sean's cheap thrills, 90 1.6 with subaru td04

#461

SADFab Destructive Testing Engineer

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

<p>I thought the wrapping held the heat in and caused corrosion. Like even on stainless.</p><p>I just have my license plate shield, some wrap around the heater hoses, brake master. And everything is working fine.</p>

#462

I never want to have to split my turbo from the manifold, it's locked hard on chinese studs and nuts somehow.

I would look into a way to remove the downpipe without moving the turbo, but I'm lazy and hate dealing with coolant and oil. My downpipe is two v-band nuts and the two band clamp bolts, unplugging the stupid wideband is the hardest part, of course mine is a lot simpler setup, though.

Are you sure you can't just piviot it down and out the bottom?

My searching says no wrap, but heatshield the trans from the exhaust if you can, and gas tank which I'm still using the stock one back there.

I would look into a way to remove the downpipe without moving the turbo, but I'm lazy and hate dealing with coolant and oil. My downpipe is two v-band nuts and the two band clamp bolts, unplugging the stupid wideband is the hardest part, of course mine is a lot simpler setup, though.

Are you sure you can't just piviot it down and out the bottom?

My searching says no wrap, but heatshield the trans from the exhaust if you can, and gas tank which I'm still using the stock one back there.

#464

SadFab CEO

Thread Starter

iTrader: (3)

Join Date: Sep 2012

Location: your mom's house phoenix, AZ

Posts: 4,560

Total Cats: 1,142

Current plan:

I bought 18" of 5/8" round 750x inconel(great choice of alloy IMO) from the ebays for $20.

Friend machines aerospace alloys for a living. I replaced fork seals on dirtbike, he turns rod into studs.

hardware store nuts

total cost ~$25. If it works, thatll be awesome. If not, another $50-80 for resbond and stg 8 nuts

#467

SadFab CEO

Thread Starter

iTrader: (3)

Join Date: Sep 2012

Location: your mom's house phoenix, AZ

Posts: 4,560

Total Cats: 1,142

Ok no wrap then, I go back on forth on that so much.

I might be able to install the DP from the bottom, it just looked tight. Im going to weld it all up and go try though, we'll see what happens. Like I said, worst case scenario, if I bake my studs and it becomes a PITA to get the nuts , then ill just cut it where I would have anyway and weld one in.

O2 is going right before or right after the v band, mounted vertically. Its an AEM with a decent pigtail, unplugging should be a non issue.

I might be able to install the DP from the bottom, it just looked tight. Im going to weld it all up and go try though, we'll see what happens. Like I said, worst case scenario, if I bake my studs and it becomes a PITA to get the nuts , then ill just cut it where I would have anyway and weld one in.

O2 is going right before or right after the v band, mounted vertically. Its an AEM with a decent pigtail, unplugging should be a non issue.

#472

maybe corky should be against powdercoated mild steel intercooler pipes that rot to crap on 99% of his turbo kits.

.....oh wait

I've wrapped stuff here with excellent results, because CA.

If you take underwater snorkeling adventures with your car, you should probably ceramic and/or heat shield.

...personally tho I like heat shielding

.....oh wait

I've wrapped stuff here with excellent results, because CA.

If you take underwater snorkeling adventures with your car, you should probably ceramic and/or heat shield.

...personally tho I like heat shielding

#473

SadFab CEO

Thread Starter

iTrader: (3)

Join Date: Sep 2012

Location: your mom's house phoenix, AZ

Posts: 4,560

Total Cats: 1,142

Its also cheaper and easier to roll a thread into challenging material like inconel when you do any sort of volume, which is why i think companies like begi and TSE do it. In fact I recall reading corky discuss how cutting threads was a joke unless you are specifically set up for and experienced with inconel.

Dont get me wrong rolling threads definitely makes a better fastener, I just dont think it applys as a requirment in this scenario.

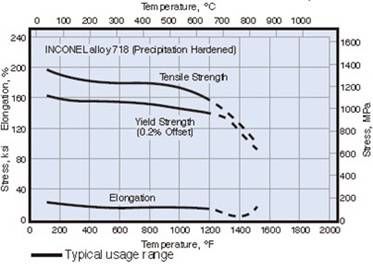

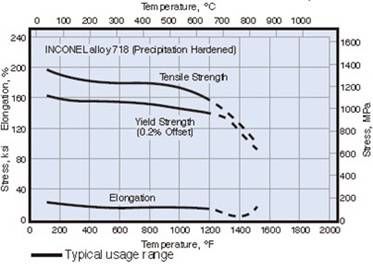

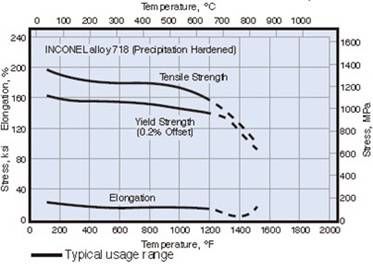

You see the knee at the right of the curve? Thats what we care about. Whether you roll the threads or not, that knee follows the same curve for a given material choice. SS, and mild steel and a few hundred degree to the left. Rolling the threads just brings the curve prior to the knee up a little.

Having said all that im no expert, just a google jockey, and im talking out my ***.

Last edited by hi_im_sean; 07-27-2015 at 07:03 PM.

#476

SadFab CEO

Thread Starter

iTrader: (3)

Join Date: Sep 2012

Location: your mom's house phoenix, AZ

Posts: 4,560

Total Cats: 1,142

maybe corky should be against powdercoated mild steel intercooler pipes that rot to crap on 99% of his turbo kits.

.....oh wait

I've wrapped stuff here with excellent results, because CA.

If you take underwater snorkeling adventures with your car, you should probably ceramic and/or heat shield.

...personally tho I like heat shielding

.....oh wait

I've wrapped stuff here with excellent results, because CA.

If you take underwater snorkeling adventures with your car, you should probably ceramic and/or heat shield.

...personally tho I like heat shielding

Common 18, talk me into it...

#477

The wiring on my sensor is stiff and doesn't turn very easily especially while still installed.

My charge pipes seem to be doing fine, I took lots of extra time to make sure I solidly coated the inside though, I have no idea what corky's doing.

Ceramic coating would cost more than double what I spent on most of my ****, I could just wrap it and remake it if it melts. I don't care what it looks like, so it really don't make sense to spend for it. Wish it were something I could do myself...

My charge pipes seem to be doing fine, I took lots of extra time to make sure I solidly coated the inside though, I have no idea what corky's doing.

Ceramic coating would cost more than double what I spent on most of my ****, I could just wrap it and remake it if it melts. I don't care what it looks like, so it really don't make sense to spend for it. Wish it were something I could do myself...

#478

As far as I understand, the stretch issue isnt with ultimate or notch strength(rolled threads), but thermal creep(material choice). They are 2 completely different failure modes and I have never seen anyone discuss the latter here. The studs stretch due to creep, not because they are being fatigued by tensile forces. If it wasnt for the heat, we know even grade 5, crap 8mm bolts will hold the turbo to the mani just fine.

Its also cheaper and easier to roll a thread into challenging material like inconel when you do any sort of volume, which is why i think companies like begi and TSE do it. In fact I recall reading corky discuss how cutting threads was a joke unless you are specifically set up for and experienced with inconel.

Dont get me wrong rolling threads definitely makes a better fastener, I just dont think it applys as a requirment in this scenario.

You see the knee at the right of the curve? Thats what we care about. Whether you roll the threads or not, that knee follows the same curve for a given material choice. SS, and mild steel and a few hundred degree to the left.

Having said all that im no expert, just a google jockey, and im talking out my ***.

Its also cheaper and easier to roll a thread into challenging material like inconel when you do any sort of volume, which is why i think companies like begi and TSE do it. In fact I recall reading corky discuss how cutting threads was a joke unless you are specifically set up for and experienced with inconel.

Dont get me wrong rolling threads definitely makes a better fastener, I just dont think it applys as a requirment in this scenario.

You see the knee at the right of the curve? Thats what we care about. Whether you roll the threads or not, that knee follows the same curve for a given material choice. SS, and mild steel and a few hundred degree to the left.

Having said all that im no expert, just a google jockey, and im talking out my ***.

I'm no injuneer either though, and I like how you word things. I'll probably try and make some as well when I eventually lift my cheap crap.

#479

SadFab CEO

Thread Starter

iTrader: (3)

Join Date: Sep 2012

Location: your mom's house phoenix, AZ

Posts: 4,560

Total Cats: 1,142

I used to turn inconel and monel for the oil industry all the time, so I'm familiar with what a ---- it is. You are right that it would be best, fastest, most reliable and consistent to roll them. Making a set or two, then billing them at 2000% material cost for a small run to a customer with the pockets is what I'm familiar with.

I'm no injuneer either though, and I like how you word things. I'll probably try and make some as well when I eventually lift my cheap crap.

I'm no injuneer either though, and I like how you word things. I'll probably try and make some as well when I eventually lift my cheap crap.

The most challenging stuff ive worked with was 304, maybe it was 316... Im not experienced so it was difficult to say the least. Ive heard what a bitch the nickel super alloys can be even compared to 304. I was happy to find 750x as it is supposed to one of the easiest to machine among the inconels.

I did some reasearch and found this wonderful publication. Look at the "work hardening graph" on page one. youll see how 750 approximates 304SS.

http://www.specialmetals.com/assets/smw_docs/Mach.pdf

Another benefit is, the linear CTE of 750 is almost identical to 1018.

X-750 Data Sheet

And heres a decent article on thermal creep.

http://www.nationalboard.org/Index.aspx?pageID=181

As long as you aren't completely ditching the possibility it should be fine.</p>

As long as you aren't completely ditching the possibility it should be fine.</p>