Nothing to see here, just project Sisyphus, move along

#471

Elite Member

Thread Starter

iTrader: (37)

Join Date: Apr 2010

Location: Very NorCal

Posts: 10,441

Total Cats: 1,899

I think I'm going to start test fitting things this weekend if I doesn't rain on me. I'm way to excited to stare at this stuff any longer and not do things to it.

I've hit a slight snag though. TSE's official stance is that the current 10mm studs do not work with the 6x58 EFR turbos. As Soviet has shown us, they can be MADE to fit, but it involves many hours with a dremel assaulting the cast stainless steel turbine housing with a tungsten carbide dremel bit.

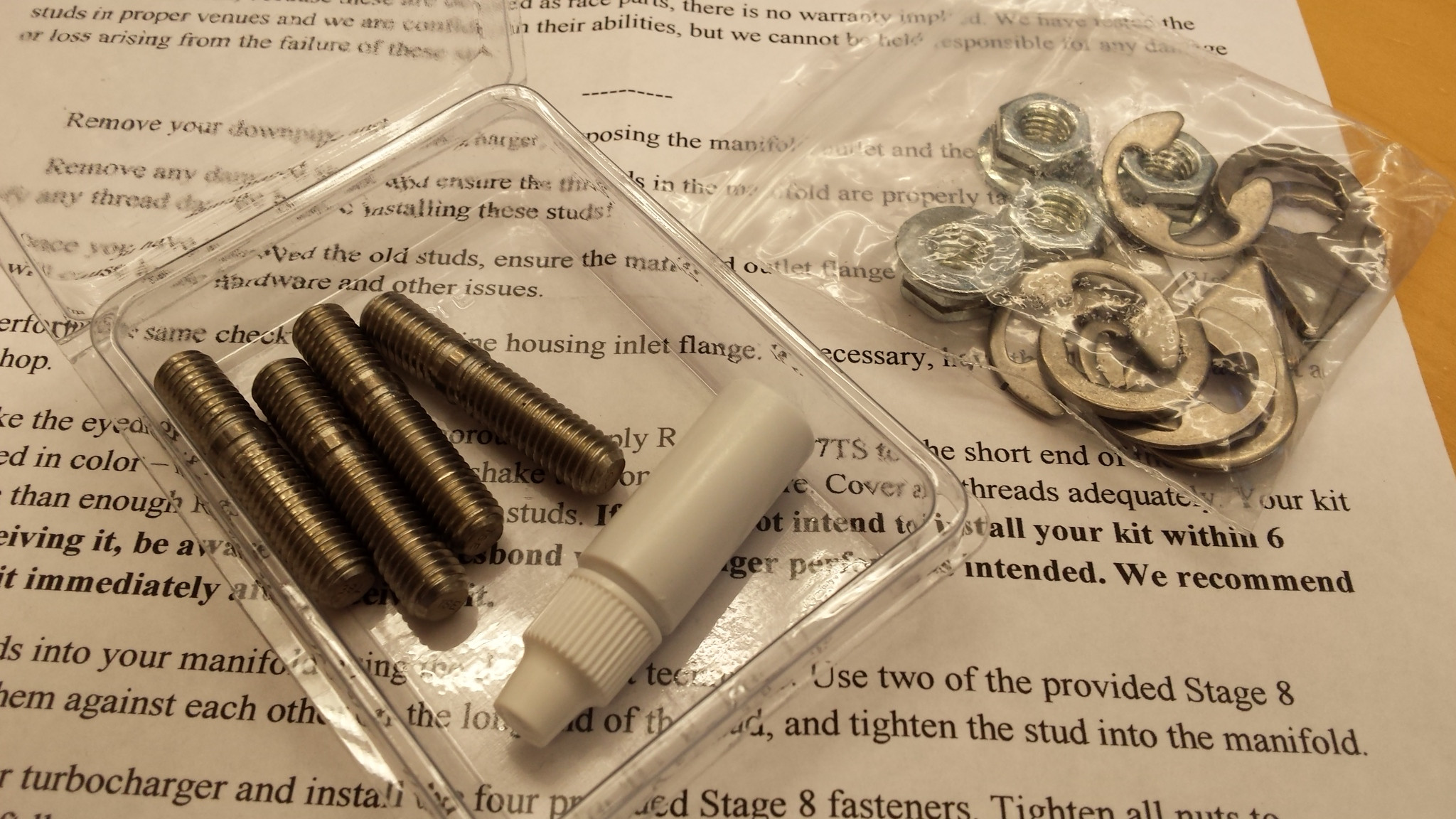

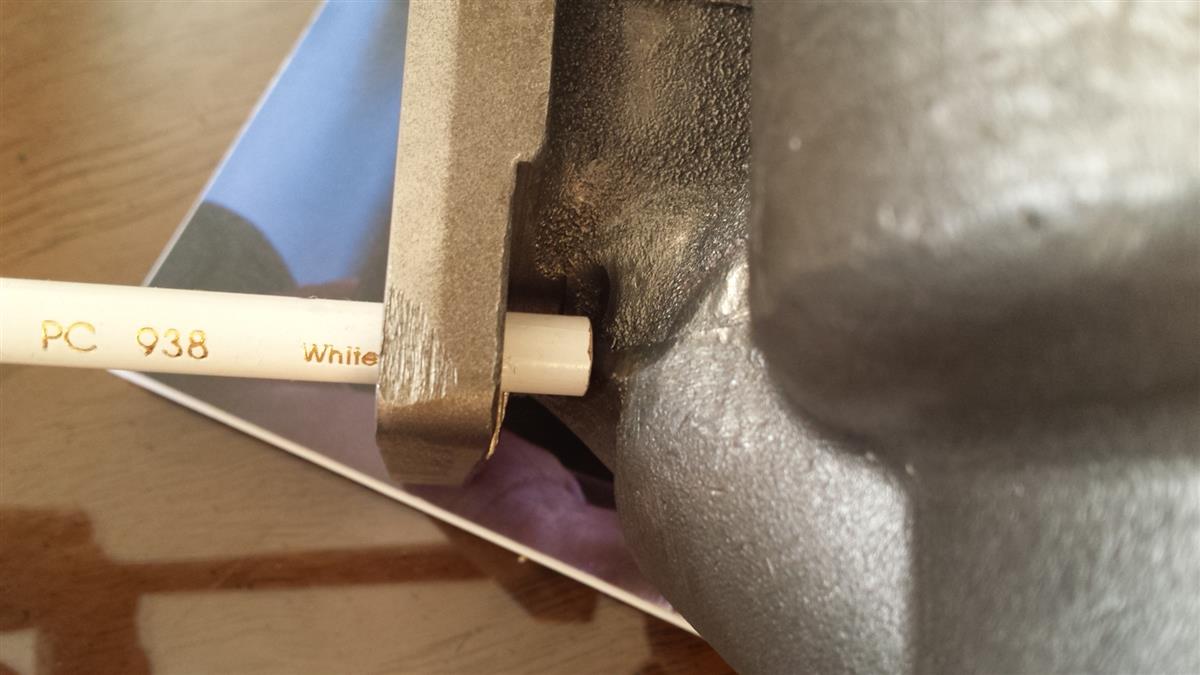

To avoid this, I've purchased 8mm inconel studs. Unfortunately, the Stage8 nuts are just too tall to fit all the way back into the spare available. Also, the studs I've got are too long for that one hole. Long enough that they interfere with the housing in that same location. Its just the one stud:

So it looks like I'm going to have to shorten an inconel stud and grind some clearance in the turbine housing. le sigh.

I'm also super disappointed there was no ARTech sticker in the box with my manifold and downpipe :(

I've hit a slight snag though. TSE's official stance is that the current 10mm studs do not work with the 6x58 EFR turbos. As Soviet has shown us, they can be MADE to fit, but it involves many hours with a dremel assaulting the cast stainless steel turbine housing with a tungsten carbide dremel bit.

To avoid this, I've purchased 8mm inconel studs. Unfortunately, the Stage8 nuts are just too tall to fit all the way back into the spare available. Also, the studs I've got are too long for that one hole. Long enough that they interfere with the housing in that same location. Its just the one stud:

So it looks like I'm going to have to shorten an inconel stud and grind some clearance in the turbine housing. le sigh.

I'm also super disappointed there was no ARTech sticker in the box with my manifold and downpipe :(

#472

I had to cut the studs on my TSE kit as well. Too long. As strong as they are it only took me about a minute a stud to zip through them with my dremmel. Drilling the new holes in the manifold isn't too bad either, but for drilling the manifold and tapping the holes for the studs I took it to a machine shop. I didn't trust myself to get that perfect.

#474

Elite Member

Thread Starter

iTrader: (37)

Join Date: Apr 2010

Location: Very NorCal

Posts: 10,441

Total Cats: 1,899

Yup, its no big deal. I knew going into this it was going to take a little tweaking to get things in place. I destroyed the one tungsten cutter I had clearancing the stainless turbine housing (it was on its way out anyway) so I ordered the ones Soviet linked in his build thread. Amazon says they'll be here in a couple days and I'll post up some before and after pics when I get it sorted out.

Soviet had said he modified the nut to clear the housing, but I'd rather modify the housing to clear the nut. I don't want to compromise the groove for the locking ring and loose the advantage of using the Stage 8 hardware in the first place.

I'm also considering not having the turbine housing coated. The more I touch this thing the more I realize its a giant chunk of cast stainless steel and I doubt coating will have much of an effect on its thermal retention. The manifold on the other hand... that bad boy is getting coated.

I got distracted grinding on things so no testfit pr0n pics this weekend

Soviet had said he modified the nut to clear the housing, but I'd rather modify the housing to clear the nut. I don't want to compromise the groove for the locking ring and loose the advantage of using the Stage 8 hardware in the first place.

I'm also considering not having the turbine housing coated. The more I touch this thing the more I realize its a giant chunk of cast stainless steel and I doubt coating will have much of an effect on its thermal retention. The manifold on the other hand... that bad boy is getting coated.

I got distracted grinding on things so no testfit pr0n pics this weekend

#475

Elite Member

Thread Starter

iTrader: (37)

Join Date: Apr 2010

Location: Very NorCal

Posts: 10,441

Total Cats: 1,899

When the EFR was announced, there was much fanfare about how awesome smooth the investment cast turbine housings were, and you can see great examples of this on MotoIQ and in Soviets build thread.

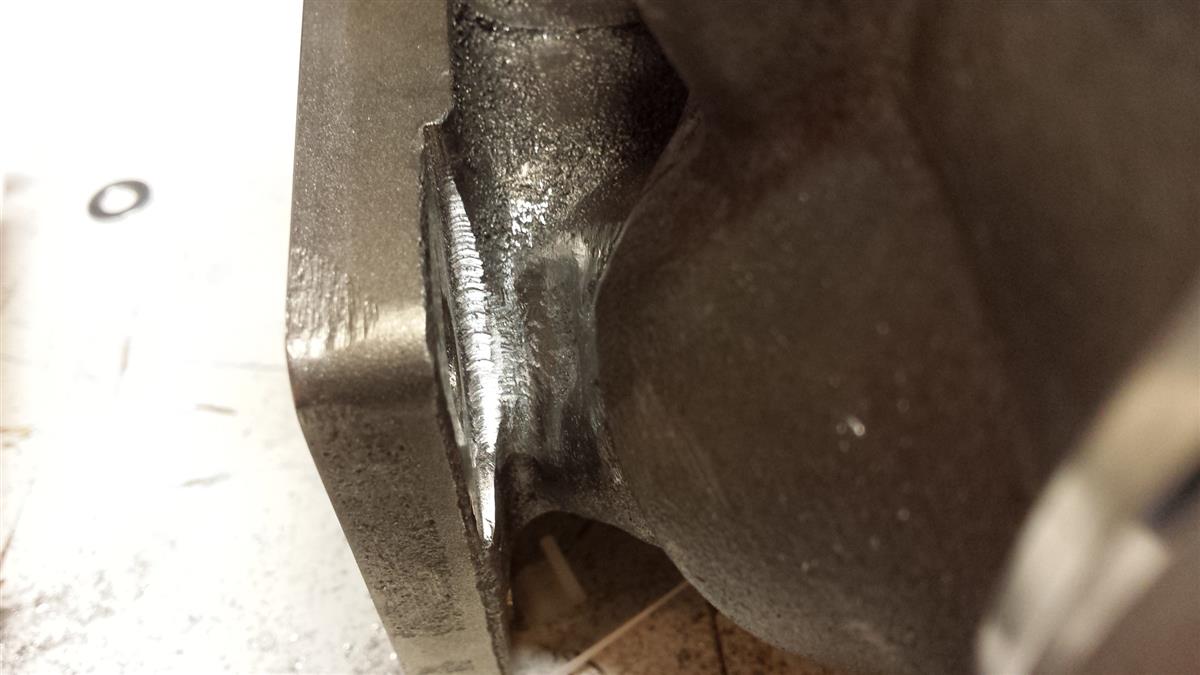

Let me show you the inside of my "gen2" sand cast turbine housing:

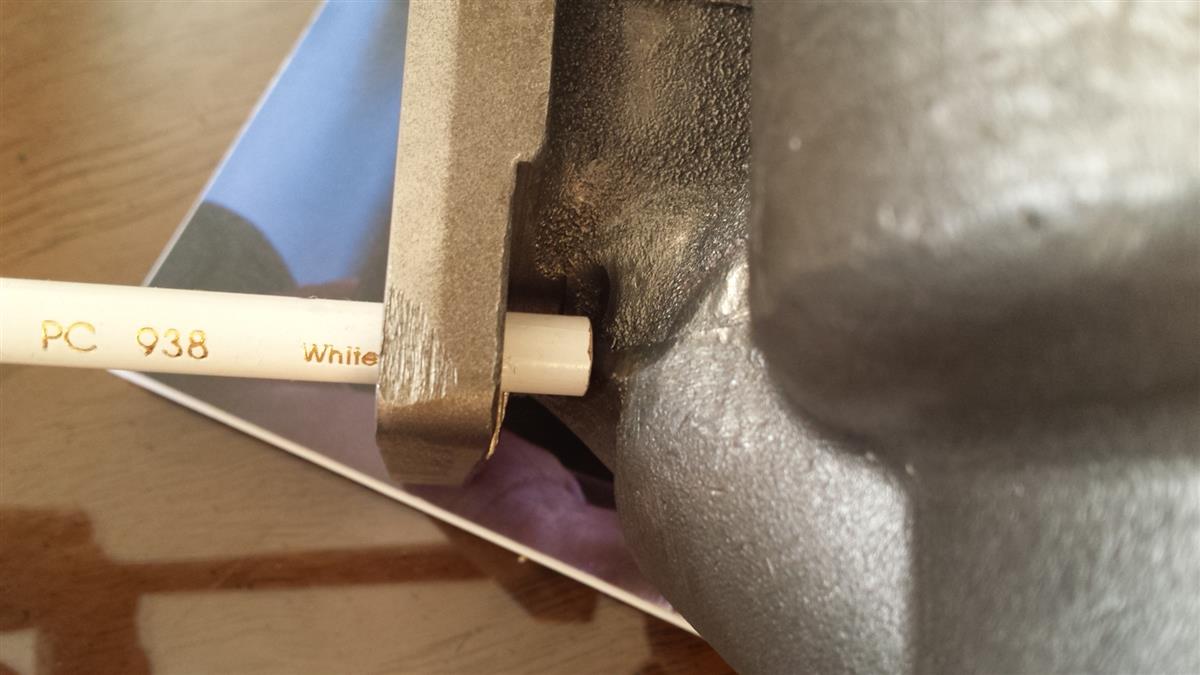

So that sets the stage for what I'm fighting today:

As you can see, there is a seam in the mold that left a giant stainless steel booger/ridge that prevents me from getting a nut far enough back into the pocket to line up with the hole in the flange. The flange is 10mm thick and I have exactly 6mm of space as it sits currently. I find this funny because the BW documentation states that the studs cannot me "more than 18mm last the face of the flange" so I'm already 2mm under minimum spec. The Stage8 nut is 7.7mm tall, so I've got some work to do. There is actually a pocket in the casting in this area, but I think its a casting flaw rather than clearance for the nut/stud because its way out of place.

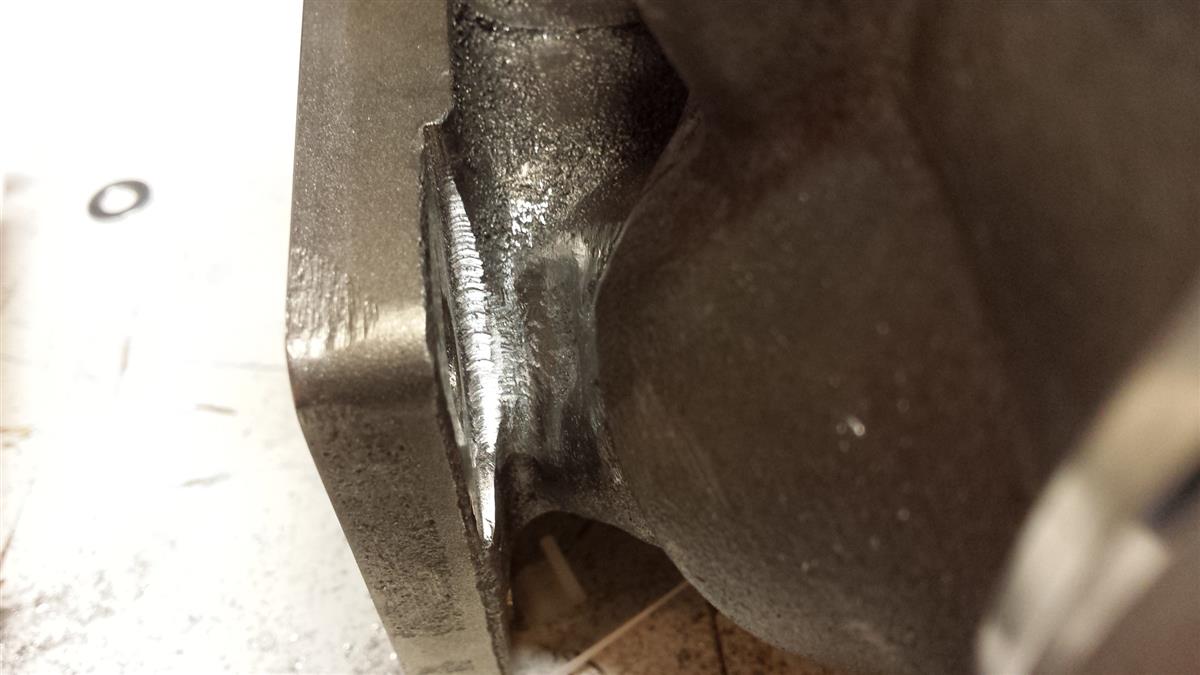

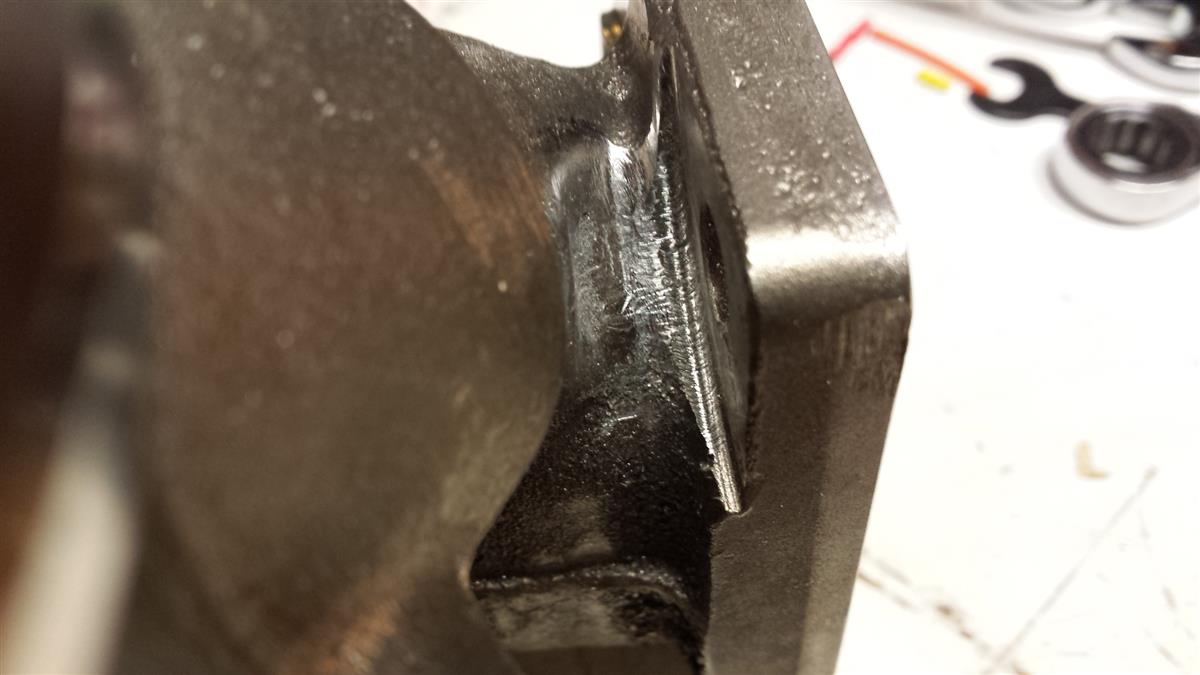

After an hour with a dremel and a couple tungsten carbide cutters...

I hogged out a buttload of material and cleaned up the casting in that area

Here you can see the pocket I was referring to previously.

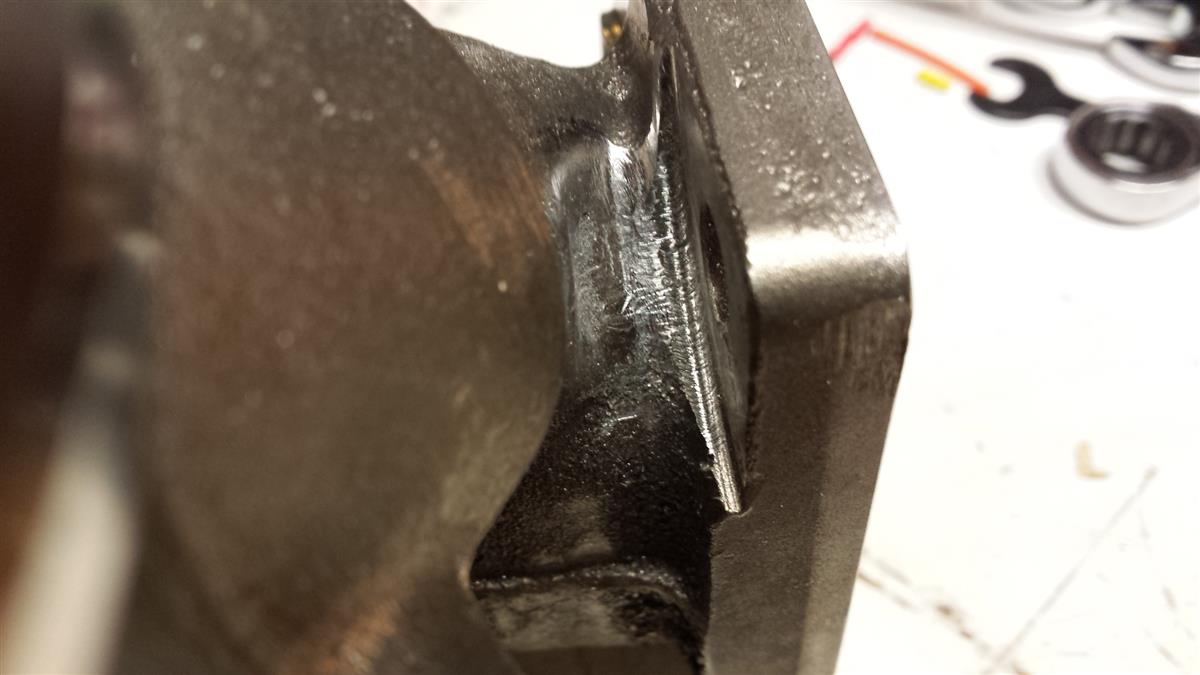

And here is the clearance with the nut. I can get a full 20mm worth of stud from the face of the manifold to the point where it contacts the turbine housing. I call that winning

I also took some time and took down the "surface of the moon" imperfections along the entry to the turbine housing. I could only get about 1" into the throat because the dremel just does not have that much throw. At least now I don't have to worry about razor sharp nubbins slicing into the pads of my fingers should I stick them in the hole.

Its 96°F in my back yard right now, so I have no desire to pull the rest of the exhaust stuff out of the car to finish test fitting things. I'll either hit it later tonight after things cool off a bit or early tomorrow morning.

bare minimum list of things to do before boost:

So maybe I'll have some boost by next spring

Let me show you the inside of my "gen2" sand cast turbine housing:

So that sets the stage for what I'm fighting today:

As you can see, there is a seam in the mold that left a giant stainless steel booger/ridge that prevents me from getting a nut far enough back into the pocket to line up with the hole in the flange. The flange is 10mm thick and I have exactly 6mm of space as it sits currently. I find this funny because the BW documentation states that the studs cannot me "more than 18mm last the face of the flange" so I'm already 2mm under minimum spec. The Stage8 nut is 7.7mm tall, so I've got some work to do. There is actually a pocket in the casting in this area, but I think its a casting flaw rather than clearance for the nut/stud because its way out of place.

After an hour with a dremel and a couple tungsten carbide cutters...

I hogged out a buttload of material and cleaned up the casting in that area

Here you can see the pocket I was referring to previously.

And here is the clearance with the nut. I can get a full 20mm worth of stud from the face of the manifold to the point where it contacts the turbine housing. I call that winning

I also took some time and took down the "surface of the moon" imperfections along the entry to the turbine housing. I could only get about 1" into the throat because the dremel just does not have that much throw. At least now I don't have to worry about razor sharp nubbins slicing into the pads of my fingers should I stick them in the hole.

Its 96°F in my back yard right now, so I have no desire to pull the rest of the exhaust stuff out of the car to finish test fitting things. I'll either hit it later tonight after things cool off a bit or early tomorrow morning.

bare minimum list of things to do before boost:

- Figure out oil feed to turbo

- Fabricate the rest of the exhaust

- Clean & figure out how to mount behemoth Precision 600 intercooler

- Fabricate intercooler plumbing

So maybe I'll have some boost by next spring

#476

Oil feed to turbo I'd suggest ATPturbo. I have their custom -10an return line and it is perfect. You put in the length you want, the type of fitting on the line, and it is around $30-50.

Intercooler mounting I'd recommend how mine is done. Weld flanges to the intercooler to bolt to the factory front tow hook area, easy peasy.

If you don't mind paying more, which I know you don't with all the expensive parts just sitting on your shelf , flyin miata silicone hoses are hard to beat for convenience/weight/clean looking pipes.

, flyin miata silicone hoses are hard to beat for convenience/weight/clean looking pipes.

Sucks about the casting flaws, after reading several responses from BW I guess it is negligible how it affects performance. Plus it will be under a heatshield anyways(or should be).

Intercooler mounting I'd recommend how mine is done. Weld flanges to the intercooler to bolt to the factory front tow hook area, easy peasy.

If you don't mind paying more, which I know you don't with all the expensive parts just sitting on your shelf

, flyin miata silicone hoses are hard to beat for convenience/weight/clean looking pipes.

, flyin miata silicone hoses are hard to beat for convenience/weight/clean looking pipes.Sucks about the casting flaws, after reading several responses from BW I guess it is negligible how it affects performance. Plus it will be under a heatshield anyways(or should be).

#477

Elite Member

Thread Starter

iTrader: (37)

Join Date: Apr 2010

Location: Very NorCal

Posts: 10,441

Total Cats: 1,899

Yepper, either ATP or BatInc for the oil feed. I'm having all this mental damage about the feed. The oil line for the FM2 turbo kit that follows the traditional "behind the block" routing is -4 SS and 52" long. That's astonishingly long as far as I'm concerned. I'm a little worried about that kind of length seeing as BorgWarner specifically states in the manual that if the feed is longer than 18" it is "recommended" that you step up to a -6 line. That's a HUGE feed line, but I feel like they are recommending -6 to minimize pumping losses on a longer run. I can easily open up one of the ports on my samich plate to something closer to -6 and use that, but I'm pretty sure those ports are "pre filter" and I'd rather not feed unfiltered oil to the turbo. Arghhh....

The return I already have taken care of, I plan on using the gates blue LOL hose. If it melts or leaks or otherwise does something stupid I'll build something AN, but I'm not going to worry about it right now.

As for the intercooler stuff, I'd LOVE to use the FM silicone, but the inlet and outlet on the absolutely massive Precision 600 are 2.75" OD. I had the FM silicone and it just wouldn't fit without butchery, and I really didn't feel like cutting up such expensive hoses. They are beautiful and absolute worth the cash, but I think I'm going to be better off custom fabricating something in this particular case. As I've said, I plan to abuse Gesso's skills with the tig when the time comes

The return I already have taken care of, I plan on using the gates blue LOL hose. If it melts or leaks or otherwise does something stupid I'll build something AN, but I'm not going to worry about it right now.

As for the intercooler stuff, I'd LOVE to use the FM silicone, but the inlet and outlet on the absolutely massive Precision 600 are 2.75" OD. I had the FM silicone and it just wouldn't fit without butchery, and I really didn't feel like cutting up such expensive hoses. They are beautiful and absolute worth the cash, but I think I'm going to be better off custom fabricating something in this particular case. As I've said, I plan to abuse Gesso's skills with the tig when the time comes

#478

I'm trying to think of where you could pull oil from that is less than 18" and I'm drawing a blank. I've always had a lower than "spec" hot idle oil pressure, and now I'm suspecting that long *** oil feed line.

I'm gonna have to look into this.

Also this would solve your 2.75" diameter problems....

Transition Hose 2.50" to 2.75"

I'm gonna have to look into this.

Also this would solve your 2.75" diameter problems....

Transition Hose 2.50" to 2.75"

#479

Elite Member

Thread Starter

iTrader: (37)

Join Date: Apr 2010

Location: Very NorCal

Posts: 10,441

Total Cats: 1,899

Tap the block in the 94 1.8 location or (horror of horrors) use the port on the head. I like the former more than the latter, but both have some merit. I dunno, maybe -6 off the sammich but I'd make things complicated and try to add an additional filter...

Or just say "fuckit!" and run -4 like everyone else and not worry about it

Or just say "fuckit!" and run -4 like everyone else and not worry about it

#480

not sure if serious about tapping the block.

if serious.......put down whatever you're drinking or don't go near the engine

my thoughts on oil feed: either run it from the other side like every human being on earth, and ignore the stupid comment by BW about length since it was probably penned by lawyers. or take a small risk and draw from the head. either way, those two are way less silly than tapping the block on an NB1 with no internal passages in that location.

if serious.......put down whatever you're drinking or don't go near the engine

my thoughts on oil feed: either run it from the other side like every human being on earth, and ignore the stupid comment by BW about length since it was probably penned by lawyers. or take a small risk and draw from the head. either way, those two are way less silly than tapping the block on an NB1 with no internal passages in that location.