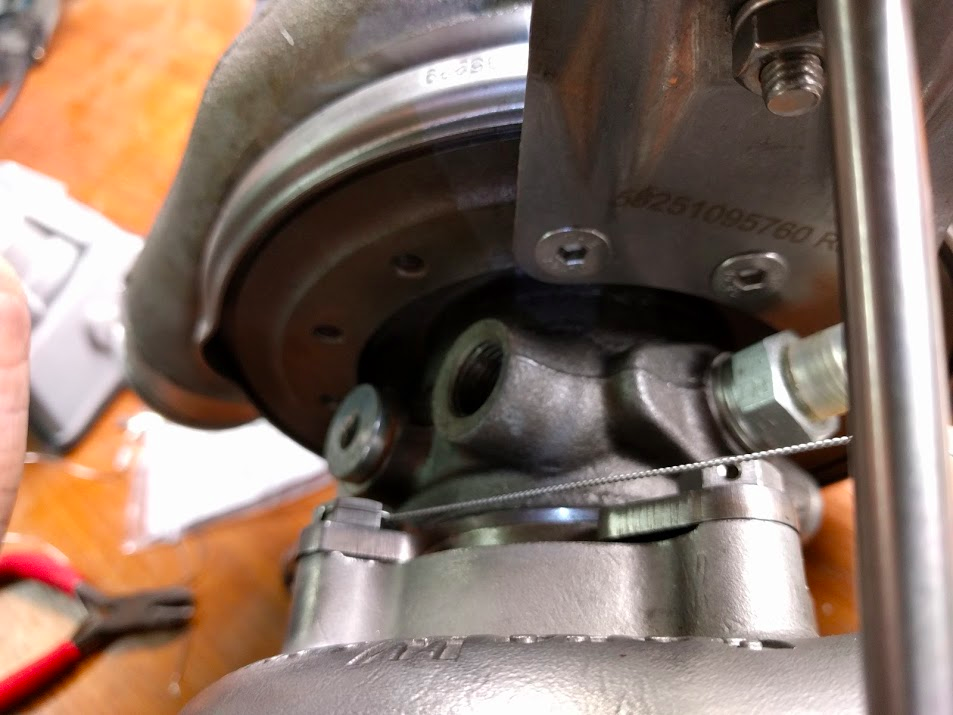

@Lokiel is this what you were talking about? Looks like I might have to slot the wastegate bracket. Basically the arc of the wastegate shaft moves outside of the wastegate flapper lever. Wont connect at all without some binding.

Initially when I had the low-mount manifold made, the engine was still stock so I just had the wastegate wired open and no actuator (NitroDann built/fitted it for me; he's in Newcastle, I'm in Brisbane, 772km/480mi apart, and I didn't trust myself to drive it that far without being tempted to "floor it" - no self control).

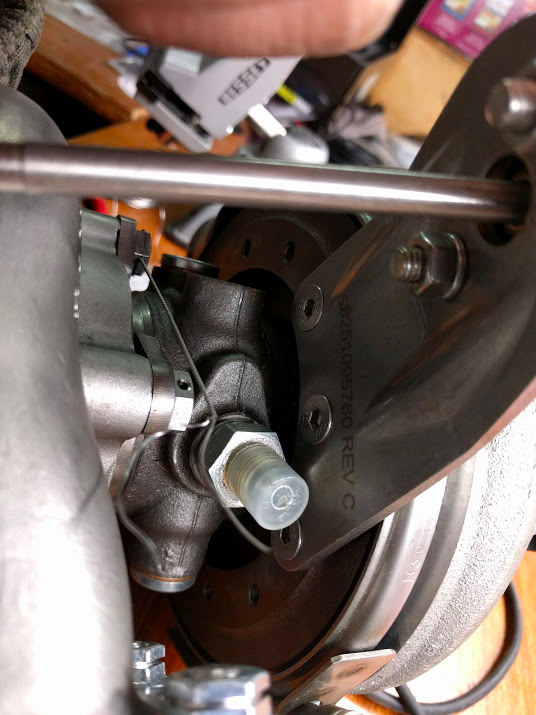

When I had the engine built in Brisbane, they had to rotate the actuator's bracket and bent/shaped the shaft, to make it work:

Note: I had an early generic Turbosmart wastegate IWG-75 actuator which had a longer shaft

They found that the wastegate valve was binding badly and that the Turbosmart diaphram had pinched/torn due to the twisting of the shaft.

They sent the manifold, turbo and several wastegates actuators I supplied to MTQ, turbo specialists, to come up with a solution since they'd already spent too much time on it.

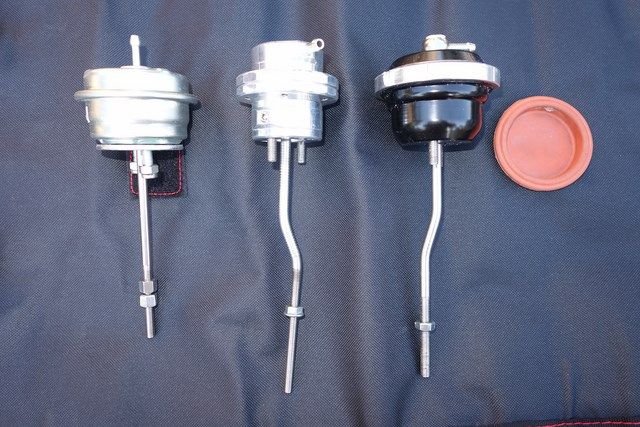

Here's the 3 wastegate actuators I got back (none worked):

OEM (left), Forge (middle), Turbosmart (right)

- the original EFR6258 wastegate actuator on the left was too short with my actuator's location/orientation since the shaft isn't long enough.

... and what was fitted (modded Ford XR6 6psi actuator with an elongated shaft which was shaped/bent):

Even this solution had some binding issues, which is why they didn't recommend more than a 6psi actuator, so I decided to wait for the TSE "kit", figuring if MTQ couldn't make it work, I had no hope.

You've confirmed what I always suspected, that it's the bracket that needed modding to make it work - all the effort was spent trying to modify the actuator shaft to make it move correctly rather than orienting the actuator to the correct alignment to allow it to work as it was designed. This is why I wanted to give you the "heads-up", if it doesn't work correctly, you're wasting your time doing anything further.

Great job! (and thanks for the video showing that it is aligned correctly)

In hindsight, I wish I'd got NitroDann to fit the wastegate, I'm sure that he would have realised that the bracket was the issue and gotten it to work correctly since he's "a fabricator", as opposed to a "turn-over shop".

Last edited by Lokiel; 02-13-2017 at 02:44 AM.

#8564

SADFab Destructive Testing Engineer

Thread Starter

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

Thanks for all the info. I literally took my big set of channel locks and bent the bracket till it all fit. So hopefully it will work as is. The bracket flexes more than expected, but shaft travel seems pretty straight.

#8570

Former Vendor

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,099

I have set up a bunch of these and never once have I needed to bend the bracket or the wastegate actuator rod. The height varies depending on how the actuator is clocked. You need to clock the entire CHRA to make this happen. Your oil feed/drain lines probably won't be vertical, but that's fine. This is very much a case of taking a hammer or channel locks to a problem which really just needed a 13mm box wrench and 5 minutes of thought.

#8571

SADFab Destructive Testing Engineer

Thread Starter

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

Nope, I had the CHRA bolts loosened, and was clocking the housing any way possible. As stated before, as I clocked the CHRA the arc of the end of the wastegate traveled outside of the wastegate lever.

I spent 15-20 minutes trying all possible clocking positions before the hammer came out, I definitely didn't start with it.

This very well be a specialized case, and nobody else will have my problem, but I know for a fact that mine would not fit.

I spent 15-20 minutes trying all possible clocking positions before the hammer came out, I definitely didn't start with it.

This very well be a specialized case, and nobody else will have my problem, but I know for a fact that mine would not fit.

#8572

Former Vendor

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,099

Could also be that it was a used turbo. Who knows who fucked with it before you got to it.

My sample size is a lot larger than yours or lokiel's, so I am confident that your experience is an outlier. I've set up ~6 of them here, myself, with brand new turbos straight out of the box, and have had no issues with any of them.

My sample size is a lot larger than yours or lokiel's, so I am confident that your experience is an outlier. I've set up ~6 of them here, myself, with brand new turbos straight out of the box, and have had no issues with any of them.

#8573

SADFab Destructive Testing Engineer

Thread Starter

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

It is a "used" turbo (never ran), who knows. Also a somewhat older turbo.

I definitely wouldn't tell people not to buy the actuator, but as we have found out, both the actuator and efr's are very finnicky in regards to wastegate alignment, so it should be checked closely.

Have you played with a 4 port solenoid on your setup yet?

I definitely wouldn't tell people not to buy the actuator, but as we have found out, both the actuator and efr's are very finnicky in regards to wastegate alignment, so it should be checked closely.

Have you played with a 4 port solenoid on your setup yet?

#8576

That's actually a really good video. We didn't do a reverse twist at the end but then again it may be a mistake in the way I was taught. The "barrel roll" and the "snap" that he refers to are key to getting a nice tight safety wire job. Honestly I did most of my safety wiring by hand but those pliars are very helpful.

If you weren't so darn far away I would just come over and do it for you (unless you were interested in learning). I kinda miss it sometimes. I was an Avionics tech on EA-6B Prowler in the Marine Corps.

If you weren't so darn far away I would just come over and do it for you (unless you were interested in learning). I kinda miss it sometimes. I was an Avionics tech on EA-6B Prowler in the Marine Corps.

#8577

Safety wire pliers are a huge help getting the right twist.

https://smile.amazon.com/Aircraft-Sa...ty+wire+pliers

https://smile.amazon.com/Aircraft-Sa...ty+wire+pliers