ARP Head Studs

#1

Elite Member

Thread Starter

iTrader: (12)

Join Date: May 2007

Location: Austin, TX

Posts: 1,881

Total Cats: 2

What am I supposed to tighten my ARP head studs to for a 1.8? Also is there anything else besides tightening to the proper torque required for these in a Miata application? I can't believe how small the studs are either.

#2

Follow the directions listed on the sheet that came with them. I think it goes something along the lines of hand tighten into the block, install head, apply their moly lube, and tighten to the torque specified on the sheet. Unless you don't have that sheet?

Make sure you follow the correct tightening pattern though.

Make sure you follow the correct tightening pattern though.

#4

Oh. You're missing their moly lube then too.

I found the basic instructions online, but I don't have the torque they list. The sheet is over at my dad's where my car and engine is. Sorry.

I found the basic instructions online, but I don't have the torque they list. The sheet is over at my dad's where my car and engine is. Sorry.

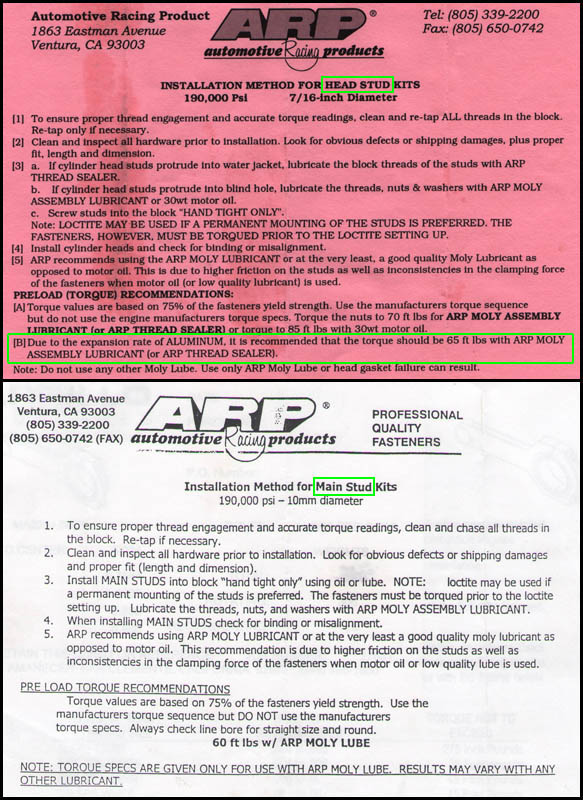

1) To ensure proper thread engagement and accurate torque readings,

clean and re - tap, if necessary, ALL threads in the block.

2) Clean and inspect all hardware prior to installation. Look for obvious

defects or shipping damages, plus proper fit, length and dimension.

3) a. If cylinder head studs protrude into water jacket, lubricate the block

threads of the studs with ARP THREAD SEALER.

b. If cylinder head studs protrude into blind hole, lubricate the threads,

nuts and washers with ARP THREAD LUBRICANT or 30wt oil.

c. Screw studs into block "HAND TIGHT ONLY" .

NOTE: LOCTITE MAY BE USED IF A PERMANENT MOUNTING OF THE

STUDS IS PREFERRED. THE FASTENERS, HOWEVER MUST BE

TORQUED PRIOR TO THE LOCTITE SETTING UP.

4) Install cylinder heads and check for binding or misalignment.

5) ARP recommends using the ARP MOLY LUBRICANT or at the very least,

a good quality Moly Lubricant as opposed to motor oil. This is due to

higher friction on the studs as well as inconsistencies in the clamping

force of the fasteners when motor oil ( or low quality lubricant) is used.

clean and re - tap, if necessary, ALL threads in the block.

2) Clean and inspect all hardware prior to installation. Look for obvious

defects or shipping damages, plus proper fit, length and dimension.

3) a. If cylinder head studs protrude into water jacket, lubricate the block

threads of the studs with ARP THREAD SEALER.

b. If cylinder head studs protrude into blind hole, lubricate the threads,

nuts and washers with ARP THREAD LUBRICANT or 30wt oil.

c. Screw studs into block "HAND TIGHT ONLY" .

NOTE: LOCTITE MAY BE USED IF A PERMANENT MOUNTING OF THE

STUDS IS PREFERRED. THE FASTENERS, HOWEVER MUST BE

TORQUED PRIOR TO THE LOCTITE SETTING UP.

4) Install cylinder heads and check for binding or misalignment.

5) ARP recommends using the ARP MOLY LUBRICANT or at the very least,

a good quality Moly Lubricant as opposed to motor oil. This is due to

higher friction on the studs as well as inconsistencies in the clamping

force of the fasteners when motor oil ( or low quality lubricant) is used.

#5

Elite Member

Thread Starter

iTrader: (12)

Join Date: May 2007

Location: Austin, TX

Posts: 1,881

Total Cats: 2

I've got the moly lube for them. Did a little searching over on m.net and found one person recommending 65 ft/lbs and that sounds about right. Few other posts had some numbers that I know are way wrong. I guess I'll make some calls in the morning to know for sure.

#9

Did you guys notice that the studs don't thread into the block to a uniform depth?

I've chased the threads, soaked with PB blaster, then blown the holes out with air and some studs sit deeper into the block than others. I don't have a spare head to check thread engagement on the top side, unfortunately.

I've chased the threads, soaked with PB blaster, then blown the holes out with air and some studs sit deeper into the block than others. I don't have a spare head to check thread engagement on the top side, unfortunately.

#10

Did you guys notice that the studs don't thread into the block to a uniform depth?

I've chased the threads, soaked with PB blaster, then blown the holes out with air and some studs sit deeper into the block than others. I don't have a spare head to check thread engagement on the top side, unfortunately.

I've chased the threads, soaked with PB blaster, then blown the holes out with air and some studs sit deeper into the block than others. I don't have a spare head to check thread engagement on the top side, unfortunately.

Also, when I re-torqued them (like you're suppose to with the stock head bolts) they didn't budge a bit. Normal you think?

And to the OP, the weird suggested numbers you found on m.net were likely the 85ft/lbs numbers that you have to use when lubing the studs with engine oil instead of the moly lube.

#13

Me neither, I'm pretty sure they all went in evenly.

__________________

Best Car Insurance | Auto Protection Today | FREE Trade-In Quote

__________________

Best Car Insurance | Auto Protection Today | FREE Trade-In Quote

#14

Elite Member

iTrader: (1)

Join Date: Feb 2008

Location: Birmingham Alabama

Posts: 7,930

Total Cats: 45

Two of the studs do sit higher, but its because of the hole location, not actual depth. I think it was the front two studs. The casting on the head are also higher to account for this. Unless my **** was messed up and its not right like that... unless you guys meant each bolt not going in evenly. All of the other ones seemed to be equal to one another in depth.

#16

FWIW, my studs look just like those in the picture above. I guess it was at the front of the head that they didn't sink like the rest, not the back like I remembered.

#17

Elite Member

Thread Starter

iTrader: (12)

Join Date: May 2007

Location: Austin, TX

Posts: 1,881

Total Cats: 2

Got mine in and bolted everything back together. I still can't believe that nobody has problems with head studs on these cars. These things are tiny compared to any other car that I have messed with, especially for a boosted application.