Ian's 99 build thread

#1221

Retired Mech Design Engr

iTrader: (3)

Join Date: Jan 2013

Location: Seneca, SC

Posts: 5,009

Total Cats: 856

DNM

#1222

Elite Member

Thread Starter

Join Date: Mar 2007

Location: Santa Clara, CA

Posts: 5,165

Total Cats: 855

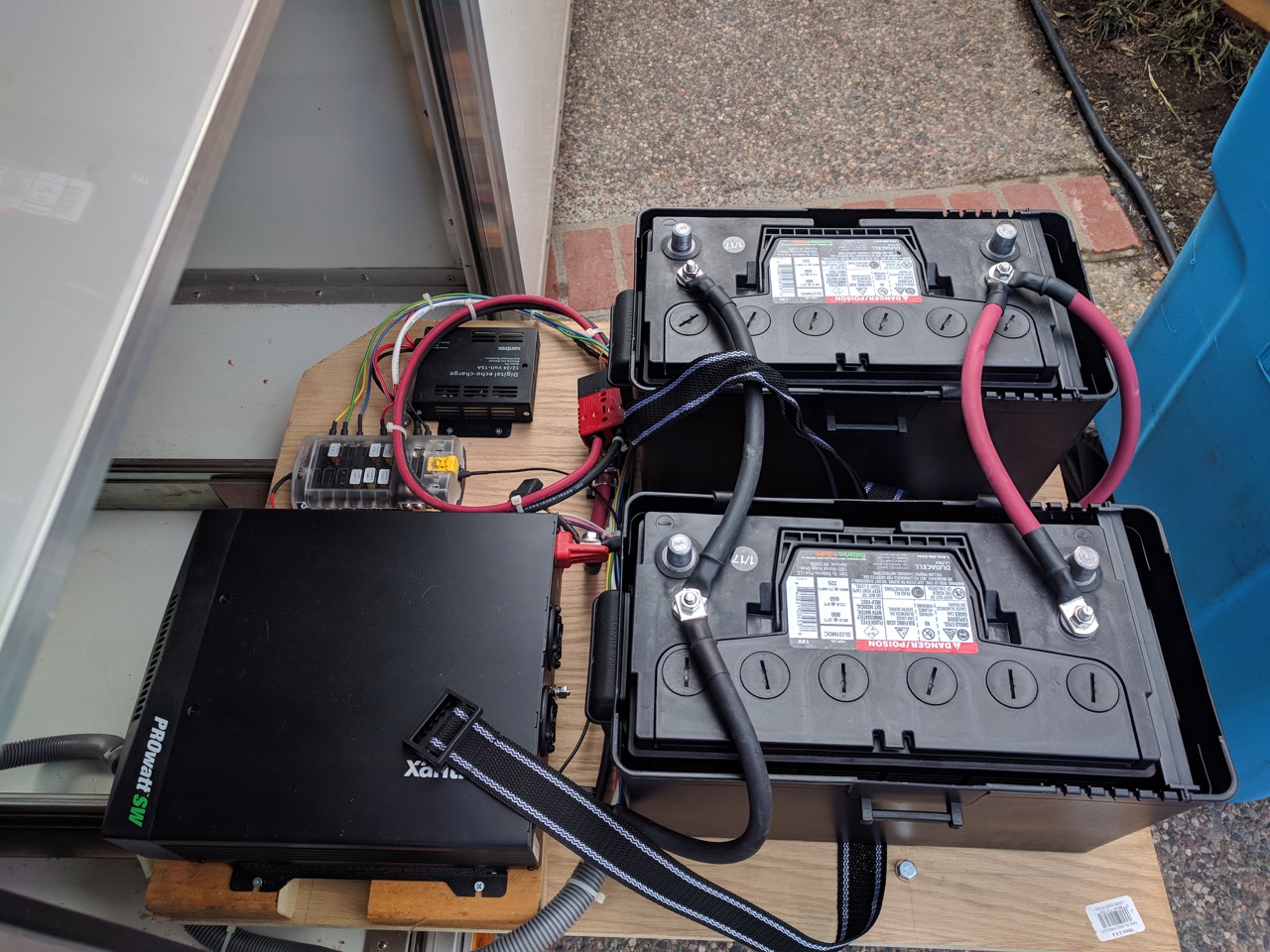

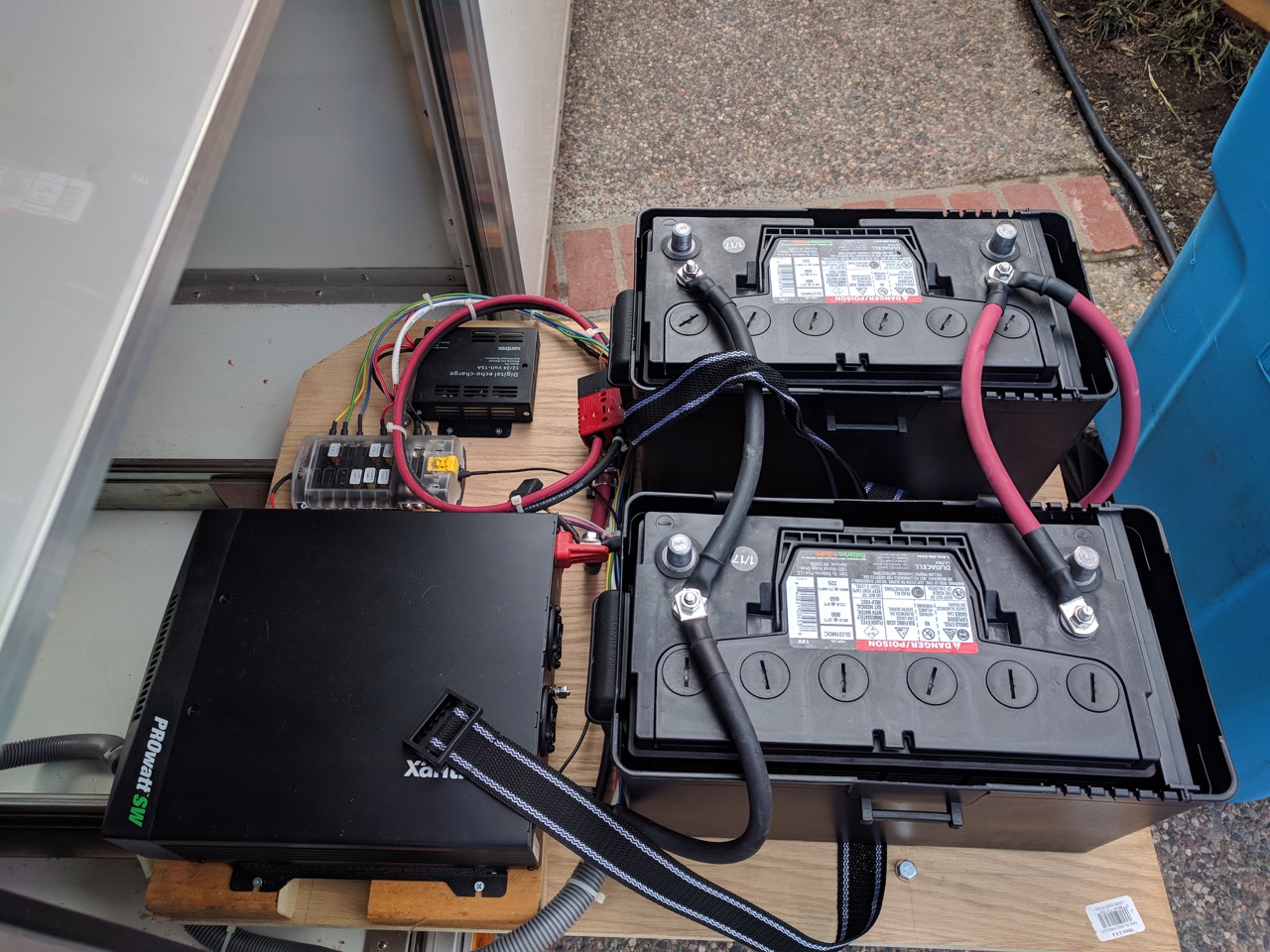

Spent the day screwing around with the trailer before Miatas@WRLS. I have a pair of batteries in it, for running a 2KW inverter, but they were awfully low on charge.

Checked the electrolyte levels, but no, they were fine. I've got two built-in charging systems for them, a 15A charger that runs off the +12 coming from the truck, and a small solar panel on the roof (only good for about 2A, basically it's there to keep them topped up). Neither of them was working properly. I dunno what's up with the solar, maybe the panel is dying, maybe the charge controller is busted.

I did manage to sort out the charger from the truck, though. After following a couple of red herrings I realized that GM doesn't install a fuse for the +12 trailer aux power on the 7-way connector at the factory. Instead there's a small red plastic dummy fuse labelled "B+". I have no idea why, but once I fixed that it all worked again. So yay. I'd tested this out when I put the trailer together, but I guess the previous owner of the old truck had installed the fuse, whereas the previous owner of the new truck hadn't.

Stupid fake fuse top left:

Anyway, car loaded and ready to go. Heading down to Laguna around noon tomorrow.

--Ian

Checked the electrolyte levels, but no, they were fine. I've got two built-in charging systems for them, a 15A charger that runs off the +12 coming from the truck, and a small solar panel on the roof (only good for about 2A, basically it's there to keep them topped up). Neither of them was working properly. I dunno what's up with the solar, maybe the panel is dying, maybe the charge controller is busted.

I did manage to sort out the charger from the truck, though. After following a couple of red herrings I realized that GM doesn't install a fuse for the +12 trailer aux power on the 7-way connector at the factory. Instead there's a small red plastic dummy fuse labelled "B+". I have no idea why, but once I fixed that it all worked again. So yay. I'd tested this out when I put the trailer together, but I guess the previous owner of the old truck had installed the fuse, whereas the previous owner of the new truck hadn't.

Stupid fake fuse top left:

Anyway, car loaded and ready to go. Heading down to Laguna around noon tomorrow.

--Ian

#1223

This is a perfect example of why I am so negative toward the American auto industry and GM in particular. Your truck is no bargain-priced loss leader. What kind of idiot thinks saving 0.0001 cent on a dummy fuse instead of a real fuse is a good idea? If I were in the meeting where this decision was made, I think I would have killed someone out of frustration.

Rant over.

Have fun at the track.

I realized that GM doesn't install a fuse for the +12 trailer aux power on the 7-way connector at the factory. Instead there's a small red plastic dummy fuse labelled "B+". I have no idea why, but once I fixed that it all worked again. So yay. I'd tested this out when I put the trailer together, but I guess the previous owner of the old truck had installed the fuse, whereas the previous owner of the new truck hadn't.

Stupid fake fuse top left:

--Ian

Rant over.

Have fun at the track.

I realized that GM doesn't install a fuse for the +12 trailer aux power on the 7-way connector at the factory. Instead there's a small red plastic dummy fuse labelled "B+". I have no idea why, but once I fixed that it all worked again. So yay. I'd tested this out when I put the trailer together, but I guess the previous owner of the old truck had installed the fuse, whereas the previous owner of the new truck hadn't.

Stupid fake fuse top left:

--Ian

#1225

Elite Member

Thread Starter

Join Date: Mar 2007

Location: Santa Clara, CA

Posts: 5,165

Total Cats: 855

So, MIatas@WRLS 2018. Loaded up the truck/trailer on Thursday, drove down Friday around 12:30.

Got to the track around 2, they told me I was too early to drop off stuff in the paddock, so I turned around and went to the hotel to check in. They've remodelled it since 2 years ago. It's a nice camp site.

Hung out there until registration opened at 4, got in line about 15 minutes before the doors opened. When I got out from reg (took about 10 minutes) the line went back and forth across the hotel lobby several times.

Went back to the track and they let me into the paddock to drop off stuff. Staked out a spot for miataturbo folks.

Also went and filled the car with 100 octane so that I wouldn't have to do it in the morning.

Went back to the hotel, walked around the car show. Met up with Aidan and Ed and a bunch of other people, saw the mythical miatabusa. Very cool sounds coming from that car.

So then Saturday was the first track day. The first session went great, except for the stupid "throw the checkered at the corkscrew" procedure that leaves you 2 corners' worth of cooldown lap. That's nowhere close to enough time for me (or for several other people I talked to), so I had to carefully watch the clock and try to guess when to start my own cooldown lap.

My car has a tendency to heat soak the brakes. They're fine on track, but after I come off track (especially without enough cool down), it will boil the fluid when sitting in the paddock, so when I get in it to go back out the pedal will be squishy. At many events I've taken to doing circles in unused parts of the paddock for 5 minutes to cool them more, but this time I brought an alternate solution with me. I grabbed a couple box fans and ran them off the 2kw inverter in the trailer, pointing in the wheels.

Alas, it wasn't completely successful, the pedal was still getting pretty mushy by the third session. As it turned out that, that was moot though.

After the second session I pulled off the passenger front wheel to check the brake wear. It appeared to be somewhat better than it had been at GGLC, in particular there didn't appear to be any taper in the pads, so it looks like replacing the Dynapros was the right call. When putting the wheel back on, though, I noticed that it had rubbed on the car and chewed all the way through to cord on the outside edge. It did this back at Thunderhill in May (on the driver's side), which I decided was caused by some combination of wheel spacers and extra bump travel on the Xidas. I did some surgery on protruding things inside the fender and ditched the spacers (they were a holdover from the original TSE 11.75 kit that I had installed -- I had upgraded to the gen2 kit after one of the brackets got damaged, and didn't realize that the spacers were no longer needed), and ran it at Laguna with GGLC in July. That event went flawlessley, and I was using the same tires, same car, same setup this time (hell, I barely even drove the car between the two events). Still, it had killed one tire already. I poked at it some more in the paddock, trimmed a little bit more off the bracket where the fender attaches to the bumper, put on a spare RR that I had in the trailer, and took it out for the third session. This one was short (only 10 minutes -- I guess the parade laps ran overtime, grr), but when I got back to the paddock the car was trailing strips of rubber from the tire, this one was now ruined too.

First tire:

Strips of rubber:

And that was basically it for me. I gave the box of goodies from Lars to Aidan, loaded up the trailer and drove home. Another frustrating track day.

--Ian

Got to the track around 2, they told me I was too early to drop off stuff in the paddock, so I turned around and went to the hotel to check in. They've remodelled it since 2 years ago. It's a nice camp site.

Hung out there until registration opened at 4, got in line about 15 minutes before the doors opened. When I got out from reg (took about 10 minutes) the line went back and forth across the hotel lobby several times.

Went back to the track and they let me into the paddock to drop off stuff. Staked out a spot for miataturbo folks.

Also went and filled the car with 100 octane so that I wouldn't have to do it in the morning.

Went back to the hotel, walked around the car show. Met up with Aidan and Ed and a bunch of other people, saw the mythical miatabusa. Very cool sounds coming from that car.

So then Saturday was the first track day. The first session went great, except for the stupid "throw the checkered at the corkscrew" procedure that leaves you 2 corners' worth of cooldown lap. That's nowhere close to enough time for me (or for several other people I talked to), so I had to carefully watch the clock and try to guess when to start my own cooldown lap.

My car has a tendency to heat soak the brakes. They're fine on track, but after I come off track (especially without enough cool down), it will boil the fluid when sitting in the paddock, so when I get in it to go back out the pedal will be squishy. At many events I've taken to doing circles in unused parts of the paddock for 5 minutes to cool them more, but this time I brought an alternate solution with me. I grabbed a couple box fans and ran them off the 2kw inverter in the trailer, pointing in the wheels.

Alas, it wasn't completely successful, the pedal was still getting pretty mushy by the third session. As it turned out that, that was moot though.

After the second session I pulled off the passenger front wheel to check the brake wear. It appeared to be somewhat better than it had been at GGLC, in particular there didn't appear to be any taper in the pads, so it looks like replacing the Dynapros was the right call. When putting the wheel back on, though, I noticed that it had rubbed on the car and chewed all the way through to cord on the outside edge. It did this back at Thunderhill in May (on the driver's side), which I decided was caused by some combination of wheel spacers and extra bump travel on the Xidas. I did some surgery on protruding things inside the fender and ditched the spacers (they were a holdover from the original TSE 11.75 kit that I had installed -- I had upgraded to the gen2 kit after one of the brackets got damaged, and didn't realize that the spacers were no longer needed), and ran it at Laguna with GGLC in July. That event went flawlessley, and I was using the same tires, same car, same setup this time (hell, I barely even drove the car between the two events). Still, it had killed one tire already. I poked at it some more in the paddock, trimmed a little bit more off the bracket where the fender attaches to the bumper, put on a spare RR that I had in the trailer, and took it out for the third session. This one was short (only 10 minutes -- I guess the parade laps ran overtime, grr), but when I got back to the paddock the car was trailing strips of rubber from the tire, this one was now ruined too.

First tire:

Strips of rubber:

And that was basically it for me. I gave the box of goodies from Lars to Aidan, loaded up the trailer and drove home. Another frustrating track day.

--Ian

#1227

Elite Member

Thread Starter

Join Date: Mar 2007

Location: Santa Clara, CA

Posts: 5,165

Total Cats: 855

Spent some more time staring at the fender today. I've lined up another track day at Laguna on Oct 15 with the Miata and want to avoid destroying more tires.

The main problem is the bracket where the fender bolts to the front bumper. I'd trimmed this on the driver's side a bunch at Thunderhill last May, the passenger side was fine there and was fine at Laguna in July, but rubbing in September. I have no idea why it reverted, but I trimmed it down after Miatas@WRLS to here:

So today I pulled the spring out of the Xida and moved stuff up and down again to recheck stuff

I could manage to get it to touch when the tire was high enough that it started lifting the car off the rolling bridge jack, so I trimmed it some more. Forgot to take a pic of it, though. Now the first thing that hits is the trailer corner of the front bumper. I can't trim that, so we'll just have to see how it works. I've ordered some bumpstop packers and will take them to the track with me to limit the bump travel if necessary.

--Ian

The main problem is the bracket where the fender bolts to the front bumper. I'd trimmed this on the driver's side a bunch at Thunderhill last May, the passenger side was fine there and was fine at Laguna in July, but rubbing in September. I have no idea why it reverted, but I trimmed it down after Miatas@WRLS to here:

So today I pulled the spring out of the Xida and moved stuff up and down again to recheck stuff

I could manage to get it to touch when the tire was high enough that it started lifting the car off the rolling bridge jack, so I trimmed it some more. Forgot to take a pic of it, though. Now the first thing that hits is the trailer corner of the front bumper. I can't trim that, so we'll just have to see how it works. I've ordered some bumpstop packers and will take them to the track with me to limit the bump travel if necessary.

--Ian

#1228

Elite Member

Thread Starter

Join Date: Mar 2007

Location: Santa Clara, CA

Posts: 5,165

Total Cats: 855

So the bumpstop packers arrived. They're 16mm ID, which seems to fit nicely on the Xida shaft.

I loaded the car up in the trailer for a track day at Laguna with the Alfa Romeo Owners of SoCal:

Beautiful day:

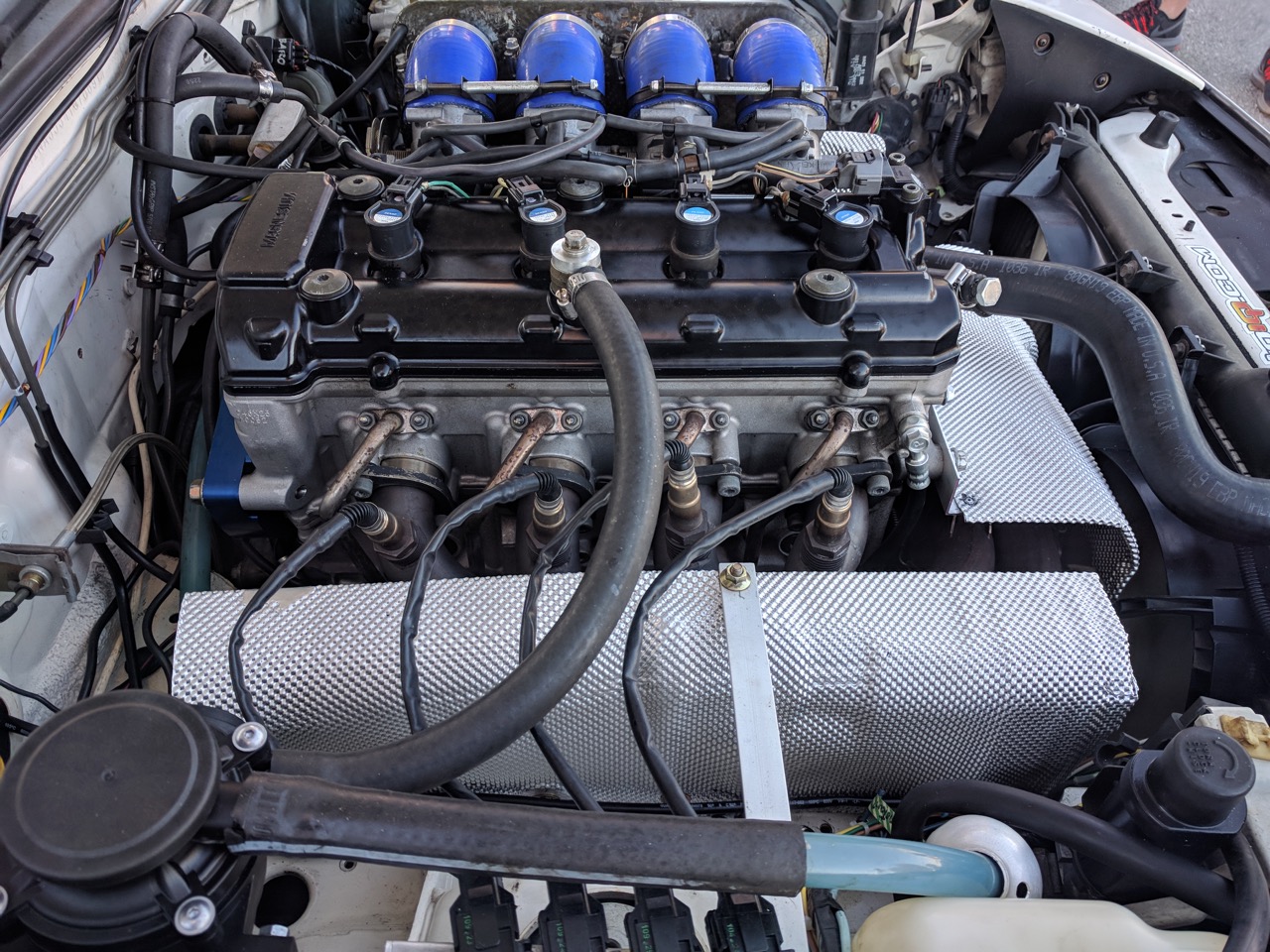

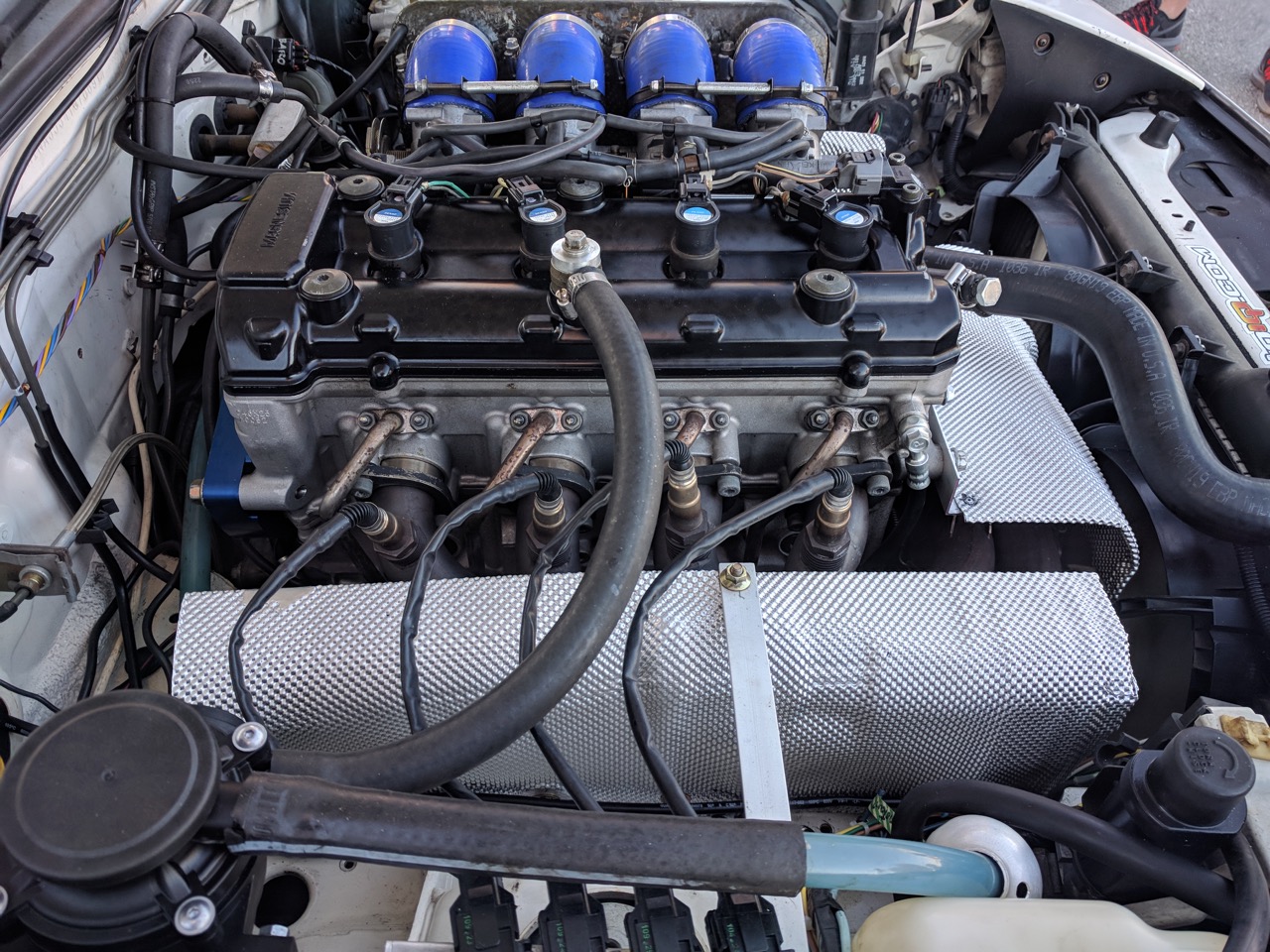

Went out for the first session, lots of traffic, but the car was running really well. It's definitely faster on the Xidas than it was on the FatCats, even with significant traffic I was still doing 1:45s which is equal to the best time I ever did on the FCMs. Unfortunately I never got a chance to really see what it would do because the second session it blew the power steering hose again. Just like last time I had smoke in the cabin in turn 2, slowed down, pointed everyone by, pulled off behind the wall in 5, and got towed back to the paddock. Oil all over the hot side of the engine bay, nothing in the PS reservoir, and no assist while turning.

I haven't torn it down too far yet, but it looks like the banjo fitting on the pressure hose failed in the same location as before. My theory for the cause of the failure last time was that the support bracket had fatigued over 19 years, 95K miles, 70 track days and 100+ autocrosses. Once the support bracket failed, the pressure hose is unsupported and vibrations busted loose the hard line where it's brazed/pressed/whatever to the banjo fitting. This time, however, the support bracket was intact, but the hard line came loose in exactly the same spot. So I dunno what's going on with that. For the short term I've ordered another OEM hose to get the car running again, and let me think about how to fix it properly.

(And no, I still don't want to delete the power steering.)

The AROSC event was a last minute thing -- I had been scheduled to go to Laguna the previous Monday with a different group (CFRA), but that event was cancelled due to the tragic death of a corner worker in a collision on the track the preceding day. :(

--Ian

I loaded the car up in the trailer for a track day at Laguna with the Alfa Romeo Owners of SoCal:

Beautiful day:

Went out for the first session, lots of traffic, but the car was running really well. It's definitely faster on the Xidas than it was on the FatCats, even with significant traffic I was still doing 1:45s which is equal to the best time I ever did on the FCMs. Unfortunately I never got a chance to really see what it would do because the second session it blew the power steering hose again. Just like last time I had smoke in the cabin in turn 2, slowed down, pointed everyone by, pulled off behind the wall in 5, and got towed back to the paddock. Oil all over the hot side of the engine bay, nothing in the PS reservoir, and no assist while turning.

I haven't torn it down too far yet, but it looks like the banjo fitting on the pressure hose failed in the same location as before. My theory for the cause of the failure last time was that the support bracket had fatigued over 19 years, 95K miles, 70 track days and 100+ autocrosses. Once the support bracket failed, the pressure hose is unsupported and vibrations busted loose the hard line where it's brazed/pressed/whatever to the banjo fitting. This time, however, the support bracket was intact, but the hard line came loose in exactly the same spot. So I dunno what's going on with that. For the short term I've ordered another OEM hose to get the car running again, and let me think about how to fix it properly.

(And no, I still don't want to delete the power steering.)

The AROSC event was a last minute thing -- I had been scheduled to go to Laguna the previous Monday with a different group (CFRA), but that event was cancelled due to the tragic death of a corner worker in a collision on the track the preceding day. :(

--Ian

#1231

The first was a bracket failure on my old 94, which I didn't notice. This lead to the failure of the hose at the fitting. I replaced the bracket and the hose and all was fine.

The second was the bracket failed on my 2001, which I did notice since I'd added checking that bracket to my list of pre-trackday checks. I replaced the bracket and ~1500 track miles later it's still fine.

My theory is that it's a modal response issue (like I suspect the throttle shaft issue to be), ie high revs on track, 7000rpm = modal input of 233Hz, which is getting near (or even exceeding) the resonant frequency of the bracket. The bracket fails, which leads to rapid modal fatigue of the hose (the modal frequency of this is likely much lower, so will fail a lot quicker, say the modal frequency of the hose alone corresponds to 4000rpm, residency time at 4000rpm is a lot higher than 7000rpm). I'd suspect that your hose was damaged from running with the damaged bracket.

So new hose + adding bracket check to your pre-trackday checks, is probably sufficient, and changing the hose with the bracket if you find another failure would be a wise idea. A better fix would be to fabricate a stiffening brace for the bracket to bring the resonant frequency of that little tab that holds the stud out of range of the engine. I think the knowledge for these issues isn't here (like it is for throttle bodies), since most of the people that build up a lot of track miles on this board run without the OEM PAS.

As an aside, when the hose failed on the 94, I spent hours at the track trying to fix it before just running it without the PAS belt for the rest of the day. The steering felt horrible, but I was still able to lap.

#1232

Elite Member

Thread Starter

Join Date: Mar 2007

Location: Santa Clara, CA

Posts: 5,165

Total Cats: 855

My theory is that it's a modal response issue (like I suspect the throttle shaft issue to be), ie high revs on track, 7000rpm = modal input of 233Hz, which is getting near (or even exceeding) the resonant frequency of the bracket. The bracket fails, which leads to rapid modal fatigue of the hose (the modal frequency of this is likely much lower, so will fail a lot quicker, say the modal frequency of the hose alone corresponds to 4000rpm, residency time at 4000rpm is a lot higher than 7000rpm). I'd suspect that your hose was damaged from running with the damaged bracket.

), but as far as I can tell the support bracket is still intact this time. Both bracket and hose failed in July 2017, I replaced them both at that point (at the same time), now the hose is broken but the bracket appears to still be intact, so this hose has never been run without an intact support bracket. I will go examine it more closely to see if I'm missing something on it, but when the old one failed it was obvious as soon as I poked at it.

), but as far as I can tell the support bracket is still intact this time. Both bracket and hose failed in July 2017, I replaced them both at that point (at the same time), now the hose is broken but the bracket appears to still be intact, so this hose has never been run without an intact support bracket. I will go examine it more closely to see if I'm missing something on it, but when the old one failed it was obvious as soon as I poked at it.thanks,

--Ian

#1233

This makes sense (at least to a software guy who didn't take any ME classes and isn't really sure what 'modal' means in this context  ), but as far as I can tell the support bracket is still intact this time. Both bracket and hose failed in July 2017, I replaced them both at that point (at the same time), now the hose is broken but the bracket appears to still be intact, so this hose has never been run without an intact support bracket. I will go examine it more closely to see if I'm missing something on it, but when the old one failed it was obvious as soon as I poked at it.

), but as far as I can tell the support bracket is still intact this time. Both bracket and hose failed in July 2017, I replaced them both at that point (at the same time), now the hose is broken but the bracket appears to still be intact, so this hose has never been run without an intact support bracket. I will go examine it more closely to see if I'm missing something on it, but when the old one failed it was obvious as soon as I poked at it.

thanks,

--Ian

), but as far as I can tell the support bracket is still intact this time. Both bracket and hose failed in July 2017, I replaced them both at that point (at the same time), now the hose is broken but the bracket appears to still be intact, so this hose has never been run without an intact support bracket. I will go examine it more closely to see if I'm missing something on it, but when the old one failed it was obvious as soon as I poked at it.

), but as far as I can tell the support bracket is still intact this time. Both bracket and hose failed in July 2017, I replaced them both at that point (at the same time), now the hose is broken but the bracket appears to still be intact, so this hose has never been run without an intact support bracket. I will go examine it more closely to see if I'm missing something on it, but when the old one failed it was obvious as soon as I poked at it.thanks,

--Ian

If the hoses was weakened by being run without a support bracket, then the fatigue crack might have propagated 95% as far as it needed to, then the little bit of vibration left with the bracket in place (ie replaced bracket) may have been enough. The support bracket won't eliminate the vibration of the hose, just reduce it. It's mad watching the simulations of various resonant frequencies of engine components with seemingly "solid" bits of structure vibrating like crazy!

#1234

Elite Member

Thread Starter

Join Date: Mar 2007

Location: Santa Clara, CA

Posts: 5,165

Total Cats: 855

Sorry, I should have said. By modal frequency, I mean resonant frequency, natural frequency etc, ie Tacoma Narrows.

If the hoses was weakened by being run without a support bracket, then the fatigue crack might have propagated 95% as far as it needed to, then the little bit of vibration left with the bracket in place (ie replaced bracket) may have been enough. The support bracket won't eliminate the vibration of the hose, just reduce it. It's mad watching the simulations of various resonant frequencies of engine components with seemingly "solid" bits of structure vibrating like crazy!

If the hoses was weakened by being run without a support bracket, then the fatigue crack might have propagated 95% as far as it needed to, then the little bit of vibration left with the bracket in place (ie replaced bracket) may have been enough. The support bracket won't eliminate the vibration of the hose, just reduce it. It's mad watching the simulations of various resonant frequencies of engine components with seemingly "solid" bits of structure vibrating like crazy!

--Ian

#1238

Elite Member

Thread Starter

Join Date: Mar 2007

Location: Santa Clara, CA

Posts: 5,165

Total Cats: 855

https://www.miataturbo.net/build-thr...8/#post1428294

--Ian

#1240

Elite Member

Thread Starter

Join Date: Mar 2007

Location: Santa Clara, CA

Posts: 5,165

Total Cats: 855

Took a closer look at the Miata, the failure is exactly the same as last time. Haven't figured out what to do yet. The outlet on the pump isn't a normal banjo fitting -- it has two O-rings that seal radially, rather than crush washers that seal axially, and it's a "banjo stud" rather than a bolt, which means if I try to use crush washers instead then there's a sneak path for fluid through the threads. I dunno if I can find an adapter to convert that to AN.

Perhaps a hydraulic shop can build me a hose that'll work on there (if it's a standard hydraulic fitting, rather than a custom Mazda thing), but will that be any stronger than the OEM hoses? I dunno.

One suggestion was to put in an NA power steering pump instead, apparently they use a more common flare fitting for the pressure outlet.

On to a different topic. Last year I replaced my LB7 2002 Duramax with an LBZ 2007 Duramax. Same chassis (crew cab shortbed), but newer motor, more power, 6-speed Allison instead of 5. The LB7 was a bit lacking in power for pulling the TPD enclosed trailer around, and the LBZ addresses that.

A few teething issues, though. These trucks are known to have lousy steering feel after 50K miles or so -- I replaced the steering box, idler arm, pitman arm, and intermediate shaft shortly after I bought it and that helped some. It's still got some on-center knocking, which is probably the lower bearing for the column. More annoying, though, is that it's got a tendency not to hold a consistent arc when driving through a sweeping turn on the freeway. This gets pretty tiring with the trailer, having to correct left & right, and it wasn't something my old truck did. I took it back to the dealer that did the steering component replacement before, they swapped in a new steering box. That one was DOA (drove out of the dealer, got onto the freeway and it bound up in a curve, tried to kill me. Took it right back), so they put in a THIRD steering box and it's reasonably tight but still does the wandering thing on the freeway.

So OK, one other difference between the old truck and the new is that the old truck had a set of helper air springs in the back. (original owner on the old truck had used it to pull a gooseneck horse trailer). Maybe the TPD has too much tongue weight and it's unloading the front? To test that theory, I decided to add a set of air sprangs to the LBZ.

Didn't take any pics of them before installing though:

I did not opt for the compressor system (would have doubled the price, $360 for this, another $400 for compressor), so they're filled with schrader valves on the rear bumper.

It really seems like the axle bracket should be bottoming out on the spring bracket, though, rather than having an inch of unsupported bolt on both sides. I need to call them about this, maybe my kit included the wrong brackets.

--Ian

Perhaps a hydraulic shop can build me a hose that'll work on there (if it's a standard hydraulic fitting, rather than a custom Mazda thing), but will that be any stronger than the OEM hoses? I dunno.

One suggestion was to put in an NA power steering pump instead, apparently they use a more common flare fitting for the pressure outlet.

On to a different topic. Last year I replaced my LB7 2002 Duramax with an LBZ 2007 Duramax. Same chassis (crew cab shortbed), but newer motor, more power, 6-speed Allison instead of 5. The LB7 was a bit lacking in power for pulling the TPD enclosed trailer around, and the LBZ addresses that.

A few teething issues, though. These trucks are known to have lousy steering feel after 50K miles or so -- I replaced the steering box, idler arm, pitman arm, and intermediate shaft shortly after I bought it and that helped some. It's still got some on-center knocking, which is probably the lower bearing for the column. More annoying, though, is that it's got a tendency not to hold a consistent arc when driving through a sweeping turn on the freeway. This gets pretty tiring with the trailer, having to correct left & right, and it wasn't something my old truck did. I took it back to the dealer that did the steering component replacement before, they swapped in a new steering box. That one was DOA (drove out of the dealer, got onto the freeway and it bound up in a curve, tried to kill me. Took it right back), so they put in a THIRD steering box and it's reasonably tight but still does the wandering thing on the freeway.

So OK, one other difference between the old truck and the new is that the old truck had a set of helper air springs in the back. (original owner on the old truck had used it to pull a gooseneck horse trailer). Maybe the TPD has too much tongue weight and it's unloading the front? To test that theory, I decided to add a set of air sprangs to the LBZ.

Didn't take any pics of them before installing though:

I did not opt for the compressor system (would have doubled the price, $360 for this, another $400 for compressor), so they're filled with schrader valves on the rear bumper.

It really seems like the axle bracket should be bottoming out on the spring bracket, though, rather than having an inch of unsupported bolt on both sides. I need to call them about this, maybe my kit included the wrong brackets.

--Ian