Boost pressure vs air flow vs power

#24

Well... i'm talking more like... take a BP, then cut the flow in half. In Soviet's case, i'd be spinning his same turbo to the point that it would be making 60psi and still only 460whp. (Bullshit maths, but you get the idea)

Is this bad? Would it actually be spinning too high? Or would it spin the same, just with more pressure because shitty motor?

I just want to know how to know at what pressure amount a turbo will become asploded.

#25

Elite Member

iTrader: (1)

Join Date: May 2009

Location: Jacksonville, FL

Posts: 5,155

Total Cats: 406

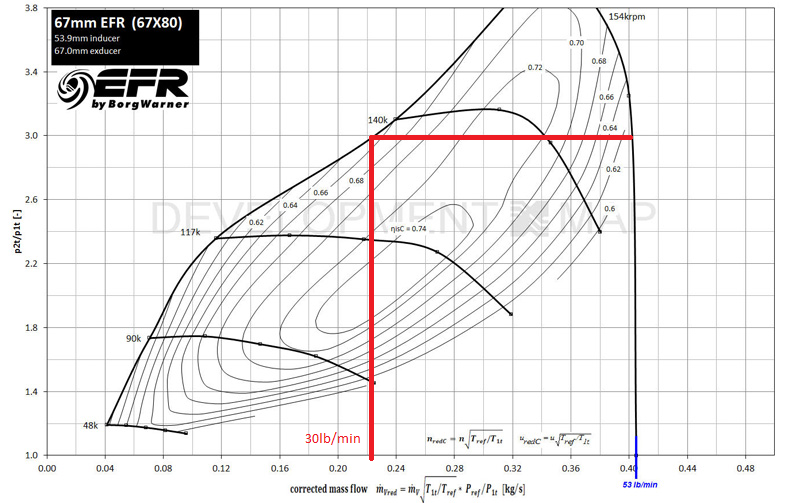

Look at the compressor map

You may need compound turbos to get that kind of boost is something like a GTX cant do it.

Although, the turbo may survive going spinning above where its supposed to. I know DSM guys will push their little stock turbos way off of the compressor map. They like to set turbo records.

You may need compound turbos to get that kind of boost is something like a GTX cant do it.

Although, the turbo may survive going spinning above where its supposed to. I know DSM guys will push their little stock turbos way off of the compressor map. They like to set turbo records.

#28

Nooooooooo . Damn backspace killed my description. I never use backspace to go back on my browser. I hate whoever invented that.

So anyway.. since I wrote a pretty technical section on this bare with me as i use the wrong words like bigger and smaller and whatever to describe turbos and things.

Basically the gist is. Smaller turbos spool quicker right? When they spool quicker it causes more heat. If gas is held at a constant pressure then it will expand to fill a larger volume. Since a smaller turbo will spool quicker it will constantly be applying more pressure to the molecules. Larger turbo will have more dense air.

Think about someone boosting in Colorado or in Florida. Which of the two states gets more power out of the same amount of boosties?

So anyway.. since I wrote a pretty technical section on this bare with me as i use the wrong words like bigger and smaller and whatever to describe turbos and things.

Basically the gist is. Smaller turbos spool quicker right? When they spool quicker it causes more heat. If gas is held at a constant pressure then it will expand to fill a larger volume. Since a smaller turbo will spool quicker it will constantly be applying more pressure to the molecules. Larger turbo will have more dense air.

Think about someone boosting in Colorado or in Florida. Which of the two states gets more power out of the same amount of boosties?

#29

I understand speed, but speed doesn't have a direct relationship with pressure by itself without bringing a motor (restriction) into play.

If the 2560 is on a big block, it might only make 5psi before it hits 143406rpm and dies. If it's on an F2T, it might do almost 30psi before it hits 143406rpm and dies.

If the motor is shitty enough, you could go off the pressure end of the chart while staying in the "safe" zone in terms of RPM. Is this still bad, then? (And yes, i realize that we'd likely be walking on the nasty side of the surge line.)

If the 2560 is on a big block, it might only make 5psi before it hits 143406rpm and dies. If it's on an F2T, it might do almost 30psi before it hits 143406rpm and dies.

If the motor is shitty enough, you could go off the pressure end of the chart while staying in the "safe" zone in terms of RPM. Is this still bad, then? (And yes, i realize that we'd likely be walking on the nasty side of the surge line.)

#30

Retired Mech Design Engr

iTrader: (3)

Join Date: Jan 2013

Location: Seneca, SC

Posts: 5,009

Total Cats: 856

Following on Soviet's map post:

It's not what a turbo can do, but what is the operating point. The question is, at the flow required at a given engine RPM and torque, will the large and small turbo end up operating at about the same pressure and flow. I think they will, less a little for efficiency, and a little for IC and charge piping. The latter variables go away if we look at MAP only.

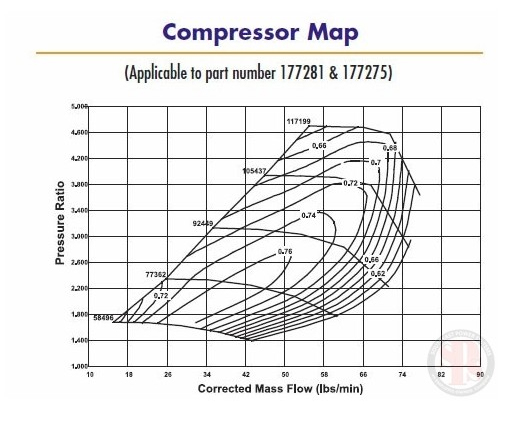

Comparing (2) maps.

2554 @ 25 lbs/min and 2.0 P/R 69% efficiency

2871 @ 25 lbs/min and 2.0 P/R 75% efficiency.

So the 2871 is 75/69 = 9% more efficient so it has that much advantage on the compressor side. This does assume equal pressure drops in the IC and other intake areas.

It's not what a turbo can do, but what is the operating point. The question is, at the flow required at a given engine RPM and torque, will the large and small turbo end up operating at about the same pressure and flow. I think they will, less a little for efficiency, and a little for IC and charge piping. The latter variables go away if we look at MAP only.

Comparing (2) maps.

2554 @ 25 lbs/min and 2.0 P/R 69% efficiency

2871 @ 25 lbs/min and 2.0 P/R 75% efficiency.

So the 2871 is 75/69 = 9% more efficient so it has that much advantage on the compressor side. This does assume equal pressure drops in the IC and other intake areas.

#31

I understand speed, but speed doesn't have a direct relationship with pressure by itself without bringing a motor (restriction) into play.

If the 2560 is on a big block, it might only make 5psi before it hits 143406rpm and dies. If it's on an F2T, it might do almost 30psi before it hits 143406rpm and dies.

If the motor is shitty enough, you could go off the pressure end of the chart while staying in the "safe" zone in terms of RPM. Is this still bad, then? (And yes, i realize that we'd likely be walking on the nasty side of the surge line.)

If the 2560 is on a big block, it might only make 5psi before it hits 143406rpm and dies. If it's on an F2T, it might do almost 30psi before it hits 143406rpm and dies.

If the motor is shitty enough, you could go off the pressure end of the chart while staying in the "safe" zone in terms of RPM. Is this still bad, then? (And yes, i realize that we'd likely be walking on the nasty side of the surge line.)

#32

That sounds awesome.

"Dear BW,

I'm writing to you to let you know that i've found a new and interesting way for your turbos to fail. I've been using an EFR with the turbo RPM logged so i know that it was not the RPMs that caused this particular example to fail.

I've attached a log showing what happens when you remove the wastegate from one of your EFRs and weld chains around your motor to keep the head attached to the block.

Yours Truly,

The Swanky One"

#34

Given the power goals i'm looking at and how little this motor flows (double digits on the bench awwwwwwww yiss) pressure may very well be something i need to look at, since the acceptable answer isn't "oversize the **** out of your turbo."

#35

I am in no way a turbo engineer but I'd imagine that the factors that determine the life of the wheel would be things like lubrication and heat. If it can't be cooled properly it's most likely going to suffer some heat failure and warp or whatever... causing some sort of eventual or catastrophic failure.

#36

Elite Member

Thread Starter

iTrader: (10)

Join Date: Jan 2010

Location: VA

Posts: 3,493

Total Cats: 268

I'm glad that this thread makes sense to some people. I'm not crazy, I guess.

My turbine wheel sheared off the shaft while mostly intact, then rattled in the downpipe. The force was not enough to go through the downpipe, unlike in some cases

My turbine wheel sheared off the shaft while mostly intact, then rattled in the downpipe. The force was not enough to go through the downpipe, unlike in some cases

#40

Elite Member

Thread Starter

iTrader: (10)

Join Date: Jan 2010

Location: VA

Posts: 3,493

Total Cats: 268