Oil drain leakage

#1

I EAT CUM

Thread Starter

iTrader: (6)

Join Date: Sep 2008

Location: Redneck, Texas

Posts: 1,198

Total Cats: 0

For some reason the diy 1/2 npt is still dripping a tiny bit of oil here and there. I've put jb weld around the seal several times(so the layer is pretty thick) but after a couple weeks of driving (or sitting) it has just enough oil leaking so you can touch it and feel it on your fingers. It isn't leaking down the tube and doesn't appear to be coming from anywhere else. I've replaced the drain hose with a better hose but still the same leak. Without ripping the bung out is there any other options besides more jb weld?

#2

I don't think plastering more jbweld will do anything. I think you didn't clean the area good enough with acetone before the jb weld so its not really bonding or developed leaks. I'd take it out, clean it very very thoroughly, and try again.

of course the best solution is to weld it like I did with mine. it was leaking too.

of course the best solution is to weld it like I did with mine. it was leaking too.

#3

I EAT CUM

Thread Starter

iTrader: (6)

Join Date: Sep 2008

Location: Redneck, Texas

Posts: 1,198

Total Cats: 0

Is it possible to have it welded while it is still on the car? I have a shop downtown that has done all my exhaust work and what not and I could see if I could scrape off the jb weld and have them weld it up for real.

#8

Cpt. Slow

iTrader: (25)

Join Date: Oct 2005

Location: Oregon City, OR

Posts: 14,179

Total Cats: 1,129

That's why, although a pain, its recommend to take the pan off. Most exhaust shops don't have a tig machine, which you'll need to weld to the pan. Your fitting isn't bottoming out before the threads get tight, is it?

#11

Elite Member

iTrader: (7)

Join Date: Jan 2007

Location: Renton Washington

Posts: 1,731

Total Cats: 4

How far did you take the tap in? The first time i tapped my pan i didnt run the plug in as far as i should which gave very limited threads. NPT is designed to start and taper up so eventually it gets to a point where its tight. Unlike bolts which have the same thread.

#12

I EAT CUM

Thread Starter

iTrader: (6)

Join Date: Sep 2008

Location: Redneck, Texas

Posts: 1,198

Total Cats: 0

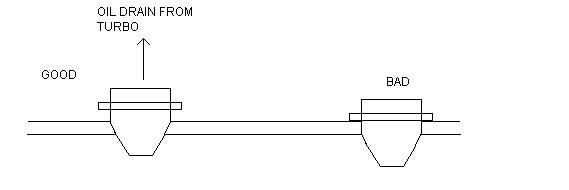

I put my tap about half way through. Also my flange looks like the "good" picture where it is not flush with the pan.

Edit> I think I might have uncovered a different problem, fuel leak. I'm pretty stuffed up right now and couldn't really smell the liquid. I had the g/f smell it and she said straight gas. I think I might be having a fuel leak that is dripping down somewhere and getting covered in grime/dirt so it has a thicker consistency.

Edit> I think I might have uncovered a different problem, fuel leak. I'm pretty stuffed up right now and couldn't really smell the liquid. I had the g/f smell it and she said straight gas. I think I might be having a fuel leak that is dripping down somewhere and getting covered in grime/dirt so it has a thicker consistency.

#17

Anyone tried something like this welded on the pan, instead of the npt?

Holley Performance Products -8 AN Male Weld Fitting 997108ERL

I ask because I'm going to be doing this soon.

Holley Performance Products -8 AN Male Weld Fitting 997108ERL

I ask because I'm going to be doing this soon.