External wastegate on Hks 1.8 manifold

#1

Junior Member

Thread Starter

iTrader: (6)

Join Date: Mar 2007

Location: Greece

Posts: 349

Total Cats: -14

Hello,

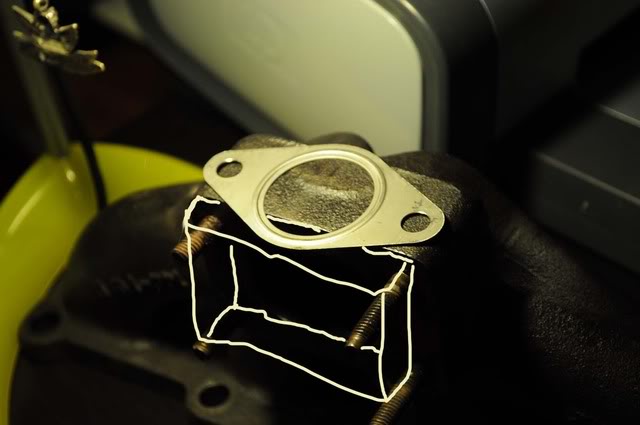

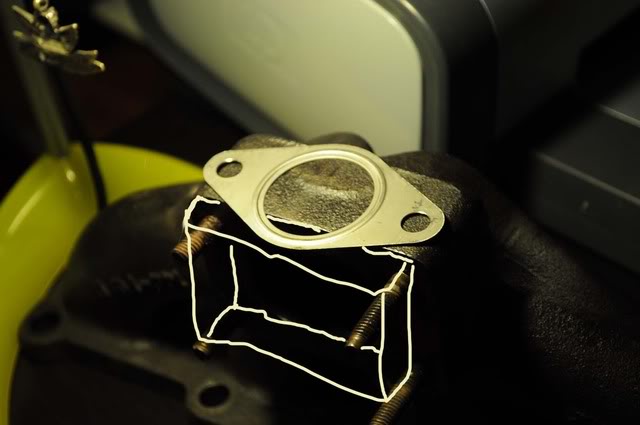

I am going to install a tial 38mm on my hks manifold.

As you can see from the photo the side that I am going to mount doesn't allow the wastegate to fit ideally.

So I came up with 2 solutions.

1. Drilling a smaller hole than 38mm (could this work or am I going to have boost controlling related problems?)

2. Make a flange like in the newb drawing below

Any other ideas or solutions are welcome!

I am going to install a tial 38mm on my hks manifold.

As you can see from the photo the side that I am going to mount doesn't allow the wastegate to fit ideally.

So I came up with 2 solutions.

1. Drilling a smaller hole than 38mm (could this work or am I going to have boost controlling related problems?)

2. Make a flange like in the newb drawing below

Any other ideas or solutions are welcome!

#2

IIRC the HKS is a top mount which already puts the turbo up pretty high with minimal hood clearance- won't any kind of spacer cause problems? If those attributes are true, then you'd be better off putting the port opposite the flange opening (where the runners converge) using a short tube. The top mount should allow room for this position since that makes more space under the manifold.

#5

Elite Member

iTrader: (28)

Join Date: May 2008

Location: St. Augustine FL

Posts: 2,299

Total Cats: 2

Your SOL..... get a better mani with a EWG bung already designed in it..... Best solution bar none..... less headache and probably less problems just my

Your SOL..... get a better mani with a EWG bung already designed in it..... Best solution bar none..... less headache and probably less problems just my  onther than that you could buy the cheap ebay spacer with one already in it...

onther than that you could buy the cheap ebay spacer with one already in it...http://cgi.ebay.com/ebaymotors/TURBO...Q5fAccessories

or

http://cgi.ebay.com/ebaymotors/t3-tu...#ht_500wt_1182

#11

Tour de Franzia

iTrader: (6)

Join Date: Jun 2006

Location: Republic of Dallas

Posts: 29,085

Total Cats: 375

Over the last 4-years of track action, I've seen numerous cast manifolds fail, especially cast iron with welding. Maybe its a failure in execution, but not something i would jack with if you EVER want to see the track. I wouldn't trust it on the street either, but if it fails on the street you're not out any track time/$$$.

#12

I have the same HKS mani, and hood clearance is a huge issue. You can't really go up any higher, and the way the manifold is designed, there really isn't any place to put an external wastegate. It's pretty much new manifold if you don't want to run internal.

On that note, my HKS 1.8 manifold has been awesome.

On that note, my HKS 1.8 manifold has been awesome.

#13

Elite Member

iTrader: (7)

Join Date: Jan 2007

Location: Renton Washington

Posts: 1,731

Total Cats: 4

Over the last 4-years of track action, I've seen numerous cast manifolds fail, especially cast iron with welding. Maybe its a failure in execution, but not something i would jack with if you EVER want to see the track. I wouldn't trust it on the street either, but if it fails on the street you're not out any track time/$$$.

To properly weld cast iron you have to preheat 300* F weld and ping the weld in between passes. While finishing up with post heat treatment. To be honest its not worth the hassel. Thats why its fun to pick up some steel and build something bullet proof. No preheating bullshit just turn on the heat and go.

#14

To properly weld cast iron you have to preheat 300* F weld and ping the weld in between passes. While finishing up with post heat treatment. To be honest its not worth the hassle. Thats why its fun to pick up some steel and build something bullet proof. No preheating bullshit just turn on the heat and go.

/thread

#17

Moderator

iTrader: (12)

Join Date: Nov 2008

Location: Tampa, Florida

Posts: 20,645

Total Cats: 3,009

If you decide to stick with cast iron manifolds, there is more room to drill a hole on the Flyin Miata manifold and the iron is thicker and stronger. It moves your turbo to a side mount instead of a top mount. Right there on top is a good location for the wastegate.

Flyin' Miata : Turbochargers : Parts and upgrades : 1994-05 FM turbo manifold

But I would recommend that you buy a good fabricated steel manifold that is designed for an external wastegate. It will flow better and make much more power. And it is beautiful.

This is ABSURDflow:

ABSURDflow - Available Products

#20

I think there's a big difference between cutting the hole in an existing casting and having the port engineered into the casting. Given the small amount of metal dividing the two ports, it will have to sustain a lot of stress from heat and load.

I'd be tempted to find a spare turbine housing and try to mod that for an external wg port. Or find one made for the purpose.

Found a modified turbine housing, albeit it's from the Gurney Toyota Eagle MKIII. It can work. These engines made 700hp from 2.1L with lots of boost running for hours and hours on end without failing.

I'd be tempted to find a spare turbine housing and try to mod that for an external wg port. Or find one made for the purpose.

Found a modified turbine housing, albeit it's from the Gurney Toyota Eagle MKIII. It can work. These engines made 700hp from 2.1L with lots of boost running for hours and hours on end without failing.

not actually solutions to his problems just ideas that he could look into that's all.

not actually solutions to his problems just ideas that he could look into that's all.