FMU fuel pressure question, with chart

#1

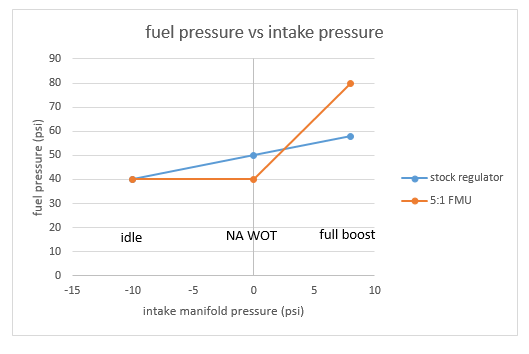

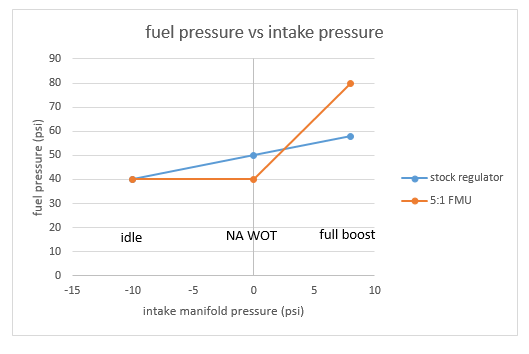

trying to understand how to adjust the FMU, so i created a little chart to help me visualize what's going on...

* when the engine is operating not boosted (as if NA) i want the engine to run close to its stock fuel delivery calibration, and so i need stock fuel pressure up to the "NA WOT" point; that's the BLUE line

* the stock fuel pressure regulator will control to about a 1:1 ratio, so only another 8 psi or so will be generated when the turbo begins to build boost

* let's assume that i need 40 psi additional fuel pressure for my 8 psi turbo

* that means i'll need a 5:1 FMU; that's the RED line

* it will reference pre-throttle body pressure (non vacuum), otherwise it alters my non boosted fuel pressure too much

* so as to maintain the stock pressure during non-boosted operation, i need to adjust my FMU base pressure to no higher than 40 psi; that way the stock FPR has control during that part of the operating range

* the resulting pressure curve is the upper combination (max value) of both lines

So, my question is, since the FMU doesnt really begin to add any supplemental pressure until 3 psi of boost or so - will that create a dead spot during that transition?

if i adjust my base FP up by 5-10 psi to get rid of that "flat" spot, i'm afraid the engine will run too rich at the low end (the NA portion).

* when the engine is operating not boosted (as if NA) i want the engine to run close to its stock fuel delivery calibration, and so i need stock fuel pressure up to the "NA WOT" point; that's the BLUE line

* the stock fuel pressure regulator will control to about a 1:1 ratio, so only another 8 psi or so will be generated when the turbo begins to build boost

* let's assume that i need 40 psi additional fuel pressure for my 8 psi turbo

* that means i'll need a 5:1 FMU; that's the RED line

* it will reference pre-throttle body pressure (non vacuum), otherwise it alters my non boosted fuel pressure too much

* so as to maintain the stock pressure during non-boosted operation, i need to adjust my FMU base pressure to no higher than 40 psi; that way the stock FPR has control during that part of the operating range

* the resulting pressure curve is the upper combination (max value) of both lines

So, my question is, since the FMU doesnt really begin to add any supplemental pressure until 3 psi of boost or so - will that create a dead spot during that transition?

if i adjust my base FP up by 5-10 psi to get rid of that "flat" spot, i'm afraid the engine will run too rich at the low end (the NA portion).

#2

Sir,

The regulator you have sounds like one built in the mid-70's.

The RRR is a good device for fuel up to about 6 psi, but for reasons of high pressure pumps, additional ign equipment and such, it is no longer a good enough part for Miatas.

I doubt anyone knows these things better than I do, as my group introduced them to the market when Grant was President. The one you have sounds like a copy of our original one.

Needed:

One: To be of any value at all, the rate of gain must be adjustable.

Two: The "onset" of gain needs to adjustable as well.

You are correct to surmise a flat spot will exist. It starts at about 3 inches/vac and ends when around 2 psi boost

That is easy to counter with a proper regulator, as the fuel pressure gain can be enacted by the "onset" screw at any vac you choose. This allows greater fuel pressure to exist when passing through zero/atmo and overcomes the flat. Easy enough. It must also be arranged so vac pulls the fuel pressure down below the stock reg's curve.

If the leap up is too rapid, put an .030 restrictor in the signal line.

An adjustable regulator, or any other for that matter, needs to read BOTH vac & boost. The vac is the off button. Besides, boost is often in the tubes but throttled back at the throttle, thus a false signal.

No 5 exists as a redline, rather the fuel pump's available pressure is the redline. HP pumps can be had up to 140 psi. 8 psi boost will require abot 115/125 psi to reach a 11/12 to one.

That is all workable, but you will find more success and little extra expense with a MeagerSquirt.

corky

The regulator you have sounds like one built in the mid-70's.

The RRR is a good device for fuel up to about 6 psi, but for reasons of high pressure pumps, additional ign equipment and such, it is no longer a good enough part for Miatas.

I doubt anyone knows these things better than I do, as my group introduced them to the market when Grant was President. The one you have sounds like a copy of our original one.

Needed:

One: To be of any value at all, the rate of gain must be adjustable.

Two: The "onset" of gain needs to adjustable as well.

You are correct to surmise a flat spot will exist. It starts at about 3 inches/vac and ends when around 2 psi boost

That is easy to counter with a proper regulator, as the fuel pressure gain can be enacted by the "onset" screw at any vac you choose. This allows greater fuel pressure to exist when passing through zero/atmo and overcomes the flat. Easy enough. It must also be arranged so vac pulls the fuel pressure down below the stock reg's curve.

If the leap up is too rapid, put an .030 restrictor in the signal line.

An adjustable regulator, or any other for that matter, needs to read BOTH vac & boost. The vac is the off button. Besides, boost is often in the tubes but throttled back at the throttle, thus a false signal.

No 5 exists as a redline, rather the fuel pump's available pressure is the redline. HP pumps can be had up to 140 psi. 8 psi boost will require abot 115/125 psi to reach a 11/12 to one.

That is all workable, but you will find more success and little extra expense with a MeagerSquirt.

corky

#3

thanks Corky, that's the sort of explanation i was hoping for - someone who can help me develop my basic understanding. (and for the benefit of others too i guess)

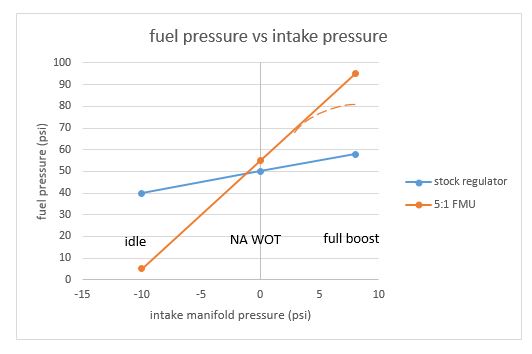

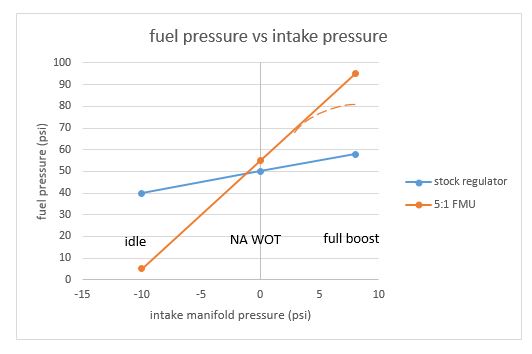

so, if i move the signal line to downstream of the TB, then the impact of the RRR is linear through the range. and since the resulting pressure (red line) when not under boost is lower than the blue line, it doesnt have any effect in that range. that works.

to your point about the adjustability of the "rate", because the slope of the line is strictly based on the diameter of the diaphragm, the only way to modify the ratio between fuel pressure and boost is to lower the actual pressure acting on the diaphragm. having never seen a fancy RRR, i'm guessing that's done with a bleed valve that drops the signal pressure.

putting all this together i get the new chart below. note that with the base pressure up to 55 psi to eliminate the flat spot (with the same 5:1 RRR), the max pressure is too high. so i either need to bleed off some pressure (dashed line), or go with a lower rate RRR, like maybe 4:1. of course, this all theoretical - i just want to get the basic idea.

am i getting close???

so, if i move the signal line to downstream of the TB, then the impact of the RRR is linear through the range. and since the resulting pressure (red line) when not under boost is lower than the blue line, it doesnt have any effect in that range. that works.

to your point about the adjustability of the "rate", because the slope of the line is strictly based on the diameter of the diaphragm, the only way to modify the ratio between fuel pressure and boost is to lower the actual pressure acting on the diaphragm. having never seen a fancy RRR, i'm guessing that's done with a bleed valve that drops the signal pressure.

putting all this together i get the new chart below. note that with the base pressure up to 55 psi to eliminate the flat spot (with the same 5:1 RRR), the max pressure is too high. so i either need to bleed off some pressure (dashed line), or go with a lower rate RRR, like maybe 4:1. of course, this all theoretical - i just want to get the basic idea.

am i getting close???

#4

In my view, you've got the picture. Perhaps a couple details.

The pressure changes between nozzle and intake manifold do not produce a linear flow change. It does curve, but the curve is easy to keep within the ranges needed.

You are correct on the boost bleed adjustment. A simple needle valve. Look up Clippard.

On your graph, imagine the rate of gain adjustment changes the slope of the line. The onset screw, with a spring under the screw that pushes on the valve, will then move the whole graph up or down the Y axis.

Juggling the two adjustments allows an increase at the top and decrease of the low end, or the other way around.

Seldom is more than 45 pis of fuel pressure needed at gage reading of atmo (zero), to remove the flat spot. With vac hooked up, the RRR reg is pulled out of function around 4 inches. This requires a one way valve on the exit of the needle valve to allow boost out and check the vac.

The max rate of your RRR is not adequate for the 8 psi boost. Take the thing apart and decrease the fuel side area. It may be that the support disc under the big diaphragm is too small. If it has more that .060 clearance (or so) to the body, make a new disc.

We shoot for a 12 to 1 inherent ratio, then tune down by the needle valve as required.

corky

The pressure changes between nozzle and intake manifold do not produce a linear flow change. It does curve, but the curve is easy to keep within the ranges needed.

You are correct on the boost bleed adjustment. A simple needle valve. Look up Clippard.

On your graph, imagine the rate of gain adjustment changes the slope of the line. The onset screw, with a spring under the screw that pushes on the valve, will then move the whole graph up or down the Y axis.

Juggling the two adjustments allows an increase at the top and decrease of the low end, or the other way around.

Seldom is more than 45 pis of fuel pressure needed at gage reading of atmo (zero), to remove the flat spot. With vac hooked up, the RRR reg is pulled out of function around 4 inches. This requires a one way valve on the exit of the needle valve to allow boost out and check the vac.

The max rate of your RRR is not adequate for the 8 psi boost. Take the thing apart and decrease the fuel side area. It may be that the support disc under the big diaphragm is too small. If it has more that .060 clearance (or so) to the body, make a new disc.

We shoot for a 12 to 1 inherent ratio, then tune down by the needle valve as required.

corky

Thread

Thread Starter

Forum

Replies

Last Post

stoves

Suspension, Brakes, Drivetrain

5

04-21-2016 03:00 PM

JesseTheNoob

DIY Turbo Discussion

15

09-30-2015 02:44 PM