Austin's Rotrex Build

#1

Yup, I have one of those belt driven turbo things on my car and although majority of the build has been done already I thought I'd share some photos and stuff like that.

The goal:

"To test the limits of the stock 1.6L powertrain - "high" compression, Rotrex"

The purpose:

Mainly HPDE championships, occasional street driving

The equipment:

200whp (Conservative, you'll see why below)

- Stock 1.6L block (170,000km)

- Refreshed head with cams

- Rotrex C30-94 (Falcon's old setup)

So prior to this whole Rotrex idea, I have had Miatas since highschool. Being the young dumbass I was, I managed to write both of them off, and thats when I landed on the black NA I have now.

Over the years I had collected parts from all the Miatas I wrote off. Not really having the budget to do a "full build" so there were different stages of mods I had done. I think I was the first and only person that I knew of that had a stock 1.6L with lightweight flywheel with a 6spd tranny and 4.3 FD. Lots of fun with that gearing and it was really fun to flog around on track. The engine was nice and healthy, and the car it came out of (my silver NA) was soooo clean that when I picked up the car, the boot cover still had its pleather smell.

Fast forward a few years, One of my friends went 1.7L ITB and began selling off his old parts, thats when I came across the re-ground cams. At the time I was going to stick to being N/A, but falcon eventually parted out some of his car and I snagged up the Rotrex.

First everything came off and then came the cleaning process. The plan was to put on a fresh head (w/ slight deck shave) and the cams and bolt everything back together. You can see the block above was cleaned out as well, that Mopar combustion chamber cleaner does wonders on the carbon buildup.

Started from this dirty head with plenty of blowby.

To eventually this cleaned out head.

Bought a friend's TIG welder off him as he was in a bit of a financial rut and started re-learning how to TIG. Never really got the chance to sit down at jobs that I had access to one, so it was nice to go at my own pace and experiment.

Made plenty of these PS welds (pigeon ****) all in preparation for making my 3" exhaust (which some of you may have seen in the fabrication forum.

#4

Scrappy Jack, Point taken! I will change that around, I realize its a bit weird to read after the pictures.

I just came back from watching some historic races which included 911s, Alfa Romeos, GT40s, Corvettes, Mustangs, and the like, hopefully post some of that along as some updates on the miata!

#5

Reflecting on some of the pictures from the fabrication thread, I had been reading a lot on anti-reversion chambers for use in Honda applications namely from Hytech. Well there was no way I was going to have the patience, time or skill to fabricate an anti-reversion chamber for each individual runner like the Hytech header, so instead I chose to make one large one.

First thing first was to enlarge the downpipe portion of the header. Based on some dyno-data from my friend Winky's build, it showed me made power by enlarging the Maxim Works header. Matching the curves was one hell of a task, I literally spent an entire night after work hammering out the exact shape as close as I could.

The 2.5" mandrel bend then transitions to a 3" exhaust via this tapered piece. The 2.5" bend extends past into where the flex pipe is to try to reduce some of the back pressure waves from bouncing back and interrupting the power pulse. No dyno results if it actually worked though.

1993ka24det, you were asking if I was backgassing the welds, well here is my setup. It's not the best method, using masking tape as a method of sealing had its downsides. For example if it heats up too much then the tape tends to burn and leave a residue on the steel. I had it happen to me a couple of times when I wasnt careful. Also you have to be sure your tube doesn't fall out since masking tape isnt the strongest to use. I've heard some people use tin foil or aluminum tape with better results.

Here is a closeup shot of my welding. Not the best out there I'll openly admit and this exhaust project was good practice to get consistent speeds.

Just thought it was kind of cool to see the difference in flow between a 2.25" and 3" pipe. Definitely a lot more flow is going to go through these pipes.

As for flanges, I chose to slip them on where possible with a washer between and tack them on. Then I used a portable bandsaw to cut the pipe and finish it off on the belt sander. Not really the fastest way to do things but it ensured that things would line up. I probably spent a lot more time than necessary on this exhaust but I wanted things to turn out perfect.

#7

So, back from the dead.

Fast forward to mid-may and my car gets strapped onto the dyno. I decided to take it to Dominic Acia @ Maxwell Power Services, as a lot of friend's had positive experiences there.

He usually tunes Subarus or American V8's and this was his second Megasquirt tune. Usually he doesn't touch MS stuff due to a lot of people doing DIY the WRONG way, and it ends up being more headache for him to try and fix.

Luckily enough my friend Arthur has taken his STI to get tuned for some crazy power there numerous times so I sort of got a referral to go there. Here's a video of one of his dyno pulls:

Strapped down and ready to go!

Honestly speaking this is the first time I've ever taken my own car to get dyno'd. I've seen lots of friend's cars go in to see what numbers would be put down but being my own personal car it was kind of exciting.

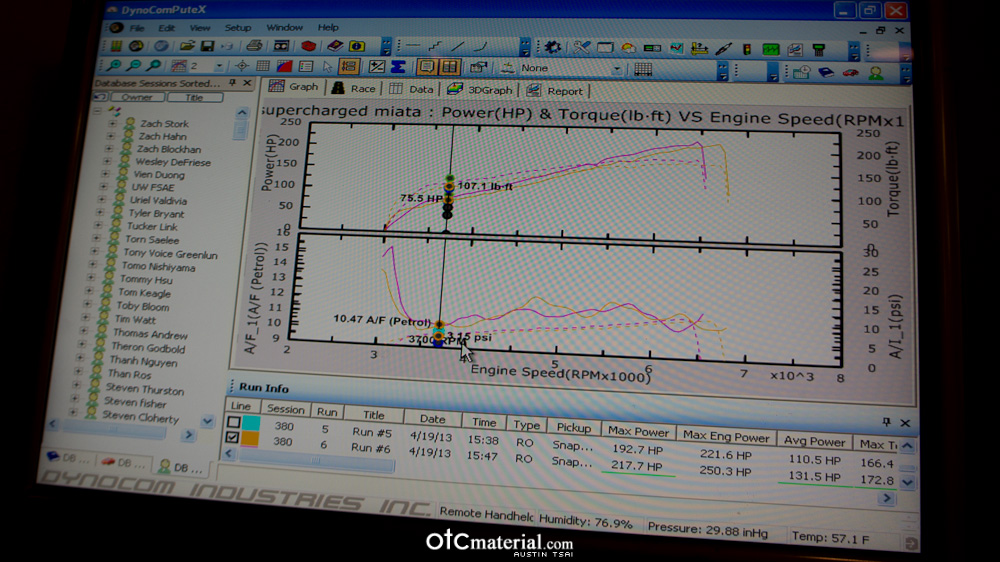

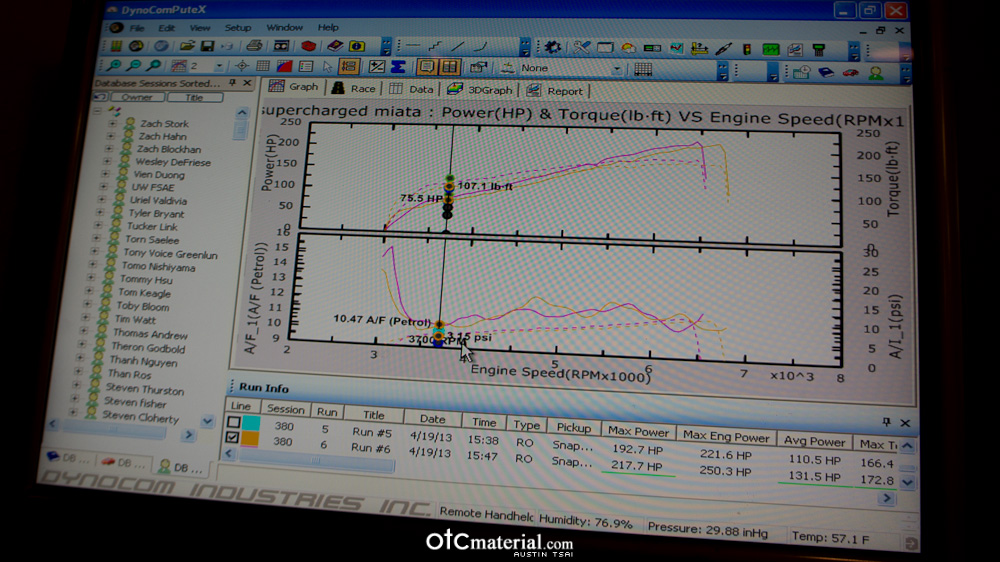

Initial pulls after some small touch ups on my street tune showed some good results. Honestly I was expecting a conservative 200whp, but since the first pull went past that I was more than happy! 217whp and 172wtq not too shabby if I say so myself.

At the end of the day I put down 235whp, 18wtq on a Dynocom roller dyno. This is on a stock 1991 1.6L long nose bottom end, with a refreshed head with new valve guides and a decked head. I also have some regrind cams, and a header but for the most part the engine is stock.

Fast forward to mid-may and my car gets strapped onto the dyno. I decided to take it to Dominic Acia @ Maxwell Power Services, as a lot of friend's had positive experiences there.

He usually tunes Subarus or American V8's and this was his second Megasquirt tune. Usually he doesn't touch MS stuff due to a lot of people doing DIY the WRONG way, and it ends up being more headache for him to try and fix.

Luckily enough my friend Arthur has taken his STI to get tuned for some crazy power there numerous times so I sort of got a referral to go there. Here's a video of one of his dyno pulls:

Strapped down and ready to go!

Honestly speaking this is the first time I've ever taken my own car to get dyno'd. I've seen lots of friend's cars go in to see what numbers would be put down but being my own personal car it was kind of exciting.

Initial pulls after some small touch ups on my street tune showed some good results. Honestly I was expecting a conservative 200whp, but since the first pull went past that I was more than happy! 217whp and 172wtq not too shabby if I say so myself.

At the end of the day I put down 235whp, 18wtq on a Dynocom roller dyno. This is on a stock 1991 1.6L long nose bottom end, with a refreshed head with new valve guides and a decked head. I also have some regrind cams, and a header but for the most part the engine is stock.

#10

oh you guys...  180wtq for all those that care haha

180wtq for all those that care haha

EDIT** Just for my own fails, here are some fun videos I took over the past month

Just being street tuned, I was ricing around for a day after getting my alignment done. Decided to take a few friends for an initial spin

My neighbours sure love me, heres a free rev video of how the combination of a 949twindisc and a 3" *almost* straight through exhaust sound like.

My buddy (who has a K20 EG Civic) and I have been having a friendly duel between the build up of our cars, as well as comparison between laptimes this year. Since our cars are putting out similar power we took turns one day to feel how each other's car was like. This is his video from my passenger seat after coming back from the dyno tune. His best explanation of how my car felt was that it was "like turbo, but reverse". I couldn't stop laughing the entire day.

180wtq for all those that care haha

180wtq for all those that care hahaEDIT** Just for my own fails, here are some fun videos I took over the past month

Just being street tuned, I was ricing around for a day after getting my alignment done. Decided to take a few friends for an initial spin

My neighbours sure love me, heres a free rev video of how the combination of a 949twindisc and a 3" *almost* straight through exhaust sound like.

My buddy (who has a K20 EG Civic) and I have been having a friendly duel between the build up of our cars, as well as comparison between laptimes this year. Since our cars are putting out similar power we took turns one day to feel how each other's car was like. This is his video from my passenger seat after coming back from the dyno tune. His best explanation of how my car felt was that it was "like turbo, but reverse". I couldn't stop laughing the entire day.

Last edited by Deepstriker; 06-09-2013 at 03:35 AM.

#13

I have the pulley's geared to 8000rpm, although I have set my fuel cut at 7600rpm. I figure Id give myself some "safety" and I'm only on a stock valve train anyways, with the exception of exhaust springs for both intake and exhaust sides. There is really no headwork done on this motor so I doubt there is much gain spinning it that high.

Here's the video of the actual pull that put down the final numbers:

Here's the video of the actual pull that put down the final numbers:

#16

A few weeks ago I went to Pacific Raceways to do a shakedown. Some of you may have seen the thread in the Megasquirt forum as to what happened that day. Basically my DIYPNP went on me, and I didn't end up running most of the day.

My friend Matt who came down with us took some nice shots so I thought I'd share:

My friend Eric and I were supposed to chase each other that day.

Unfortunately that didn't happen, car was decomissioned.

Comparison between a stack of Hoosiers and NT01s.

#19

Well, lets see and work backwards:

Now if you wanted to find that at 7600rpm:

100,000rpm rev limit = (130mm/ nose) * 8000 * 9.49

nose = 130*8000*9.49/100,000rpm = 98.696mm

So the closest would be 100mm

Now if you wanted to find that at 7600rpm:

rev limit = 1.3*7600*9.49 = 98,696rpm.

Last edited by Deepstriker; 06-12-2013 at 12:18 PM. Reason: wrong numbers in calc

Thread

Thread Starter

Forum

Replies

Last Post

its even funnier that this happens in a rotrex thread

its even funnier that this happens in a rotrex thread