FM turbb manifold modification (studs)

#1

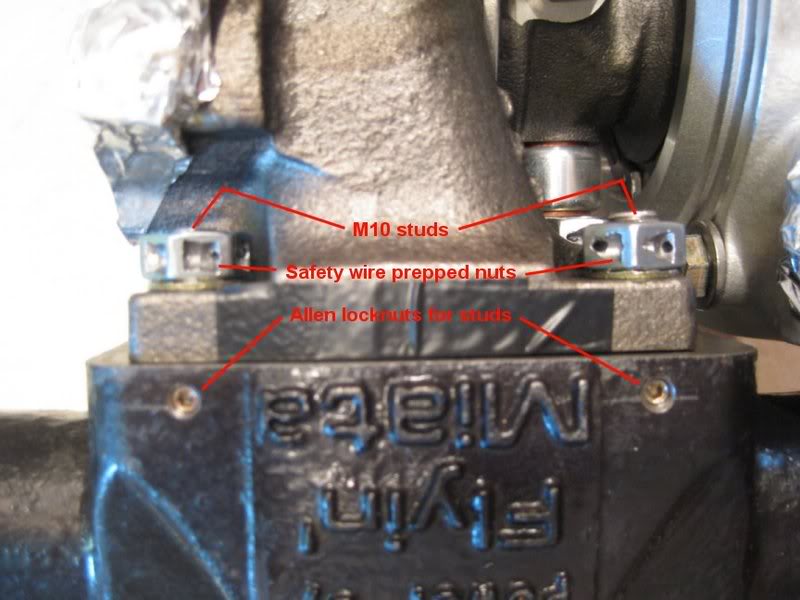

I've heard that some people have been having issues with the studs on their FM turbo manifolds backing out. This has sometimes necessitated track cars to have to have their manifold nuts retorqued after each session during track days. There have even also been reports of stud failure because of the repeated retorquing of the nuts. So here's my proposed solution...

My solution is threefold:

-First, the size of the manifold studs were upgraded from M8 to M10.

-Second, nuts that are prepped to be safety wired in place will be used so that they can't back off. Each nut will be safety wired to TWO other nuts on the manifold.

-Third, setscrew holes were drilled and tapped into the turbo manifold. Setscrews are then put in place which screw into the manifold's M10 studs, locking them in place and preventing them from backing out.

Other typical hardware is also used (ie the special lockwashers) as are found on other installs.

Here's a pic. It's just hand tightened, not safety wired, and the turbo orifaces are still taped...but you should get the idea:

I'm open to any opinions/suggestions/criticism on this solution. Thanks!

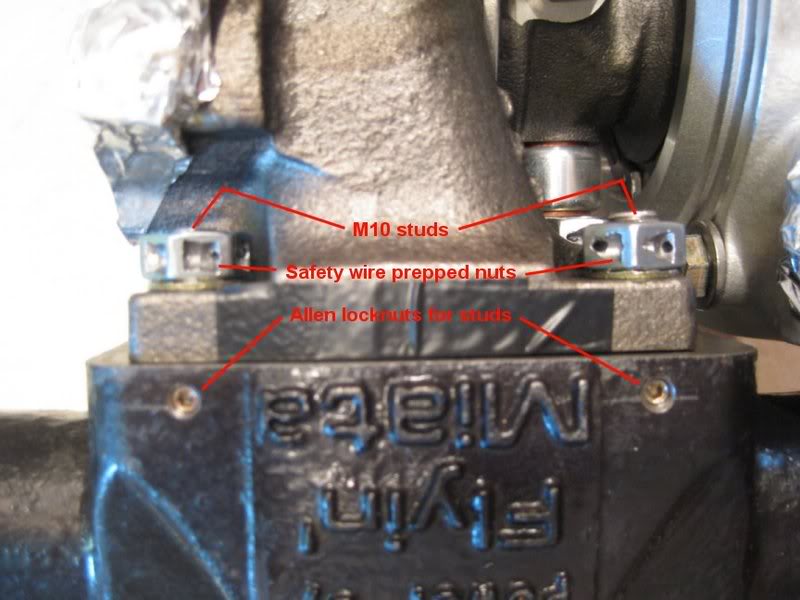

My solution is threefold:

-First, the size of the manifold studs were upgraded from M8 to M10.

-Second, nuts that are prepped to be safety wired in place will be used so that they can't back off. Each nut will be safety wired to TWO other nuts on the manifold.

-Third, setscrew holes were drilled and tapped into the turbo manifold. Setscrews are then put in place which screw into the manifold's M10 studs, locking them in place and preventing them from backing out.

Other typical hardware is also used (ie the special lockwashers) as are found on other installs.

Here's a pic. It's just hand tightened, not safety wired, and the turbo orifaces are still taped...but you should get the idea:

I'm open to any opinions/suggestions/criticism on this solution. Thanks!

#2

Totally badass. Damn. You could have drilled through the nut/stud and then just wired them, then you wouldn't have needed to setscrew the studs into place. I did this, only I used bolts so I just drilled through the head of the bolt. I actually haven't wired them all together yet though, but it shouldn't be a problem.

Did you cut a flat on the studs for the set screw to hit? This would be ideal. Also, where did you but those nuts?

Did you cut a flat on the studs for the set screw to hit? This would be ideal. Also, where did you but those nuts?

#3

I'll offer one improvement possibly...

I was gonna do studs before I realized they wouldn't fit. Meaning, if they were installed int the manifold, I couldn't put the turbo on. My turbo already hangs off the side a lot, so if I used studs, I'd have to install them while holding the turbo in place. But assuming there was no fitment issues with the studs already installed, I was going to drill through the manifold and through the stud, and then press a locking pin in. That would be a bit more bullet-proof reliable than a set screw as it too could back out.

I was gonna do studs before I realized they wouldn't fit. Meaning, if they were installed int the manifold, I couldn't put the turbo on. My turbo already hangs off the side a lot, so if I used studs, I'd have to install them while holding the turbo in place. But assuming there was no fitment issues with the studs already installed, I was going to drill through the manifold and through the stud, and then press a locking pin in. That would be a bit more bullet-proof reliable than a set screw as it too could back out.

#4

Former Vendor

iTrader: (31)

Join Date: Nov 2006

Location: Sunnyvale, CA

Posts: 15,442

Total Cats: 2,099

Set screws aren't going to come out. There's no force pushing/pulling on them. They WILL seize in place, however, so good luck removing them when the time comes.

That is pretty cool, though. Safety wire is the way to go for sure.

That is pretty cool, though. Safety wire is the way to go for sure.

#5

The ones in cast are easier to get out vs. mild steel or aluminum. I used to know why too, something in the iron (maybe lead?) keeps it lubricated in a sense.

The ones in cast are easier to get out vs. mild steel or aluminum. I used to know why too, something in the iron (maybe lead?) keeps it lubricated in a sense.

#6

lol just saw this on FM's website

Flyin' Miata : Turbochargers : Parts and upgrades : Stage 8 locking turbo hardware

Flyin' Miata : Turbochargers : Parts and upgrades : Stage 8 locking turbo hardware

#7

lol just saw this on FM's website

Flyin' Miata : Turbochargers : Parts and upgrades : Stage 8 locking turbo hardware

Flyin' Miata : Turbochargers : Parts and upgrades : Stage 8 locking turbo hardware

Thread

Thread Starter

Forum

Replies

Last Post