Noob question about compressors?

#1

I'm Miserable!

Thread Starter

iTrader: (1)

Join Date: Mar 2010

Location: North Carolina

Posts: 464

Total Cats: 0

I recently ditched my T3/T04E .50 trim for a smaller but more reliable Garrett T3 ".42 .48". It spools much faster but does offer some very unexciting top end results. It sees full 10psi by 2800-3100 on my stock 1.8 but just falls flat from there on out.

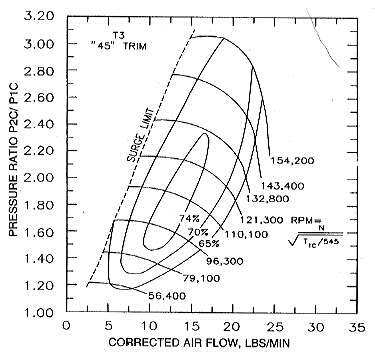

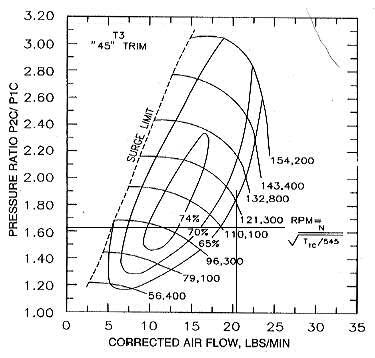

I gathered what I believe is the correct compressor map for said turbo above and started to work on finding out just how efficient this compressor was for my engine. (correct me if I'm wrong on this map)

Now according to some of Corky's calculations and mine as well from his book Maximum Boost, I figured up the following calculations and numbers.

Pressure Ratio = 1.68 (for 10psi)

Calculating airflow rate in "cfm" for my particular setup without boost I came up with the following the numbers.

1.8 = roughly 112cid.

My own personal redline set at 6600RPM.

An estimated 85% volumetric efficiency (real VE unknown).

Plugging in his formula to calculate these, I came up with a CFM of 181.80, with the basic flow rate established I can figure out the CFM under boost. Using said PR above of 1.68 multiplied by 181.80 I come to a boosted CFM of 305.43. Now to find out the correct value to read the compressor map I must have 2 things, the PR and a number to represent my pound of air per minute. I found pounds per minute by simply googling a conversion and come up with .070 x 305.43. This gives me 21.38 pound of air/minute. Do correct me if any of these formulas are wrong, but using the said numbers I made a rough sketch on shown compressor map above.

For turbo's sake, am I really that far off the compressor map? Is efficiency really that bad on this small displacement engine? If so, are things as simple as swapping on a new compressor and wheel, what kind of equipment other then hand tools do I need to be able to do that? Or should I be looking for a different turbine?

I gathered what I believe is the correct compressor map for said turbo above and started to work on finding out just how efficient this compressor was for my engine. (correct me if I'm wrong on this map)

Now according to some of Corky's calculations and mine as well from his book Maximum Boost, I figured up the following calculations and numbers.

Pressure Ratio = 1.68 (for 10psi)

Calculating airflow rate in "cfm" for my particular setup without boost I came up with the following the numbers.

1.8 = roughly 112cid.

My own personal redline set at 6600RPM.

An estimated 85% volumetric efficiency (real VE unknown).

Plugging in his formula to calculate these, I came up with a CFM of 181.80, with the basic flow rate established I can figure out the CFM under boost. Using said PR above of 1.68 multiplied by 181.80 I come to a boosted CFM of 305.43. Now to find out the correct value to read the compressor map I must have 2 things, the PR and a number to represent my pound of air per minute. I found pounds per minute by simply googling a conversion and come up with .070 x 305.43. This gives me 21.38 pound of air/minute. Do correct me if any of these formulas are wrong, but using the said numbers I made a rough sketch on shown compressor map above.

For turbo's sake, am I really that far off the compressor map? Is efficiency really that bad on this small displacement engine? If so, are things as simple as swapping on a new compressor and wheel, what kind of equipment other then hand tools do I need to be able to do that? Or should I be looking for a different turbine?

Last edited by na8psi; 06-14-2010 at 06:13 AM.

#2

Elite Member

iTrader: (2)

Join Date: Jan 2007

Location: Los Angeles, CA

Posts: 8,682

Total Cats: 130

You should see the compressor map for the stock turbo on my Forester XT. I was wondering why boost goes from 12psi at 5000RPM to 9psi at 6500RPM-- the EBC pulls down the boost to follow the shape of the compressor map, which is shaped pretty differently than your map. Basically, it's a midrange turbo :|

Your calculations look correct to me. It's not like your turbo isn't working off the map though, it's just not being very efficient. I don't know about swapping compressor wheels etc or much about your turbo but my guess is that a 2871 or 2876 would run efficiently to redline without comprimise up top?

Your calculations look correct to me. It's not like your turbo isn't working off the map though, it's just not being very efficient. I don't know about swapping compressor wheels etc or much about your turbo but my guess is that a 2871 or 2876 would run efficiently to redline without comprimise up top?

#3

Boost Czar

iTrader: (62)

Join Date: May 2005

Location: Chantilly, VA

Posts: 79,493

Total Cats: 4,080

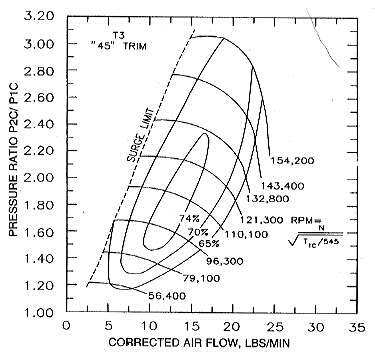

the 45 trim will act like a 2554.

I'm running a 50 trim myself and it's running out of steam a lot earlier than my s60trim ever did. But it's spooling a little faster and making more mid-range torque like I was hoping for.

Solution: run more boost at higher rpms!

easy math for wheels is this:

If the efficiency island ends at 25 lb/min, then 25 * 10 = a 250BHP turbo. or you can do 25 / AFR / (.55/60) = 237BHP

Basically if you're making more than 200rwhp or so, you're pushing hot air.

Let me show you an example of this:

This is Paul's dyno running at 14psi and then 17psi...you can see he's clearly making more TQ at 17psi, but it's apparent there's just no more efficiency range left in the turbo to output much more power. It's maxed.

I'm running a 50 trim myself and it's running out of steam a lot earlier than my s60trim ever did. But it's spooling a little faster and making more mid-range torque like I was hoping for.

Solution: run more boost at higher rpms!

easy math for wheels is this:

If the efficiency island ends at 25 lb/min, then 25 * 10 = a 250BHP turbo. or you can do 25 / AFR / (.55/60) = 237BHP

Basically if you're making more than 200rwhp or so, you're pushing hot air.

Let me show you an example of this:

This is Paul's dyno running at 14psi and then 17psi...you can see he's clearly making more TQ at 17psi, but it's apparent there's just no more efficiency range left in the turbo to output much more power. It's maxed.

#9

In theory, theory and practice are the same. In practice, they are not.

#10

I'm Miserable!

Thread Starter

iTrader: (1)

Join Date: Mar 2010

Location: North Carolina

Posts: 464

Total Cats: 0

I can't speak for Garrett turbochargers with certainty, but mitsubishi turbos are all component balanced and can have parts swapped without the need to re-balance. YMMV, but I've definately known a few people to rebuild garrett turbos and run them for quite a while.

In theory, theory and practice are the same. In practice, they are not.

In theory, theory and practice are the same. In practice, they are not.

If its as simple as unbolting a few things and throwing on a new housing and wheel and then drive it, then i'm all ears...

#11

Boost Czar

iTrader: (62)

Join Date: May 2005

Location: Chantilly, VA

Posts: 79,493

Total Cats: 4,080

ask me how many times I've swapped compressors and CHRAs and **** around, then ask how many times I've balanced the turbo or had a failure.

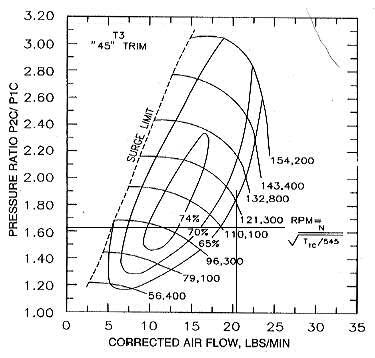

To make it easy: My t3 came with a 45 trim wheel, that I swapped with a to4b-s wheel, then a t3 50 trim, then a t3 super 60. I had one failure due to under oiling when I started using a .040" restrictor where I replaced the turbine and everything was fine again...and not "balanced"

one of these days ill get un-lazy and swap my garret turbine and 50 trim or super 60 compressor wheel into my chinacharger's turbine housing and CHRA.

To make it easy: My t3 came with a 45 trim wheel, that I swapped with a to4b-s wheel, then a t3 50 trim, then a t3 super 60. I had one failure due to under oiling when I started using a .040" restrictor where I replaced the turbine and everything was fine again...and not "balanced"

one of these days ill get un-lazy and swap my garret turbine and 50 trim or super 60 compressor wheel into my chinacharger's turbine housing and CHRA.

#12

I'm Miserable!

Thread Starter

iTrader: (1)

Join Date: Mar 2010

Location: North Carolina

Posts: 464

Total Cats: 0

ask me how many times I've swapped compressors and CHRAs and **** around, then ask how many times I've balanced the turbo or had a failure.

To make it easy: My t3 came with a 45 trim wheel, that I swapped with a to4b-s wheel, then a t3 50 trim, then a t3 super 60. I had one failure due to under oiling when I started using a .040" restrictor where I replaced the turbine and everything was fine again...and not "balanced"

To make it easy: My t3 came with a 45 trim wheel, that I swapped with a to4b-s wheel, then a t3 50 trim, then a t3 super 60. I had one failure due to under oiling when I started using a .040" restrictor where I replaced the turbine and everything was fine again...and not "balanced"

#18

Boost Czar

iTrader: (62)

Join Date: May 2005

Location: Chantilly, VA

Posts: 79,493

Total Cats: 4,080

https://www.miataturbo.net/useful-saved-posts-8/rebuilding-t3-turbo-10995/

ahh crap let me update the images.

ahh crap let me update the images.

Thread

Thread Starter

Forum

Replies

Last Post

bigmackloud

Miata parts for sale/trade

19

01-08-2021 11:24 AM

JesseTheNoob

DIY Turbo Discussion

15

09-30-2015 02:44 PM