Pat's Ebay Turbo Compound Boost Build

#63

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,292

Total Cats: 475

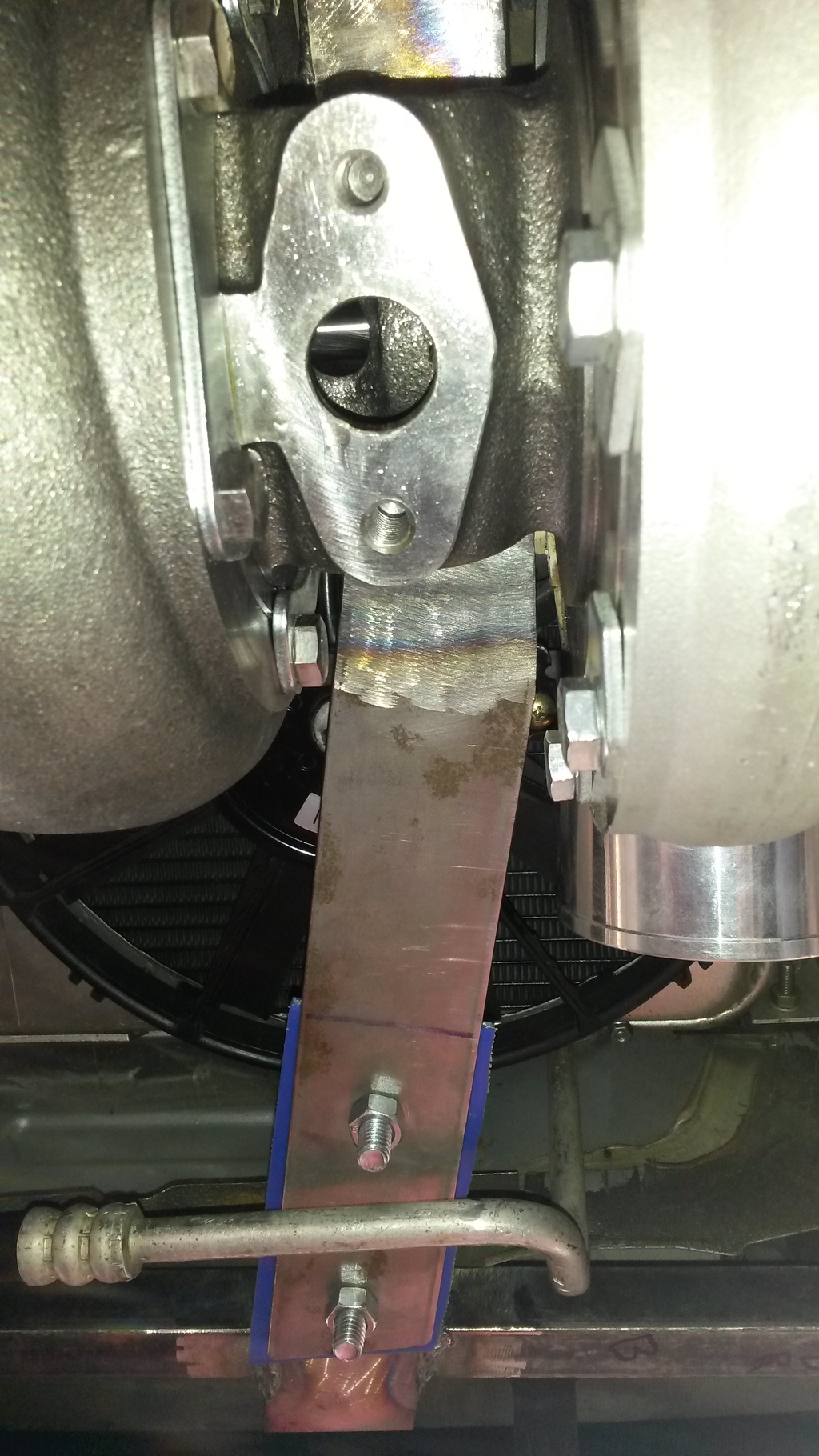

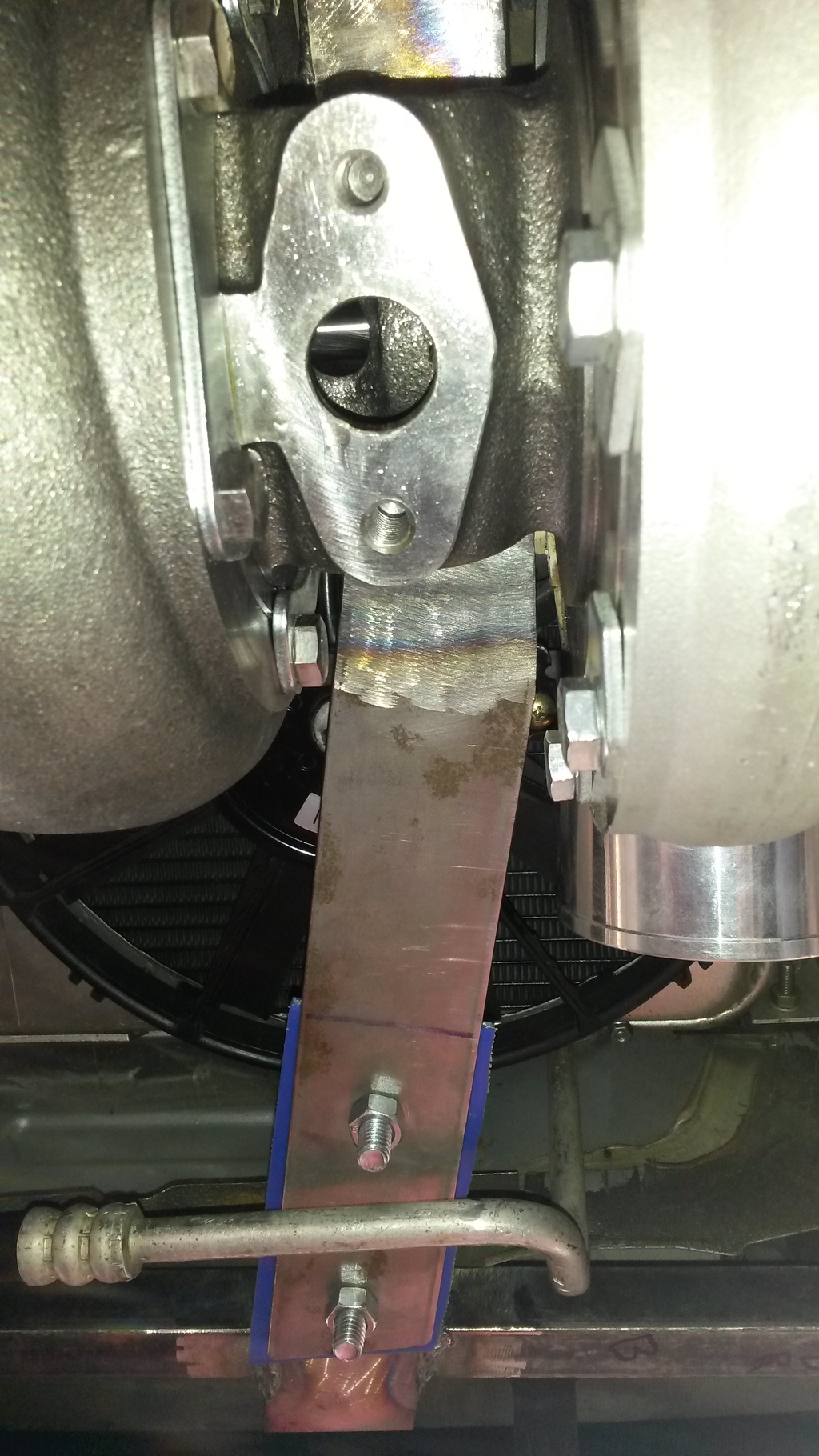

Drilled/tapped top of CHRA for 1/4" NPT so I could use a fitting without using the two bolts on the CHRA. Then used those bolts for a mounting system, since it's basically holding it in the CG of the turbo more or less.

Mounting system has silicone vibration isolators/flex pieces so that the turbo can bend/move a bit. To allow the exhaust system to flex a bit without cracking the exhaust.

Basically you bolt the turbo to the mount (2 bolts to CHRA, then install it into the car. The front lands on a tab to hold the weight, then raise the rear in and bolt it together.

Mounting system has silicone vibration isolators/flex pieces so that the turbo can bend/move a bit. To allow the exhaust system to flex a bit without cracking the exhaust.

Basically you bolt the turbo to the mount (2 bolts to CHRA, then install it into the car. The front lands on a tab to hold the weight, then raise the rear in and bolt it together.

#66

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,292

Total Cats: 475

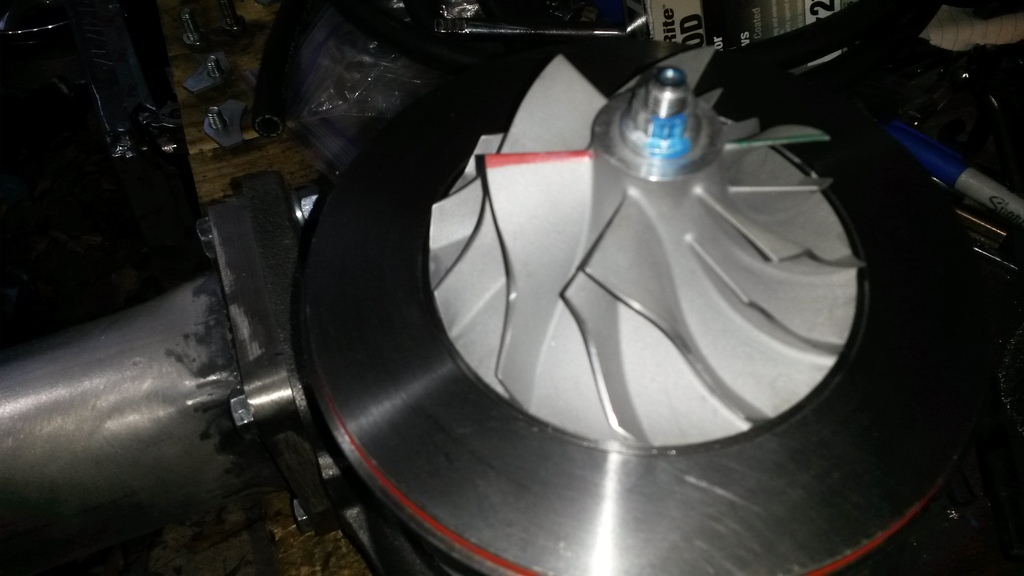

Thanks. I'm behind schedule actually, goal is to be driving it on 2/12/2016.... But crap happens. I'm hoping now that the turbo is home, the rest won't take so long. Working on boost pipe to front now. Turbo outlet is a weird size (3.375") and I just sanded/filed it down to 3" so I can connect to it.

#68

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,292

Total Cats: 475

So the rear turbo is hanging on the oil feed studs? Is that strong enough?

What do you plan to do for control? Two PID loops for the two WGs? For ideal spool you're going to need to close the little WG as you crack open the big one -- synchronizing that sounds tricky.

--Ian

What do you plan to do for control? Two PID loops for the two WGs? For ideal spool you're going to need to close the little WG as you crack open the big one -- synchronizing that sounds tricky.

--Ian

Working on how to route boost pipe right now, trying to find the best path that won't drag the ground when I launch.

#70

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,292

Total Cats: 475

So the rear turbo is hanging on the oil feed studs? Is that strong enough?

What do you plan to do for control? Two PID loops for the two WGs? For ideal spool you're going to need to close the little WG as you crack open the big one -- synchronizing that sounds tricky.

--Ian

What do you plan to do for control? Two PID loops for the two WGs? For ideal spool you're going to need to close the little WG as you crack open the big one -- synchronizing that sounds tricky.

--Ian

#72

Why use a silicone 180 like that instead of clocking the compressor 180 degrees so it points forwards?

I guess the 12 psi thing will probably work, so long as it's a 2-port wastegate so you can reference it off the compress inlet charge instead of atmospheric. I think you'll get 24 though, not 34, because a mechanical wastegate is additive, not multiplicative. I think you'll also need a much stronger WG spring to hold against the higher exhaust manifold pressure.

--Ian

I guess the 12 psi thing will probably work, so long as it's a 2-port wastegate so you can reference it off the compress inlet charge instead of atmospheric. I think you'll get 24 though, not 34, because a mechanical wastegate is additive, not multiplicative. I think you'll also need a much stronger WG spring to hold against the higher exhaust manifold pressure.

--Ian

#74

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,292

Total Cats: 475

Also to add to this, a lot of rear mount turbo setups I see don't support the turbo at all, and use the exhaust pipe to support it instead. Given this is a big turbo, I didn't like the idea of that at all. My exhaust system will have hangers too, this will just be extra support. Also makes removing the exhaust a lot easier to service stuff, since the turbo doesn't have to be removed.

#76

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,292

Total Cats: 475

If I could weld aluminum, I'd cut that thing off, weld a 2.25" pipe to it, clock it, and bamm.

EDIT: Those U-bends also transition from 3.25" to 2.25" BTW.

#77

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,292

Total Cats: 475

Also I have AWR motor mounts and poly diff mounts.

#78

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,292

Total Cats: 475

...

I guess the 12 psi thing will probably work, so long as it's a 2-port wastegate so you can reference it off the compress inlet charge instead of atmospheric. I think you'll get 24 though, not 34, because a mechanical wastegate is additive, not multiplicative. I think you'll also need a much stronger WG spring to hold against the higher exhaust manifold pressure.

--Ian

I guess the 12 psi thing will probably work, so long as it's a 2-port wastegate so you can reference it off the compress inlet charge instead of atmospheric. I think you'll get 24 though, not 34, because a mechanical wastegate is additive, not multiplicative. I think you'll also need a much stronger WG spring to hold against the higher exhaust manifold pressure.

--Ian

#80

The big turbo has a 12 psi (80 kpa) WG can, so it's taking in 100 kpa atmospheric air and putting out 180 kpa into the intake of the small turbo.

The small turbo also has a 12 psi (80 kpa) WG can, with the "atmospheric" side of it connected to the outlet of the first turbo. Since it's a diaphragm and a spring, it's going to regulate the WG to produce a fixed delta pressure above the inlet pressure. So it takes 180 kpa inlet air, adds 80 kpa to it and gets 260 kpa, or about 24 psi of boost.

At least, I *think* that's the way a mechanical WG can works?

--Ian

The small turbo also has a 12 psi (80 kpa) WG can, with the "atmospheric" side of it connected to the outlet of the first turbo. Since it's a diaphragm and a spring, it's going to regulate the WG to produce a fixed delta pressure above the inlet pressure. So it takes 180 kpa inlet air, adds 80 kpa to it and gets 260 kpa, or about 24 psi of boost.

At least, I *think* that's the way a mechanical WG can works?

--Ian